Académique Documents

Professionnel Documents

Culture Documents

API Oil Engine Classifications 2013

Transféré par

sinhleproviet0 évaluation0% ont trouvé ce document utile (0 vote)

31 vues10 pagesPhân loại dầu động cơ theo API

Mr Sinh - AP SAIGON PETRO LUBRICANT EXPERT.

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentPhân loại dầu động cơ theo API

Mr Sinh - AP SAIGON PETRO LUBRICANT EXPERT.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

31 vues10 pagesAPI Oil Engine Classifications 2013

Transféré par

sinhleprovietPhân loại dầu động cơ theo API

Mr Sinh - AP SAIGON PETRO LUBRICANT EXPERT.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 10

CRANKCASE LUBRICANT SPECIFICATIONS. urns)

API Engine Oil Classifications

SERVICE FILL OILS FOR GASOLINE, LIGHT-DUTY DIESEL AND HEAVY-DUTY DIESEL ENGINES

ec Infineum>

€INFINEUM INTERNATIONAL LMMTED 2014 A aight resend.

Pa

TECHNOLOGY RELIABILITY COLLABORATION

EXCELLENCE

Sa ees

API Engine Oil Classifications

For Service Fill Oils

Requirements for API SN are the same as those for API SN-RC,

except as noted in the table to the right.

Footnotes

(1) Not required for SAE ow-20,

(2) Not required for SN Non-ILSAC GS viscosity grades.

(6) 45 max for SN NorsILSAC GF wscosty grades.

(@) No maximum for SN NonsLSAC GF-5 viscosity grades.

(6) IF API Ck and/or Ch categories precede the °S" category and there is no API Certification Mark,

the Sequence VG (ASTM D653), Ball Rust (ASTM D6557), and Gelatin index (ASTM DS133) tests

are not required

(© Viscosity grades are mite to SAE OW, SW and TOW muligrade ois.

(7) Not required for monograde and SAE 15M, 20W, and 25W mutigrade oils.

(6) Galulated conversions specified in ASTM D5800 ae allowed.

(0) For all viscosity grades: I API CH-4, 4 and/or C-4 categories precede the °S’ category and there

isn API Certification Mark, the °S category mits for phosphors, sulfur, and the TEOST MHT do

not apply. However, the C4 limits for phosphorus and sulfur do apply fr C-4 ols

(10) This isa non-critical speciation as described in ASTM D244,

(11) After I-minut settling period forall ILSAC viscosity grades and all SN-RC ols

(12) after 10-minute setting period for nonLSAC GF-5 viscosity grades which are not SN-RC.

(13) Shall remain homogeneous and, when miked with ASTM reference ols, shall remain miscible.

(14) Tobe evaluated from -5'C to temperature at which 40,000 es attained or ~40°C or2 Celsius

degrees below the appropriate MRV TP-1 temperature (defined by SRE 1500), whichever occurs ist.

(15) Not Required for SW ILSAC GF viscosity grades which do not also contain the API Certification

Matk or are not SN-RC.

(16) The aged ols an endo test sample generated either in the Sequence IGA test (ASTM D7320)

or the ROBO test (ASTM 07528).

(17) The temperature at which the ASTM D4684 (NIRV TP-1) testis conducted i determined by fist

measuring the low-temperature cranking viscosity (CCS) ofthe aged oil sample atthe temperature

comtesponding tothe original viscosity grade in SAE 1300.

(8) CCS viscosity measured is less than or equal tothe maximum CCS viscosity specified

forthe origina viscosity grade, run ASTM 04684 at the low-temperature pumping viscosity

temperatute specified in SAE [500 forthe orginal viscosity grade.

(b) IFCCS viscosity measured is higher than the maximum CCS viscosity spected forthe orginal

\iscosity grade in SRE 1300, un ASTM D46B4 at 5°C higher temperature.

3

‘© ININEUMIVTERNATONAL UTED 2018, igh reene.

