Académique Documents

Professionnel Documents

Culture Documents

Figure 7Ï11 Flexible Duct Liner Installation: 7.12 HVAC Duct Construction Standards Metal and Flexible - Third Edition

Transféré par

esagcojr0 évaluation0% ont trouvé ce document utile (0 vote)

327 vues1 pageMETAL NOSING MUST BE USED WHEREVER LINER IS PRECEDED BY UNLINED METAL. NOSING MAY BE FORMED ON DUCT OR BE CHANNEL OR ZEE ATTACHED BY SCREWS, RIVETS OR WELDS. ALL TRANSVERSE EDGES TO BE COATED WITH ADHESIVE.

Description originale:

Titre original

Hvac Duct Liner - Smacna

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMETAL NOSING MUST BE USED WHEREVER LINER IS PRECEDED BY UNLINED METAL. NOSING MAY BE FORMED ON DUCT OR BE CHANNEL OR ZEE ATTACHED BY SCREWS, RIVETS OR WELDS. ALL TRANSVERSE EDGES TO BE COATED WITH ADHESIVE.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

327 vues1 pageFigure 7Ï11 Flexible Duct Liner Installation: 7.12 HVAC Duct Construction Standards Metal and Flexible - Third Edition

Transféré par

esagcojrMETAL NOSING MUST BE USED WHEREVER LINER IS PRECEDED BY UNLINED METAL. NOSING MAY BE FORMED ON DUCT OR BE CHANNEL OR ZEE ATTACHED BY SCREWS, RIVETS OR WELDS. ALL TRANSVERSE EDGES TO BE COATED WITH ADHESIVE.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

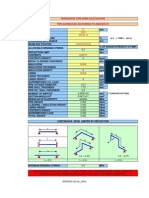

NOTE:

AIR FLOW

SEE TYPICAL DUCT BRANCH ENTRY CONDITION IN FIG. 26.

METAL NOSING MUST BE USED WHEREVER LINER IS PRECEDED

BY UNLINED METAL; OTHERWISE WHEN VELOCITY EXCEEDS

4000 FPM (20.3 MPS) USE METAL NOSING ON EVERY LEADING

EDGE. NOSING MAY BE FORMED ON DUCT OR BE CHANNEL

OR ZEE ATTACHED BY SCREWS, RIVETS OR WELDS.

DETAIL A

METAL NOSING

CHANNEL OR ZEE

INTERIOR WIDTH OF 8 (200 mm) AND LESS DOES NOT

REQUIRE PINS.

LAPPED AND BUTTED CORNER

THE VELOCITY RATED

SIDE OF LINER MUST

FACE THE AIR FLOW

PLACE PINS

3 (76 mm) ALONG

EACH SIDE OF A

BUTTED LONGITUDINAL

LINER SEAM THAT

IS AWAY FROM A

CORNER

D

E

B

B

ALL TRANSVERSE

EDGES TO BE

COATED WITH

ADHESIVE EXCEPT

WHEN NOSING IS

PRESENT

DUCT

SECTION

(TYPICALLY 4 FT. (1.2 m)

OR 5 FT. (1.52 m))

MAXIMUM SPACING FOR FASTENERS.

ACTUAL INTERVALS ARE APPROXIMATE.

LINER ADHERED TO

THE DUCT WITH 90%

MIN. AREA COVERAGE

OF ADHESIVE

A PIN ROW MAY BE OMITTED WHEN METAL NOSING IS

USED. E THEN STARTS FROM THE NOSING.

Velocity *

ALTERNATE

FOLDED

CORNER

Dimensions

B

C

0 2500 FPM

(0 12.7 MPS)

3

(76.2)

12

(305)

4

(102)

6

(152)

18

(457)

2501 6000 FPM

(12.7 30.5 MPS)

3

(76.2)

6

(152)

4

(102)

6

(152)

16

(406)

* UNLESS A LOWER

LEVEL IS SET BY

MANUFACTURER

OR LISTING

AGENCY

FIGURE 711 FLEXIBLE DUCT LINER INSTALLATION

7.12

HVAC Duct Construction Standards Metal and Flexible Third Edition

Vous aimerez peut-être aussi

- RYA-MCA Coastal Skipper-Yachtmaster Offshore Shorebased 2008 AnswersDocument28 pagesRYA-MCA Coastal Skipper-Yachtmaster Offshore Shorebased 2008 AnswersSerban Sebe100% (4)

