Académique Documents

Professionnel Documents

Culture Documents

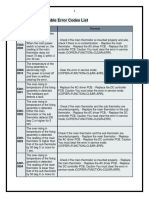

Canon IR Advance C2025 Trouble Error Codes - 1

Transféré par

nafeesTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Canon IR Advance C2025 Trouble Error Codes - 1

Transféré par

nafeesDroits d'auteur :

Formats disponibles

1

Canon iR Advance C2025 Trouble Error Codes List page 1 (from 24)

Code

Description

Remedy

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/J12) and the Fixing Assembly

(UN37/J123,UN13/J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

Main Thermistor high

case of trapped cable/open circuit 2. Disconnect the

temperature detection

connector of DC Controller PCB (UN09/J12) and

E001- Main Thermistor 2 detected start the host machine to check the reading value of

the following: service mode > COPIER > DISPLAY

0001 a temperature of 230 deg

C or higher for 0.1 sec or

> ANALOG > FIX-C => When the value is 40 deg C

longer.

or higher 3-1. Replace the DC Controller PCB

(UN09) => When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly NOTE: After

performing the above remedy work, go through the

following to clear the error: COPIER > FUNCTION

> CLEAR > ERR

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/ J12) and the Fixing Assembly (UN37/

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

Center Thermistor high

case of trapped cable/open circuit 2. Disconnect the

temperature detection

connector of DC Controller PCB (UN09/ J12) and

E001- Main Thermistor 1 detected start the host machine to check the reading value of

the following: service mode > COPIER > DISPLAY

0002 a temperature of 283 deg

C or higher for 0.1 sec or

> ANALOG > FIX-E => When the value is 40 deg C

longer.

or higher 3-1. Replace the DC Controller PCB

(UN09) => When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly NOTE: After

performing the above remedy work, go through the

following to clear the error: COPIER > FUNCTION

> CLEAR > ERR

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

Edge Thermistor high

PCB (UN09/ J12) and the Fixing Assembly (UN37/

temperature detection

J123, UN13/ J13) (trapped cable, open circuit,

E001- Sub Thermistor 1 detected

connector disconnection). -> Replace the part in the

0003 a temperature of 283 deg

case of trapped cable/open circuit 2. Disconnect the

C or higher for 0.1 sec or

connector of DC Controller PCB (UN09/ J12) and

longer.

start the host machine to check the reading value of

the following: service mode > COPIER > DISPLAY

> ANALOG > FIX-E2 => When the value is 40 deg

C or higher 3-1. Replace the DC Controller PCB

(UN09) => When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly NOTE: After

performing the above remedy work, go through the

following to clear the error: COPIER > FUNCTION

> CLEAR > ERR

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/ J12) and the Fixing Assembly (UN37/

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

Edge Thermistor high

case of trapped cable/open circuit 2. Disconnect the

temperature detection

connector of DC Controller PCB (UN09/ J12) and

E001- Sub Thermistor 2 detected start the host machine to check the reading value of

the following: service mode > COPIER > DISPLAY

0004 a temperature of 283 deg

C or higher for 0.1 sec or

> ANALOG > FIX-E3 => When the value is 40 deg

longer.

C or higher 3-1. Replace the DC Controller PCB

(UN09) => When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly NOTE: After

performing the above remedy work, go through the

following to clear the error: COPIER > FUNCTION

> CLEAR > ERR

Center Thermistor high

temperature detection

E001- Main Thermistor 1

0005 hardware signal is

continued for 1 sec or

longer.

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/ J12) and the Fixing Assembly (UN37/

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

case of trapped cable/open circuit 2. Disconnect the

connector of DC Controller PCB (UN09/ J12) and

start the host machine to check the reading value of

the following: service mode > COPIER > DISPLAY

> ANALOG > FIX-E => When the value is 40 deg C

or higher 3-1. Replace the DC Controller PCB

(UN09) => When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly NOTE: After

performing the above remedy work, go through the

following to clear the error: COPIER > FUNCTION

> CLEAR > ERR

Edge Thermistor high

temperature detection

E001- Sub Thermistor 1 hardware

0006 error detection signal is

continued for 1 sec or

longer.

