Académique Documents

Professionnel Documents

Culture Documents

Cable Tray BKM 7105

Transféré par

Utku Can KılıçTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cable Tray BKM 7105

Transféré par

Utku Can KılıçDroits d'auteur :

Formats disponibles

TOTAL 10 PAGES

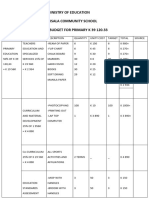

TITLE HERE

(Including Cover)

PROJECT NAME

: Khabat Thermal Power Plant Units 1&2

DOCUMENT NO.

For Information

TITLE

: Method of Statement for Khabat PP

Cable Tray and Ladder Installation Works

For Review

OWNER

: Ministry of Electricity (MOE) of

Kurdistan Regional Government

01.09.2015

Rev.

No.

DATE

Purpose

For Approval

For Construction

As-Built

First Issue

DESCRIPTION

PREPARED

CHECKED

REVIEWED

APPROVED

GAMA POWER SYSTEMS ENG &CONTRACTING,INC.

Owner

Ministry of Electricity (MOE)

of Kurdistan Regional Government

Contractor

POSCO ENGINEERING

& CONSTRUCTION CO., LTD.

Main Subcontractor

GAMA POWER SYSTEMS

ENGINEERING & CONTRACTING,INC.

KHABAT TPP UNITS 1&2

Method Statement

for Electrical Works Cable tray and ladder Installation

works

Doc. No

KP-00+++-CY712B7105

Rev. No.

Page

A

2 of 8

1. Introduction and Scope of this method statement

1.1

This method statement is written for the purpose of establishing method and procedures for the Installation of Cable

Tray and G.I Trunking System for the building MEP services.

1.2

1.3

2. Applicable Projects Specification

Section: ELECTRICAL CONTAINMENT

Division: INSTALLATION

Sub Division: Subdivision

3. Location of Activity

Inside and outside the building.

1.4

4. Health and Safety Hazards

Specific safety measures have to follow as applicable, and all the safety measures are covered separately in the project

safety plan.

KHABAT TPP UNITS 1&2

Method Statement

for Electrical Works Cable tray and ladder Installation

works

Doc. No

KP-00+++-CY712B7105

Rev. No.

Page

1.5

A

3 of 8

5. Operation

1. Materials: Materials used will be as per the material submittal approved by the engineer and routing

as well and sizes will be as per the approved drawings in co-ordination with other services.

2. Storage / Protection: Cable Trays, Trunking and Accessories shall be unloaded with care to avoid

any damages. If they are shipped in packs or pallets, each pack of pallet shall be lifted individually

with suitable lifting equipment. Every precaution shall be taken to preserve their cleanliness before

installation.

1.6

6. Installation Of Cable Tray Or Trunking System For Building Electrical Services

1. To make sure that the entire installation is in conformance and in accordance with the design intent

of the project for the Electrical and Low Voltage System in addition to the specification and as per

approved shop drawings and comply with Local and International Standards.

2. Adhere to the drawings as closely as possible. The right is reserved to vary the runs and sizes of

Cable Trays / Trunking and to make offsets but maintain as far as possible the free area of each duct

work section, where necessary to accommodate conditions arising at the building.

3. Before beginning installation in any area, examine all parts of the adjoining work onto which

applicable work is to be placed. Should any condition be found which will prevent the proper

execution of the work, installation shall not proceed in that area until such conditions are corrected

by the contractor.

4. Cable Tray / Trunking shall be stored on site under cover in dry, well ventilated storage facilities.

5. Where sizes of Cable Trays / Trunking are not detailed on drawing then tray shall be adequately

sized to support the cables without bunching and a 25% reserve margin shall be allowed in size and

weight be loaded.

KHABAT TPP UNITS 1&2

Method Statement

for Electrical Works Cable tray and ladder Installation

works

Doc. No

KP-00+++-CY712B7105

Rev. No.

Page

A

4 of 8

6. All routes are chosen to allow ease of access to all cables when installed. All horizontal cables are to

be set around all vertical rising services as necessary. Ensure sufficient clearance from soffit for

every installation.

