Académique Documents

Professionnel Documents

Culture Documents

Base Plate Calculation

Transféré par

anbuaedTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Base Plate Calculation

Transféré par

anbuaedDroits d'auteur :

Formats disponibles

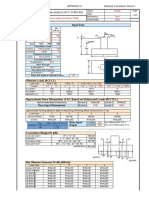

DESIGN OF CIRCULAR BASE SUPPORT FOR V-51

Diameter of Base plate

Db

0.6064

Area of Base plate

Ar

0.2886609536

m2

Outer diameter of the skirt

Ds

0.4064

Area within the Skirt

As

0.1296513536

m2

Circumferencial length of the skirt

Cs

1.276096

Safe Bearing Load on Structure for the given material

fb

114000

Distance between skirt OD & Base plate OD

L1

0.1

Distance between Centre of bolt & Skirt OD

L2

0.0533

Distance between Centre of bolt & Base plate OD

L3

0.0467

Wind Load

m

kN/m2

WL

=

4880

N

(Calculated Using API-RP-2A considering given Wind Velocity)

=

3983.248

mm

19438.25024

N-m

C.O.G of Vessel ( From Vessel Calculation)

Moment at the base due to Wind

33999.498

Maximum Compression per unit length

Pc=(( 12 * M / As) + ( W / Cs))

1825768.4575

Approximate thickness

tb= 0.32 * L1

=

=

Operating Weight of the vessel (From Vessel Calculation)

Actual Thickness Used

N

N/m

The whole calculation is

taken from Pressure Vessel Hand book

0.032

Under the topic Base Ring calculation

0.035

Bearing Stress

S1 = Pc * Cs /Ar

8071.2538239

#NAME?

kN/m2

Bending stress

S2=3 * S1*L12 / tb2

197663.35895

kN/m2

(NB: Blue Coloured Font Indicates Inputs)

Attached in Next sheet

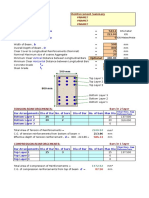

WELD STRENGTH CALCULATION - CHECKING FOR BENDING MOMENT

Diameter of the Support

406.4

mm

Enter the size of the weld

mm

Throat thickness for the weld size

4.949

mm

Area of the Throat

At

6315.399104

mm2

Shear Load acting on the weld

4880

Direct Shear Stress

772.71442701

Distance of COG point of vessel from weld section

4018

mm

Bending Moment

19607.84

N-m

Section Modulus of Weld Section

0.0006416445

m3

Calculated Bending Stress

30558.72606

kN/m2

30578.252604

kN/m2

15298.889574

kN/m2

114457

kN/m2

Max.Normal Stress

Max.Shear Stress

Allowable Stress value For A-36

(0.5 * b)+(0.5 * ((b)2+(4 * t2)))

(0.5 * ((b)2+(4 * t2)))

Sa

#NAME?

N

kN/m2

WELD STRENGTH CALCULATION - CHECKING FOR TORSIONAL MOMENT

Diameter of the Support

0.4064

Wind load

WL

4880

Horizontal Force due to Ship Motion

WH

30599.55

Enter the size of the weld

mm

Throat thickness for the weld size

4.949

mm

Torisonal Load acting on the weld

35479.55

Do

1000

mm

Torsional Moment

17739.775

N-m

Polar Moment of Inertia

0.0002607643

m3

Shear Stress due to Torsion

13823677.789

N/m2

Allowable Stress value For A-36

Sa

114457000

N/m2

The Maximum distance over which the wind acts causing torsion

DESIGN SAFE

WELD STRENGTH CALCULATION - CHECKING FOR WELD THICKNESS

VERTICAL LOADS

Operating Weight of Vessel

WO

33999.498

Vertical Force due to Ship Motion

WH

47599.2972

Wind Load

WL

4880

Horizontal Force due to Ship Motion

WH

30599.5482

Diameter of the circular weld

0.4064

Efficiency of weld joint

0.7

Thickness of throat

0.004949

Max. Shearing Force

35479.5482

Max. Tensile Force

81598.7952

(2*(H+V))/(2***D* t)

14903127.395

N/m2

Sa

114457000

N/m2

HORIZONTAL LOADS

Shearing stress on weld

Allowable Stress value For A-36

DESIGN SAFE

(THIS FORMULA IS TAKEN FROM THEIR

DOCUMENT WHICH U SENT TO US)

Vous aimerez peut-être aussi

- Discrete Element Method to Model 3D Continuous MaterialsD'EverandDiscrete Element Method to Model 3D Continuous MaterialsPas encore d'évaluation