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/ J12) and the Fixing Assembly (UN37/

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

case of trapped cable/open circuit 2. Disconnect the

connector of DC Controller PCB (UN09/ J12) and

start the host machine to check the reading value of

the following: service mode > COPIER > DISPLAY

> ANALOG > FIX-E2 => When the value is 40 deg

C or higher 3-1. Replace the DC Controller PCB

(UN09) => When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly NOTE: After

performing the above remedy work, go through the

following to clear the error: COPIER > FUNCTION

> CLEAR > ERR

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/ J12) and the Fixing Assembly (UN37/

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

case of trapped cable/open circuit 2. Disconnect the

Edge Thermistor high

connector of DC Controller PCB (UN09/ J12) and

temperature detection

start the host machine to check the reading value of

E001- Sub Thermistor 2 hardware the following: service mode > COPIER > DISPLAY

> ANALOG > FIX-C Check the reading value of the

0007 error detection signal is

continued for 1 sec or

following: service mode > COPIER > DISPLAY >

longer.

ANALOG > FIX-E3 => When the value is 40 deg C

or higher 3-1. Replace the DC Controller PCB

(UN09) => When the value is lower than 40 deg C

3-2. Replace the Fixing Assembly NOTE: After

performing the above remedy work, go through the

following to clear the error: COPIER > FUNCTION

> CLEAR > ERR

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/ J12) and the Fixing Assembly (UN37/

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

Displacement detection

case of trapped cable/open circuit 2. Disconnect the

The temperature difference

connector of DC Controller PCB (UN09/ J12) and

between the Sub

start the host machine to check the reading value of

E001Thermistor 1 (TH3) and the

the following: service mode > COPIER > DISPLAY

0008

Sub Thermistor 2 (TH4)

> ANALOG > FIX-E2,FIX-E3 => When the value of

remained 45 deg C or

either one is 40 deg C or higher 3-1. Replace the

more for 1 second or more.

DC Controller PCB (UN09) => When the both

values are lower than 40 deg C 3-2. Replace the

Fixing Assembly NOTE: After performing the above

remedy work, go through the following to clear the

error: COPIER > FUNCTION > CLEAR > ERR

E002- Detection of abnormal

1. Check the location for voltage of the Fixing

0006

temperature increase

Fixing Assembly error,

Fixing temperature

detection error

Assembly -> Replace with a correct Fixing

Assembly for the location in the case of

mismatching. 2. Check the location for voltage of

the AC Driver PCB (UN14) -> Replace with a

correct AC Driver PCB (UN14) for the location in

the case of mismatching. 3. Check failure between

the AC Driver PCB (UN14/J103) and the Fixing

Assembly (UN37/J123, UN13/J13). (trapped cable,

open circuit, connector disconnection) -> Replace

the part in the case of trapped cable/open circuit 4.

Replace the AC Driver PCB (UN14) 5. Replace the

Fixing Assembly 6. Replace the DC Controller PCB

(UN09) NOTE: After performing the above remedy

work, go through the following to clear the error:

COPIER > FUNCTION > CLEAR > ERR

Fixing Assembly error, Fixing temperature detection

Thermistor open circuit

error 1. Check failure between the DC Controller

detection

PCB (UN09/ J12) and the Fixing Assembly (UN37/

In the period from initial

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

E003- rotation to printing, Main

case of trapped cable/open circuit 2. Replace the

0001 Thermistor 1 detected a

temperature of 22 deg C or Fixing Assembly 3. Replace the DC Controller PCB

lower for more than 5

(UN09) NOTE: After performing the above remedy

seconds.

work, go through the following to clear the error:

COPIER > FUNCTION > CLEAR > ERR

Thermistor open circuit

detection

In the period from initial

E003- rotation to printing, Main

0002 Thermistor 2 detected a

temperature of 40 deg C or

lower for more than 3

seconds.

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/ J12) and the Fixing Assembly (UN37/

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

case of trapped cable/open circuit 2. Replace the

Fixing Assembly 3. Replace the DC Controller PCB

(UN09) NOTE: After performing the above remedy

work, go through the following to clear the error:

COPIER > FUNCTION > CLEAR > ERR

Thermistor open circuit

detection

In the period from initial

E003- rotation to printing, Sub

0003 Thermistor 1 detected a

temperature of 40 deg C or

lower for more than 3

seconds.

