Académique Documents

Professionnel Documents

Culture Documents

Talpac - Memoria Mineral 36P PDF

Transféré par

Darwin AjomadoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Talpac - Memoria Mineral 36P PDF

Transféré par

Darwin AjomadoDroits d'auteur :

Formats disponibles

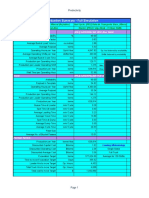

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.88

5.52

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

219.16

2,155 Max. prod. based on 100% avail.

1,062,447 Avg. production factored by avail.

24.50

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.37

243.51

2,155

1,062,447

0.28

0.40

5.24

5.50

0.33

0.50

12.25

1

10.03

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

1,062,447

0.60

1.39

1.99

565,465.00

194.40

2,580

2,322

1,125,703

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

364

10.0

3

Superficie con Pendiente

336

4.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

336

-4.0

9

Rampa del Pit (Regreso)

364

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

1,700

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.24

0.41

1.79

0.99

0.00

0.32

0.33

0.50

0.26

0.00

0.57

0.75

0.41

2.3

3.3

42.8

3.4

14.6

8.1

0.0

2.6

2.7

4.1

2.1

0.0

4.7

6.1

3.4

12.25

100.00

20.0

20.0

21.3

19.0

17.5

20.0

12.0

19.0

19.0

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Retard

Retard

Final Sp.

14.6

12.2

20.4

0.0

9.5

0.0

36.4

13.4

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

35.2

29.3

14.6

0.0

0.0

-13.4

-36.4

0.0

8.3

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

96.0

#NUM! Undefined

0.0

0.0

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

12.8

0.0

0.0

0.0

8.3

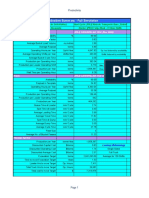

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.88

5.53

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

205.82

Max. prod. based on 100% avail.

2,024

997,797 Avg. production factored by avail.

25.89

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.36

228.69

2,024

997,797

0.28

0.40

5.23

6.30

0.33

0.50

13.05

1

10.01

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

997,797

0.64

1.48

2.12

576,160.00

210.91

2,799

2,519

1,221,311

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

468

10.0

3

Superficie con Pendiente

323

5.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

323

-5.0

9

Rampa del Pit (Regreso)

468

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

1,882

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.23

0.41

2.31

1.08

0.00

0.32

0.33

0.50

0.26

0.00

0.55

0.95

0.41

2.1

3.1

40.1

3.1

17.7

8.3

0.0

2.4

2.5

3.8

2.0

0.0

4.2

7.3

3.1

13.05

100.00

20.0

20.0

18.2

18.2

17.8

20.0

12.0

18.2

18.2

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.1

17.9

0.0

9.5

0.0

46.8

16.2

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

35.0

29.4

14.6

0.0

0.0

-16.2

-46.8

0.0

8.7

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

0.0 Undefined

0.0

0.0

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

9.8

0.0

0.0

0.0

8.3

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.88

5.53

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

165.72

1,630 Max. prod. based on 100% avail.

803,395 Avg. production factored by avail.

29.67

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.35

184.14

1,630

803,395

0.28

0.40

5.23

9.38

0.33

0.50

16.12

1

10.01

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

803,395

0.80

1.83

2.63

575,771.00

261.76

3,474

3,127

1,515,813

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

936

10.0

3

Superficie con Pendiente

280

5.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

280

-5.0

9

Rampa del Pit (Regreso)

936

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

2,732

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.23

0.41

4.66

0.94

0.00

0.32

0.33

0.50

0.26

0.00

0.49

1.89

0.41

1.7

2.5

32.4

2.5

28.9

5.8

0.0

2.0

2.0

3.1

1.6

0.0

3.0

11.7

2.5

16.12

100.00

20.0

20.0

18.2

18.2

17.8

20.0

12.0

18.2

18.2

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.1

17.8

0.0

9.5

0.0

93.6

14.0

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

34.3

29.7

14.6

0.0

0.0

-14.0

-93.6

0.0

10.2

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

0.0 Undefined

0.0

0.0

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

11.1

0.0

0.0

0.0

8.3

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.87

5.52

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

174.28

Max. prod. based on 100% avail.