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- Simply Support Beam. Centre LoadDocument7 pagesSimply Support Beam. Centre LoadjhsompuraPas encore d'évaluation

- Steel Stanchion Design Calcsheet v.0Document2 pagesSteel Stanchion Design Calcsheet v.0Olusegun S. Ajibola100% (2)

- Design Calculations of Storage Tank: According To API 650 Code, 11 EditionDocument3 pagesDesign Calculations of Storage Tank: According To API 650 Code, 11 EditionAkash Kazama100% (1)

- Jn1399 - 71t Lifting LugDocument5 pagesJn1399 - 71t Lifting LugRiyan EsapermanaPas encore d'évaluation

- Design of Ring Girder SupportDocument3 pagesDesign of Ring Girder Supportvishal guptaPas encore d'évaluation

- Anchor Bolt CalculationDocument8 pagesAnchor Bolt CalculationRajput Pratiksingh100% (1)

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amar100% (1)

- Welded Connection 1Document2 pagesWelded Connection 1engineeringyusufPas encore d'évaluation

- Cdo CalcDocument3 pagesCdo CalcJeric FarinPas encore d'évaluation

- Isolated Footing 277Document60 pagesIsolated Footing 277Affan Alam100% (1)

- Support CalculationDocument16 pagesSupport Calculationhosny1987Pas encore d'évaluation

- Calculation of Davit ArmDocument1 pageCalculation of Davit Armpiziyu100% (1)

- Calculation of DavitDocument2 pagesCalculation of DavitpiziyuPas encore d'évaluation

- Skid LiftDocument2 pagesSkid LiftAmi PutraPas encore d'évaluation

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- API 650 Tank Nozzle Stand OutDocument5 pagesAPI 650 Tank Nozzle Stand Outtry&try100% (1)

- Heat ExchangersDocument30 pagesHeat ExchangersvpjagannaathPas encore d'évaluation

- Sendai: Eversendai Consulting Engineers (P) LTDDocument6 pagesSendai: Eversendai Consulting Engineers (P) LTDfsijestPas encore d'évaluation

- Welded Beam CalculationDocument2 pagesWelded Beam CalculationVeenoyPas encore d'évaluation

- Platform Cleat CalculationDocument1 pagePlatform Cleat Calculationmiteshpatel191Pas encore d'évaluation

- Calculation Trunion (By Maniacs)Document5 pagesCalculation Trunion (By Maniacs)SyahkullahPas encore d'évaluation

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag50% (2)

- Screw Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoDocument2 pagesScrew Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoTheodoros AtheridisPas encore d'évaluation

- R D H W FW: Design of Tailing LugDocument2 pagesR D H W FW: Design of Tailing LugvpjagannaathPas encore d'évaluation

- Design-Calculation Acid Wash TankDocument5 pagesDesign-Calculation Acid Wash TankWiz DomPas encore d'évaluation

- Saddle SupportDocument12 pagesSaddle SupportrustamriyadiPas encore d'évaluation

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocument4 pagesSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRPas encore d'évaluation

- Chimney Hight CalculationDocument4 pagesChimney Hight CalculationlohitakshvraoPas encore d'évaluation

- Design of Lifting Lug: InputsDocument4 pagesDesign of Lifting Lug: InputsBahtiar Anak LaNangPas encore d'évaluation

- Ldo Storage Tank Calculation 170Document6 pagesLdo Storage Tank Calculation 170م.ذكى فضل ذكى100% (1)

- Vdocuments - MX Rectangular Tank CalculationDocument34 pagesVdocuments - MX Rectangular Tank CalculationAtilla TekinPas encore d'évaluation

- 8224 Grating No HeaderDocument69 pages8224 Grating No HeadervishalnalwarPas encore d'évaluation

- Design of Hopper Bottoms: Note:-Before Using This Excel Sheet Please See The Page 321 of Reynold'S BookDocument1 pageDesign of Hopper Bottoms: Note:-Before Using This Excel Sheet Please See The Page 321 of Reynold'S BookSOURAVPas encore d'évaluation

- Youngs Modulus b3 2010Document2 pagesYoungs Modulus b3 2010bakellyPas encore d'évaluation

- Rectangular Tanks:: Rectangle Tank DesignDocument23 pagesRectangular Tanks:: Rectangle Tank Designshna jabarPas encore d'évaluation

- Hinge For Cover CalculationDocument2 pagesHinge For Cover CalculationamaPas encore d'évaluation

