Académique Documents

Professionnel Documents

Culture Documents

11.-Ttt Truck Anfo

Transféré par

Darwin AjomadoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

11.-Ttt Truck Anfo

Transféré par

Darwin AjomadoDroits d'auteur :

Formats disponibles

TTT Truck

Technical

Information

Properties

Products

The range of bulk explosives available from the truck comprise ANFO, Heavy

ANFO to wet condition emulsion blends.

Product

ANFO

Heavy ANFO

Gassed Heavy ANFO

Gassed Emulsion

Solid Sensitised Emulsion

Discharge Method

Auger discharge

Auger discharge

Auger discharge

Down hole pump

Down hole pump

Description

Safety Systems

The 17.1 tonne TTT is a Mobile Processing Unit (MPU) designed to provide a

complete range of bulk explosive products direct to the blast hole. The truck

consists of a Volvo FM series 8x4 cab chassis with a nominal 5,800mm wheel

base with segregated product bins, pump and auger systems mounted on the

back.

Low pressure and high pressure detection are provided on the discharge of

the emulsion and product pumps. On detection of no flow or high pressure

during normal running, the pumps are stopped immediately and the control

system within the cab warns the driver.

The truck is designed to incorporate large product bins to maximise the carrying

capacity and thereby minimise turn-around times. Discharge rates are optimised

for 150mm diameter and greater blast holes.

Raw Materials carried in the bins are as follows:

Ammonium Nitrate Prill

Diesel Fuel

TITAN Series Emulsion

Water

Gassing Chemicals

Version 3

November 2013

An emergency stop is provided at the main panel in the cab and on the end of

the discharge auger.

TTT Truck

Cab Chassis

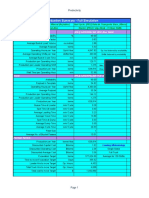

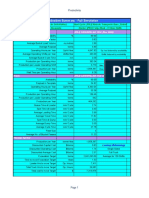

Nominal Capacities

Bin/Tank

AN

Fuel Oil

Emulsion

Trace N17

Trace N33/L3

Product Pump

9,200kg

800kg

7,100kg

120kg

120kg

Technical

Information

Flow Rate

min max

100 1,000kg/min

6 75kg/min

100 400kg/min

0.1 1.5kg/min

0.1 1.5kg/min

100 400kg/min

Control Systems

The cab chassis selected for this application is a Volvo FM Series 8x4. This has

been selected due to its combination of load carrying capacity, highway drivability

and off road tractability. The chassis has been proven over years of service. The

axle ratings allow a large capacity to be carried on the mine site -

Front Axle:

Rear Axle:

15 Tonnes

26 Tonnes

Transmission is a VT 2514B 14 speed gear box with 12 forward, 2 crawler and 2

reverse speeds. Rear axles RTH2610B with 4 planetary gear hub reduction with a

3.76:1 final drive ratio give good low speed tractability. Tyres are Bridgestone

8.25 x 22.5. These are standardised across the fleet and are mounted on ISO 10

stud rims.

A complete in-cab control system is provided. The main panel (photo below left) is

mounted to the drivers left and contains all safety shut downs, indicators and flow

and rate indicators. It is supplemented by a right-hand side DYNO

remote

panel (photo

NOBEL

Vehicle History

Pacificbased

Limitedupon

below right) for frequently used controls. It is mounted in a Asia

position

DYNO NOBEL

Paringa

Road, Gibson Island The standard TTT truck has been developed over a number of years of product

ergonomic principles which allows the operator full control of 282

theAsia

loading

Pacificfunctions

Limited

Murarrie Qld 4172

282 Paringa Road, Gibson Island

experience in both Australia and overseas. The current standard truck has been

without twisting of the back or neck.

Australia

Murarrie Qld 4172

established as a benchmark design within Dyno Nobels global operations.

Australia

The current fleet size of the TTT units in DNAP exceeds 90 units in operation. The

process and control equipment are fabricated and supported through three

vendors IEE, Varley and Tradestar.

