Académique Documents

Professionnel Documents

Culture Documents

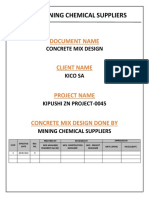

Grade of Concrete M20: Dy - Quality Head

Transféré par

Asha JyothiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Grade of Concrete M20: Dy - Quality Head

Transféré par

Asha JyothiDroits d'auteur :

Formats disponibles

GRADE OF CONCRETE M20

CEMENT CONTENT

FREE WATER

FREE W/C RATIO

3

310 kgs / m

3

140 kgs / m

0.45

=

=

=

DETERMINATION OF CA & FA CONTENT

310

FA -

1000 =

140.00

3.15

310

CA -

1000 =

140.00

fa

0.38

2.57

Ca

+

3.15

1

X

744 Kgs

1247 Kgs

1000

1

X

0.62

2.64

1000

TOTAL DRY CA & FA

1990 kgs

CEMENT

CA 20 mm ( SSD )

CA 10 mm ( SSD )

RIVER SAND ( SSD )

CRUSHER SAND ( SSD )

WATER

DENSITY

=

=

=

=

=

=

=

310

623

623

521

223

140

2440

kgs

kgs

kgs

kgs

kgs

kgs

kgs

Dy.Quality Head

CONCRETE INDIA

PROJECT

: M/s Navayuga Engineering Company Ltd

LOCATION

: Bengaluru

DATE : 28-01-2016

GRADE OF CONCRETE

TARGET MEAN STRENGTH

MAXIMUM SIZE OF AGGREGATE, mm

SLUMP OF CONCRETE, mm

( AT SITE )

BASIC DATA

BRAND OF CEMENT

TYPE OF CEMENT

SPECIFIC GRAVITY OF CEMENT

SOURCE OF FINE AGGREGATE ( MANUFACTURED SAND )

SOURCE OF FINE AGGREGATE ( CRUSHER SAND )

AVE. SPECIFIC GRAVITY OF FINE AGGREGATE

WATER ABSORPTION OF FINE AGG ( MANUFACTURED SAND )

WATER ABSORPTION OF FINE AGG ( CRUSHER SAND )

FA IN TOTAL AGGREGATE ( MANUFACTURED SAND & CRUSHER SAND )

SOURCE OF COARSE AGGREGATE

TYPE OF COARSE AGGREGATE

AVE. SPECIFIC GRAVITY OF COARSE AGGREGATE

AVE. WATER ABSORPTION OF COARSE AGGREGATE

COARSE AGGREGATE IN TOTAL AGG (20mm & 10mm)

SUPPLIER NAME OF CHEMICAL ADMIXTURE

TYPE OF CHEMICAL ADMIXTURE

PRODUCT NAME OF CHEMICAL ADMIXTURE

DOSAGE OF ADMIXTURE - (% BY Wt OF CEMENT)

RECOMMENDED REDOSAGE AT SITE MAX. (% BY Wt OF CEMENT)

%

%

%

%

%

%

%

:

:

:

:

M20

26.60 N/mm2

20

120. +/- 20 mm

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

BHARATHI/ULTRA TECH

OPC (53 GRADE)

3.15

CHIKKABALAPUR

HOSKOTE

2.57

2.5

3.5

38.00

CHIKKABALAPUR

CRUSHED ROCK

2.64

0.5

62.00

ECMAS

SUPERPLASTICIZER

ECMAS HP 890

0.55

0.2

MATERIAL REQUIRED PER CUM OF CONCRETE

CEMENT

CA 20 mm ( SSD )

CA 10 mm ( SSD )

M.SAND ( SSD )

CRUSHER SAND ( SSD )

WATER

ADMIXTURE

TOTAL DENSITY OF FRESH CONCRETE

:

:

:

:

:

:

:

:

