Académique Documents

Professionnel Documents

Culture Documents

APQP

Transféré par

Sachin KumbharDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

APQP

Transféré par

Sachin KumbharDroits d'auteur :

Formats disponibles

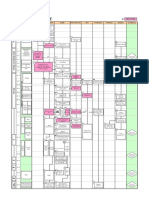

ADVANCED QUALITY PLANNING WORKSHEET

Part Number:

Part Name:

Program:

Customer:

Production Plans:

Scheduled Date for Initial Samples:

Scheduled Date for First Production:

Scheduled Date for Regular Production:

Quality Planning Elements

16

15

14

13

Quality Plan Report:

Original Issue Date:

Revision Date(s):

12

11

10

Weeks Prior to

Production Start

Initial Quality Assessments

Preliminary Feasibility

Quality History Review

Customer Complaints

Warranty Info (if applicable)

Prior Statistical Info

All Other Indicators

Process FMEA

Major Characteristics (Process/Product)

Gage & Test Equipment

Variable

Attribute

Standards Preparation

Process Flowchart including Control Points

Control Plan including SPC Requirements

Inspection Instruction Sheet

Prototype Build/Verification

Prototype Build with Process Potential for Feasiblity

Final Feasibility & Sign-off

Processing Equipment/Verification

Order Production Tooling, Gages, & Test Equipment

Process Potential Studies on Vendor's Floor

Setup & Debug Production & Inspection Equipment

Process Potential Studies for all Major Characs.

Evaluation Activities

Process Review/Production Sign-off

Process Sheets

Gage & Test Equipment

Packaging

Initial Sample & First Production Part Evaluation

SPC Data

Adapted from the APQP Ref. Manual

http://thequalityportal.com

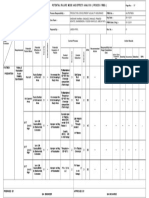

ADVANCED PRODUCT QUALITY PLANNING

STATUS REPORT

Date:

Supplier Name:

Part Number:

Location:

Part Name:

Supplier Code:

Revision Level:

RISK ASSESMENT

New:

Site

Technology

Team Members

Process

Company

Title / Position

Contact Information (tele, fax, mobile, pager, etc.)

Report the Ppk of each KPC on an on-going basis, as the process changes and new lots are manufactured

CAPABILITY STUDIES

KPC #

Date

APQP ELEMENTS

1

2

3

4

5

6

7

8

9

10

11

12

Design FMEA

Team Feasibility Commitment

Preliminary Process Flow and PFMEA

Design Review(s)

Facilities & Tools

Gauging and Test Equipment

Prototype Build Control Plan

Design, Drawings and Specifications

Logistics/EDI Capability

Packaging Specifications

Manufacturing Process Flow Chart

Process FMEA & Control Plan Review

Measurement Systems Evaluation

Pre-Launch Control Plan GP12

15 Operator Process Instructions

13

14

16

17

Production Trial Run (Capacity Verified)

Production Control Plan

19

Production Source Approval

Production Part Approval (PPAP)

20

Production Readiness

18

Additional Comments:

AIAG

APQP

Element

Status

(G/Y/R or

N/A)

Program

Date

Supplier

Date

Closed

Date

Resp.

Engineer

Initials

Remarks or Note Assistance Required

Vous aimerez peut-être aussi

- Procedure APQPDocument9 pagesProcedure APQPAzmul Fadhli80% (10)

- Advanced quality planning worksheetDocument1 pageAdvanced quality planning worksheetFernando MejíaPas encore d'évaluation

- Advanced Product Quality PlanningDocument35 pagesAdvanced Product Quality Planninggerry3854100% (2)

- APQP MatrixDocument4 pagesAPQP MatrixVikas KashyapPas encore d'évaluation

- CD6 Prototype Control PlanDocument3 pagesCD6 Prototype Control Planmpedraza-1Pas encore d'évaluation

- Advance Product Quality Planning - MatrixDocument6 pagesAdvance Product Quality Planning - Matrixomm100% (1)

- Apqp FormsDocument32 pagesApqp FormsAnonymous A2jnZ5MNPxPas encore d'évaluation

- Apqp Workflow - EXAMPLEDocument1 pageApqp Workflow - EXAMPLEMiguel NetoPas encore d'évaluation

- APQP Phases ActivitiesDocument1 pageAPQP Phases Activitiesaorto3919Pas encore d'évaluation

- S ApqpDocument15 pagesS ApqpIram ChaviraPas encore d'évaluation

- APQP Process AssessmentDocument3 pagesAPQP Process AssessmentSergio ArellanoPas encore d'évaluation

- PPAP Check List FormDocument5 pagesPPAP Check List FormRaju.PalPas encore d'évaluation

- Special Characteristics PDFDocument11 pagesSpecial Characteristics PDFKristof MCPas encore d'évaluation