1,714

844,881 Avg. production factored by avail.

28.89

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.37

193.64

1,714

844,881

0.28

0.40

5.24

8.62

0.33

0.50

15.37

1

10.03

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

844,881

0.76

1.74

2.50

576,085.00

249.05

3,306

2,975

1,442,169

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

806

10.0

3

Superficie con Pendiente

311

5.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

311

-5.0

9

Rampa del Pit (Regreso)

806

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

2,534

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.24

0.41

4.01

1.04

0.00

0.32

0.33

0.50

0.26

0.00

0.54

1.63

0.41

1.8

2.6

34.1

2.7

26.1

6.8

0.0

2.1

2.1

3.2

1.7

0.0

3.5

10.6

2.7

15.37

100.00

20.0

20.0

18.2

18.2

17.8

20.0

12.0

18.2

18.2

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.1

17.9

0.0

9.5

0.0

80.6

15.6

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

34.8

29.7

14.6

0.0

0.0

-15.6

-80.6

0.0

9.9

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

#NUM! Undefined

0.0

0.0

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

10.1

0.0

0.0

0.0

8.3

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.88

5.52

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

178.81

Max. prod. based on 100% avail.

1,758

866,822 Avg. production factored by avail.

28.43

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.36

198.67

1,758

866,822

0.28

0.40

5.24

8.24

0.33

0.50

14.99

1

10.03

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

866,822

0.74

1.70

2.44

575,718.00

242.59

3,220

2,898

1,404,770

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

676

10.0

3

Superficie con Pendiente

368

7.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

368

-7.0

9

Rampa del Pit (Regreso)

676

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

2,388

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.24

0.41

3.36

1.49

0.00

0.32

0.33

0.50

0.26

0.00

0.62

1.37

0.41

1.9

2.7

34.9

2.7

22.4

10.0

0.0

2.1

2.2

3.3

1.7

0.0

4.1

9.1

2.7

14.99

100.00

20.0

20.0

14.9

14.9

16.8

20.0

12.0

14.9

14.9

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.1

14.8

0.0

9.4

0.0

67.6

25.8

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

35.6

29.6

14.6

0.0

0.0

-25.8

-67.6

0.0

9.6

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

#NUM! Undefined

0.0

5.3

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

2.5

0.0

0.0

0.0

8.3

10

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.87

5.52

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

165.76

Max. prod. based on 100% avail.

1,630

803,592 Avg. production factored by avail.

29.65

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.35

184.18

1,630

803,592

0.28

0.40

5.24

9.42

0.33

0.50

16.17

1

10.03

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

803,592

0.80

1.83

2.63

575,896.00

261.76

3,474

3,127

1,515,771

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

11

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

780

10.0

3

Superficie con Pendiente

394

9.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

394

-9.0

9

Rampa del Pit (Regreso)

780

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

2,648

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.24

0.41

3.88

1.90

0.00

0.32

0.33

0.50

0.26

0.00

0.66

1.58

0.41

1.7

2.5

32.4

2.5

24.0

11.8

0.0

2.0

2.0

3.1

1.6

0.0

4.1

9.8

2.5

16.17

100.00

20.0

20.0

12.4

12.4

15.5

20.0

12.0

12.4

12.4

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.1

12.4

0.0

9.2

0.0

78.0

35.5

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

35.8

29.7

14.6

0.0

0.0

-35.5

-78.0

0.0

9.8

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

#NUM! Undefined

0.0

7.3

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

1.7

0.0

0.0

0.0

8.3

12

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.88

5.52

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

155.02

Max. prod. based on 100% avail.

1,524

751,490 Avg. production factored by avail.