The units are directly supported under DNAPs SAP based maintenance planning,

scheduling and controlling system. The DNAP TTT design meets all licensing

requirements.

Product Disclaimer The explosive products discussed in this document should only be handled by persons with the appropriate technical skills, training and licences. While Dyno Nobel has made every effort to

ensure the information in this document is correct, every user is responsible for understanding the safe and correct use of the products. If you need specific technical advice or have any questions, you should contact

your Dyno Nobel representative. This information is provided without any warranty, express or implied, regarding its correctness or accuracy and, to the maximum extent permitted by law, Dyno Nobel expressly

disclaims any and all liability arising from the use of this document or the information contained herein. It is solely the responsibility of the user to make enquiries, obtain advice and determine the safe conditions for use

of the products referred to herein and the user assumes liability for any loss, damage, expense or cost resulting from such use. DYNO, GROUNDBREAKING PERFORMANCE, TITAN and the Person and Pipe

device are registered trademarks of the Dyno Nobel / Incitec Pivot Group. Dyno Nobel Asia Pacific Pty Limited 2013 Reproduction without permission strictly prohibited.

Dyno Nobel Asia Pacific Pty Limited (ACN 003 269 010)

is a subsidiary of Incitec Pivot Limited (ACN 004 080 264)

Level 8, 28 Freshwater Place, Southbank Vic 3006

Vous aimerez peut-être aussi

- Firearms in America 1600 - 1899Document310 pagesFirearms in America 1600 - 1899Mike100% (3)

- Y62 Patrol Full EditionDocument163 pagesY62 Patrol Full EditionEric Golden100% (8)

- 7GCBC PohDocument75 pages7GCBC PohEyal Nevo100% (1)

- Manual de TallerDocument252 pagesManual de TallerEdison RodriguezPas encore d'évaluation

- Weilding TechnologyDocument15 pagesWeilding TechnologyRAMALAKSHMI SUDALAIKANNANPas encore d'évaluation

- Aa Afrg 000002Document52 pagesAa Afrg 000002stignz100% (1)

- Despiece Completo ThwaittesDocument60 pagesDespiece Completo ThwaittesJuan Antonio Cano Diaz100% (1)

- Cosmos Works FatigueDocument24 pagesCosmos Works FatigueflorinelvvPas encore d'évaluation

- TM 5-5065 Le Roi Compressor, 1954Document356 pagesTM 5-5065 Le Roi Compressor, 1954Advocate100% (1)

- Manitou TMT (EN)Document16 pagesManitou TMT (EN)ManitouPas encore d'évaluation

- NPS 75 - 45-155 SERVICEPACK X - ARK 1250 - v04 PDFDocument4 pagesNPS 75 - 45-155 SERVICEPACK X - ARK 1250 - v04 PDFAal CassanovaPas encore d'évaluation

- Mackay Flex Isolators CatalogueDocument142 pagesMackay Flex Isolators Cataloguemuss21Pas encore d'évaluation

- Whole-Body Vibrations Exposure - Dr. Tammy Eger - CROSHDocument64 pagesWhole-Body Vibrations Exposure - Dr. Tammy Eger - CROSHNereu NunesPas encore d'évaluation

- EES011 Technical Principles For Design of Electrical SystemsDocument17 pagesEES011 Technical Principles For Design of Electrical Systemsoadipphone7031Pas encore d'évaluation

- TRN 2007 CG CNLDocument66 pagesTRN 2007 CG CNLRene D. ArrietaPas encore d'évaluation

- The Cosmos Companion: Material Properties Used in CosmosworksDocument23 pagesThe Cosmos Companion: Material Properties Used in Cosmosworksjontylee87Pas encore d'évaluation

- RF Steel Fatigue Members Manual en PDFDocument53 pagesRF Steel Fatigue Members Manual en PDFSakthivel VPas encore d'évaluation

- Chapter 5 SteelDocument62 pagesChapter 5 SteelHtet Myat AungPas encore d'évaluation

- The Basic Bridge CircuitDocument8 pagesThe Basic Bridge CircuitMuhammad QasimPas encore d'évaluation