Passenger Car Engine Oil Laboratory/Bench Test and Engine Test Requirements For API SN-RC/ILSAC GF-5 Categories

1. LABORATORY/ BENCH TESTS

ety Grades te 100 lose that app, pel Se 0 20, anulcare at tgs

(3, 51-20, 5130 anon 30 within SAE B00 petition

Foam Tes {ASTN.DES2, Option A Sequence tendency ml 10/0 mae

Seguenee i tendency aby 9 a sty mae

Sequence Il tedeney/ aby a 10/0 mae

‘Asi 06082, option A Seuene end) a ‘og/a mx

fon Ast 06795 Fiery Seow econ somax

Four ‘asia 6794 itera with 68 Water Seow edcion Oma

Fiery oath 10% Water Seow eden Soman

Fitri oth 20% Wer Selo redocion Soma

Fiery nth 30% Wer Sef eden Somax

deed ast O68 IMRT Apart scot and Vid Stess @andPa “a0 wth yl se 6877

LeyrTemperatre Pupil

TeOsTSC AST DS igh temperate depests tol depot weigh ng 30 maxi

TEOSTAT® ‘asia 07097 High temperate depests epost wight, 35a)

Erulsionreteton ASIN 07565 (i mite wih 10% tr and 108 85 € nd25 8 24 haus No wate separation 5

Homogeneity & Miscbiliy | AST D6s22 0 Compaity None Pas

Genin nes ASTM 153 Scanning Bock Vico eld Sess Glested amare

‘iy ‘ASIN 05600 ‘epoation oss Noad) all @ 250 sma

ssi beet? Simulted dation (GD) Sot sre Toman

Bal Rs Test ‘S14 00557 ust ‘eroge Gey Vl 100 min

aomercompstbly ASTM D726, anes A2

Polycyste Rubber asmaen \olume sechange

‘AO (SE 2643) asia 220 ardness

ASIN Dela Tera stenth sodinge

ycogestd Nite asm oer \olane Sechange

NBR AE 2683) asin O20 Hardness a

asin bet? Tene tenth sechnge

Silene ruber asm oer \olume Sechange

‘Yat (SAE 12685) ASIN 02240 Hares

asin beta ‘ale tenth sedinge

Furcatbon Rubber ASTM 0e7 \olune secange

Pra AE 2683) ssi D220 Hares e

asin bet2 Tena tenth sodhnge 0

Bliyene Acc Rubber | AST DET \olume sechange 530

EAL CAE 2683) asin 220 Harness ° 2610

ASIN Dela Tena tenth sodinge 3030

Phosphor ASTM De Phosphows content © ‘06min

Phosphor ASTM 0655 Posphows content * ‘08 max

Sul ASTM DESI Sul conten of SHE OW and 51 muligades % as mane

sal asia 02622 Sal conten of SHE 10 ligrades « 6 mao"

2 ENGINE TESTS

Sequence ASIN O70 nematic Vos nese 3 @ aC ater oO hous ‘soar

‘nage weatted ptm capes nents 40min

‘nerge caps teres! eons oma

Hotstck ings * rere

Sequence 6B Asm O7520 Phosphows retention * Femina

Sequence va ‘Ast E51 erage Com wea (postion vg) ions ‘soma

rence AST 06595 ere engines mets aomin

om ergs ke coe si ments aS

soge pon sit ana ments mn

‘erge engine vars ments 30

Otero sludge te Ismat

Hot std compression sings . ne

(ald ck as ‘ rte breport

Olving coggg aes ie beepr

Osten debs aes fate hepa

Sequel ast e709 ering night ss me max

Io‘our tipped Knemai Viscsty exe tone Stay nog!