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/ J12) and the Fixing Assembly (UN37/

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

case of trapped cable/open circuit 2. Replace the

Fixing Assembly 3. Replace the DC Controller PCB

(UN09) NOTE: After performing the above remedy

work, go through the following to clear the error:

COPIER > FUNCTION > CLEAR > ERR

Fixing Assembly error, Fixing temperature detection

Thermistor open circuit

error 1. Check failure between the DC Controller

detection

PCB (UN09/ J12) and the Fixing Assembly (UN37/

In the period from initial

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

E003- rotation to printing, Sub

case of trapped cable/open circuit 2. Replace the

0004 Thermistor 2 detected a

temperature of 40 deg C or Fixing Assembly 3. Replace the DC Controller PCB

lower for more than 3

(UN09) NOTE: After performing the above remedy

seconds.

work, go through the following to clear the error:

COPIER > FUNCTION > CLEAR > ERR

Main Thermistor 2 low

temperature detection at

printing

In the period from printing

E003to last rotation, Main

0005

Thermistor 1 detected a

temperature of 70 deg C or

lower for more than 5

seconds.

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/ J12) and the Fixing Assembly (UN37/

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

case of trapped cable/open circuit 2. Replace the

Fixing Assembly 3. Replace the DC Controller PCB

(UN09) NOTE: After performing the above remedy

work, go through the following to clear the error:

COPIER > FUNCTION > CLEAR > ERR

Center Thermistor low

temperature detection at

printing

In the period from printing

E003to last rotation, Main

0006

Thermistor 2 detected a

temperature of 80 deg C or

lower for more than 1

second.

Fixing Assembly error, Fixing temperature detection

error 1. Check failure between the DC Controller

PCB (UN09/ J12) and the Fixing Assembly (UN37/

J123, UN13/ J13) (trapped cable, open circuit,

connector disconnection). -> Replace the part in the

case of trapped cable/open circuit 2. Replace the

Fixing Assembly 3. Replace the DC Controller PCB

(UN09) NOTE: After performing the above remedy

work, go through the following to clear the error:

COPIER > FUNCTION > CLEAR > ERR

Code

Description

Remedy

Edge Thermistor low

temperature detection at

printing

E003- In the period from printing to

0007 last rotation, Sub Thermistor 1

detected a temperature of 80

deg C or lower for more than 1

second.

Fixing Assembly error, Fixing temperature

detection error 1. Check failure between the

DC Controller PCB (UN09/ J12) and the

Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector

disconnection). -> Replace the part in the

case of trapped cable/open circuit 2.

Replace the Fixing Assembly 3. Replace the

DC Controller PCB (UN09) NOTE: After

performing the above remedy work, go

through the following to clear the error:

COPIER > FUNCTION > CLEAR > ERR

Edge Thermistor low

temperature detection at

printing

E003- In the period from printing to

0008 last rotation, Sub Thermistor 2

detected a temperature of 80

deg C or lower for more than 1

second.

Fixing Assembly error, Fixing temperature

detection error 1. Check failure between the

DC Controller PCB (UN09/ J12) and the

Fixing Assembly (UN37/ J123, UN13/ J13)

(trapped cable, open circuit, connector

disconnection). -> Replace the part in the

case of trapped cable/open circuit 2.

Replace the Fixing Assembly 3. Replace the

DC Controller PCB (UN09) NOTE: After

performing the above remedy work, go

through the following to clear the error:

COPIER > FUNCTION > CLEAR > ERR

Fixing Relay PCB welding

Electrical trouble with abnormal fixing safety

E004- detection error

circuit relay Replace the AC Driver PCB

0001 Zero cross interruption although

(UN14)

relay is not ON.

Failure in electrical current

detection circuit (abnormal

small current)

E004Failure in electrical current

0005

detection circuit (Less than the

specified range of current

value)

Electrical trouble with abnormal fixing

current detection circuit 1. Check failure

between the AC Driver PCB (UN14/ J122)

and the DC Controller PCB (UN09/ J10).

(trapped cable, open circuit, connector

disconnection) -> Replace the part in the

case of trapped cable/open circuit 2.

Replace the AC Driver PCB (UN14) 3.

Replace the DC Controller PCB (UN09)

Failure in electrical current

detection circuit (abnormal

E004large current)

0006

Failure in electrical current

detection circuit (More than the

Electrical trouble with abnormal fixing

current detection circuit 1. Check failure

between the AC Driver PCB (UN14/ J122)

and the DC Controller PCB (UN09/ J10).

(trapped cable, open circuit, connector

specified range of current

value)

Fixing Film Unit engagement /

disengagement error

There is no change in the result

E009- of detection by the Fixing

0000 Pressure Release Sensor even

after five seconds elapsed after

counterclockwise rotation of the

Fixing Motor started.

disconnection) -> Replace the part in the

case of trapped cable/open circuit 2.

