Académique Documents

Professionnel Documents

Culture Documents

ITP For Piping Systems

Transféré par

P SHANKAR BABUTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ITP For Piping Systems

Transféré par

P SHANKAR BABUDroits d'auteur :

Formats disponibles

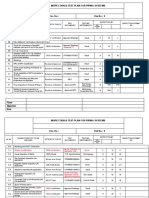

INSPECTION & TEST PLAN FOR PIPING SYSTEMS

Doc. No. :

SR. NO.

Name

Signature

Date

CHARACTERISTICS TO BE

CHECKED

EXTEND OF CHECK

Rev No. : 0

REF.

DOCUMENTS

TESTING

INSTRUMENTS

INSPECTION BY

SUBCONTRACT

OR

INSPECTION FORMAT

NO.

INSPECTION & TEST PLAN FOR PIPING SYSTEMS

Doc. No. :

CHARACTERISTICS TO BE

CHECKED

SR. NO.

EXTEND OF CHECK

1.0

Pipe Spool Fabrication

1.1

Check availability of latest Drawings /

Spec.

2.0

Raw Material Verification (During Fit-Up)

2.1

Check the correctness of specified

materials used and Fit-Up of Pipe spool

3.0

Fit up Clearance

3.1

Selection of WPS. Fit Up Checked,

bevel ends free from contamination

prior to tack welding.

4.0

Welding

4.1

REF.

DOCUMENTS

TESTING

INSTRUMENTS

INSPECTION BY

INSPECTION FORMAT

NO.

SUBCONTRACT

OR

Approved Drawings

Visual

100% Verification

Approved Drawings

& Material TC

Visual

100% Verification

VTKN/9001/TP/001

Visual

WPS & WPQ Qualification

Review & Approval

VTKN/9001/TP/001

TCE Specifications

Visual

4.2

Check proper backing of electrode as

applicable.

Random Verification

Temperature Gun

RW

RW

4.3

Check availability of WPS and welders

Id at site..

Random Verification

Visual

RW

4.4

Check Preheating and Inter pass

temperature as applicable

Random Verification

Visual

RW

4.5

Fit up Inspection & Preheat (If Reqd.)

Random verification

Approved WPS

Root Gauge,

Weld gauge

RW

RW

4.6

Welding In process Inspection as Correct

Random verification

Electrode, Interpass Temp etc.,

Approved WPS

Weld gauge

Temperature Gun

RW

Name

Signature

Date

100% Verification

Rev No. : 0

WPS

VTKN/9001/TP/001

WPS

INSPECTION & TEST PLAN FOR PIPING SYSTEMS

Doc. No. :

CHARACTERISTICS TO BE

CHECKED

SR. NO.

EXTEND OF CHECK

Rev No. : 0

REF.

DOCUMENTS

TESTING

INSTRUMENTS

5.0

Welding and NDT Clearance

5.1

Welder Qualification

100% Verification

As Per TCE Spec. &

Applicable Code

5.2

Visual Inspection of Welds

100% Welds

TCE Specifications

5.3

Dye Penetrant Inspection (As

applicable)

Where ever Reqd.

VTKN/9001/QM/014

5.4

Magnetic Particle Inspection (As

Applicable)

10% Fillet Welds

5.5

Ultrasonic Inspection(As applicable)

Where ever Reqd.

5.6

Radiography Inspection (As

applicable)

5.7

Pneumatic Test on reinforcement pad

(As applicable)

6.0

Spool Preservation

6.1

6.2

Ensure Spools are correctly Tagged

with relevant details

Ensure Spools are correctly cleaned,

stored & protected during temporary

storage

6.3

Release for painting and Erection

6.4

Spool Hydro Test (If required)

Name

Signature

Date

Visual

INSPECTION BY

INSPECTION FORMAT

NO.

SUBCONTRACT

OR

Visual

DR

VTKN/9001/QM/013

Visual

DR

VTKN/9001/QM/012

Visual

As per material spec Applicable Code &

Film Viewer

All RF Pads

VTKN/9001/QM/015

Pressure Gauge

100% Verification

Approved Drawings

Visual

100% Verification

Approved Drawings

Visual

Random Verification VTKN/9001/TP/001

Visual

Pressure Gauge

Weld gauge

As Per TCE Spec.

Approved Procedure

100%

VTKN/9001/TP/001

INSPECTION & TEST PLAN FOR PIPING SYSTEMS

Doc. No. :

CHARACTERISTICS TO BE

CHECKED

SR. NO.