[ | | sem stony rae

Sequences | ASTNIDT389 FEISUM min FE rin So FESUM [oF 26min / 12min

(Reuiedtornsacces | SHEOn-20and

Sed SRC oni 5W-20 scent grdes

SHE On-50 and FEISUM min / Fin ‘FSU /o Fea 19 in /09 in

WO vscaty grades

SHE 10-50 and FEISUN in FED in Fe su /So Fe 15 in/ 06 min

‘Ht vscoiy gas

4

“6 ININEUMINTERNATONAL ATED 2018, A gts

Passenger Car Engine Oil Laboratory/Bench Test and Engine Test Requirements For API SM and ILSAC GF-4 Categories

Coro

1, LABORATORY/BENCH TESTS

11 Wiscosty Grades SAE 1300 Athos that pp typically SAE OW-20, Marfa ss tages

(OW 30, 51.20 5030 and 130. win SAE 300 specttion

1.2 Foam Test ‘ASTM D892, ‘Sequence I, tendency/stabilty ml initial 10/0 max

(Option 8) ‘Sequence Il tendency/tabilty ©? Foam/ml 50/0 max

Sequence Il tendenc/ sabi ae setting 10/0 max

stu ps0e2 Sequence endeny/sabity > 100/0 max

1.3 Phosphons Asm #851 Phosphorus content % 06 min

208 max

14eoR sri 6795 (5 Water with dy ice reduction in ow ered 50 max

Seow asm 6796 with 0.63 ater Sereducion s0max

vith LO ter Sereducin 50 max

with 203 ter Soreducton 50 max

with 30% ater Sereduction sO max

16 TEST (UAT) sri 7087 Total Deposits ng 35a

1.7 Homogeneity & Miscibity ‘ASTM 6922 ‘Oil Compatibity pass

1.8 Glaton index AST D138 Scan Brookied Wscosty, ald Stress (aalated Tmax”

1.9 Volatility. ‘ASTM 05800 Volatility (Noack) % off @ 250°C ‘15max

ASTM 06417 ‘Volatility (GOD) % off @ 571°C 1Omax

110 Bal Rust es © AST 06557 Rust ating ‘ig Gay Vue 100 min

11 Sule ‘ASTM E851 or Sillur content of SAE OW and SW mutigades * 05 max

sri 2622 Sill content of SAE TOW mutigzades % 7 max”

112Aged Ol Low-Temperature ASTILDA684 1URV TP Apparent Vcosty and Ved Sess cPandPa | <6000withno

Pumpability yield stress 10"

2. ENGINE TESTS

211 Sequence iG asm 7320 Vscosty incease at 100 hours * 1somax

‘erage eigited piston deposts mers 35min

Hot stuck igs * one

‘erage cam ps iter wear ricons 6omax

22Sequence NA sri 6891 om wear average ricons 0 max

Sequence VG asm es85, ‘erage engine shudge ests 18min

Rocker arm cover sludge merits 80min

‘erage piston she vaish mets 15min

‘Arage engine varish eis asmin

Oilszeen costing * 20 max

ot stuck ings ' one

(old stuck gs & sate report

Oil ring dogging % sate & report

Follower pin wear, fl #8, avg microns rate & report

Ring gap increase | #1 & #8, avg ‘microns rate & report

Ol seen debris 9 ae ‘ae report

2a Sequence i ‘asm 06708 Bearing weight oss mg 26 max

10 hr. stripped viscosity st stay in grade

2.5 Sequence VIB asm 6857 SAE 0W-20 and 5W?20 viscosity grades Sorel /s0F8i2| 23min / 20min

(Requited for ILSAC GF-4 ony) ‘SAE OW-30 and 5W-30 viscosity grades FEIN /9% FED) 18min f 15.min

SAE 101-30 and lather scot) grades FEN /96 F822 | LA min/ 08min

© by ar 1 mint seting pod 1301 C.4 adjocccagaespcedethe's cater and__ the aged ian endo et srl ented inte

© by ke nt setlig pod ther ie AP Ceteton are Sequare VAST DESS),_Sequene IGA tt ASTI S20,

© tregure fr omlSHC GF vscsty sae, Bal Us (ASIDES), and Gelato dex ASTM S153) tess The ASTM DAES (ARV TP) et cond at te gal

4S matornon SAC G4 vay gud enol rau SAE 0 say ge pert ie mesiued CS

© Stal ena emogareos and when mined wth Ta be ewhistdom-S'to temper atubih 40000 < is vey is eum equa othe oe cost grade