7. Earth continuity conductors shall be provided across gaps in all Cable Tray / Trunking runs and

bolted connections.

8. Support shall be by means of steel brackets installed at intervals necessary to provide a rigid fixing

and to ensure that deflection does not exceed 5mm mid span of support when fully loaded.

Treatment of cut edges as per cut edges to be included. Supports for Tray / Trunking (spacing) shall

be as per standard practice and manufacturer's recommendations.

9. Additional support shall be provided where the Cable Tray / Trunking changes direction or cables

drop out of the cable tray. Dome headed bolts, nuts and washers of finish suitable to the tray shall be

used between trays.

10. Suspension sets comprise threaded M10 zinc or cadmium plated hanger rods together with nuts and

locking washers, supports channel hold down clips all of which shall have a galvanized finish. Any

cut ends supports, rods, etc, must be corrosion protected by use of galvanized or equal. No

extended rods to be left.

11. The cable tray shall be installed with a 40mm minimum space between the structure and the tray.

12. All cable shall be securely fixed to the tray, work and the complete installation must be carried out in

a neat and workmanlike manner without crossovers.

13. Cables on face-up horizontally fixed tray must be secured by use of the tie wraps where not in view.

If cables are bunched or single cables greater than 25sq mm are installed, cleats or metal straps

shall be used.

KHABAT TPP UNITS 1&2

Method Statement

for Electrical Works Cable tray and ladder Installation

works

Doc. No

KP-00+++-CY712B7105

Rev. No.

Page

1.7

A

5 of 8

7. Responsibilities

1. Project Manager:

1. To ensure that all the preparation and application works are carried out according to the

Contract Specification.

2. To ensure that the progressing of works is carried out according to the planned program and

as per the approved method statement.

3. To ensure that all equipment and material required executing the work are available

according to the planned Construction Programme.

4. To co-ordinate with the Main Contractor, MEP co-coordinator and Safety Officer for a safe

and proper execution of the works.

2. Site Engineer:

1. To ensure that the works are carried out according to the Contract Specifications approved

method statement.

2. To provide all necessary information and distribute responsibilities to his construction team.

3. To monitor the progress of work in relation with the work program and to report to the Project

Manager.

KHABAT TPP UNITS 1&2

Method Statement

for Electrical Works Cable tray and ladder Installation

works

Doc. No

KP-00+++-CY712B7105

Rev. No.

Page

A

6 of 8

4. To co-ordinate with the safety officer and to ensure that the works are carried out in safe

practicing methods.

3. Foreman:

1. The foreman will carryout his duties by maintaining continuous coordination with the site

engineer on daily basis, and ensure proper distribution of the workforce in the required and

planned locations.

2. To ensure that his assistant foreman/ charge hands are aware of the job requirements and

they have enough information to carry out their duties properly.

3. To ensure in consultation with the site engineer that the manpower involved in the works are

moving as agreed and planned for the work.

4. To ensure that the daily work is progressing as planned and advise the Site Engineer of any

requirement for the additional resources.

5. To control disposal of waste materials according to the instructions received from the site

engineer.

6. To ensure full coordination with the safety officer to maintain safe working and proper house

keeping of the site, following the approved safety measures and further ensure that all his

working team are aware of the same to prevent accident and losses.

7. To inform the site engineer and of the areas ready for inspection.

8. Distribution and the control of materials shall be monitored by foreman and storekeeper.

4. Safety Engineer:

1. Ensure the implementation of all the safety measures in accordance with the HSE plan and

everybody aware of it for it's proper implementation.

2. Ensure all the implemented safety measures are adequate to maintain the safe working on

the site.

3. Inspect all the site activities and train the persons to prevent accidents and its proper

reporting to the project manager and the client.

4. Ensure that the site is maintained clean and tidy.

KHABAT TPP UNITS 1&2

Doc. No

Method Statement

for Electrical Works Cable tray and ladder Installation

works

KP-00+++-CY712B7105

Rev. No.