Replace the AC Driver PCB (UN14) 3.

Replace the DC Controller PCB (UN09)

Possible cause is overload or rotation failure

of the motor due to an electrical trouble 1.

Check if the Fixing Assembly is installed. 2.

Remove and reinstall the Fixing Assembly 3.

Check the gear 4. Replace the Fixing

Assembly 5. Check the harness/connector

between the DC Controller PCB (UN09/

J210) and the Fixing Motor (M17). 6. Check

the harness/connector between the DC

Controller PCB (UN09/ J12) and the Fixing

Pressure Release Sensor (PS24) 6. Check

conduction of FU1153 in the AC Driver PCB

(UN14) => Replace the AC Driver PCB

(UN14) in the case of disconnection. 7.

Replace the Fixing Motor (M17) 8. Replace

the DC Controller PCB (UN09)

Possible cause is overload or rotation failure

of the motor due to an electrical trouble 1.

Check the Main Drive Unit (turn the unit by

hand to see if it rotates) Replace the Main

Drive Unit when the unit failed to rotate

When the unit rotates 2. Check failure of the

harness between the ITB Motor (M02/

ITB Motor startup error

J6027) and the DC Controller PCB (UN09/

E010- Within a specified period of

J210W) (trapped cable, open circuit,

0001 time from the startup, the speed

connector disconnection) 3. Check

fails to be OK.

conduction of the fuse (FU4) in the DC

Controller PCB (UN09) When the fuse is not

blown out 4-1. Replace the ITB Motor (M02)

5-1. Replace the DC Controller PCB (UN09)

6-1. Replace the Main Drive Unit When the

fuse is blown out 4-2. Replace the DC

Controller PCB (UN09)

E010ITB Motor speed error

0002

Possible cause is overload or rotation failure

of the motor due to an electrical trouble 1.

Check the Main Drive Unit (turn the unit by

hand to see if it rotates) Replace the Main

Drive Unit when the unit failed to rotate

When the unit rotates 2. Check failure of the

harness between the ITB Motor (M02/

J6027) and the DC Controller PCB (UN09/

J210W) (trapped cable, open circuit,

connector disconnection) 3. Check

conduction of the fuse (FU4) in the DC

Controller PCB (UN09) When the fuse is not

blown out 4-1. Replace the ITB Motor (M02)

5-1. Replace the DC Controller PCB (UN09)

6-1. Replace the Main Drive Unit When the

fuse is blown out 4-2. Replace the DC

Controller PCB (UN09)

ITB Motor lock detection

E010- Within a specified period of

0003 time from the startup, signal is

not received.

Possible cause is overload or rotation failure

of the motor due to an electrical trouble 1.

Check the Main Drive Unit (turn the unit by

hand to see if it rotates) Replace the Main

Drive Unit when the unit failed to rotate

When the unit rotates 2. Check failure of the

harness between the ITB Motor (M02/

J6027) and the DC Controller PCB (UN09/

J210W) (trapped cable, open circuit,

connector disconnection) 3. Check

conduction of the fuse (FU4) in the DC

Controller PCB (UN09) When the fuse is not

blown out 4-1. Replace the ITB Motor (M02)

5-1. Replace the DC Controller PCB (UN09)

6-1. Replace the Main Drive Unit When the

fuse is blown out 4-2. Replace the DC

Controller PCB (UN09)

Possible cause is overload or rotation failure

of the motor due to an electrical trouble 1.

Check the Main Drive Unit (turn the unit by

hand to see if it rotates) Replace the Main

Drive Unit when the unit failed to rotate

When the unit rotates 2. Check failure of the

CL Drum Motor speed error

harness between the Motor (M04/ J6025)

and the DC Controller PCB (UN09/ J210W)

E012- Within a specified period of

0001 time from the startup, the speed (trapped cable, open circuit, connector

fails to be OK.

disconnection) 3. Check conduction of the

fuse (FU7) in the DC Controller PCB (UN09)

When the fuse is not blown out 4-1. Replace

the Drum Motor (M04) 5-1. Replace the DC

Controller PCB (UN09) When the fuse is

blown out 4-2. Replace the DC Controller

PCB (UN09)

E012CL Drum Motor speed error

0002

Possible cause is overload or rotation failure

of the motor due to an electrical trouble 1.