- APQP Flow Chart and ProcedureDocument7 pagesAPQP Flow Chart and Procedurearun100% (1)

- APQPDocument3 pagesAPQPapi-3742290100% (10)

- APQP Timing Plan SampleDocument3 pagesAPQP Timing Plan SampleDhananjay Patil75% (4)

- Control plan optimizationDocument11 pagesControl plan optimizationRadhika GuptaPas encore d'évaluation

- APQP Documentation ChecklistsDocument67 pagesAPQP Documentation ChecklistsNeumar NeumannPas encore d'évaluation

- APQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionDocument6 pagesAPQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionParveen KumarPas encore d'évaluation

- APQP 3 - 1 Pan Brand Reporter V7c (586) Rev 19Document49 pagesAPQP 3 - 1 Pan Brand Reporter V7c (586) Rev 19Pranjal JangidPas encore d'évaluation

- AIAG PPAP Cover SheetDocument1 pageAIAG PPAP Cover SheetSCHOPENHAUERPas encore d'évaluation

- Sr. No. Requirements: Ppap Check ListDocument3 pagesSr. No. Requirements: Ppap Check Listkamlesh kuchekarPas encore d'évaluation

- Customer:: Potential Failure Mode and Effect Analysis (Process FMEA)Document8 pagesCustomer:: Potential Failure Mode and Effect Analysis (Process FMEA)Rajnish PotdarPas encore d'évaluation

- APQP TemplateDocument7 pagesAPQP TemplateBob ZepfelPas encore d'évaluation

- NPIDocument1 pageNPIsuree_leo0% (1)

- 48 Point Ppap Check SheetDocument39 pages48 Point Ppap Check SheetSanjay KumarPas encore d'évaluation

- Responsibility Matrix 1of ApqpDocument4 pagesResponsibility Matrix 1of ApqpanuailddPas encore d'évaluation

- SPC FormatDocument1 pageSPC FormatM.saravanan100% (4)

- NPD Check SheetDocument6 pagesNPD Check Sheets.charliePas encore d'évaluation

- AIAG & VDA PFMEA FormatDocument1 pageAIAG & VDA PFMEA Formatmahesh KhatalPas encore d'évaluation

- Fsqm-080 Ppap ChecklistDocument14 pagesFsqm-080 Ppap ChecklistMohamed Khalifa100% (1)

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDocument3 pagesRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanPas encore d'évaluation

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageDocument6 pagesAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (2)

- Product Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDocument8 pagesProduct Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDavid MorenoPas encore d'évaluation

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- Evidences To Be Maintained As Per APQP For PMDocument3 pagesEvidences To Be Maintained As Per APQP For PMSachin RamdurgPas encore d'évaluation

- PPAP TemplatesDocument23 pagesPPAP Templatestejesh77100% (1)

- CD6 Prototype PFMEADocument4 pagesCD6 Prototype PFMEAmpedraza-1Pas encore d'évaluation

- Control Plan 1st Edition - AnalysisDocument9 pagesControl Plan 1st Edition - AnalysisYassin Serhani100% (1)

- Manual - APQP 20121017 PDFDocument135 pagesManual - APQP 20121017 PDFBerk NoyanPas encore d'évaluation

- Complete PPAP OverviewDocument166 pagesComplete PPAP OverviewblkdirtymaxPas encore d'évaluation

- Sop SeDocument60 pagesSop SemanttupandeyPas encore d'évaluation

- APQP OS Procedure ExampleDocument8 pagesAPQP OS Procedure Exampleali qaPas encore d'évaluation

- Fmea CastingDocument4 pagesFmea CastingSuraj RawatPas encore d'évaluation

- Server Room Planning PortfolioDocument326 pagesServer Room Planning PortfolioAbdel Nasser AdamPas encore d'évaluation

- IATF 16949 GM CSR Aug 2023Document30 pagesIATF 16949 GM CSR Aug 2023Cisca NattPas encore d'évaluation

- Part Submission Warrant for GROM P473 BDocument1 pagePart Submission Warrant for GROM P473 BTrivesh SPas encore d'évaluation

- Layout Inspection Report XH5DR June 20 2012Document17 pagesLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- APQP ENG SiemensDocument12 pagesAPQP ENG SiemensVikash KumarPas encore d'évaluation

- GM APQP Manual - GM1927 - Revision 1Document57 pagesGM APQP Manual - GM1927 - Revision 1Vaspeo100% (2)

- PPAPDocument16 pagesPPAPOsvaldo Da Silva Neto100% (1)

- APQP Timing Plan TemplateDocument9 pagesAPQP Timing Plan TemplatemuthuselvanPas encore d'évaluation

- Plating FMEADocument1 pagePlating FMEAshiv jangale80% (5)

- With What (Infrastructure) With Who (Personnel) Risk Assessment ModelDocument3 pagesWith What (Infrastructure) With Who (Personnel) Risk Assessment Model80ALLA86i100% (2)