EXTEND OF CHECK

Rev No. : 0

REF.

DOCUMENTS

TESTING

INSTRUMENTS

INSPECTION BY

INSPECTION FORMAT

NO.

SUBCONTRACT

OR

7.0

Piping Erection

7.1

Pre Fabricated Spools verification

Random Verification

Approved Drawings

Visual

7.2

Verification of erected Piping System for

its Completeness and Mechanical

Clearance

100% Verification

Approved Drawings

Visual

7.3

Spool to Spool Fit up Inspection, Joint

No. Welder Id

100% Verification

Approved Drawings

WPS

Root gauge

RW

7.4

Final Weld Visual

Random Verification,

&Weld History Sheet

Approved Drawings

WPS

Weld Gauge

8.0

Valves Erection

8.1

Installation of WN valves

Random Verification Approved Drawing

Visual

RW

8.2

Fit up & Welding

100% Verification

Approved WPS

Root Gauge

RW

8.3

Installing Gasket (original)

100% Verification

Approved Drawing

Visual

8.4

Flow direction all valves & tag.no.

Include in-line items.

100% Verification

Approved Drawing

Visual

Name

Signature

Date

INSPECTION & TEST PLAN FOR PIPING SYSTEMS

Doc. No. :

CHARACTERISTICS TO BE

CHECKED

SR. NO.

EXTEND OF CHECK

Rev No. : 0

REF.

DOCUMENTS

TESTING

INSTRUMENTS

INSPECTION BY

INSPECTION FORMAT

NO.

SUBCONTRACT

OR

8.6

Bolting & Torqueing

100% Verification

Approved Drawing

TCE Specifications

Torque Wrench

9.0

Supports Fabrication

Random Verification

Approved Drawing

Measuring Tape

RW

9.1

Supports Erection

100% Verification

Approved Drawing

Visual

Measuring Tape

RW

10.0

Hydro Test

10.1

Isometric Clearence

100% Verification

Approved Drawing

Visual &

Document Review

10.2

Release for Hydrotest

100% Verification

Approved Drawings

P&ID and LHS

Nil

10.3

Line walk & Punch Points

100% Verification

Approved Drawings

Visual

10.4

Flushing of pipe system

100% Verification

Approved Drawings

TCE Specification

Visual

10.5

Hydrotest

100% Verification

VTKN/9001/TP/003

Pressure gauges

11.0

Painting

100% Verification

VTKN/9001/TP/004,

As Per approved

Painting FQP

Elcometer

Name

Signature

Date

INSPECTION & TEST PLAN FOR PIPING SYSTEMS

Doc. No. :

CHARACTERISTICS TO BE

CHECKED

SR. NO.

EXTEND OF CHECK

12.0

Insulation (As required)

100% Verification

13.0

Piping Test Pack Clearence

100% Verification

Rev No. : 0

REF.

DOCUMENTS

Approved Drawings,

& As per approved

Insulation FQP

Approved Drawings

TESTING

INSTRUMENTS

INSPECTION BY

INSPECTION FORMAT

NO.

SUBCONTRACT

OR

Visual

Visual

Legends:

H:

Hold Point is a mandatory inspection point and work shall not proceed without the presence of a representative of the organization. Activity designated as Hold must

be signed off by the Owners Representative.

W:

Witness Inspection Point: Designated Witness Points for the involved personnel, which are required to be signed off by the personnel who witnessed. All activities, which

have a W point, will require a written notification to owner representative. In the event the owner representative does not attend within an agreed period the work may

proceed. In such cases, the owner representative will record in the appropriate signature space on the forms as Not Witnessed, and sign off.

RW:

Witness Inspection point: Designated % witness points assigned by the owners representative, which will require written notification from the owner representative. In the

event owner representative does not attend within agreed the work, may proceed. In such cases, the owner representative will record in the appropriate signature space

on the forms as Not Witnessed, and sign off. The percentage means a minimum of 10% inspection over all. However this may be increased at the discretion of

construction manager or his designee.

S:

Surveillance Over seeing or monitoring of activities by visiting. Activities designated as surveillance will Not be signed off by the owners representative.

DR:

Document Review: This entails review of appropriate documentation and does not require signature of owner representative.