Check the Main Drive Unit (turn the unit by

hand to see if it rotates) Replace the Main

Drive Unit when the unit failed to rotate

When the unit rotates 2. Check failure of the

harness between the Motor (M04/ J6025)

and the DC Controller PCB (UN09/ J210W)

(trapped cable, open circuit, connector

disconnection) 3. Check conduction of the

fuse (FU7) in the DC Controller PCB (UN09)

When the fuse is not blown out 4-1. Replace

the Drum Motor (M04) 5-1. Replace the DC

Controller PCB (UN09) When the fuse is

blown out 4-2. Replace the DC Controller

PCB (UN09)

Possible cause is overload or rotation failure

of the motor due to an electrical trouble 1.

Check the Main Drive Unit (turn the unit by

hand to see if it rotates) Replace the Main

Drive Unit when the unit failed to rotate

When the unit rotates 2. Check failure of the

CL Drum Motor lock detection harness between the Motor (M04/ J6025)

and the DC Controller PCB (UN09/ J210W)

E012- Within a specified period of

0003 time from the startup, the speed (trapped cable, open circuit, connector

fails to be OK.

disconnection) 3. Check conduction of the

fuse (FU7) in the DC Controller PCB (UN09)

When the fuse is not blown out 4-1. Replace

the Drum Motor (M04) 5-1. Replace the DC

Controller PCB (UN09) When the fuse is

blown out 4-2. Replace the DC Controller

PCB (UN09)

Possible cause is overload or rotation failure

of the motor due to an electrical trouble 1.

Check if the Fixing Assembly is installed. 2.

Remove and reinstall the Fixing Assembly 3.

Check the gear 4. Replace the Fixing

Fixing Motor startup error

Assembly 5. Check the harness/connector

E014- Within a specified period of

between the DC Controller PCB (UN09/

0001 time from the startup, the speed

J210) and the Fixing Motor (M17). 6. Check

fails to be OK.

conduction of FU1153 in the AC Driver PCB

(UN14) =>Replace the AC Driver when the

fuse is blown out 7. Replace the Fixing

Motor (M17) 8. Replace the DC Controller

PCB (UN09)

E014Fixing Motor speed errorond.

0002

Possible cause is overload or rotation failure

of the motor due to an electrical trouble 1.

Check if the Fixing Assembly is installed. 2.

10

Remove and reinstall the Fixing Assembly 3.

Check the gear 4. Replace the Fixing

Assembly 5. Check the harness/connector

between the DC Controller PCB (UN09/

J210) and the Fixing Motor (M17). 6. Check

conduction of FU1153 in the AC Driver PCB

(UN14) =>Replace the AC Driver when the

fuse is blown out 7. Replace the Fixing

Motor (M17) 8. Replace the DC Controller

PCB (UN09)

Fixing Motor lock detection.

E014- Within a specified period of

0003 time from the startup, signal is

not received.

Code

Description

Possible cause is overload or rotation failure

of the motor due to an electrical trouble 1.

Check if the Fixing Assembly is installed. 2.

Remove and reinstall the Fixing Assembly 3.

Check the gear 4. Replace the Fixing

Assembly 5. Check the harness/connector

between the DC Controller PCB (UN09/

J210) and the Fixing Motor (M17). 6. Check

conduction of FU1153 in the AC Driver PCB

(UN14) =>Replace the AC Driver when the

fuse is blown out 7. Replace the Fixing

Motor (M17) 8. Replace the DC Controller

PCB (UN09)

Remedy

ATR Sensor (Y) error or

toner supply error

Error in detected TD ratio.

E020- The average of ATR

0020 reference value is the

specified value or lower at

the time of ATR Sensor (Y)

initialization.

1. Check if the Drum Unit (Y) is installed. 2. Check

the Drum Unit Relay PCB (Y) (UN26) 3. Check the

Drum Unit Memory PCB (Y) (UN30) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (Y)

(UN26). 5. Replace the Drum Unit (Y). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (Y) error or

toner supply error

Error in detected TD ratio.

E020- The average of ATR

0030 reference value is the

specified value or higher at

the time of ATR Sensor (Y)

initialization.

1. Check if the Drum Unit (Y) is installed. 2. Check

the Drum Unit Relay PCB (Y) (UN26) 3. Check the

Drum Unit Memory PCB (Y) (UN30) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (Y)

(UN26). 5. Replace the Drum Unit (Y). 6. Replace

the DC Controller PCB (UN09)

11

1. Check if the Drum Unit (Y) is installed. 2. Check

ATR Sensor (Y) error or

the Drum Unit Relay PCB (Y) (UN26) 3. Check the

toner supply error

Drum Unit Memory PCB (Y) (UN30) 4. Check the

E020Unable to adjust the control harness/connector between the DC Controller PCB

0040

voltage at the time of ATR (UN09/ J25) and the Drum Unit Relay PCB (Y)

Sensor (Y) initialization.