- Production Part Approval Process A Complete Guide - 2019 EditionD'EverandProduction Part Approval Process A Complete Guide - 2019 EditionPas encore d'évaluation

- Supplier Performance Management Process A Complete Guide - 2019 EditionD'EverandSupplier Performance Management Process A Complete Guide - 2019 EditionPas encore d'évaluation

- Advanced Quality Planning Status ReportDocument2 pagesAdvanced Quality Planning Status ReportrajivggocPas encore d'évaluation

- Apqp PpapDocument50 pagesApqp PpapEvandro Ribeiro50% (2)

- Cópia de Bulk Material Checklist - Material A GranelDocument1 pageCópia de Bulk Material Checklist - Material A GranelPaulaMagalhãesPas encore d'évaluation

- ALL INDIA SAINIK SCHOOLS ENTRANCE EXAM AISSEE - AISSEE - 2024_ India Vidhi kumbharDocument1 pageALL INDIA SAINIK SCHOOLS ENTRANCE EXAM AISSEE - AISSEE - 2024_ India Vidhi kumbharSachin KumbharPas encore d'évaluation

- Gratuity Application Sachin KumbharDocument1 pageGratuity Application Sachin KumbharSachin KumbharPas encore d'évaluation

- 040501503439SheetDocument24 pages040501503439SheetSachin KumbharPas encore d'évaluation

- Side Hsg LH & RH Cold Patch 14.2.23 detailsDocument2 pagesSide Hsg LH & RH Cold Patch 14.2.23 detailsSachin KumbharPas encore d'évaluation

- S.G.Iron GuidelinesDocument28 pagesS.G.Iron GuidelinesTarun Chakraborty100% (3)

- 040501535731SheetDocument24 pages040501535731SheetSachin KumbharPas encore d'évaluation

- APR-22 CLD 4th weekDocument10 pagesAPR-22 CLD 4th weekSachin KumbharPas encore d'évaluation

- 07.Data For ppt OCT-21Document94 pages07.Data For ppt OCT-21Sachin KumbharPas encore d'évaluation

- MAPL day wise plan vs actual May week1-4Document36 pagesMAPL day wise plan vs actual May week1-4Sachin KumbharPas encore d'évaluation

- MAPL plan 23 jan to 31 janDocument28 pagesMAPL plan 23 jan to 31 janSachin KumbharPas encore d'évaluation

- Observations 05.11.2022Document7 pagesObservations 05.11.2022Sachin KumbharPas encore d'évaluation

- final ProgrammeDocument4 pagesfinal ProgrammeSachin KumbharPas encore d'évaluation

- 8 D For ShrinkageDocument6 pages8 D For ShrinkageSachin KumbharPas encore d'évaluation

- Aspect ImpactsDocument36 pagesAspect ImpactsSachin KumbharPas encore d'évaluation

- Eat That Frog!: A Seminar On Brian Tracy's Famous Time Management BookDocument10 pagesEat That Frog!: A Seminar On Brian Tracy's Famous Time Management BookThoi Duong100% (4)

- 06613G SampleDocument10 pages06613G SampleMuhammad FadhlanPas encore d'évaluation

- Flow ChartDocument1 pageFlow ChartSachin KumbharPas encore d'évaluation

- Environmental Requirements STDDocument13 pagesEnvironmental Requirements STDSachin KumbharPas encore d'évaluation

- 05 Lustrous Carbon Incl PDFDocument2 pages05 Lustrous Carbon Incl PDFbvphimanshuPas encore d'évaluation

- Core MFG Process ChartDocument4 pagesCore MFG Process ChartSachin KumbharPas encore d'évaluation

- Feeding Systems Product DatasheetDocument6 pagesFeeding Systems Product DatasheetSachin KumbharPas encore d'évaluation

- SapreDocument20 pagesSapreSachin KumbharPas encore d'évaluation

- Vastu Colors For HomeDocument2 pagesVastu Colors For HomeSachin KumbharPas encore d'évaluation

- 3.1 Certficate PDFDocument13 pages3.1 Certficate PDFSachin KumbharPas encore d'évaluation

- 05 Lustrous Carbon Incl PDFDocument2 pages05 Lustrous Carbon Incl PDFbvphimanshuPas encore d'évaluation

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesSachin KumbharPas encore d'évaluation

- Thermal Analysis PDFDocument25 pagesThermal Analysis PDFSachin Kumbhar0% (1)

- Workplace Inspection Checklist: General Yes No NotesDocument4 pagesWorkplace Inspection Checklist: General Yes No NotesSachin KumbharPas encore d'évaluation

- Graphite NodulesDocument10 pagesGraphite NodulesSachin KumbharPas encore d'évaluation

- PFMEA RankingDocument1 pagePFMEA RankingSachin KumbharPas encore d'évaluation