- MMM Lecture - Unit 3 - Strain MeasurementDocument40 pagesMMM Lecture - Unit 3 - Strain MeasurementAlanka BhanuPas encore d'évaluation

- Winter Dpa IdeasDocument20 pagesWinter Dpa Ideasapi-454675280Pas encore d'évaluation

- Electrical Strain Gauges: A Report OnDocument31 pagesElectrical Strain Gauges: A Report OnAnonymous GRY6OCJPas encore d'évaluation

- Time and Distance PDFDocument11 pagesTime and Distance PDFImtiaz AhmedPas encore d'évaluation

- Lecture Notes Lessson 5 StressesDocument5 pagesLecture Notes Lessson 5 StressesKate Arbie LacdooPas encore d'évaluation

- Strain GaugeDocument7 pagesStrain GaugeIanosi SorinPas encore d'évaluation

- Presentation1 Pak IrmaDocument10 pagesPresentation1 Pak IrmaJayus WibowoPas encore d'évaluation

- Prowritingaid Ebook PDFDocument25 pagesProwritingaid Ebook PDFAllen TanalaPas encore d'évaluation

- Prediction of Pressure Drop For Tubulent Flow in 90 BendsDocument3 pagesPrediction of Pressure Drop For Tubulent Flow in 90 BendsNakkolopPas encore d'évaluation

- Reedrill SKF: No. Unit: MU 108 Manufactured Year: 2006 Power UnitDocument1 pageReedrill SKF: No. Unit: MU 108 Manufactured Year: 2006 Power Unitslamat widodoPas encore d'évaluation

- Improving Writing - PunctuationDocument28 pagesImproving Writing - PunctuationAgha Zeeshan Khan SoomroPas encore d'évaluation

- Warranty Report TrainingDocument48 pagesWarranty Report TrainingRichard Henry Sanchez CalderonPas encore d'évaluation

- CH 01Document60 pagesCH 01LeonardoMadeira11Pas encore d'évaluation

- StrainDocument13 pagesStrainspanandk0% (1)

- Loadcells Quarter Half and Full BridgeDocument25 pagesLoadcells Quarter Half and Full BridgeCharles le MagnePas encore d'évaluation

- PID Controls:: Hydraulic Design Game ChangerDocument36 pagesPID Controls:: Hydraulic Design Game ChangerJoseph JosePas encore d'évaluation

- MEng6302 Lecture 3 Fundamental Concepts ASM 2021Document22 pagesMEng6302 Lecture 3 Fundamental Concepts ASM 2021KKDhPas encore d'évaluation

- Writing For The Ear - Revolutionize What You Write Through StorytellingDocument20 pagesWriting For The Ear - Revolutionize What You Write Through Storytellingapi-223662783Pas encore d'évaluation

- Strategies For Solving Subtraction Problems: Adding UpDocument4 pagesStrategies For Solving Subtraction Problems: Adding Upapi-241570227Pas encore d'évaluation

- C10338811 PDFDocument8 pagesC10338811 PDFCapacitaciones RutasPas encore d'évaluation

- BOOK (21st Century Skills Library - Cool STEM Careers) Wil Mara - Wind Turbine Service Technician-Cherry Lake Publishing (2013) PDFDocument36 pagesBOOK (21st Century Skills Library - Cool STEM Careers) Wil Mara - Wind Turbine Service Technician-Cherry Lake Publishing (2013) PDFfernandochinas2253Pas encore d'évaluation

- StrainGauges E1007DDocument100 pagesStrainGauges E1007DOWEMPas encore d'évaluation

- Isuzu F Series Brochure Effmar14Document12 pagesIsuzu F Series Brochure Effmar14Berhanu DiribaPas encore d'évaluation

- Strain Gauges: Precise & FlexibleDocument96 pagesStrain Gauges: Precise & FlexibleCobra BabaPas encore d'évaluation

- Track and Wheel TorqueDocument64 pagesTrack and Wheel TorqueAnderson ertsPas encore d'évaluation

- Earthmoving EquipmentDocument63 pagesEarthmoving EquipmentCakama MbimbiPas encore d'évaluation