30.64

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.36

172.24

1,524

751,490

0.28

0.40

5.24

10.52

0.33

0.50

17.26

1

10.03

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

751,490

0.85

1.96

2.81

578,419.00

281.13

3,731

3,358

1,627,963

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

13

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

936

10.0

3

Superficie con Pendiente

394

9.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

394

-9.0

9

Rampa del Pit (Regreso)

936

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

2,960

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.24

0.41

4.66

1.90

0.00

0.32

0.33

0.50

0.26

0.00

0.66

1.89

0.41

1.6

2.3

30.3

2.4

27.0

11.0

0.0

1.9

1.9

2.9

1.5

0.0

3.8

10.9

2.4

17.26

100.00

20.0

20.0

12.4

12.4

15.5

20.0

12.0

12.4

12.4

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.1

12.4

0.0

9.2

0.0

93.6

35.5

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

35.8

29.7

14.6

0.0

0.0

-35.5

-93.6

0.0

10.3

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

#NUM! Undefined

0.0

7.3

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

1.7

0.0

0.0

0.0

8.3

14

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.88

5.52

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

148.17

Max. prod. based on 100% avail.

1,457

718,280 Avg. production factored by avail.

31.29

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.40

164.63

1,457

718,280

0.28

0.40

5.24

11.25

0.33

0.50

18.00

1

10.03

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

718,280

0.89

2.05

2.94

576,115.00

292.96

3,888

3,499

1,696,449

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

15

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

1040

10.0

3

Superficie con Pendiente

394

9.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

394

-9.0

9

Rampa del Pit (Regreso)

1040

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

3,168

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.24

0.41

5.18

1.90

0.00

0.32

0.33

0.50

0.26

0.00

0.66

2.10

0.41

1.6

2.2

29.1

2.3

28.8

10.6

0.0

1.8

1.8

2.8

1.5

0.0

3.7

11.7

2.3

18.00

100.00

20.0

20.0

12.4

12.4

15.5

20.0

12.0

12.4

12.4

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.0

12.4

0.0

9.2

0.0

104.0

35.5

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

35.8

29.8

14.6

0.0

0.0

-35.5

-104.0

0.0

10.6

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

#NUM! Undefined

0.0

7.3

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

1.7

0.0

0.0

0.0

8.3

16

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.88

5.52

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

142.08

Max. prod. based on 100% avail.

1,397

688,791 Avg. production factored by avail.

31.88

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.37

157.87

1,397

688,791

0.28

0.40

5.24

11.98

0.33

0.50

18.72

1

10.02

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

688,791

0.93

2.14

3.07

576,280.00

305.59

4,056

3,650

1,769,585

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

17

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

1144

10.0

3

Superficie con Pendiente

394

9.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

394

-9.0

9

Rampa del Pit (Regreso)

1144

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

3,376

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.24

0.41

5.70

1.90

0.00

0.32

0.33

0.50

0.26

0.00

0.66

2.30

0.41

1.5

2.1

28.0

2.2

30.5

10.2

0.0

1.7

1.8

2.7

1.4

0.0

3.5

12.3

2.2

18.72

100.00

20.0

20.0

12.4

12.4

15.5

20.0

12.0

12.4

12.4

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.0

12.4

0.0

9.2

0.0

114.4

35.5

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

35.8

29.8

14.6

0.0

0.0

-35.5

-114.4

0.0

10.8

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

#NUM! Undefined

0.0

7.3

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

1.7

0.0

0.0

0.0

8.3

18

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.88

5.52

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

136.87

Max. prod. based on 100% avail.

1,346

663,503 Avg. production factored by avail.