SIM erence shal ena ie. ‘ined or ATG oC eps bel sper NR nd tS igh pent oer

TP temperature defn by SAE 500) hicheer cers

© INFNEUM INTERNATIONAL UTED 2014 phi recone

Passenger Car Engine Test Category For API SJ and SL

Ce

Do

1. LABORATORY TESTS

1.1 Viscosity Grades Al those that app, pial SAE OW-20, Monufactre sts togets

(0-30, 51730 and 101-30. within SAE 1500 specication

1.2 Foam Test ASTM 0892 | Sequence ail 10/0 max 10/0 max

Sequence Foam/ml 50/0 max 50/0 max

Sequence afer setting | 10/0max 1/0 max

Sequence W 200/50 max 4100/0 max

13 Phosphons ASTM D4951_|_Phosphonus Content % 0.10 max 0.10 max

or 05185

1AEOFT (GM.9089P 0.6% Wter- ith dy ice - reduction in ow % 50 max 50 max

1SEOWTT ASTM D6734 0636 tr without dry ice 9 eof change % report 50 max

1.0% Wier - without dry ice 5 ate of change &% report 50max

203 Wate without ry ice = ae of change % report 50 max

53.0% Wate without ry ice- ate of change % repo 50 max

6 E0sT ASTM D6535 | Total Deposits max mg 60.max NR

1.7 TOS (MAT ASTMD7097 Total Deposit, max mg NR 45 max

1.8Homogeneiy and Miscbilty —FTMSTD 731C_| Oil Compatiitiy pass ass

1.9 Scaming Brookfield ASTM 5133. Geletion Index Tamax remax

|.10\eltiity ASTM1D5800 | Voltiy (Noack), 4 off % 2m Sma

ASTM D6417_—_|_Voltity (CCD), 8 ff % Vmax toma.