310

623

623

521

223

140

1.705

2442

MIX PROPORTION BY WEIGHT

CEMENT

1

F.A

2.4

C.A

4.02

Note :1 FOR WEIGH BATCHING CORRECTION FOR MOISTURE IN AGGREGATES SHOULD BE DONE DAILY

Dy.Quality Head

CONCRETE INDIA

Kgs

Kgs

Kgs

Kgs

Kgs

Kgs

Kgs

Kgs

Report on Concrete Mix Design ( M20 )

The Concrete mix design is a process of selecting suitable ingredient for concrete and determining

their proportions i.e. concrete having a certain minimum compressive strength , workability and

durability. The mix design has been carried out as per stipulation of Indian Standard IS : 10262 - 1982

( Reaff 1989 & 1999 ). Keeping in view the recommended standard deviation and target mean strength .

In this method of mix design,the water content and proportion of fine aggregate corresponding to a

maximum size of aggregate are first determined for referred values of workability water cement ratio

and grading of fine aggregate. The batch weight of materials per unit volume of concrete is finally ,

calculated by the absolute volume method. The mix proportion have suitably modified successively

based on trial mixes to arrive at an optimum mix proportion . It satisfies the requirement of desired

workability and 28 days strength of concrete .

BATCH SHEET

QUANTITY OF MATERIAL, M3

BY WEIGHT

1.000

CEMENT

310 Kgs

CA 20 mm ( DRY )

620 Kgs

CA 10 mm ( DRY )

620 Kgs

M.SAND ( DRY )

515 Kgs

CRUSHER SAND ( DRY )

218 Kgs

WATER

157 Kgs

ADMIXTURE

1.705 Kgs

Note

1.

2.

3.

4.

5.

For Weigh Batching correction for moisture in aggregate should be done daily.

Mix design calculation are based on IS : 10262 & IS : 456

Concrete Specimens cured in water & tested as per IS : 516

Compressive Strength conducted on standard specimen of 150mm cubes .

Proportions of Aggregate may vary, as per grading available at time of pour .

References

1. IS : 10262 - 1982 ( Reaffirmed 1989 - 1999 )

2. IS : 456 - 2000

3. SP : 23

Dy.Quality Head

CONCRETE INDIA

Vous aimerez peut-être aussi

- Training at Gurjar Ki Thadi Under Pass, JaipurDocument37 pagesTraining at Gurjar Ki Thadi Under Pass, JaipurDevendra SharmaPas encore d'évaluation

- A Practical Guide to Concrete Pavement Technology for Developing CountriesD'EverandA Practical Guide to Concrete Pavement Technology for Developing CountriesPas encore d'évaluation

- New Rabbit and Tortoise StoryDocument31 pagesNew Rabbit and Tortoise StoryAbd Rahman IbrahimPas encore d'évaluation

- Andhra Maha Bhagavatam Part 01Document150 pagesAndhra Maha Bhagavatam Part 01KumarPas encore d'évaluation

- Problem Set 3 Simulation ActivityDocument12 pagesProblem Set 3 Simulation Activityapi-182809945Pas encore d'évaluation

- Crane Pedestral DesignDocument18 pagesCrane Pedestral Designgautham21brickPas encore d'évaluation

- Surface Preparation and Coating Inspection Report for Tasiast Tailings ThickenerDocument2 pagesSurface Preparation and Coating Inspection Report for Tasiast Tailings ThickenerRekhis OussamaPas encore d'évaluation

- Concrete Mix Design M60 Grade of Concrete OPC 53 GradeDocument3 pagesConcrete Mix Design M60 Grade of Concrete OPC 53 GradeAjinkya MahajanPas encore d'évaluation

- Is Concrete Mix DesignDocument21 pagesIs Concrete Mix DesignahmedanyPas encore d'évaluation

- Concrete Mix DesignDocument22 pagesConcrete Mix DesignkevalPas encore d'évaluation

