Académique Documents

Professionnel Documents

Culture Documents

PBT - The Plastic Material

Transféré par

AmolPagdal0 évaluation0% ont trouvé ce document utile (0 vote)

55 vues2 pagesPBT - The plastic Material

Titre original

PBT - The plastic Material

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentPBT - The plastic Material

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

55 vues2 pagesPBT - The Plastic Material

Transféré par

AmolPagdalPBT - The plastic Material

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

PBT (Polybutylene Terephthalates)

Typical Applications

Household appliances (e.g., food processor blades, vacuum cleaner parts, fans, hair dryer

housings, coffee makers)

Electronics (e.g., switches, motor housings, fuse cases, key caps for computer keyboards,

connectors, fiber optic buffer tubing)

Automotive (e.g., grilles, body panels, wheel covers, and components for doors and

windows)

Injection Molding Processing Conditions

Drying:

This material is sensitive to hydrolysis at high temperatures. It is therefore

important to dry the material prior to molding. Suggested drying conditions

(in air) are 120 C (248 F) for 6 - 8 hours (or 150 C (300 F) for 2 - 4 hours).

Moisture levels must be below 0.03%. When using a desiccant dryer, drying

at 120 C (248 F) for 2.5 hours is recommended.

Melt Temperature:

225 - 275 C (437 - 527 F); aim: 250 C (482 F)

Mold Temperature:

40 - 60 C (104 - 140 F) for unreinforced grades. For other grades, a wide

range of temperatures can be used, depending on the grade (15 - 120 C / 59 248 F). Cooling channels should be properly designed to minimize part

warpage. The heat removal must be fast and uniform. Cooling channels of

12 mm diameter are recommended.

Injection Pressure:

Moderate (up to maximum of 1500 bar / 21750 psi).

Injection Speed:

Fastest possible speeds should be used (due to fast solidification of PBTs)

Runners and Gates

Full round runners are recommended to impart maximum pressure transmission (rule of thumb:

runner diameter = part thickness + 1.5 mm). A wide variety of gates may be used. Hot runners

may also be used, taking care to avoid drool and material degradation. Gate diameters or depths

should preferably be between 0.8 - 1.0 * t where "t" is the part thickness. When using submarine

gates, the minimum recommended diameter is 0.75 mm.

Chemical and Physical Properties

PBT is one of the toughest engineering thermoplastics. It is a semicrystalline resin and has

excellent chemical resistance, mechanical strength, electrical properties (high dielectric strength

and insulation resistance), and heat resistance, all of which are stable over a broad range of

environmental conditions. It has very low moisture absorption.

PBT, which is a polyester, is produced by the polycondensation reaction of dimethyl

terephthalate an butanediol.

Tensile strength ranges from 50 MPa (7,250 psi) for unfilled grades to 170 MPa (24,650 psi) for

glass reinforced grades. High levels of glass fillers make the material more brittle. Crystallization

is rapid and this could cause warpage due to non-uniform cooling. In the case of glass filled

grades, shrinkage is reduced in the flow direction, but in the cross-flow direction it may be equal

to that of the base resin. Shrinkage is of the order of 0.015 - 0.028 mm/mm (1.5 -2.8%). A 30%

glass-filled resin has a shrinkage range of 0.3 - 1.6%. The melting point (approximately 225 C /

437 F) and heat distortion temperatures are lower than that of PET. The Vicat softening point is

approximately 170 C (338 F). The glass transition temperature ranges from 22 - 43 C (71 - 109

F).

The melt viscosity is fairly low and due to fast crystallization rates, cycle times are typically low.

Major Manufacturers

BASF (Ultradur)

Hoechst Celanese (Celanex)

GE Plastics (Lomod, Valox)

Bayer (Pocan)

Huls (Vestoduv)

Mitsubishi Engineering Plastics (Novadur)

Teijin Chemicals

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The God Code by Gregg BradenDocument1 pageThe God Code by Gregg BradenAmolPagdal57% (7)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Creating Affluence The A-to-Z Steps... by Deepak Chopra Download Now PDFDocument7 750 pagesCreating Affluence The A-to-Z Steps... by Deepak Chopra Download Now PDFAmolPagdal10% (10)

- BASF Snap Fit Design GuideDocument24 pagesBASF Snap Fit Design GuidewantamanualPas encore d'évaluation

- Study of Seat AssemblyDocument53 pagesStudy of Seat AssemblyAmolPagdalPas encore d'évaluation

- Suspension DiagramsDocument35 pagesSuspension Diagramsakti gonzo100% (1)

- PHEONWJ-M-SPE-0023 1 Valve SpecificationDocument46 pagesPHEONWJ-M-SPE-0023 1 Valve Specificationmizbah93100% (2)

- 15 Samss 502Document10 pages15 Samss 502Praba Hiruthya SPas encore d'évaluation

- Catia SymbolsDocument9 pagesCatia SymbolsAmolPagdalPas encore d'évaluation

- Automotive Interior Solutions Optimised Performance and Surface AestheticsDocument16 pagesAutomotive Interior Solutions Optimised Performance and Surface AestheticsAmolPagdal100% (1)

- Catia Tip No - Inc 006Document3 pagesCatia Tip No - Inc 006AmolPagdalPas encore d'évaluation

- BIW Design PDFDocument17 pagesBIW Design PDFAmolPagdalPas encore d'évaluation

- Volvo ApqpDocument30 pagesVolvo ApqpAmolPagdalPas encore d'évaluation

- Green Planet Store ManagementDocument2 pagesGreen Planet Store ManagementAmolPagdalPas encore d'évaluation