- ChimneyDocument20 pagesChimneyA.K.M Shafiq MondolPas encore d'évaluation

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong Su100% (1)

- Wind Speed Calculation As Per SP-1275Document7 pagesWind Speed Calculation As Per SP-1275Siva baalanPas encore d'évaluation

- Padeye .5MT CHKDocument12 pagesPadeye .5MT CHKDhanraj VasanthPas encore d'évaluation

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiPas encore d'évaluation

- Calculation of Lifting ForcesDocument9 pagesCalculation of Lifting ForcesprantikduarahPas encore d'évaluation

- Comp 2Document9 pagesComp 2YYo YudiPas encore d'évaluation

- 350 V Pressure Vessel Strength CalculationDocument3 pages350 V Pressure Vessel Strength CalculationTanCM100% (1)

- LIFTING LUG Weld Check KGDocument4 pagesLIFTING LUG Weld Check KGjoerijiPas encore d'évaluation

- Holevolume CalcDocument59 pagesHolevolume Calcalsahel2004666Pas encore d'évaluation

- Lug For SkidDocument12 pagesLug For Skidsurefooted1Pas encore d'évaluation

- Pressure Vessel Lifting Lug CalculationDocument2 pagesPressure Vessel Lifting Lug Calculationtekstep767% (3)

- My Padeye CalcDocument10 pagesMy Padeye CalcReda Elawady100% (1)

- Steel BeamCal - Pointed Load + Beam's WeightDocument6 pagesSteel BeamCal - Pointed Load + Beam's WeightMana MungkornkritPas encore d'évaluation

- Beam DesignDocument6 pagesBeam DesignrustamriyadiPas encore d'évaluation

- Pad Footing DesignDocument15 pagesPad Footing DesignMalayan TigerPas encore d'évaluation

- 3 PilesDocument37 pages3 PilesAnonymous nwByj9LPas encore d'évaluation

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- Combined Footing CheckDocument34 pagesCombined Footing ChecksudarshanPas encore d'évaluation

- Aci BeamDocument6 pagesAci BeamkumsbamaPas encore d'évaluation

- Composite Steel GirderDocument10 pagesComposite Steel GirdersorowarePas encore d'évaluation

- Input Data: Subject: Base Plate ConnectionDocument5 pagesInput Data: Subject: Base Plate ConnectionSambhav PoddarPas encore d'évaluation

- Factsheet PDFDocument1 pageFactsheet PDFanbuaedPas encore d'évaluation

- Questionnaire PDFDocument5 pagesQuestionnaire PDFanbuaedPas encore d'évaluation

- Kalingarayan Canal - Wikipedia, The Free EncyclopediaDocument1 pageKalingarayan Canal - Wikipedia, The Free EncyclopediaanbuaedPas encore d'évaluation

- Perumpallam Dam - Wikipedia, The Free EncyclopediaDocument2 pagesPerumpallam Dam - Wikipedia, The Free EncyclopediaanbuaedPas encore d'évaluation

- Kunderipallam Dam - Wikipedia, The Free EncyclopediaDocument2 pagesKunderipallam Dam - Wikipedia, The Free EncyclopediaanbuaedPas encore d'évaluation

- Template - Bhavani River - Wikipedia, The Free EncyclopediaDocument1 pageTemplate - Bhavani River - Wikipedia, The Free EncyclopediaanbuaedPas encore d'évaluation

- Discharge Unit Values BS.5572:1978: Type of Sanitary Fitting Interval Between UseDocument6 pagesDischarge Unit Values BS.5572:1978: Type of Sanitary Fitting Interval Between UseArvensisdesign100% (3)

- Agriculture: 3.1. Soil Classification SL - No. Type of Soil Places in District (Taluks)Document12 pagesAgriculture: 3.1. Soil Classification SL - No. Type of Soil Places in District (Taluks)anbuaedPas encore d'évaluation

- Aibp PDFDocument17 pagesAibp PDFanbuaedPas encore d'évaluation

- Area and Population: Source: Census of India 2011Document4 pagesArea and Population: Source: Census of India 2011anbuaedPas encore d'évaluation

- Irrigation: Source: District G-Return Fasli-1423Document3 pagesIrrigation: Source: District G-Return Fasli-1423anbuaedPas encore d'évaluation

- 4 IrrigationDocument4 pages4 IrrigationanbuaedPas encore d'évaluation

- MEP Electrical CalculationDocument12 pagesMEP Electrical Calculationanbuaed100% (1)