- Concrete Mix Design C30 - ACI METHODDocument4 pagesConcrete Mix Design C30 - ACI METHODMitendra Kumar ChauhanPas encore d'évaluation

- Concrete Mix Design C30 - ACI METHODDocument4 pagesConcrete Mix Design C30 - ACI METHODMitendra Kumar ChauhanPas encore d'évaluation

- Exploratory Project ON Concrete Mix DesignDocument28 pagesExploratory Project ON Concrete Mix DesignAMAN GUPTAPas encore d'évaluation

- Concrete Mix DesignDocument27 pagesConcrete Mix DesignMahadi HasanPas encore d'évaluation

- Mix Design M-40Document10 pagesMix Design M-40psjjoshiPas encore d'évaluation

- M60 Grade Concrete Mix Design Using OPC 53 Grade CementDocument2 pagesM60 Grade Concrete Mix Design Using OPC 53 Grade CementgreatpicPas encore d'évaluation

- M-15 PCCDocument38 pagesM-15 PCCRaj PandeyPas encore d'évaluation

- Concrete Mix DesignDocument7 pagesConcrete Mix DesignUma MaheshwaraPas encore d'évaluation

- Cube Tests Doc-20181030-Wa0009Document6 pagesCube Tests Doc-20181030-Wa0009kundayi shavaPas encore d'évaluation

- Design of Concrete Mix of M30 Grade: Report Prepared ForDocument5 pagesDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathPas encore d'évaluation

- Concrete Mix Design: A S M Fahad Hossain Assistant Professor Department of Civil Engineering, AUSTDocument28 pagesConcrete Mix Design: A S M Fahad Hossain Assistant Professor Department of Civil Engineering, AUSTshifatPas encore d'évaluation

- Material Test Data and Concrete Mix DesignDocument3 pagesMaterial Test Data and Concrete Mix DesignlombangrurusPas encore d'évaluation

- Mix Design M40 Grade Per IS 10262 & IS 456Document6 pagesMix Design M40 Grade Per IS 10262 & IS 456Sanjoy RoyPas encore d'évaluation

- Project On Partial Replacement of Cement With Marble PowderDocument11 pagesProject On Partial Replacement of Cement With Marble PowderSaurabh Pandey100% (2)

- Mix DesignDocument6 pagesMix DesignSwapnika BodapatiPas encore d'évaluation

- Evaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSDocument14 pagesEvaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSumadevi rangaswamyPas encore d'évaluation

- M30 Normal - Mix Design With Trial SheetDocument4 pagesM30 Normal - Mix Design With Trial Sheetabir senguptaPas encore d'évaluation

- Dharmendra Kumar Roll No 7259363Document27 pagesDharmendra Kumar Roll No 7259363Neeraj MehtaPas encore d'évaluation

- M 20 Mix Design Sample ReportDocument3 pagesM 20 Mix Design Sample ReportRakesh ReddyPas encore d'évaluation

- Group 1Document67 pagesGroup 1santoshPas encore d'évaluation

- Concrete Mix Design M20 GradeDocument4 pagesConcrete Mix Design M20 GradeSyerifaizal Hj. MustaphaPas encore d'évaluation

- Concrete Mix Design ExplainedDocument21 pagesConcrete Mix Design ExplainedPratyush Kumar DoraPas encore d'évaluation

- Concrete Mix DesignDocument92 pagesConcrete Mix Designtanveer100% (1)

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Document6 pagesConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)jishad_nalakath50% (2)

- Advances in Rigid Pavement DesignDocument108 pagesAdvances in Rigid Pavement Designdhanush gtPas encore d'évaluation

- Chapter 5-Mix DesignDocument51 pagesChapter 5-Mix DesignJaphet LudovickPas encore d'évaluation

- Partial Replacement of Cement with Marble PowderDocument11 pagesPartial Replacement of Cement with Marble PowderDipin Raj D KPas encore d'évaluation