1.11 BRT ASTM D6557 | Rust ing Gray value 100 min 100 min

2. ENGINE TESTS FOR API SI and SL

21 Sequence IF ASTM D149) | esas increase 60 hours, max % 325 max NR

é Viscosity increase at 80 hours, max % NR 2%

Average piston sit amish rating in ments 85min 80min

Weighted pion depost rating min ments 32min 40min

Cam pus iter wea vg, max micons 20 max 20 max

Hot stuck ngs + one nove

(il consumption max liters 65 52 max

Low temperature viscsty performance e NR rate and report

22 Sequence WA ASTM 06881. Cam wear average, max microns 120max 120max

23 Sequence VG ASTM 06593. Average engine sud min ments 7B min 78min

Rocke arm cover loge, in ments 80min 80min

Average psion st varish min ments 1S min 75 min

Average engine vaish, min mets 83 min 89 min

Olsen clogging, max % 20 max 20 max

Hot stuck compression ings + none none

old stuckrings + rate and report ate and report

Gi sceen debris % fate and report ate and report

i ing dogging % fate andreport rate and report

24 Sequence VE ASTM 05302 | Cam wear

(Onli of Phosphorus < 008%) Average, max micons| NR Vmax

Masi max icons Ne 380 max

25 Sequence il ASTM 06709 Beating weight oss, max mg 264 max 264 max

Thr sipped viscosity ot Stayin rade Stayin grade

26 sequence VIB ASTM 06837 | Forvicosty grades

(Ei sing BC before ony) SAE 0420 and S20 Se improverent 20min NR

(ther SAE OW and SW multirades Sb improverent| 1.6 min NR

AMISAE 100% mutigrades Seimprovement 09min NR

27 Sequence VIB ASTM 06837 SAEOW-20 and 51-20 (FII/FI2/sum), in Se improverent NR 2.0/1.77NR min

SAE 0430 and S30 (FEI/FE2/sum), min Se improverent NR 16/13/50min

Allother viscosity grades (EI/FE2/sum), min Se improvernent NR 09/06/1.6min

© Tee isabo a 008 in Preqiement, 6

unless a sucessful Sequence VG st hasbeen

© INFNEUM INTERNATIONAL UTED 2014 pts rezone

Heavy-Duty Diesel Engine Test Category For API CJ-4

Limits

Cet Dos

i i oo

1. LABORATORY TESTS FOR APIS

1.1 iscsi Grades SAE 1300 Manufacture species viscosity target

thin SAE 1500 specication

1.2 high Temperature ASTM'D6594 Copper, sed ol increase, max ppm 20 No TAC 81

Corosion, 135¢ Lead, used olincease, max ppm 1%

Copper Sip Rating, max . 3

1 Foaming ‘ASTIN DGS Foaing/Setling, max No Tac 081

Sequence % 10/0

Sequence % 290

Sequence I % too

1.4 Shear Stability ASTIMD7109 KV @ 100% ater 90-pases fo SAE 0, min s nas No wTAC o1

HV. 00%C afer 90-passes for SAE X30, min o 93

1.5 Noack oli {ASTIADS600 Bp Loss @ 280 Ws Giades ther than SAE 101030, max_— 5 No MRC 2

Evap oss 8 250%, SAE 100-30, max % 5

1.6 igh Temperature) ASTIADEGES Viscosity @ 150+, nin ° 35 NowTAc 0

igh Shear

17 Sooted 01 RV ASTIND6896 180 hou sample rom Mack For F118 NowTAc 8

Viscosity @ 20° max ° 25000

Wilts Pa 35

1.8 Cheical ims (Non-iteal) ASTALD7S Slee Ash, max % 10 Nowra O01

ASTIADE951—_Phosphows max ® on

ASTINDAS51 Su; max % 04

Volume Change Hardness Tensile stengh Bongaton

1.9 Seal Compatbity Nite 45/3 4/5 ++10/mci008 +10 /-TMCI008

asm o7216) ‘Slicone +IMCIO05 /-3 45 /TMCI006 10/45 420/30

Palyacrate 45/3 48/5 +18/-15 410/35

FM 35/2 ars +10 /-THCI006 +10 /-TMCI006

Vamae -IMCI006 /-3 45 /-CI006 +10 /uci008 “0 /-TMCI005

; Limits

2. ENGINE TESTS FOR API Cit Unit

rrest | tess | tess

21 Mack ASTMDTIS6 | Soot @ Actin min % 35 34 33

Soot @ 12S min % 60 59 59

Soa 15Stne min % 57 55 55

22Mack 12 ASTINO7A22 Ment in ooo 10008 | 1000

25 Cummins 18 ASTMD?4G4 Tapp Wess mac me 100 108 ne

Cam Wea, max miizons | 55 3 6

Gossead Weight Loss ime, | Rtejepor | Ratereport | Rate/eport

218 Cummins is ASTID7468 | Mess, in ooo 1000 | 10008

Top Ring Wt Loss, max me 109 100 109

25 Cotepilar 1N ASTINDG7SO. | Top Land Heavy Carbon, max % 3 4 5

“op Groove Fl, max % 2 2 %

Weighted Demers, max demeits | 2862 SILT.) 3280

Oil Consupion (0252) h, max i 0888

Ring / ier Scag None None None

26 Cater C15 ASTIAD7S49 Mest min ooo 1000 | 1000.

Hot Suc igs None None | None

27 Engine 01 Aeration ASTIADE595 Ol Aeration Volume, max % 80 BOQ aO(MIAC,

‘BR Fllower WearTest ASTM 05966 Roller Followe in Wear,max mnigons | 76 84 3

(rls) | (030) ——038)——(036)

29 Sequence IF ASTIADE96S __Vcosty nat EOT,max % 2325 (MAC) | 275 (MAC)

(Not an ACCT.