- EnteliVIZ Application Reference GuideDocument70 pagesEnteliVIZ Application Reference Guideesagcojr100% (2)

- H-Beam, Channel Sleeper FabricationDocument64 pagesH-Beam, Channel Sleeper FabricationVipin Dhanwaliya100% (5)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Table 6.1 AWS D1.1 D1.1M-2010Document1 pageTable 6.1 AWS D1.1 D1.1M-2010gigiphi75% (8)

- BMS Design GuideDocument90 pagesBMS Design Guideesagcojr85% (13)

- ASTM B828 Cobre Soldering PDFDocument7 pagesASTM B828 Cobre Soldering PDFFranco Guillermo Huanca ZuñigaPas encore d'évaluation

- Lta StandardDocument178 pagesLta Standardkokuei100% (5)

- 03 HCMC - HAP - Energy Simulation ManualDocument200 pages03 HCMC - HAP - Energy Simulation ManualesagcojrPas encore d'évaluation

- State Immunity Cases With Case DigestsDocument37 pagesState Immunity Cases With Case DigestsStephanie Dawn Sibi Gok-ong100% (4)

- Week 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student HandoutDocument3 pagesWeek 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student Handoutdwkwhdq dwdPas encore d'évaluation

- The Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageDocument5 pagesThe Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageHenny ZahranyPas encore d'évaluation

- Abu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationDocument27 pagesAbu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationPaulWolfPas encore d'évaluation

- 1169 - USA - 49 CFR 192 - Eff 03 2016Document21 pages1169 - USA - 49 CFR 192 - Eff 03 2016Enoch TwumasiPas encore d'évaluation

- Curb InletDocument1 pageCurb InletJoseph MathewPas encore d'évaluation

- Structural Notes and SpecificationsDocument5 pagesStructural Notes and SpecificationsMohamad Tomindug BauloPas encore d'évaluation

- D Pi 175Document2 pagesD Pi 175reza329329Pas encore d'évaluation

- Pdvsa: Engineering Design ManualDocument5 pagesPdvsa: Engineering Design ManualnoxleekPas encore d'évaluation

- A L F I: Cceptance Imit OR MperfectionsDocument29 pagesA L F I: Cceptance Imit OR MperfectionsDavid MacatangayPas encore d'évaluation

- Spec (1) .11 KV Rocking Type Tpgo IsolatorDocument7 pagesSpec (1) .11 KV Rocking Type Tpgo Isolatorarindam90Pas encore d'évaluation

- PS NotesDocument6 pagesPS NotesnidhisasidharanPas encore d'évaluation

- Aa 036007 001Document1 pageAa 036007 001narutothunderjet216Pas encore d'évaluation

- NotesDocument1 pageNotessatydevsinghnegiPas encore d'évaluation

- Shorings and Bracings of The Structure For All Loads That Maybe Imposed During ConstructionDocument7 pagesShorings and Bracings of The Structure For All Loads That Maybe Imposed During ConstructionNatalie WrightPas encore d'évaluation

- Competency 5Document3 pagesCompetency 5Jae RiondangaPas encore d'évaluation

- A Proposed Mixed-Use Development: I. Structural Design CriteriaDocument28 pagesA Proposed Mixed-Use Development: I. Structural Design CriteriaAnonymous sOSxA7SPas encore d'évaluation

- 2 0.2 Acsr Panther Conductor 1 14Document14 pages2 0.2 Acsr Panther Conductor 1 14Anurag SanodiaPas encore d'évaluation

- 7.1 Longitudinal Reinforcement: S.No Description Status Remarks 7 Columns and Inclined MembersDocument4 pages7.1 Longitudinal Reinforcement: S.No Description Status Remarks 7 Columns and Inclined MembersJagadish kumar.kPas encore d'évaluation

- Lighting Wiring MethodsDocument12 pagesLighting Wiring MethodstemamPas encore d'évaluation

- Pipe Span Without Point LoadsDocument36 pagesPipe Span Without Point Loadsbakelly100% (4)

- ANSI-AISC 358-20 - C7SA - InglésDocument7 pagesANSI-AISC 358-20 - C7SA - InglésmanuelPas encore d'évaluation

- Section VII. Technical SpecificationDocument10 pagesSection VII. Technical SpecificationBalkrishna PangeniPas encore d'évaluation

- Macro Examination StandardDocument4 pagesMacro Examination StandardMohd Akmal ShafiePas encore d'évaluation