- Specific Gravity & Water Absorption Test (I S 2386 Iii/63)Document11 pagesSpecific Gravity & Water Absorption Test (I S 2386 Iii/63)End EndPas encore d'évaluation

- Concrete Mix DesignDocument4 pagesConcrete Mix DesignZakir AliPas encore d'évaluation

- Coconut Shell As Partial Replacement of Coarse Aggregate in ConcreteDocument4 pagesCoconut Shell As Partial Replacement of Coarse Aggregate in ConcreteGelo LibanPas encore d'évaluation

- CONCRETE MIX DESIGN GUIDEDocument7 pagesCONCRETE MIX DESIGN GUIDEJaime Manalili Landingin0% (1)

- Second Review - Batch 03-1Document16 pagesSecond Review - Batch 03-119114 GovindPas encore d'évaluation

- Partillay Replacement of Sand by Artifical Sand in Ferrocement Used in Road ConstructionDocument28 pagesPartillay Replacement of Sand by Artifical Sand in Ferrocement Used in Road ConstructionNagaraj GuptaPas encore d'évaluation

- Exploratory Project 2Document43 pagesExploratory Project 2AMAN GUPTAPas encore d'évaluation

- Mechanical Properties of Self-Compacting Concrete with Sandstone SlurryDocument8 pagesMechanical Properties of Self-Compacting Concrete with Sandstone SlurryVishal VyasPas encore d'évaluation

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument61 pagesTest Report: M/S Abhi Engg Corporation PVT LTDimran khanPas encore d'évaluation

- Irjet V8i7747Document6 pagesIrjet V8i7747KhanPas encore d'évaluation

- Project Report On Marble DustDocument13 pagesProject Report On Marble Dustchandru civil100% (1)

- Pipe Thickness Design For 1900mm DiameterDocument8 pagesPipe Thickness Design For 1900mm DiameterAjayvidyanand SharmaPas encore d'évaluation

- Concrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDocument5 pagesConcrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDattatreya DattuPas encore d'évaluation

- New Microsoft Word DocumentDocument5 pagesNew Microsoft Word DocumentDattatreya Dattu0% (1)

- New Microsoft Word DocumentDocument5 pagesNew Microsoft Word DocumentDattatreya DattuPas encore d'évaluation

- Design Mix MethodDocument18 pagesDesign Mix Methodaryan royPas encore d'évaluation

- Mix DesignDocument6 pagesMix DesignCharan Tej RudralaPas encore d'évaluation

- Concrete Mix Design GuideDocument15 pagesConcrete Mix Design Guidekarthiksamp100% (1)

- Concrete Mix Design C30 - MKICO SITEDocument7 pagesConcrete Mix Design C30 - MKICO SITEMitendra Kumar Chauhan0% (1)

- Experimental Investigation On Partial Replacement of Sand by Pond Ash and Coarse Aggregate by Steel FibreDocument19 pagesExperimental Investigation On Partial Replacement of Sand by Pond Ash and Coarse Aggregate by Steel FibreAbhinav ChaharPas encore d'évaluation

- Material Testing Laboratory ExperimentDocument25 pagesMaterial Testing Laboratory ExperimentPriyankaPas encore d'évaluation

- Concrete Mix Design: by K.ShahDocument48 pagesConcrete Mix Design: by K.ShahBùi Quang MinhPas encore d'évaluation

- Comparing Durability of Locally Produced OPC and PCC Cements Using RCPTDocument6 pagesComparing Durability of Locally Produced OPC and PCC Cements Using RCPTToufik AhmedPas encore d'évaluation

- Abstract: Problem Based LearningDocument10 pagesAbstract: Problem Based LearningHaris RiazPas encore d'évaluation

- 1) Summary of RequirementsDocument4 pages1) Summary of RequirementsSolomon MehariPas encore d'évaluation

- Ceramic Waste As Coarse Aggregate PDFDocument4 pagesCeramic Waste As Coarse Aggregate PDFT N Roland BourgePas encore d'évaluation