MTC ia sats method for tesing mull engine le ress if appleabl. Cons our ss epee forthe infrmation.

nies iain megs be quae peat Conyers preset ier eka,

‘essing Seq IG iscsi increase at APSM sen aceptble aerate,

‘© INPNEUMIVERNATIONAL LMITED 2014. A ight reson

Heavy-Duty Diesel Engine Test Category For API Cl-4 and Cl-4 PLUS

Bo

1. LABORATORY TESTS FOR API C-8 AND C-4 PLUS

1.1 Viscosity Grades SAE 1300 Manufacture species isos target

‘within SAE 1500 specication

1.2 igh Temperature ASTD6594 Copper incase, max ppm 20 No MTAC 3c

Corrosion Bench Test, ppm 20

Copper stp rating, max (0130) 3

Tinncease, max ppm report

1.3 fom Test ASTM 882 | Foaming/Seting max No mace

(pion el mL 100

rotalloned) | Sequence mL 20/0

Sequence th mt ‘0/0

14 Shear Stability ASTM D628 Aer shear viscos, SAE TOW, min st 83 NoMTAC A

Afr shear viscosity, SAE 150-40, min a 125

15 Voltity ASTM S800 Evaporative loss a 250°, max % 8 No uTac =

(Noack)

‘.6High Temperature/High Shear As allowed Viens, min Pas 35 NoMTAc 3

in EJ300

17 Low Temperature Pumpabiliy ASTMD4684 Viscosity of 75hused oil sample Pas 25000 No MAC

(Q4RVTP-1) | fom FO Testat-20¢ max

Modified D484 Viscosity t-20% max mas 25000

(yids) | Vield tes, max Pa 3

18 Elastomer Limits

Compatibility Volume change Hardness Limits Tense strength Elongation

ete 45/3 31/5 +10/-TMcI006 +0 ™MC1006

Sticone -FIMCION6 /-3 +45/WCI006 10/45, ¥20/30

Fojacnate 45/3) 8/5 18/15 +10/-35

FAM 8/2 41/5 -+10/ MMCI006 +10/ TMCt006

2. ENGINE TESTS FOR API Cl-t

2.1 Mack FE ASTIN D5967 | Relative cost at 48% soot, max (RUM. 18 is 20

(LTE) at 4% seoiseof new ol sheared in 08278)

22Mack 10 ASTM DE967/ | Merit Rating min 1000 to00 100

Desera ®

23 Cummins MV-EGR ASTALDES7S ® | Crosshead weightloss, max mg 200 218 26

Average Top ring weight os, max mg Repot Report ———Report

Filter dete pressure a 250h, max ra 25 320 3a

ude aig min mets 78 16 5

24 Catepilar 1 ASTM 6825 WOR, max demeits 382 336 402

TGC, max ements 52 57 39

The max ements 31 3 36

Intl Of Consumption max shh iB 31 31

Final i Consumption, max gh GH OCHB Oct

Psion rng and ne sting None None None

ing Sticking None None None

2.5 Coteplar 1K ASTM'06750 | WOK, mat dements 332 347 353

TGE nat % "4 2 23

Tuc mat % 4 5 5

o i Consumption (0-252) b, max a 038 03s O38

stoning and ne scfig None None None

atria Asti 06750. | WON, max dements 2862 37-380

TGF, mat % 0 B B

TUG, mat % 3 4 5

(i Consumption (0-252) max mm 038 as Oe

Piston ing an ne scing None None None

Ring Sticking None None None

26Rollr Follower WearTest__ASTALDS966 Average Pin Wet, max ym (mis) 76(030)_@4 (033) 91 (036)

27 Engine Oil Aeration Test___ASTALDS864___Aeraon, max Vols 80 MIRC applies

28 Sequence iF ASTI 06984 Viscosity incase at 0h, max % 25 IMIAC applies

5. ENGINE TESTS FOR API C-4 PLUS (same as API CI-4 Engine Tests above in addition to following)

3.1 Mack F-11 11 Soot/ | Minimum TGA Soot Content at 120 St % 600 589 585

Ascosty Contol_ increase at 100°

Patan AC est ‘ASTM O72 (E12) isan acexptable seat

{MACs attic mtd wing tle engine cl test eu apa © AST OT46 (SM) san acepble ata

‘Const ours reteset for further nforaton 5 ASTU DEB CIP)s an acceptable senate,

© ei ter 30 ees fo APC, 80 yes for PC PLS © ASTUOTS2 (Sequence) an celal tena.