(UN26). 5. Replace the Drum Unit (Y). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (Y) error or

toner supply error

E020Unable to adjust the control

0041

voltage at the time of ATR

Sensor (Y) initialization.

1. Check if the Drum Unit (Y) is installed. 2. Check

the Drum Unit Relay PCB (Y) (UN26) 3. Check the

Drum Unit Memory PCB (Y) (UN30) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (Y)

(UN26). 5. Replace the Drum Unit (Y). 6. Replace

the DC Controller PCB (UN09)

ATR patch failed to be

created correctly or Patch

E020Sensor error

0050

High density for the target

at patch detection

1. Clean the scanners window. 2. Use your hand to

check if the shutter of the Registration Patch

Sensor Unit can be open. 3. Check if the window of

the Patch Sensor (UN43/ UN44) is soiled. 4. Check

scar on the ITB. 5. Check movement of the

Registration Shutter Solenoid (SL02). COPIER >

FUNCTION > PART-CHK > SL to move SL02 6.

Check the harness/connector between the DC

Controller PCB (UN09/J12) and the Patch Sensors

(UN43/J4007, UN44, J4006). 7.Replace the Drum

Unit (Y) 8.Replace the Registration Patch Sensor

Unit 9 Replace the ITB Unit. 10. Check conduction

of the fuses (FU5, FU8) in the DC Controller PCB

(UN09). 11. Replace the Primary Transfer High

Voltage PCB (UN04) 12. Replace the Developing

High Voltage PCB (UN07) 13. Replace the Primary

Charging High Voltage PCB (UN06) 14. Replace

the Auxiliary High Voltage PCB (UN08) 15. Replace

the Replace the DC Controller PCB (UN09)

ATR patch failed to be

created correctly or Patch

E020Sensor error

0060

High density for the target

at patch detection

1. Check the patch shape. 2. Clean the high voltage

contact point with dry wiping or air blower. 3. Check

the harness/connector between the DC Controller

(UN09) and the High Voltage PCB. Between the

DC Controller PCB (UN09/ J21) and the Primary

Charging High Voltage PCB (UN06/ J441, J442)

Between the DC Controller PCB (UN09/ J21, J22)

and the Developing High Voltage PCB (UN07/

J451, J452) Between the DC Controller PCB

(UN09/ J19) and the Auxiliary High Voltage PCB

(UN08/J461, J462) Between the DC Controller PCB

(J205) and the Primary Transfer High Voltage PCB

12

(UN04/J1001) 4. Replace the Drum Unit (Y) 5.

Replace the Registration Patch Sensor Unit 6.

Replace the ITB Unit. 7. Check conduction of the

fuses (FU5, FU8) in the DC Controller PCB (UN09).

8. Replace the Primary Transfer High Voltage PCB

(UN04) 9. Replace the Developing High Voltage

PCB (UN07) 10. Replace the Primary Charging

High Voltage PCB (UN06) 11. Replace the Auxiliary

High Voltage PCB (UN08) 12. Replace the DC

Controller PCB (UN09)

Patch Sensor error

The Patch Sensor could

E020not read a patch properly.

0070

(Patch error due to

software or the ITB Unit)

1.Turn OFF and then ON the power. 2.Replace the

ITB Unit.

ATR Sensor (Y) error or

toner supply error

E020- The average of ATR

0090 Sensor (Y) detection value

is the specified value or

lower.

1. Check if the Drum Unit (Y) is installed. 2. Check

the Drum Unit Relay PCB (Y) (UN26) 3. Check the

Drum Unit Memory PCB (Y) (UN30) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (Y)

(UN26). 5. Replace the Drum Unit (Y). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (Y) error or

toner supply error

E020- The average of ATR

0091 Sensor (Y) detection value

is the specified value or

higher.