- Lecture Notes on Reinforced Concrete DesignD'EverandLecture Notes on Reinforced Concrete DesignPas encore d'évaluation

- Interface / Interphase in Polymer NanocompositesD'EverandInterface / Interphase in Polymer NanocompositesAnil N. NetravaliPas encore d'évaluation

- Speci of Highway LandscapingDocument1 pageSpeci of Highway LandscapingAsha JyothiPas encore d'évaluation

- Grade of Concrete M20: Dy - Quality HeadDocument3 pagesGrade of Concrete M20: Dy - Quality HeadAsha JyothiPas encore d'évaluation

- Grade of Concrete M20: Dy - Quality HeadDocument3 pagesGrade of Concrete M20: Dy - Quality HeadAsha JyothiPas encore d'évaluation

- National Highway Fee Rulle 2008Document28 pagesNational Highway Fee Rulle 2008Asha JyothiPas encore d'évaluation

- RtoDocument1 pageRtoAsha JyothiPas encore d'évaluation

- Rental AgrementDocument4 pagesRental AgrementAsha JyothiPas encore d'évaluation

- Bus Shelter ModelDocument1 pageBus Shelter ModelAsha JyothiPas encore d'évaluation

- Cost Indices of HighwaysDocument9 pagesCost Indices of HighwaysAsha JyothiPas encore d'évaluation

- Rathaya Garu ModelDocument1 pageRathaya Garu ModelAsha JyothiPas encore d'évaluation

- Asha Jyothi Sajja ResumeDocument2 pagesAsha Jyothi Sajja ResumeAsha JyothiPas encore d'évaluation

- Sai Vrat Katha in English PDFDocument7 pagesSai Vrat Katha in English PDFsaipmpatil67% (3)

- Pavement Design Report Rev2!15!11 2011Document64 pagesPavement Design Report Rev2!15!11 2011Asha JyothiPas encore d'évaluation

- Labour Off 2Document1 pageLabour Off 2Asha JyothiPas encore d'évaluation

- Chilly Prawn RecipeDocument3 pagesChilly Prawn RecipeAsha JyothiPas encore d'évaluation

- Cauliflower RecipesDocument41 pagesCauliflower Recipespoosky2061Pas encore d'évaluation

- Crochet BagDocument23 pagesCrochet Bagpsstpapers100% (8)

- Lead Statement 2012-13Document2 pagesLead Statement 2012-13Asha JyothiPas encore d'évaluation

- MSP - SyllabusDocument1 pageMSP - SyllabusAsha JyothiPas encore d'évaluation

- MBA STATISTICS - CLASS INTERVALS, DATA TYPESDocument17 pagesMBA STATISTICS - CLASS INTERVALS, DATA TYPESAsha JyothiPas encore d'évaluation

- WPI Dec 2013Document1 pageWPI Dec 2013Asha JyothiPas encore d'évaluation

- Managerial Economics - Set - 2Document15 pagesManagerial Economics - Set - 2Asha JyothiPas encore d'évaluation

- Managerial Economics - Set - 1Document25 pagesManagerial Economics - Set - 1Asha JyothiPas encore d'évaluation

- Management Process - Set - 2Document17 pagesManagement Process - Set - 2Asha JyothiPas encore d'évaluation

- Management Process - Set - 1Document12 pagesManagement Process - Set - 1Asha JyothiPas encore d'évaluation

- Improve Employee SkillsDocument12 pagesImprove Employee SkillsAsha JyothiPas encore d'évaluation

- OPTIMIZE CASH FLOWDocument10 pagesOPTIMIZE CASH FLOWAsha JyothiPas encore d'évaluation

- HRM-set - 1Document17 pagesHRM-set - 1Asha JyothiPas encore d'évaluation

- Geotechnical Design Manual FinalDocument190 pagesGeotechnical Design Manual FinalBrhane W Ygzaw100% (4)