- AS1418.8-2008 Rated Capacity For Earthmoving Machines: Plant AssessorDocument3 pagesAS1418.8-2008 Rated Capacity For Earthmoving Machines: Plant AssessorTAIYONG GUOPas encore d'évaluation

- MD 08 Ch8 FasternersDocument45 pagesMD 08 Ch8 FasternersAbdulPas encore d'évaluation

- Strain Gauge Installation Methods - Short Guide - 786Document12 pagesStrain Gauge Installation Methods - Short Guide - 786Anton MerkulovPas encore d'évaluation

- STD - Iso 27956 Load Restraint System PDFDocument12 pagesSTD - Iso 27956 Load Restraint System PDFOscar Marino Campo BonellPas encore d'évaluation

- 6.protection Components RelaysDocument66 pages6.protection Components RelaysRian KamekPas encore d'évaluation

- Chapter 5. Two-Dimensional Finite Elements: Plane Stress (Thin Members) Out-Of-Plane Normal and Shear Stress Are Zero X yDocument16 pagesChapter 5. Two-Dimensional Finite Elements: Plane Stress (Thin Members) Out-Of-Plane Normal and Shear Stress Are Zero X ysakeriraq81Pas encore d'évaluation

- FEM Strusoft Applied Theory and DesignDocument118 pagesFEM Strusoft Applied Theory and DesignkothavijaykrishnaPas encore d'évaluation

- Autodesk Inventor - Using The Content Center PT 2Document6 pagesAutodesk Inventor - Using The Content Center PT 2Ndianabasi UdonkangPas encore d'évaluation

- Isuzu Trucks News Winter 2015Document16 pagesIsuzu Trucks News Winter 2015Nguyễn Ngọc VănPas encore d'évaluation

- 500 Series - Fe 1426 HinoDocument4 pages500 Series - Fe 1426 Hinolouis donyPas encore d'évaluation

- Accurate - Design - Simulations - White Paper PDFDocument18 pagesAccurate - Design - Simulations - White Paper PDFsamar kadamPas encore d'évaluation

- ME374 Module 4Document22 pagesME374 Module 4Christian Breth BurgosPas encore d'évaluation

- Hitachi CaseDocument15 pagesHitachi CaseManish Goyal0% (1)

- Vicroads Guide To Restraining Concrete Panels & BeamsDocument18 pagesVicroads Guide To Restraining Concrete Panels & BeamsStuart EdwardsPas encore d'évaluation

- Hino Bus Specificationspdf PDFDocument54 pagesHino Bus Specificationspdf PDFGunawan AjahPas encore d'évaluation

- Hit Ex5500 27m3 Face Shovel Wear Package AssyDocument2 pagesHit Ex5500 27m3 Face Shovel Wear Package AssyRoynino Martinez venturaPas encore d'évaluation

- 2008 Fall Catalog-New Titles!: Middle & High SchoolDocument132 pages2008 Fall Catalog-New Titles!: Middle & High SchoolvivekkamathPas encore d'évaluation

- Unitrigmt6500 Dump PumpDocument11 pagesUnitrigmt6500 Dump PumpnikbeamPas encore d'évaluation

- Owner'S Manual: Automatic Positive Locking Traction DifferentialDocument24 pagesOwner'S Manual: Automatic Positive Locking Traction DifferentialAhmed RamadanPas encore d'évaluation

- Corona-GUIA DE INSTALACION NO SPIN PDFDocument24 pagesCorona-GUIA DE INSTALACION NO SPIN PDFAntony MorenoPas encore d'évaluation

- Owner'S Manual: Automatic Positive Locking Traction DifferentialDocument24 pagesOwner'S Manual: Automatic Positive Locking Traction Differentialhelp3r0% (1)

- Produccion - Sept 20 PDFDocument1 pageProduccion - Sept 20 PDFDarwin AjomadoPas encore d'évaluation

- 3344 f2440Document4 pages3344 f2440Darwin AjomadoPas encore d'évaluation

- Production Summary - Full SimulationDocument6 pagesProduction Summary - Full SimulationDarwin AjomadoPas encore d'évaluation