- Eaton ApqpDocument142 pagesEaton ApqpAmolPagdalPas encore d'évaluation

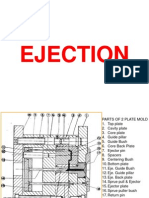

- K EjectionDocument21 pagesK EjectionAmolPagdalPas encore d'évaluation

- Natural Brilliance, Move From Feeling Stuck To Achieving Success (1997) 0925480517Document106 pagesNatural Brilliance, Move From Feeling Stuck To Achieving Success (1997) 0925480517AmolPagdalPas encore d'évaluation

- Total Quality Management (TQM) 1Document21 pagesTotal Quality Management (TQM) 1AmolPagdalPas encore d'évaluation

- Basic Hole System or Hole Basi1Document2 pagesBasic Hole System or Hole Basi1AmolPagdalPas encore d'évaluation

- Electrical Presentation & General TopicsDocument77 pagesElectrical Presentation & General TopicsAmolPagdalPas encore d'évaluation

- Concept Generation & Concept Selection PDFDocument20 pagesConcept Generation & Concept Selection PDFcadcam01Pas encore d'évaluation

- PlasticProductdesign 2 PDFDocument115 pagesPlasticProductdesign 2 PDFAmolPagdalPas encore d'évaluation

- PlasticProductdesign 3 PDFDocument116 pagesPlasticProductdesign 3 PDFAmolPagdalPas encore d'évaluation

- Crack Propagation in AnsysDocument24 pagesCrack Propagation in Ansysagrbovic100% (2)

- CA42 Holding Down Bolts To EC2Document4 pagesCA42 Holding Down Bolts To EC2zaidiamna9Pas encore d'évaluation

- ZL 471KS CF5344Document49 pagesZL 471KS CF5344pereira_wilker9835Pas encore d'évaluation

- Regulation: Main ValveDocument1 pageRegulation: Main Valvebilal almelegyPas encore d'évaluation

- CSPI - Handbook of Steel Drainage Highway Construction Products (215 320)Document106 pagesCSPI - Handbook of Steel Drainage Highway Construction Products (215 320)Ashly Bedregal GuevaraPas encore d'évaluation

- Super Duplex Stainless Steel PipesDocument3 pagesSuper Duplex Stainless Steel Pipeskumar sandeepPas encore d'évaluation

- GB1516 Sac 240 CV SP 0003 - ADocument31 pagesGB1516 Sac 240 CV SP 0003 - AkkkkPas encore d'évaluation

- 017 Blaise Feasibility - StudyDocument37 pages017 Blaise Feasibility - StudytatekPas encore d'évaluation

- Ideal Isar He30 Boiler Installation Manual - InstDocument68 pagesIdeal Isar He30 Boiler Installation Manual - InstAdamBeyonceLowePas encore d'évaluation

- 01 2023 MR Wilson Contreras ResumeDocument14 pages01 2023 MR Wilson Contreras ResumeWily ContrerasPas encore d'évaluation

- Essay 07Document5 pagesEssay 07Mohammed ZohebPas encore d'évaluation

- Noise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverDocument20 pagesNoise Barriers Supply and Installation For Burfiwala Lane & Gokhale Road Junction FlyoverAvinash JagtapPas encore d'évaluation

- Pipe Quality Manual 1Document1 pagePipe Quality Manual 1Nasir AhmadPas encore d'évaluation

- Nycotte StandardeDocument4 pagesNycotte StandardezzzaPas encore d'évaluation

- Advances in Environmental Biology: Corrosion Behavior of MAB Alloys in SeawaterDocument8 pagesAdvances in Environmental Biology: Corrosion Behavior of MAB Alloys in SeawaterBima SantosoPas encore d'évaluation

- Documentation Noise ProtectionDocument7 pagesDocumentation Noise ProtectionIv IriPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document9 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Denys Zhukov100% (1)

- HXR5 Series User ManualDocument24 pagesHXR5 Series User ManualSANTIAGO VIDAL MIRAPas encore d'évaluation

- Literature SurveyDocument6 pagesLiterature SurveyMekhaile PjPas encore d'évaluation

- Izon L : Technical Data Sheet: Izonil Hard - Renovation and Waterproof Plaster (Revision - February 2018)Document4 pagesIzon L : Technical Data Sheet: Izonil Hard - Renovation and Waterproof Plaster (Revision - February 2018)AcingEdogawaPas encore d'évaluation

- Loading Summary For A Slab On Girder Bridge According To The CAN/CSA-S6Document27 pagesLoading Summary For A Slab On Girder Bridge According To The CAN/CSA-S6Muntasir Billah100% (1)

- Installation Qudos 28h Installation and Service ManualDocument59 pagesInstallation Qudos 28h Installation and Service ManualdraxnwPas encore d'évaluation

- RCCDocument22 pagesRCClakshitaPas encore d'évaluation

- Lab Report (7 and 11) CMTDocument11 pagesLab Report (7 and 11) CMTJames Ryu ZagalaPas encore d'évaluation

- Movable Span Structures BridgeDocument8 pagesMovable Span Structures BridgeAnish TayadePas encore d'évaluation

- ?UTF-8?Q?Engine BookSHORT 2eodt? .OdtDocument146 pages?UTF-8?Q?Engine BookSHORT 2eodt? .OdtKayden HereoraPas encore d'évaluation

- Floorplans: Techcombank HQ Ho Chi Minh - 100% Concept Design For Coordination - 22/10/2018Document16 pagesFloorplans: Techcombank HQ Ho Chi Minh - 100% Concept Design For Coordination - 22/10/2018Nguyên Trịnh CaoPas encore d'évaluation