- Jee Mains Force and Newton Laws of Motion Ezyexamsolution Sol-03Document6 pagesJee Mains Force and Newton Laws of Motion Ezyexamsolution Sol-03Oyas DubeyPas encore d'évaluation

- Joule Brayton CycleDocument12 pagesJoule Brayton CyclecaptfoleyPas encore d'évaluation

- A985 A985m-2019Document12 pagesA985 A985m-2019Kamal ThummarPas encore d'évaluation

- RHA ResumeDocument2 pagesRHA ResumeJames McFarlanePas encore d'évaluation

- TOA DKK Water Quality Sensor Xseries PreDocument12 pagesTOA DKK Water Quality Sensor Xseries PrealdiniPas encore d'évaluation

- ADHD Medication For Adults and Children: Vyvanse, Ritalin, Concerta, Adderall, Strattera...Document4 pagesADHD Medication For Adults and Children: Vyvanse, Ritalin, Concerta, Adderall, Strattera...rico ruben100% (1)

- The Cassini Ion and Neutral Mass Spectrometer (Inms) InvestigationDocument119 pagesThe Cassini Ion and Neutral Mass Spectrometer (Inms) InvestigationDima FontainePas encore d'évaluation

- Aggregate Impact Value TestDocument6 pagesAggregate Impact Value Testnadz_fynazPas encore d'évaluation

- Astm e 518Document5 pagesAstm e 518Pao Dela Cruz100% (1)

- Grade 10 - ch2, 100Document2 pagesGrade 10 - ch2, 100NayLinPas encore d'évaluation

- V. Divakar Botcha Et al-MRX-2016Document14 pagesV. Divakar Botcha Et al-MRX-2016divakar botchaPas encore d'évaluation

- Coulombs Law PowerpointDocument48 pagesCoulombs Law PowerpointOmar JeCkPas encore d'évaluation

- A2 Earth ResistanceDocument2 pagesA2 Earth ResistanceSudharsanan SitrarasuPas encore d'évaluation

- MInirhizotron ThecniquesDocument16 pagesMInirhizotron ThecniquesHector Estrada MedinaPas encore d'évaluation

- Linx Duct Friction CalculatorDocument12 pagesLinx Duct Friction CalculatorLeonardo Martinho DobrianskyjPas encore d'évaluation

- DyeDocument12 pagesDyeVeby LamanepaPas encore d'évaluation

- Statistical Treatment of Some Properties of Beans: Chemistry 3225 K. PierceDocument2 pagesStatistical Treatment of Some Properties of Beans: Chemistry 3225 K. Piercespiff spacemanPas encore d'évaluation

- Harmony IIIDocument60 pagesHarmony IIIRenan GonzalezPas encore d'évaluation

- F2 = 30 kNm)2/4) 70 × 109 N/m2Document11 pagesF2 = 30 kNm)2/4) 70 × 109 N/m2Don ValentinoPas encore d'évaluation

- H02152Document1 pageH02152Javier Lora BarbaPas encore d'évaluation

- Konelab 20Document2 pagesKonelab 20mrashrafi100% (1)

- Welding Carbon Steels Thesis PDFDocument285 pagesWelding Carbon Steels Thesis PDFstanyeahPas encore d'évaluation

- The Nuclear Reactions Involved in The Synthesis of New ElementsDocument3 pagesThe Nuclear Reactions Involved in The Synthesis of New ElementsChristian Isip67% (3)

- Half Yearly - Syllabus Class - XiiDocument2 pagesHalf Yearly - Syllabus Class - XiiSky SirPas encore d'évaluation

- Mass Transfer Aka Sir AssignmentDocument4 pagesMass Transfer Aka Sir Assignmentওয়াসিমPas encore d'évaluation

- Membrane ReactorDocument9 pagesMembrane ReactorAzharuddin Ehtesham FarooquiPas encore d'évaluation