32.27

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.35

152.07

1,346

663,503

0.28

0.40

5.24

12.70

0.33

0.50

19.45

1

10.03

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

663,503

0.97

2.22

3.19

573,474.00

315.69

4,190

3,771

1,828,085

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

19

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

1248

10.0

3

Superficie con Pendiente

394

9.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

394

-9.0

9

Rampa del Pit (Regreso)

1248

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

3,584

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.24

0.41

6.22

1.90

0.00

0.32

0.33

0.50

0.26

0.00

0.66

2.51

0.41

1.4

2.1

26.9

2.1

32.0

9.8

0.0

1.7

1.7

2.6

1.3

0.0

3.4

12.9

2.1

19.45

100.00

20.0

20.0

12.4

12.4

15.5

20.0

12.0

12.4

12.4

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.0

12.4

0.0

9.2

0.0

124.8

35.5

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

35.8

29.8

14.6

0.0

0.0

-35.5

-124.8

0.0

11.1

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

#NUM! Undefined

0.0

7.3

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

1.7

0.0

0.0

0.0

8.3

20

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.88

5.53

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

129.71

Max. prod. based on 100% avail.

1,275

628,814 Avg. production factored by avail.

32.99

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.34

144.12

1,275

628,814

0.28

0.40

5.23

13.80

0.33

0.50

20.53

1

10.01

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

628,814

1.02

2.34

3.36

577,624.00

335.52

4,453

4,008

1,942,890

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

21

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

1404

10.0

3

Superficie con Pendiente

394

9.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

394

-9.0

9

Rampa del Pit (Regreso)

1404

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

3,896

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.23

0.41

7.00

1.90

0.00

0.32

0.33

0.50

0.26

0.00

0.66

2.82

0.41

1.4

1.9

25.5

2.0

34.1

9.3

0.0

1.6

1.6

2.4

1.3

0.0

3.2

13.8

2.0

20.53

100.00

20.0

20.0

12.4

12.4

15.5

20.0

12.0

12.4

12.4

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.0

12.4

0.0

9.2

0.0

140.4

35.5

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

35.8

29.8

14.6

0.0

0.0

-35.5

-140.4

0.0

11.4

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

#NUM! Undefined

0.0

7.3

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

1.7

0.0

0.0

0.0

8.3

22

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.88

5.52

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

124.93

Max. prod. based on 100% avail.

1,229

605,654 Avg. production factored by avail.

33.27

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.37

138.81

1,229

605,654

0.28

0.40

5.24

14.53

0.33

0.50

21.28

1

10.03

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Days

Op. Hours.

Op. Hours.

$

605,654

1.06

2.43

3.49

575,968.00

347.35

4,610

4,149

2,011,401

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

23

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

1508

10.0

3

Superficie con Pendiente

394

9.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

394

-9.0

9

Rampa del Pit (Regreso)

1508

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

4,104

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full

Full

Full

Full

3.0

10.0

3.0

2.5

3.0

0.0

0.0

0.0

0.0

0.0

Empty

Empty

Empty

Empty

Empty

0.28

0.40

5.24

0.41

7.53

1.90

0.00

0.32

0.33

0.50

0.26

0.00

0.66

3.03

0.41

1.3

1.9

24.6

1.9

35.4

8.9

0.0

1.5

1.6

2.4

1.2

0.0

3.1

14.3

1.9

21.28

100.00

20.0

20.0

12.4

12.4

15.5

20.0

12.0

12.4

12.4

0.0

20.0

20.0

40.0

30.0

20.0

20.0

20.0

30.0

20.0

0.0

Max. Sp.

Average Elevation

Fuel

Velocity

Change

Usage

km/h

metres litre/OpHr

Rimpull

Retard

Final Sp.

14.6

12.0

12.4

0.0

9.2

0.0

150.8

35.5

0.0

0.0

Max. Sp.

Rimpull

Final Sp.

Final Sp.

Final Sp.