Page

1.8

7 of 8

8. Manpower Required

Charge Hand and Experienced Technicians

1.9

9. Inspection And Test Plan Format For Installation Of Cable Tray Or Trunking

ITP

Inspection

Clause

Description

No

Type of

Inspection

Reference

Document

Design

and Review

of Design

Drawings

Documents

Drawings

Material

Approval

Check

Installation of

Visual

Cable Tray /

Trunking

Visual

Request

for

Measurement Approved

inspection of

Instrument,

Drawings

works

Earth Test

Approved

Review

of

Drawing,

Documents

Specification

Approved

Method

Statement

Testing Requirement/

Acceptance Criteria

All the Drawings

Verifying / Control Data

Forms

Design drawings, Authorities

Departments Requirements.

Should be as per the

approved drawing and Documents Submittals

Specification

Proper bends correct

level and Location, route

material should have Approved

minimum status of No Statement

Objection

with

comments (2)

Drawing

No obstructions Level,

Approved Drawings

Routes

Method

KHABAT TPP UNITS 1&2

Method Statement

for Electrical Works Cable tray and ladder Installation

works

Doc. No

KP-00+++-CY712B7105

Rev. No.

Page

1.10

A

8 of 8

10. Materials Requirement

Cable tray / trunking and accessories

1.11

11. Equipments Requirement

The equipments that will be engaged for Installation of Cable Trays and Trunking works will be as follows:

1. Wire cutters

2. Hacksaw

3. Measuring tape

4. Drill machine

5. Wooden hammer

6. Flat file

7. Screw drivers

8. Open and box spanners

9. Base Cutter

1.12

12. Health and Safety

Strictly followed as per the manufacturer's Health and Safety recommendations for handling and use of the materials.

Ensure all involved personnel shall be aware of the same.

1.13

13. Supporting Documentation

This method Statement should be read in conjunction with the below referenced documentations:

ITP for Cable Tray and Trunking

1.14

14. Distribution

Copies of this method statement have also been issued to the following for information/ action/ comments:

Project Manager

Site Engineer

Foremen

Vous aimerez peut-être aussi

- EW160 AlarmsDocument12 pagesEW160 AlarmsIgor MaricPas encore d'évaluation

- Sony SL HF-900 Owners ManualDocument53 pagesSony SL HF-900 Owners ManualThomas Christoph100% (1)

- Lightning Protection System Installation ChecklistDocument1 pageLightning Protection System Installation ChecklistUtku Can Kılıç50% (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- KP-00+++-CQ712-B7702 - ITP For Lightning Protection System InstallationDocument3 pagesKP-00+++-CQ712-B7702 - ITP For Lightning Protection System InstallationUtku Can KılıçPas encore d'évaluation

- KP-00+++-CQ712-B7702 - ITP For Lightning Protection System InstallationDocument3 pagesKP-00+++-CQ712-B7702 - ITP For Lightning Protection System InstallationUtku Can KılıçPas encore d'évaluation

- Cable Tray Method StatementDocument8 pagesCable Tray Method StatementNidhin Mohan0% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsD'EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Post Insulator Installation ChecklistDocument1 pagePost Insulator Installation ChecklistUtku Can KılıçPas encore d'évaluation

- Huawei Core Roadmap TRM10 Dec 14 2011 FinalDocument70 pagesHuawei Core Roadmap TRM10 Dec 14 2011 Finalfirasibraheem100% (1)

- Cable Tray Installation ProcedureDocument9 pagesCable Tray Installation ProcedureMahmoud Tobala0% (1)

- Ms For Installation & Testing of Ups - BatteriesDocument9 pagesMs For Installation & Testing of Ups - Batterieskamal8610Pas encore d'évaluation

- Tubing Leak TestDocument3 pagesTubing Leak TestOwais MalikPas encore d'évaluation

- Cable Tray Installation ProcedureDocument11 pagesCable Tray Installation ProcedurenayumPas encore d'évaluation

- QA&QC Earthing SystemDocument6 pagesQA&QC Earthing SystemMuhammadZahirKhanPas encore d'évaluation