1. Check if the Drum Unit (Y) is installed. 2. Check

the Drum Unit Relay PCB (Y) (UN26) 3. Check the

Drum Unit Memory PCB (Y) (UN30) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (Y)

(UN26). 5. Replace the Drum Unit (Y). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (Y) error or

toner supply error

T/D ratio detected by the

E020ATR Sensor (Y) (UN39) is

00B0

equal to or higher than the

specified value (high

density)

1. Check if the Drum Unit (Y) is installed. 2. Check

the Drum Unit Relay PCB (Y) (UN26) 3. Check the

Drum Unit Memory PCB (Y) (UN30) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (Y)

(UN26). 5. Replace the Drum Unit (Y). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (Y) error or

toner supply error

Error in detected delta T/D

E020- ratio T/D ratio detected by

00B1 the ATR Sensor (Y)

(UN39) is equal to or lower

than the specified value

(light density)

Possible cause: overload with the motor or motor

failure 1. Check conduction with FU2 on the DC

Controller PCB (UN09) 2. Check the

harness/connector between the DC Controller PCB

(UN09/ J23) and PS06. 3. Replace the DC

Controller PCB (UN09) 4. Check the Hopper Unit

(Y) 5. Replace the Hopper Unit (Y).

13

ATR Sensor (M) error or

toner supply error

Error in detected TD ratio.

E020- The average of ATR

0120 reference value is the

specified value or lower at

the time of ATR Sensor (M)

initialization.

1. Check if the Drum Unit (M) is installed. 2. Check

the Drum Unit Relay PCB (M) (UN27). 3. Check the

Drum Unit Memory PCB (M) (UN31). 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (M)

(UN27). 5. Replace the Drum Unit (M). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (M) error or

toner supply error

Error in detected TD ratio.

E020- The average of ATR

0130 reference value is the

specified value or higher at

the time of ATR Sensor (M)

initialization.

1. Check if the Drum Unit (M) is installed. 2. Check

the Drum Unit Relay PCB (M) (UN27). 3. Check the

Drum Unit Memory PCB (M) (UN31). 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (M)

(UN27). 5. Replace the Drum Unit (M). 6. Replace

the DC Controller PCB (UN09)

1. Check if the Drum Unit (M) is installed. 2. Check

ATR Sensor (M) error or

the Drum Unit Relay PCB (M) (UN27). 3. Check the

toner supply error

Drum Unit Memory PCB (M) (UN31). 4. Check the

E020Unable to adjust the control harness/connector between the DC Controller PCB

0140

voltage at the time of ATR (UN09/ J25) and the Drum Unit Relay PCB (M)

Sensor (M) initialization

(UN27). 5. Replace the Drum Unit (M). 6. Replace

the DC Controller PCB (UN09)

1. Check if the Drum Unit (M) is installed. 2. Check

ATR Sensor (M) error or

the Drum Unit Relay PCB (M) (UN27). 3. Check the

toner supply error

Drum Unit Memory PCB (M) (UN31). 4. Check the

E020Unable to adjust the control harness/connector between the DC Controller PCB

0141

voltage at the time of ATR (UN09/ J25) and the Drum Unit Relay PCB (M)

Sensor (M) initialization.

(UN27). 5. Replace the Drum Unit (M). 6. Replace

the DC Controller PCB (UN09)

Code

Description

ATR patch failed to be

created correctly or Patch

E020Sensor error

0150

High density for the target

at patch detection

Remedy

1. Clean the scanners window. 2. Use your hand

to check if the shutter of the Registration Patch

Sensor Unit can be open. 3. Check if the window of

the Patch Sensor (UN43/ UN44) is soiled. 4. Check

scar on the ITB. 5. Check movement of the

Registration Shutter Solenoid (SL02). COPIER >

FUNCTION > PART-CHK > SL to move SL02 6.

Check the harness/connector between the DC

Controller PCB (UN09/J12) and the Patch Sensors

(UN43/J4007, UN44, J4006). 7.Replace the Drum

14

Unit (M) 8.Replace the Registration Patch Sensor

Unit 9 Replace the ITB Unit. 10. Check conduction

of the fuses (FU5, FU8) in the DC Controller PCB

(UN09). 11. Replace the Primary Transfer High

Voltage PCB (UN04) 12. Replace the Developing

High Voltage PCB (UN07) 13. Replace the Primary

Charging High Voltage PCB (UN06) 14. Replace

the Auxiliary High Voltage PCB (UN08) 15.

Replace the Replace the DC Controller PCB

(UN09)

ATR patch failed to be

created correctly or Patch

E020Sensor error

0160

High density for the target

at patch detection

1. Check the patch shape. 2. Clean the high

voltage contact point with dry wiping or air blower.

3. Check the harness/connector between the DC

Controller (UN09) and the High Voltage PCB.