11.5

0.0

35.8

29.8

14.6

0.0

0.0

-35.5

-150.8

0.0

11.6

% Duty

Cycle

%

0.0

0.0

0.0

0.0

45.4

0.0

100.0

0.0

100.0

#NUM! Undefined

0.0

7.3

0.0

0.0

0.0

26.0

#NUM! Undefined

0.0

1.7

0.0

0.0

0.0

8.3

24

Production Summary - Full Simulation

Haulage System: Transporte de Mineral (Au)/aos)

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Material: [PRJ] Mineral (Au)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Loader

Availability

Bucket Fill Factor

Average Bucket Load Volume

Average Payload

Operating Hours per Year

Average Operating Shifts per Year

Average Bucket Cycle Time

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Wait Time per Operating Hour

%

cu.metres

tonne

OpHr/Year

shifts/Year

min

tonne

tonne

tonne

min

Truck

Availability

Payload in Template

Operating Hours per Year

Average Payload

Production per Operating Hour

Production per Loader Operating Shift

Production per Year

Queue Time at Loader

Spot Time at loader

Average Loading Time

Average Travel Time

Spot Time at Dump

Average Dump Time

Average Cycle Time

Fleet Size

Average No. of Bucket Passes

%

tonne

OpHr/Year

tonne

tonne

tonne

tonne

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

min/ Cycle

[PRJ] CATERPILLAR 385C (Dec 2006)

90.00

0.83

2.87

5.51

Op. hrs factored by availability

4,847.83

Shifts factored by availability

493.00

0.58

118.79

Max. prod. based on 100% avail.

1,168

575,876 Avg. production factored by avail.

33.77

[PRJ] CATERPILLAR 773E Dual Slope Body

90.00

54.82

4,363.05

55.34

131.99

1,168

575,876

0.28

0.40

5.25

15.62

0.33

0.50

22.38

1

10.04

Haulage System

Production per Year

Discounted Capital Cost

Discounted Operating Cost

Discounted Average Cost

Excavation Target

Time to move Excavation Target

Loader Hrs to move Target

Total Truck Hrs to move Target

Total cost to move Target

tonne/Year

$/tonne

$/tonne

$/tonne

tonne

Years

Op. Hours.

Op. Hours.

$

575,876

1.11

2.56

3.67

578,648.00

1.00

4,871

4,384

2,125,254

Loading Methodology

Single Sided

Full Truck

Average for 150 Shifts

Productivity estimates allow for insufficient time at the end of the shift to complete another cycle.

Time for the first bucket pass coincides with the truck queuing and maneuvering times.

This simulation is based on data provided by the equipment manufacturer.

Equipment data should be checked to ensure it is valid for this site.

25

Full Simulation Results

Material: [PRJ] Mineral (Au)

Haulage System: Transporte de Mineral (Au)/aos)

Roster: [PRJ] 7 day Week - 12 Hour Shifts

Haul Cycle: [PRJ] Ruta de Transporte Base_Mineral

Rolling

Curve

Segment

Cycle

Max Final

Velocity

Segment Title Distance Grade

Resist.

Angle Load

Time

Time

Vel.

Vel.

Limit.

metres

%

%

degrees

%

min

% km/h km/h

Type

[PRJ] CATERPILLAR 773E Dual Slope Body

Queue Tiempo de Espera en Carguo

Auto

Mins

Spot

Tiempo de Maniobra en Carguo

Auto

Mins

Load Carguo

Auto

Mins

1

rea de Carguo

100

0.0

2

Rampa del Pit

1664

10.0

3

Superficie con Pendiente

394

9.0

4

Rampa en Desmonte

0

10.0

5

rea de Descarga

50

0.0

Spot

Spot at Dump

Auto

Mins

Dump Dumping

Auto

Mins

6

rea de Descarga (Regreso) 50

0.0

7

Rampa en Desmonte (Regreso) 0

-10.0

8

Superficie con Pendiente(Regrso)

394

-9.0

9

Rampa del Pit (Regreso)

1664

-10.0

10

rea de Carguo (Regreso) 100

0.0

Total

4,416

3.0

2.5

3.0

10.0

3.0

0.0

0.0

0.0

0.0

0.0

Full

Full