- Electrical Cable Support System Installation Work (For Cons)Document33 pagesElectrical Cable Support System Installation Work (For Cons)Le Dinh QuangPas encore d'évaluation

- IQ347 300 EL CHL 00014 UPS and Batteries InstallationDocument2 pagesIQ347 300 EL CHL 00014 UPS and Batteries InstallationkamilPas encore d'évaluation

- REQ 565005 Electrical InstallationsDocument26 pagesREQ 565005 Electrical Installationszelda1022Pas encore d'évaluation

- Testing and Commissioning Procedure: 2007 EDITION (Incorporating Corrigendum No. Gsee01)Document98 pagesTesting and Commissioning Procedure: 2007 EDITION (Incorporating Corrigendum No. Gsee01)Khairil ZainudinPas encore d'évaluation

- SATR-J-6911Rev 0 PDFDocument6 pagesSATR-J-6911Rev 0 PDFAdel KlkPas encore d'évaluation

- Method Statement For AC PANELDocument6 pagesMethod Statement For AC PANELkamilPas encore d'évaluation

- Job Procedure 02 For TRANSFORMERDocument7 pagesJob Procedure 02 For TRANSFORMERSoumik KarPas encore d'évaluation

- Testing Electrical Equipment 26 08 00Document99 pagesTesting Electrical Equipment 26 08 00Joe GrosirPas encore d'évaluation

- p103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionDocument7 pagesp103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionAnandu AshokanPas encore d'évaluation

- External Electrical Boq R2Document15 pagesExternal Electrical Boq R2mudassir mPas encore d'évaluation

- Tender Package Electrical SystemsDocument221 pagesTender Package Electrical SystemsMohan BabuPas encore d'évaluation

- Specification For Electrical InstallationsDocument50 pagesSpecification For Electrical InstallationsJonathan VillorentePas encore d'évaluation

- Method Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDocument15 pagesMethod Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDonny Subarja100% (2)

- Ajv DPW 10 525 El MSS 2200 - 00 PDFDocument55 pagesAjv DPW 10 525 El MSS 2200 - 00 PDFmanikandanPas encore d'évaluation

- ITP Electrical New MCCDocument3 pagesITP Electrical New MCCMpuwh 'Riczky Syaputra'Pas encore d'évaluation

- Method Statement TrayDocument38 pagesMethod Statement Traywaseem kausar100% (1)

- REV - 3 MS Cable Testing - RGDocument13 pagesREV - 3 MS Cable Testing - RGRakesh KumarPas encore d'évaluation

- GI Cable Tray & Trunking MethodDocument9 pagesGI Cable Tray & Trunking Methodrkss100% (1)

- Loop Checking and Field Instrument Testing ProcedureDocument3 pagesLoop Checking and Field Instrument Testing Procedureamirubote4Pas encore d'évaluation

- HT Panel Data SheetDocument2 pagesHT Panel Data Sheetvinay nagvanshiPas encore d'évaluation

- MST - Earthing and BondingDocument4 pagesMST - Earthing and BondingMusthafa Shaik100% (1)

- Techncial Submittal For Lighting Fixtures - 1ST Ring RoadDocument546 pagesTechncial Submittal For Lighting Fixtures - 1ST Ring Roadwsiim5718Pas encore d'évaluation

- SECTION 13100 Lightning Protection Rev 0Document16 pagesSECTION 13100 Lightning Protection Rev 0Azhar AliPas encore d'évaluation

- Installation MCC Room, E&I Rooms, and Battery RoomDocument9 pagesInstallation MCC Room, E&I Rooms, and Battery RoomDario WicaksonoPas encore d'évaluation

- Cable Tray & Ladder ITPDocument1 pageCable Tray & Ladder ITPSyed Kareem Iqbal100% (1)

- QCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)Document15 pagesQCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)arockiyathassPas encore d'évaluation

- Electrical Method Statement GN 8Document5 pagesElectrical Method Statement GN 8Chandree BoonzaaierPas encore d'évaluation

- 000-Za-E-M09403 - C-MS For Cable Tray InstallationDocument15 pages000-Za-E-M09403 - C-MS For Cable Tray Installationsyam prasad100% (1)