Name

Signature

Date

Vous aimerez peut-être aussi

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankAhmed100% (5)

- Spirax Sarco Design of Fluid Systems 2Document66 pagesSpirax Sarco Design of Fluid Systems 2mahonde100% (2)

- Hydrotest Procedure for Reinforced Thermosetting Epoxy-Resin PipesDocument13 pagesHydrotest Procedure for Reinforced Thermosetting Epoxy-Resin PipesMohammad Rizwan0% (1)

- Contractor Quality Control Plan For Storage Tank ErectionDocument2 pagesContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- Inspection and Test Plan for SwitchgearDocument12 pagesInspection and Test Plan for SwitchgearShahadat HossainPas encore d'évaluation

- Inspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Document8 pagesInspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Santosh Kumar Bogela100% (12)

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuPas encore d'évaluation

- Inspection and Test Plan Rev.0Document3 pagesInspection and Test Plan Rev.0คุณพ่อน้อง บิ๊กบอสPas encore d'évaluation

- Inspection Test PlanDocument3 pagesInspection Test PlanMohd Shafuaaz Kassim100% (2)

- Tank Erection Itp & Org ChartDocument34 pagesTank Erection Itp & Org Charthasan_676489616100% (2)

- Algeria Oman Fertilizer Project Inspection and Test PlanDocument22 pagesAlgeria Oman Fertilizer Project Inspection and Test Planmister pogi100% (3)

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument10 pages5 - Tank Itp - Inspection & Test Plan For TanksAhmed Hassan100% (2)

- Inspection Test Plan - Piping FabricationDocument5 pagesInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- Itp TankDocument4 pagesItp TankAmber Chavez100% (2)

- ITP Format For New PVDocument8 pagesITP Format For New PVDavid LambertPas encore d'évaluation

- Dimensional Control Procedure (Pipe Fit Assurance)Document17 pagesDimensional Control Procedure (Pipe Fit Assurance)Joe Ripa67% (3)

- ITP - PipingDocument7 pagesITP - PipingRiaz Rasool100% (2)

- Itp For Steel Structure Erection (Content) Rev.1Document3 pagesItp For Steel Structure Erection (Content) Rev.1Anonymous nLMJGu100% (5)

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDocument5 pagesYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationAmair Cool88% (8)

- Inspection and Test Plan For New Pressure VesselDocument2 pagesInspection and Test Plan For New Pressure VesselCak Nhass0% (1)

- Inspection and Test Plan For Line Pipe PDFDocument4 pagesInspection and Test Plan For Line Pipe PDFsherviny100% (1)

- Itp For Piping Fabrication and Erection CorrectionDocument4 pagesItp For Piping Fabrication and Erection CorrectionAnand Ramachandran67% (3)

- ITP For Field Erected Tank Rev ADocument9 pagesITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- Pipe Line Works Inspection and Test PlanDocument1 pagePipe Line Works Inspection and Test PlanCrstnScribidPas encore d'évaluation

- Piping Hydrotest Procedure GuideDocument3 pagesPiping Hydrotest Procedure GuideFrank100% (6)

- Sample - Template - Itp For Piping Fabrication and InstallationDocument2 pagesSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriPas encore d'évaluation

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciPas encore d'évaluation

- Attachment 6 - Piping Test Package (Manifold 204, 205) (Pages 56 To 121) - A4A0Z7Document66 pagesAttachment 6 - Piping Test Package (Manifold 204, 205) (Pages 56 To 121) - A4A0Z7indusampath100% (2)

- Weld Defects 2Document122 pagesWeld Defects 2Pradeep Kumar Raju B100% (1)

- ITP-000 Piping Fabrication (Exemple)Document5 pagesITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- ITP For Pipeline Construction Table 1Document3 pagesITP For Pipeline Construction Table 1wahyu100% (2)

- Site QAQC PlanDocument9 pagesSite QAQC PlanP SHANKAR BABU100% (1)

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemsGia Minh Tieu TuPas encore d'évaluation

- IOCL Static Equipment ITPDocument12 pagesIOCL Static Equipment ITPaamirapi100% (3)

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Document24 pagesItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- Equipment Erection, Static and RotaryDocument8 pagesEquipment Erection, Static and RotaryHamada ELaraby60% (5)

- Faraday CupsDocument10 pagesFaraday CupsAshish SharmaPas encore d'évaluation

- Arcelormittal Pressure VesselDocument12 pagesArcelormittal Pressure VesselAnonymous UoHUagPas encore d'évaluation

- Weld Map & NDE Extent of Pressure VesselDocument32 pagesWeld Map & NDE Extent of Pressure VesselMahesh Kumar100% (2)