‘© ININEUMIVTERNATONAL UTED 2018, lights reson,

Heavy-Duty Diesel Engine Test Category For API CH-4

Ce

1. LABORATORY TESTS

1.1 Viscosity Grades SAE 300 Manulacrt species visosty

target within SAE 1500 specification

1.2 High Temperature ASTM 06594 Copper increase, max ppm 20 No MTAC ©

Conrasion Bench Test increase, max ppm 120

Tin increase, max Pom report

Copper conesion rating max (0130) 3

1.3 Foam Test ASTM 0892 Foaming/Setling, max No MTAC ©

(Option Anct alowed) | Sequence | mL 10/0 max

Sequence I mL 20/0 max

Sequence Il mL 10/0 max

1.4 Shear Stability ASTM 06278 ‘ter shear viscosity SAE 10W-30, min St 93 No MTAC ©

‘fer shear scosy SAE 1SW-40,min St 125

1.5 Volatility Noack (SAE 10W-30) Sloss 2» No MTAC ©

ASTM 05800 Noack (SAE 151-40) Sloss 8

or

ASTM 02887 or ‘GOD (SAE 10W-30 Sloss ”

ASTM 05480 GOD (SAE 151-20) Sloss 15

2 ENGINE TESTS FOR API CH-8

2.1 Mack T8E ASTM 0967-96 Et Relative viscosity @ 48% soot, max 21 22 23

Viscosity increase @ 3.8% soot, max os ns 125 150

2.2MackTS ASTM 06483 > Liner wear, max micons 25.4 266 am

Top ring weight oss, max mg 120 136 144

Anctease in lad level, max pm B 2 36

23 Cummins M11 ASTM 06838 Rocker pad average weight loss mg 65 15 80

normalized to 45% soot, max

Oil Filter deta pressure at EOT, max kPa a 3 100

‘Average Sludge rating, min merits 87 86 a5

24 Caterpillar 1P ASTM 06681 Weighted total deme, max demerits 350 378 320

Top oovectbon mat % 36 39 4

Top land carbon, max % 40 46 43

Ayerage oil consumption, max gw 124 124 12a

Final of consumption, max g/t 46 146 146

Piston ring and liner scufing None None None

25 Caterpillar 1K ASTM 06750 Weighted total demerits, max demerits 332 37 353

Groove No.1 (Top) fil max 6 4 a 2

Top land ea cabon, max % 4 5 5

consumptn, (0282) hax ww 0139 0.139039

Piston ring and liner scufing None None None

2.6 Roller Follower Wear Test ASTM 05966 Pin Wear, max pm (mis) 76(030) 84(033) 21 (036)

2:7 Engine Oil Aeration Test _ ASTM 06894 Aeration, max Sovolume 8 MIAC applies

2.8 Sequence IF ASTM 06984 Viscosity increase at 60 hours, max % 295 MTAC applies

tan AC st

MACs tis method or teting mui engine test ess if apical Cons you ses eresentativ or urthe infra,

© AST D6987/6867H (10) o ASTA DTs22 (12) are acapale eras

‘AST DT468 (SU isan aceptble ateathe.

As 07300 (Sequence I) isan acetal tema

9

‘© ININEUM TERNATIONAL UTED 2018, igh reene.

SAE Viscosity Grades For Engine Oils* ©.

Cmca Sct i Coe

Sec ‘ SGC)

lor) Paes fee ‘

Peed

29

35 (OW-40, sw, and 10W-40 grades)

5327 (15M40, 200-40, 25-40, 40 grades)

37

37

nates — 1 mBes= 1. mm St

talus withthe exception ofthe low temperature caning sos, ae cic pecans as defined by ASTM 03244 (se tnt Secon 7).

SIM 05285: Cranking wscosty - The non-caspecaton potacl in AST D524 salle apped vith Pah of O85.