- ITP For Batteries, Chargers and UPSDocument7 pagesITP For Batteries, Chargers and UPSUtku Can Kılıç100% (1)

- 1 - Method Statement For 22Kv Cable Installation Rev c02Document12 pages1 - Method Statement For 22Kv Cable Installation Rev c02Ahmed Nagy100% (2)

- 04 Electrical SpecificationDocument49 pages04 Electrical SpecificationVishal NarkhedePas encore d'évaluation

- Drawingsdocumentsrequiredforsolarprojects 131110061739 Phpapp01Document4 pagesDrawingsdocumentsrequiredforsolarprojects 131110061739 Phpapp01Battinapati Shiva100% (1)

- Instrumentation Switch ChecklistDocument5 pagesInstrumentation Switch Checklistrenjithv_4Pas encore d'évaluation

- Cable TrayDocument6 pagesCable TrayMuralimohan Pandian100% (2)

- Check List Ladder & TrayDocument5 pagesCheck List Ladder & TrayAldeline SungahidPas encore d'évaluation

- Testing and COmmissioningDocument2 pagesTesting and COmmissioningsatya_swamy20002943Pas encore d'évaluation

- ITP For Junction Box InstallationDocument4 pagesITP For Junction Box InstallationGanga Daran100% (1)

- KP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSDocument22 pagesKP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSUtku Can KılıçPas encore d'évaluation

- Blk-2 Fiber MSDDocument26 pagesBlk-2 Fiber MSDanbarasusivaprakasamPas encore d'évaluation

- Mos T&C EarthingDocument20 pagesMos T&C EarthingAhanaf TahmidPas encore d'évaluation

- Field Instrumentation (Oil and Gas)Document4 pagesField Instrumentation (Oil and Gas)Mohamed RaeesPas encore d'évaluation

- Tray DrawingDocument1 pageTray DrawingFareethAbdullahPas encore d'évaluation

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 pagesRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanPas encore d'évaluation

- Electrical Engineer ResponsibilitiesDocument4 pagesElectrical Engineer ResponsibilitiesVenkata Suresh MandavaPas encore d'évaluation

- Arshad Ali Wahab: Electrical Engineer Saudi Council Certified. 966 593067611 (KSA) +91 7903045695 (IND)Document5 pagesArshad Ali Wahab: Electrical Engineer Saudi Council Certified. 966 593067611 (KSA) +91 7903045695 (IND)RaziKhanPas encore d'évaluation

- Power Block Cable InstallationDocument20 pagesPower Block Cable InstallationAnandu AshokanPas encore d'évaluation

- Method Statement For Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMethod Statement For Installation of Electric PVC Conduits and AccessoriessamsungloverPas encore d'évaluation

- Method Statement For Cable Conduit & Tray Installation PDFDocument5 pagesMethod Statement For Cable Conduit & Tray Installation PDFUtku Can Kılıç100% (1)

- KP-00+++-CY712-BKM7103 Rev. B CONDUITDocument8 pagesKP-00+++-CY712-BKM7103 Rev. B CONDUITUtku Can KılıçPas encore d'évaluation

- Method Statement For Installation of Emt Conduit-OldDocument13 pagesMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinPas encore d'évaluation

- Conduit BKM 7102Document9 pagesConduit BKM 7102Utku Can Kılıç100% (1)

- The IEE Wiring Regulations Explained and IllustratedD'EverandThe IEE Wiring Regulations Explained and IllustratedÉvaluation : 4 sur 5 étoiles4/5 (14)

- Rsae ITP QA: Document Review and Cover Sheet Company: Construction ContractorDocument5 pagesRsae ITP QA: Document Review and Cover Sheet Company: Construction ContractorUtku Can KılıçPas encore d'évaluation

- MHI Electrical 1st Comment RSAE-ITP-QA-EL-012 ITP For LV Bus DuctDocument5 pagesMHI Electrical 1st Comment RSAE-ITP-QA-EL-012 ITP For LV Bus DuctUtku Can KılıçPas encore d'évaluation