- Production Summary - Full SimulationDocument6 pagesProduction Summary - Full SimulationDarwin AjomadoPas encore d'évaluation

- Tyres and Fuel ConsumptionDocument1 pageTyres and Fuel ConsumptionDarwin AjomadoPas encore d'évaluation

- Production Summary - Full Simulation: Loader (PRJ) CATERPILLAR 385C (Dec 2006)Document1 pageProduction Summary - Full Simulation: Loader (PRJ) CATERPILLAR 385C (Dec 2006)Darwin AjomadoPas encore d'évaluation

- Heinzmann ControlsDocument4 pagesHeinzmann ControlsShahzad AhmadPas encore d'évaluation

- Vsphere Esxi Vcenter Server 50 Monitoring Performance GuideDocument86 pagesVsphere Esxi Vcenter Server 50 Monitoring Performance GuideZeno JegamPas encore d'évaluation

- Professional Project ManagementDocument2 pagesProfessional Project ManagementVirginia Virgie100% (3)

- Application of Pinnipedvibrissae To AeropropulsionDocument31 pagesApplication of Pinnipedvibrissae To AeropropulsionShahzadPas encore d'évaluation

- Waste To Wealth Green Potential From Palm Biomass in MalaysiaDocument9 pagesWaste To Wealth Green Potential From Palm Biomass in MalaysiaLai Mei EePas encore d'évaluation

- Answers For SummariesDocument6 pagesAnswers For SummariesDaphnePas encore d'évaluation

- Sensus WP Dynamic Cold Water Meter (DN40-300)Document4 pagesSensus WP Dynamic Cold Water Meter (DN40-300)Roderikus Rendy MPas encore d'évaluation

- Mintzberg Five StructuresDocument18 pagesMintzberg Five StructuresAkshay GargPas encore d'évaluation

- Timetable Victoria Chichester PDFDocument2 pagesTimetable Victoria Chichester PDFLizzie CosterPas encore d'évaluation

- Dungeon Siege Game GuideDocument21 pagesDungeon Siege Game GuideJesse StillPas encore d'évaluation

- ElinkDocument36 pagesElinkjosemanuelarangoPas encore d'évaluation

- Literature Study Nift ChennaiDocument5 pagesLiterature Study Nift ChennaiAnkur SrivastavaPas encore d'évaluation

- Bhavin Desai ResumeDocument5 pagesBhavin Desai Resumegabbu_Pas encore d'évaluation

- Colleg Fee StructureDocument1 pageColleg Fee StructureSriram SaiPas encore d'évaluation

- Darcy Friction Loss Calculator For Pipes, Fittings & Valves: Given DataDocument2 pagesDarcy Friction Loss Calculator For Pipes, Fittings & Valves: Given DataMSPas encore d'évaluation

- Informatics in Logistics ManagementDocument26 pagesInformatics in Logistics ManagementNazareth0% (1)

- AGC IPC Slash Sheet ReferenceDocument4 pagesAGC IPC Slash Sheet ReferenceSelvakumar NatarajanPas encore d'évaluation

- Sir - 11 - 21 Rate List 2022Document10 pagesSir - 11 - 21 Rate List 2022akshayPas encore d'évaluation

- ES Service Transition PlanDocument7 pagesES Service Transition PlanShamsher Singh BainsPas encore d'évaluation

- Tyco SprinklerDocument3 pagesTyco SprinklerVitor BrandaoPas encore d'évaluation

- HVPE Syllabus of Ist Year & IInd Year Degree StudentsDocument5 pagesHVPE Syllabus of Ist Year & IInd Year Degree StudentsReddyvari Venugopal0% (1)

- Pest Control ChennaiDocument3 pagesPest Control ChennaiControler33Pas encore d'évaluation

- Proposal Tripurainfo Job PortalDocument10 pagesProposal Tripurainfo Job PortalEkta DevPas encore d'évaluation

- Eseu EnglezaDocument1 pageEseu EnglezaAndreea IoanaPas encore d'évaluation