‘ST DAs: et that th presence of any es deteabe by tis method conte are gales coy

ast Dass

‘© AST D468, ASTM O47, ATM DS4B1 or CECL-3-90.

pit a SAE 130 Ap 2015 © 2015 SAE Intemational. Fue iseor dtrbuton nat pert witht prison fe SAE

cure: Engine Ol easy Casiicato, 50, SAE. the ful publton salable am SRE st wusae eg

aassification

cor

1 360-<120 o0s% :

0 380-<120 290% and 005%

in 2120 290% and 003% 2

v PAO (Poly pha Olefin)

v Everything Ese

Companies ao use theron mating prses: “Croup 1-1/2" and "Gop 2+”

"Grup canbe egal labeled “Syne

The word Sta” sat pat of th Pl Clason

"Spe maraing tar nt etic trm

10

. INFNEUM INTERNATIONAL UMITED 2014, Aight reson

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Lubricants & Greases: A.Antony PeterDocument112 pagesLubricants & Greases: A.Antony PetersinhleprovietPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- English Speaking Club Tet Holiday2Document32 pagesEnglish Speaking Club Tet Holiday2sinhleprovietPas encore d'évaluation

- 2012 Paper Screw CompressorsDocument24 pages2012 Paper Screw CompressorsbracioPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Basicsoflubricantadditives 100423231951 Phpapp02Document40 pagesBasicsoflubricantadditives 100423231951 Phpapp02Jako MishyPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Hydraulic Fluid Care GuideDocument16 pagesHydraulic Fluid Care GuidegabrieljuarezgPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

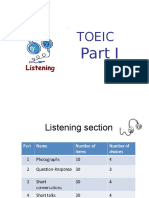

- Toeic Listening Part 1Document10 pagesToeic Listening Part 1sinhleprovietPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Roots Blower OilDocument2 pagesRoots Blower OilsinhleprovietPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shell Gadus S2 V220 2 (En) TDS GreaseDocument2 pagesShell Gadus S2 V220 2 (En) TDS Greasekevin_lim90Pas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Nano Particle Technology For Drug Delivery (2006)Document427 pagesNano Particle Technology For Drug Delivery (2006)prishly7108100% (3)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Cincinnati HydraulicDocument1 pageCincinnati HydraulicsinhleprovietPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- AeroShell Turbine Oil 560 (En) TDSDocument3 pagesAeroShell Turbine Oil 560 (En) TDSsinhleprovietPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- United States Patent n91: Newingham Et AlDocument7 pagesUnited States Patent n91: Newingham Et AlsinhleprovietPas encore d'évaluation

- How To Write A Report - Explorer Junior Library How To WriteDocument25 pagesHow To Write A Report - Explorer Junior Library How To Writesinhleproviet100% (2)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Cincinnati GearDocument1 pageCincinnati GearsinhleprovietPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- D61Document3 pagesD61rpajaro75Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Aeon PD PDFDocument4 pagesAeon PD PDFAlex NavarretePas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- WG DA SYN Blower OilDocument1 pageWG DA SYN Blower OilsinhleprovietPas encore d'évaluation

- Souther Training Metal WorkingDocument31 pagesSouther Training Metal Workingsurajit7guptaPas encore d'évaluation

- API Engine Oil Classifications 2010Document8 pagesAPI Engine Oil Classifications 2010Stefan BurbuleaPas encore d'évaluation

- Lubricant Base OilsDocument3 pagesLubricant Base OilssinhleprovietPas encore d'évaluation

- WG DA SYN Blower OilDocument1 pageWG DA SYN Blower OilsinhleprovietPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- LubricationDocument21 pagesLubricationmojiryhamid100% (1)

- D71Document2 pagesD71rpajaro75Pas encore d'évaluation

- TechBrief10 - Oil Base StocksDocument9 pagesTechBrief10 - Oil Base StockssinhleprovietPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Engine Cooling SystemDocument22 pagesEngine Cooling SystembachayadavPas encore d'évaluation

- D 3306 - 00 - RdmzmdytmdbbDocument5 pagesD 3306 - 00 - Rdmzmdytmdbbjamaljamal20100% (1)

- S - Mpo BearingthermDocument1 pageS - Mpo BearingthermsinhleprovietPas encore d'évaluation

- SAEDocument1 pageSAEsinhleprovietPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- 06 Lubricating OilsDocument32 pages06 Lubricating Oilsfarhan2ansariPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)