- FRN MST PPL Pl1 011 p4 C c1Document18 pagesFRN MST PPL Pl1 011 p4 C c1Utku Can Kılıç100% (1)

- MV&LV Switchgear Test ReportDocument4 pagesMV&LV Switchgear Test ReportUtku Can Kılıç100% (1)

- Rsae-Frm-216 Rev 00 Inspection Check List LV Bus DuctDocument1 pageRsae-Frm-216 Rev 00 Inspection Check List LV Bus DuctUtku Can Kılıç50% (2)

- Power Transformer Test Reports (For Primary)Document11 pagesPower Transformer Test Reports (For Primary)Utku Can Kılıç100% (2)

- Method Statement For DC PANELDocument6 pagesMethod Statement For DC PANELUtku Can KılıçPas encore d'évaluation

- Auto Transformer Test Reports (For Secondary)Document3 pagesAuto Transformer Test Reports (For Secondary)Utku Can Kılıç100% (1)

- Auto Transformer Test ReportsDocument11 pagesAuto Transformer Test ReportsUtku Can KılıçPas encore d'évaluation

- ITP For Batteries, Chargers and UPSDocument7 pagesITP For Batteries, Chargers and UPSUtku Can Kılıç100% (1)

- MV&LV Switchgear Test ReportDocument4 pagesMV&LV Switchgear Test ReportUtku Can Kılıç100% (1)

- VT Test ProsedureDocument7 pagesVT Test ProsedureUtku Can KılıçPas encore d'évaluation

- Att-2 Grounding & Lightning Protection - Tech - Specs.Document34 pagesAtt-2 Grounding & Lightning Protection - Tech - Specs.Utku Can Kılıç100% (1)

- For Information For Review For Approval For Construction As-BuiltDocument21 pagesFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçPas encore d'évaluation

- VT Test ProsedureDocument7 pagesVT Test ProsedureUtku Can KılıçPas encore d'évaluation

- PP13 00 Bat Enl Gam 001 PDFDocument16 pagesPP13 00 Bat Enl Gam 001 PDFUtku Can Kılıç100% (1)

- KP-00+++-CQ712-B7907 - F01 - Rev.B - MV Switchgear Installation Inspection Checklist1Document2 pagesKP-00+++-CQ712-B7907 - F01 - Rev.B - MV Switchgear Installation Inspection Checklist1Utku Can KılıçPas encore d'évaluation

- IQ347 300 EL CHL 00036 Lightning ProtectionDocument1 pageIQ347 300 EL CHL 00036 Lightning ProtectionUtku Can KılıçPas encore d'évaluation

- KP-00+++-CQ712-B7368-Rev 0-ITP Lightning Protection PDFDocument3 pagesKP-00+++-CQ712-B7368-Rev 0-ITP Lightning Protection PDFUtku Can KılıçPas encore d'évaluation

- Check List of Lightning Protection ErectionDocument1 pageCheck List of Lightning Protection ErectionUtku Can KılıçPas encore d'évaluation

- Inspection and Test Plan For Lightning Protection InstallationDocument1 pageInspection and Test Plan For Lightning Protection InstallationUtku Can Kılıç100% (1)

- KP-00+++-CQ712-G0006 - Rev.1 - ITP For Electrical Works (UnderGround Earthing Works)Document3 pagesKP-00+++-CQ712-G0006 - Rev.1 - ITP For Electrical Works (UnderGround Earthing Works)Utku Can KılıçPas encore d'évaluation

- KP-00+++-CY712-BKM7109 Method Statment For Lightning Protection System Installation WorksDocument16 pagesKP-00+++-CY712-BKM7109 Method Statment For Lightning Protection System Installation WorksUtku Can KılıçPas encore d'évaluation

- KP-00+++-CQ712-B7360-Electrical Works (Switchyard Lightning Arrester Installation)Document3 pagesKP-00+++-CQ712-B7360-Electrical Works (Switchyard Lightning Arrester Installation)Utku Can KılıçPas encore d'évaluation