- Chapter 6 - Monsoons Indian Climate Geography Lyst8370Document20 pagesChapter 6 - Monsoons Indian Climate Geography Lyst8370Deepak ShahPas encore d'évaluation

- Journal of Atmospheric Science Research - Vol.4, Iss.1 January 2021Document67 pagesJournal of Atmospheric Science Research - Vol.4, Iss.1 January 2021Bilingual PublishingPas encore d'évaluation

- Unit 3 Word ListsDocument2 pagesUnit 3 Word ListsBalungi Jacqueline KayagaPas encore d'évaluation

- Science - Grade 9 MULTIPLE CHOICE: Choose The Letter of The Correct AnswerDocument4 pagesScience - Grade 9 MULTIPLE CHOICE: Choose The Letter of The Correct AnswerBenson Corneja100% (1)

- Fluid Mechanics Assignment 2Document3 pagesFluid Mechanics Assignment 2AbcdePas encore d'évaluation

- Weather Scav HuntDocument10 pagesWeather Scav Huntapi-314363382Pas encore d'évaluation

- Analysis Design of TrussDocument29 pagesAnalysis Design of Trusssurendra_panga50% (2)

- Eupatorium Leonardii - Brittonia 2012Document8 pagesEupatorium Leonardii - Brittonia 2012Richelle FigueroaPas encore d'évaluation

- A Review On Cyclone Resistant Plants Found in Cyclone Prone Odisha IndiaDocument4 pagesA Review On Cyclone Resistant Plants Found in Cyclone Prone Odisha IndiaZiddo BiddoPas encore d'évaluation

- SkyCiv Wind Design Report - K4ABzzbmIrOe5Y4DkfYbmefYQicaeeN3 PDFDocument3 pagesSkyCiv Wind Design Report - K4ABzzbmIrOe5Y4DkfYbmefYQicaeeN3 PDFFilip CirovicPas encore d'évaluation

- 7 Science Worksheet ch8 1Document3 pages7 Science Worksheet ch8 1shanthi krishnaPas encore d'évaluation

- KhalidDocument3 pagesKhalidSyed Adnan AqibPas encore d'évaluation

- Seminar On Methods of IrrigationDocument25 pagesSeminar On Methods of IrrigationRavi MalikPas encore d'évaluation

- Block 05 Chinyalisaur - ResourceRate - MachineDocument3 pagesBlock 05 Chinyalisaur - ResourceRate - MachineManojPas encore d'évaluation

- Volcano WebquestDocument3 pagesVolcano WebquestRichard Muchow100% (1)

- Chapter One Introduction To River HydraulicsDocument53 pagesChapter One Introduction To River HydraulicsBirhan SetePas encore d'évaluation

- Coastal Wall FinalDocument8 pagesCoastal Wall Finalapi-508287240Pas encore d'évaluation

- 03 Steel Roof DesignDocument31 pages03 Steel Roof DesignvarunPas encore d'évaluation

- Course Specs Meteorology CHEDDocument9 pagesCourse Specs Meteorology CHEDReymarr Hijara100% (1)

- Rick Brant #23 Danger Below!Document188 pagesRick Brant #23 Danger Below!PastPresentFuture100% (1)

- Hydropedology Chap 2 A, PPT and MeasurementDocument34 pagesHydropedology Chap 2 A, PPT and MeasurementShado EamePas encore d'évaluation

- Class Viii Science Chap 14 NotesDocument2 pagesClass Viii Science Chap 14 NotesAbhaygyan SinghPas encore d'évaluation

- 1 SMDocument12 pages1 SMSkin 8Pas encore d'évaluation

- Convergent Plate Boundaries NOTESDocument15 pagesConvergent Plate Boundaries NOTESTracy NewKirkPas encore d'évaluation

- Cifra Club - Erasure - Blue SavannahDocument4 pagesCifra Club - Erasure - Blue SavannahfegenoliPas encore d'évaluation

- Earth Science Final Exam Review SheetDocument2 pagesEarth Science Final Exam Review SheetSteven Brian Bufford Jr.Pas encore d'évaluation

- Planet Mars Recent NASA ExploratoryDocument6 pagesPlanet Mars Recent NASA ExploratorykennedysfPas encore d'évaluation

- Cold Weather Safety Tips.Document2 pagesCold Weather Safety Tips.jgstorandt44Pas encore d'évaluation

- Mount Merapi - A Recent Eruption SummaryDocument1 pageMount Merapi - A Recent Eruption SummaryboohoosherooPas encore d'évaluation

- Celm TrasnetDocument28 pagesCelm TrasnetMarius LoleaPas encore d'évaluation