- TS-03 Air Distribution WorksDocument14 pagesTS-03 Air Distribution WorksPraveen KumarPas encore d'évaluation

- Saes S 070Document2 pagesSaes S 070Naushad AlamPas encore d'évaluation

- Zesa Installation GuideDocument10 pagesZesa Installation GuideKudakwashe Charera100% (2)

- Technical Terms About ReinforcementDocument13 pagesTechnical Terms About ReinforcementRemo DahalPas encore d'évaluation

- Acceptance CriteriaDocument10 pagesAcceptance CriteriaRavindra S. Jivani100% (2)

- Kohinoor Square ProjectDocument12 pagesKohinoor Square ProjectAnonymous zIYeDYU7zoPas encore d'évaluation

- Electrical Metallic Tubing (EMT)Document36 pagesElectrical Metallic Tubing (EMT)Jama CasayPas encore d'évaluation

- 2007 Section ViiiDocument3 pages2007 Section ViiiMiriam LopezPas encore d'évaluation

- Ductile Detailing Considerations As Per Is 13920 2016 DERSDocument41 pagesDuctile Detailing Considerations As Per Is 13920 2016 DERSAbijithPas encore d'évaluation

- Detailing of Reinforcment in Concrete Structures: 8.1 ScopeDocument34 pagesDetailing of Reinforcment in Concrete Structures: 8.1 ScopeARIFUL ISLAMPas encore d'évaluation

- Notes:: 6"-12" PIPE Flowline Removable AnchorDocument1 pageNotes:: 6"-12" PIPE Flowline Removable Anchornarutothunderjet216Pas encore d'évaluation

- Cable Tie - QCS 2014Document1 pageCable Tie - QCS 2014Modern DesignsPas encore d'évaluation

- Handrail DetailDocument1 pageHandrail Detailpicott100% (1)

- Chapter 5 - CasingDocument69 pagesChapter 5 - CasingMuhammad Nursalam100% (2)

- Chapter No. 05 Casing and CementingDocument20 pagesChapter No. 05 Casing and CementingHassan AkbarPas encore d'évaluation

- Generalcons Tructionnot ES: General NotesDocument10 pagesGeneralcons Tructionnot ES: General NotesJejomar MotolPas encore d'évaluation

- Guide For The Installation of ACSR and ACSR TW Conductors PDFDocument15 pagesGuide For The Installation of ACSR and ACSR TW Conductors PDFKevin MweneSafari100% (1)

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshPas encore d'évaluation

- NEC CHAPTER 3 QUIZ With AnswersDocument20 pagesNEC CHAPTER 3 QUIZ With AnswersAbdul RaheemPas encore d'évaluation

- Requirements of Tower/AntennasDocument8 pagesRequirements of Tower/Antennasvaram1Pas encore d'évaluation

- Ac 036660 004Document1 pageAc 036660 004narutothunderjet216Pas encore d'évaluation

- Drilling AccessoriesDocument38 pagesDrilling Accessoriesbagus100% (1)

- General Notes 2Document5 pagesGeneral Notes 2Amer GonzalesPas encore d'évaluation

- Section 610-Pipe Underdrain and Pavement Base DrainDocument5 pagesSection 610-Pipe Underdrain and Pavement Base Drainذوالفقار كريم الابراهيميPas encore d'évaluation

- Oaqøhv VLRJ VKSJ Ysiu Okys Blikr Flfyumj Fof'Kf"V: HKKJRH EkudDocument9 pagesOaqøhv VLRJ VKSJ Ysiu Okys Blikr Flfyumj Fof'Kf"V: HKKJRH EkudVijayaPas encore d'évaluation

- 3.68 BuswaysDocument21 pages3.68 Buswaysna zafiraPas encore d'évaluation

- Subject: Design: CHD: Client:: One-WayDocument3 pagesSubject: Design: CHD: Client:: One-WayIlmtalabPas encore d'évaluation

- 95000401Document1 page95000401raobabar21Pas encore d'évaluation

- Types of Conduit Fittings and SupportsDocument9 pagesTypes of Conduit Fittings and SupportsMarkPas encore d'évaluation

- Anchorage and Development LengthsDocument2 pagesAnchorage and Development LengthsSimo AliPas encore d'évaluation

- PIPEDocument10 pagesPIPEJoshua SykamPas encore d'évaluation

- Mechanical VentilationDocument22 pagesMechanical VentilationesagcojrPas encore d'évaluation

- Fish Cold Storage SchemeDocument4 pagesFish Cold Storage SchemeesagcojrPas encore d'évaluation