- KP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Document3 pagesKP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Utku Can KılıçPas encore d'évaluation

- Kayako Support Suite User Manual PDFDocument517 pagesKayako Support Suite User Manual PDFallQoo SEO BaiduPas encore d'évaluation

- Ministry of Education Musala SCHDocument5 pagesMinistry of Education Musala SCHlaonimosesPas encore d'évaluation

- Sacmi Vol 2 Inglese - II EdizioneDocument416 pagesSacmi Vol 2 Inglese - II Edizionecuibaprau100% (21)

- ML7999A Universal Parallel-Positioning Actuator: FeaturesDocument8 pagesML7999A Universal Parallel-Positioning Actuator: Featuresfrank torresPas encore d'évaluation

- BACE Marketing Presentation FINALDocument14 pagesBACE Marketing Presentation FINALcarlosfelix810% (1)

- Department of Labor: 2nd Injury FundDocument140 pagesDepartment of Labor: 2nd Injury FundUSA_DepartmentOfLabor100% (1)

- Portfolio Report Zarin Tasnim Tazin 1920143 8Document6 pagesPortfolio Report Zarin Tasnim Tazin 1920143 8Fahad AlfiPas encore d'évaluation

- TT Class XII PDFDocument96 pagesTT Class XII PDFUday Beer100% (2)

- IOSA Information BrochureDocument14 pagesIOSA Information BrochureHavva SahınPas encore d'évaluation

- Agreement Deed BangladeshDocument8 pagesAgreement Deed BangladeshVabna EnterprisePas encore d'évaluation

- Automatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Document7 pagesAutomatic Stair Climbing Wheelchair: Professional Trends in Industrial and Systems Engineering (PTISE)Abdelrahman MahmoudPas encore d'évaluation

- List of People in Playboy 1953Document57 pagesList of People in Playboy 1953Paulo Prado De Medeiros100% (1)

- Te 1569 Web PDFDocument272 pagesTe 1569 Web PDFdavid19890109Pas encore d'évaluation

- Chapter Two Complexity AnalysisDocument40 pagesChapter Two Complexity AnalysisSoressa HassenPas encore d'évaluation

- Brochure 2017Document44 pagesBrochure 2017bibiana8593Pas encore d'évaluation

- AkDocument7 pagesAkDavid BakcyumPas encore d'évaluation

- Algorithm - WikipediaDocument34 pagesAlgorithm - WikipediaGilbertPas encore d'évaluation

- Life Cycle Cost Analysis of Hvac System in Office ProjectsDocument3 pagesLife Cycle Cost Analysis of Hvac System in Office ProjectsVashuka GhritlahrePas encore d'évaluation

- Your Electronic Ticket ReceiptDocument2 pagesYour Electronic Ticket Receiptjoana12Pas encore d'évaluation

- Reference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsDocument43 pagesReference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsNisha JosephPas encore d'évaluation

- Manuscript - Batallantes &Lalong-Isip (2021) Research (Chapter 1 To Chapter 3)Document46 pagesManuscript - Batallantes &Lalong-Isip (2021) Research (Chapter 1 To Chapter 3)Franzis Jayke BatallantesPas encore d'évaluation

- PPB 3193 Operation Management - Group 10Document11 pagesPPB 3193 Operation Management - Group 10树荫世界Pas encore d'évaluation

- Possession: I. A. Definition and Concept Civil Code Art. 523-530 CasesDocument7 pagesPossession: I. A. Definition and Concept Civil Code Art. 523-530 CasesPierrePrincipePas encore d'évaluation

- MWG Installation 7.6.2 IG INSTALLATION 0516 en - PDDocument64 pagesMWG Installation 7.6.2 IG INSTALLATION 0516 en - PDjbondsrPas encore d'évaluation

- Go Ask Alice EssayDocument6 pagesGo Ask Alice Essayafhbexrci100% (2)

- Paul Milgran - A Taxonomy of Mixed Reality Visual DisplaysDocument11 pagesPaul Milgran - A Taxonomy of Mixed Reality Visual DisplaysPresencaVirtual100% (1)