- ITP Requirements and Inspection LevelsDocument7 pagesITP Requirements and Inspection LevelsRoshin99Pas encore d'évaluation

- 048-Itp For Installation of Hvac Unit PDFDocument8 pages048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- Fabrication Erection and Installation Procedure For PipingDocument36 pagesFabrication Erection and Installation Procedure For Pipinggst ajah100% (2)

- B31.3 Process Piping Course - 03 Materials-LibreDocument45 pagesB31.3 Process Piping Course - 03 Materials-LibrejacquesmayolPas encore d'évaluation

- Structural Steel PresentationDocument91 pagesStructural Steel PresentationP SHANKAR BABU75% (4)

- ITP For Piping WorksDocument3 pagesITP For Piping WorksOrlando1949100% (3)

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- Astm A265 (1999)Document5 pagesAstm A265 (1999)P SHANKAR BABUPas encore d'évaluation

- Owner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionDocument5 pagesOwner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionLuqman OsmanPas encore d'évaluation

- Mechanical ITP Inspection of Oil TankDocument2 pagesMechanical ITP Inspection of Oil TankikramPas encore d'évaluation

- 033-Itp For Piping Installation Ag and Ug PDFDocument13 pages033-Itp For Piping Installation Ag and Ug PDFKöksal Patan75% (4)

- Itp PipingDocument4 pagesItp Pipingerdemlix100% (2)

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyPas encore d'évaluation

- Itp Mandrel CCTVDocument1 pageItp Mandrel CCTVbcdavidPas encore d'évaluation

- AS/NZS 5100.6, Design of Steel and Composite Bridges: April 2017Document9 pagesAS/NZS 5100.6, Design of Steel and Composite Bridges: April 2017Krish ChandPas encore d'évaluation

- 10) Itp - Tank Fabrication PDFDocument6 pages10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- S-000-1676-0001V - 11 - ITP For Piping WorkDocument47 pagesS-000-1676-0001V - 11 - ITP For Piping WorkVO DINH TRI100% (2)

- Inspection and Test Plan (KDBK)Document5 pagesInspection and Test Plan (KDBK)Abdul Wadood Gharsheen100% (1)

- QC Form for Dung Quat Refinery Hydrotest PackageDocument1 pageQC Form for Dung Quat Refinery Hydrotest Packageminhnn75% (4)

- Ag Test Package FormatDocument25 pagesAg Test Package FormatoparoystPas encore d'évaluation

- Fit Up Report Format-1Document1 pageFit Up Report Format-1BalkishanDyavanapellyPas encore d'évaluation

- Buyer Guide 2017 Company DirectoryDocument7 pagesBuyer Guide 2017 Company DirectoryLabnesPas encore d'évaluation

- Material Inspection Procedure-General Requirement-Combined (30-P01-00)Document8 pagesMaterial Inspection Procedure-General Requirement-Combined (30-P01-00)Samira MahmoodiPas encore d'évaluation

- Technical Specification For Vacuum SystemsDocument284 pagesTechnical Specification For Vacuum SystemsUday SulePas encore d'évaluation

- ITP GolDocument2 pagesITP GolLorelai Ursea100% (1)

- Qap For Transient Heater Rev (1) .0Document3 pagesQap For Transient Heater Rev (1) .0maniyar_sajeed123Pas encore d'évaluation

- Erection ProcedureDocument4 pagesErection ProcedureRanjit BanerjeePas encore d'évaluation

- Quality Control Inspector Interview Questions and AnswersDocument4 pagesQuality Control Inspector Interview Questions and Answerszhangyili100% (1)

- H Quality and Certification Requirements-SPDocument3 pagesH Quality and Certification Requirements-SPEl_memitoPas encore d'évaluation

- QIPDocument9 pagesQIPzahid_497Pas encore d'évaluation

- Piping Inspection & Test PlanDocument5 pagesPiping Inspection & Test Plan심판자Pas encore d'évaluation

- B Section 202 To 212Document11 pagesB Section 202 To 212joshua_tan_31Pas encore d'évaluation

- Residual Stresses & DistorsionDocument61 pagesResidual Stresses & DistorsionP SHANKAR BABUPas encore d'évaluation

- Super - Commando - Dhruva - Bhoochal PDFDocument49 pagesSuper - Commando - Dhruva - Bhoochal PDFP SHANKAR BABU89% (9)