- Duct SilencersDocument125 pagesDuct SilencersesagcojrPas encore d'évaluation

- HSPCDocument2 pagesHSPCAhmed AzadPas encore d'évaluation

- Static Pa PDFDocument7 pagesStatic Pa PDFjanatunaliyahPas encore d'évaluation

- Aircon - Schedule of Maintenance ServiceDocument3 pagesAircon - Schedule of Maintenance ServiceesagcojrPas encore d'évaluation

- HVAC Calculations Mixed Air Calculator Humidification and ReheatDocument1 pageHVAC Calculations Mixed Air Calculator Humidification and ReheatesagcojrPas encore d'évaluation

- Run Around Coil Loop Heat RecoveryDocument3 pagesRun Around Coil Loop Heat RecoveryesagcojrPas encore d'évaluation

- 2001-04-17 - Energy Effy Design GuideDocument108 pages2001-04-17 - Energy Effy Design GuideesagcojrPas encore d'évaluation

- Google App EngineDocument5 pagesGoogle App EngineDinesh MudirajPas encore d'évaluation

- Doterra Enrollment Kits 2016 NewDocument3 pagesDoterra Enrollment Kits 2016 Newapi-261515449Pas encore d'évaluation

- BYJU's July PayslipDocument2 pagesBYJU's July PayslipGopi ReddyPas encore d'évaluation

- Tinplate CompanyDocument32 pagesTinplate CompanysnbtccaPas encore d'évaluation

- Final ExamSOMFinal 2016 FinalDocument11 pagesFinal ExamSOMFinal 2016 Finalkhalil alhatabPas encore d'évaluation

- Test & Drain Valve Model 1000Document2 pagesTest & Drain Valve Model 1000saifahmed7Pas encore d'évaluation

- STM - Welding BookDocument5 pagesSTM - Welding BookAlvin MoollenPas encore d'évaluation

- 6 V 6 PlexiDocument8 pages6 V 6 PlexiFlyinGaitPas encore d'évaluation

- 199437-Unit 4Document36 pages199437-Unit 4Yeswanth rajaPas encore d'évaluation

- Topic 4: Mental AccountingDocument13 pagesTopic 4: Mental AccountingHimanshi AryaPas encore d'évaluation

- Sky ChemicalsDocument1 pageSky ChemicalsfishPas encore d'évaluation

- Case Assignment 2Document5 pagesCase Assignment 2Ashish BhanotPas encore d'évaluation

- Sourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyDocument58 pagesSourcing Decisions in A Supply Chain: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyAlaa Al HarbiPas encore d'évaluation

- 4th Sem Electrical AliiedDocument1 page4th Sem Electrical AliiedSam ChavanPas encore d'évaluation

- Process States in Operating SystemDocument4 pagesProcess States in Operating SystemKushal Roy ChowdhuryPas encore d'évaluation

- 3412C EMCP II For PEEC Engines Electrical System: Ac Panel DC PanelDocument4 pages3412C EMCP II For PEEC Engines Electrical System: Ac Panel DC PanelFrancisco Wilson Bezerra FranciscoPas encore d'évaluation

- Cam Action: Series: Inch StandardDocument6 pagesCam Action: Series: Inch StandardVishwa NPas encore d'évaluation

- General Diesel Engine Diagnostic Guide PDFDocument3 pagesGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3Pas encore d'évaluation

- Business Environment Analysis - Saudi ArabiaDocument24 pagesBusiness Environment Analysis - Saudi ArabiaAmlan JenaPas encore d'évaluation

- Forecasting of Nonlinear Time Series Using Artificial Neural NetworkDocument9 pagesForecasting of Nonlinear Time Series Using Artificial Neural NetworkranaPas encore d'évaluation

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocument7 pagesPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiPas encore d'évaluation

- 2021S-EPM 1163 - Day-11-Unit-8 ProcMgmt-AODADocument13 pages2021S-EPM 1163 - Day-11-Unit-8 ProcMgmt-AODAehsan ershadPas encore d'évaluation

- Transparency Documentation EN 2019Document23 pagesTransparency Documentation EN 2019shani ChahalPas encore d'évaluation

- Kaitlyn LabrecqueDocument15 pagesKaitlyn LabrecqueAmanda SimpsonPas encore d'évaluation

- Supergrowth PDFDocument9 pagesSupergrowth PDFXavier Alexen AseronPas encore d'évaluation