- 653Document11 pages653govimanoPas encore d'évaluation

- Momentum and its conservation in collisionsDocument5 pagesMomentum and its conservation in collisionslemonitePas encore d'évaluation

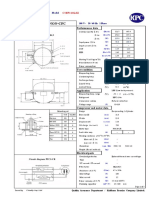

- Tubing 3.500" 9.30 LB/FT: Pipe Grade: N80 / Range: 2 Tool Joint: 4.500'' X 2.992'' EUE (8 RD)Document1 pageTubing 3.500" 9.30 LB/FT: Pipe Grade: N80 / Range: 2 Tool Joint: 4.500'' X 2.992'' EUE (8 RD)Êfrên Rôdrîgûêz TôrrêsPas encore d'évaluation

- Division 23 Hvac: 230548: Vibration Isolation / 230549: Seismic/Wind Restraints Section 230548: Vibration IsolationDocument10 pagesDivision 23 Hvac: 230548: Vibration Isolation / 230549: Seismic/Wind Restraints Section 230548: Vibration IsolationTengku Azaha Tengku IsmailPas encore d'évaluation

- Marine Gas Turbine: PerformanceDocument2 pagesMarine Gas Turbine: PerformancefrdnPas encore d'évaluation

- Wall Footing DesignDocument4 pagesWall Footing DesignAddrien DanielPas encore d'évaluation

- Sylvania BKD Dual BeamKat HID Floodlight Spec Sheet 1-87Document4 pagesSylvania BKD Dual BeamKat HID Floodlight Spec Sheet 1-87Alan MastersPas encore d'évaluation

- Air Cooler Design BHEXDocument1 pageAir Cooler Design BHEXRolando GanzonPas encore d'évaluation

- Barrel Design of BorawasDocument23 pagesBarrel Design of BorawasSunita ChaurasiaPas encore d'évaluation

- Chemical Engineering Calculations for Gases and VaporsDocument2 pagesChemical Engineering Calculations for Gases and VaporsKhristel PenoliarPas encore d'évaluation

- MP Assignment-III (Questions)Document1 pageMP Assignment-III (Questions)Raja HarisPas encore d'évaluation

- PhysicsDocument2 pagesPhysicsStephani BrownleePas encore d'évaluation

- Making Space: The SOS Guide To Control Room DesignDocument9 pagesMaking Space: The SOS Guide To Control Room DesignCássioPas encore d'évaluation

- Mechanical Properties of MaterialsDocument45 pagesMechanical Properties of MaterialsRonan SeePas encore d'évaluation

- C-BF 110L0Z PDFDocument3 pagesC-BF 110L0Z PDFWardi SupriadiPas encore d'évaluation

- Calculating Wavelength of Light Using Single Slit DiffractionDocument30 pagesCalculating Wavelength of Light Using Single Slit DiffractionRajneilPas encore d'évaluation

- Sunglass Lens Options: StandardDocument2 pagesSunglass Lens Options: StandardfufeconiPas encore d'évaluation

- Electro Chemistry (Final) - 01-TheoryDocument35 pagesElectro Chemistry (Final) - 01-TheoryRaju SinghPas encore d'évaluation

- MD Reviewer 3Document1 pageMD Reviewer 3Dave Vendivil SambranoPas encore d'évaluation

- Marine Consultant Analysis of Planing Hull PerformanceDocument6 pagesMarine Consultant Analysis of Planing Hull PerformanceNadia Quayyum100% (1)

- Water-Injected Flare Tips Reduce Radiated Heat, Noise: Rilling RoductionDocument4 pagesWater-Injected Flare Tips Reduce Radiated Heat, Noise: Rilling RoductionAnonymous cuOIjrLIPas encore d'évaluation

- Scee 271 14 Sec 1 4 PDFDocument40 pagesScee 271 14 Sec 1 4 PDFgykirankcPas encore d'évaluation

- Forces and The Laws of Motion: G9-AthsDocument25 pagesForces and The Laws of Motion: G9-AthsSalma 7assanPas encore d'évaluation

- WholeLife - Halfpenny - HBM Prenscia - NCode UGM CAE 18Document30 pagesWholeLife - Halfpenny - HBM Prenscia - NCode UGM CAE 18Felipe Dornellas SilvaPas encore d'évaluation

- Manual MIller DeltaWeld 302 NewDocument40 pagesManual MIller DeltaWeld 302 NewFreddy Giovanny ChaconPas encore d'évaluation