Between the DC Controller PCB (UN09/ J21) and

the Primary Charging High Voltage PCB (UN06/

J441, J442) Between the DC Controller PCB

(UN09/ J21, J22) and the Developing High Voltage

PCB (UN07/ J451, J452) Between the DC

Controller PCB (UN09/ J19) and the Auxiliary High

Voltage PCB (UN08/J461, J462) Between the DC

Controller PCB (J205) and the Primary Transfer

High Voltage PCB (UN04/J1001) 4. Replace the

Drum Unit (M) 5. Replace the Registration Patch

Sensor Unit 6. Replace the ITB Unit. 7. Check

conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09). 8. Replace the Primary

Transfer High Voltage PCB (UN04) 9. Replace the

Developing High Voltage PCB (UN07) 10. Replace

the Primary Charging High Voltage PCB (UN06)

11. Replace the Auxiliary High Voltage PCB

(UN08) 12. Replace the DC Controller PCB (UN09)

Patch Sensor error

The Patch Sensor could not

1.Turn OFF and then ON the power. 2.Replace the

E020read a patch properly.

ITB Unit.

0170

(Patch error due to

software or the ITB Unit)

ATR Sensor (M) error or

toner supply error

E020- The average of ATR

0190 Sensor (M) detection value

is the specified value or

lower.

1. Check if the Drum Unit (M) is installed. 2. Check

the Drum Unit Relay PCB (M) (UN27). 3. Check the

Drum Unit Memory PCB (M) (UN31). 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (M)

(UN27). 5. Replace the Drum Unit (M). 6. Replace

the DC Controller PCB (UN09)

15

ATR Sensor (M) error or

toner supply error

E020- The average of ATR

0191 Sensor (M) detection value

is the specified value or

higher.

1. Check if the Drum Unit (M) is installed. 2. Check

the Drum Unit Relay PCB (M) (UN27). 3. Check the

Drum Unit Memory PCB (M) (UN31). 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (M)

(UN27). 5. Replace the Drum Unit (M). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (M) error or

toner supply error

The T/D ratio detected by

E020the ATR Sensor (M)

01B0

(UN40) is equal to or higher

than the specified value

(high density)

1. Check if the Drum Unit (M) is installed. 2. Check

the Drum Unit Relay PCB (M) (UN27). 3. Check the

Drum Unit Memory PCB (M) (UN31). 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (M)

(UN27). 5. Replace the Drum Unit (M). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (M) error or

toner supply error

Error in detected delta T/D

E020- ratio The T/D ratio detected

01B1 by the ATR Sensor (M)

(UN40) is equal to or lower

than the specified value

(light density)

Overload of the motor or motor failure 1. Check

conduction with FU2 on the DC Controller PCB

(UN09) 2. Check the harness/connector between

the DC Controller PCB (UN09/J24) and PS07. 3.

Replace the DC Controller PCB (UN09) 4. Check

the Hopper Unit (M) 5. Replace the Hopper Unit

(M).

ATR Sensor (C) error or

toner supply error

Error in detected TD ratio.

E020- The average of ATR

0220 reference value is the

specified value or lower at

the time of ATR Sensor (C)

initialization.

1. Check if the Drum Unit (C) is installed. 2. Check

the Drum Unit Relay PCB (C) (UN28) 3. Check the

Drum Unit Memory PCB (C) (UN32) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (C)

(UN28). 5. Replace the Drum Unit (C). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (C) error or

toner supply error

Error in detected TD ratio.

E020- The average of ATR

0230 reference value is the

specified value or higher at

the time of ATR Sensor (C)

initialization.

1. Check if the Drum Unit (C) is installed. 2. Check

the Drum Unit Relay PCB (C) (UN28) 3. Check the

Drum Unit Memory PCB (C) (UN32) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (C)

(UN28). 5. Replace the Drum Unit (C). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (C) error or

toner supply error

E020Unable to adjust the control

0240

voltage at the time of ATR

Sensor (C) initialization.

1. Check if the Drum Unit (C) is installed. 2. Check

the Drum Unit Relay PCB (C) (UN28) 3. Check the

Drum Unit Memory PCB (C) (UN32) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (C)

(UN28). 5. Replace the Drum Unit (C). 6. Replace

16

the DC Controller PCB (UN09)

1. Check if the Drum Unit (C) is installed. 2. Check

ATR Sensor (C) error or

the Drum Unit Relay PCB (C) (UN28) 3. Check the

toner supply error

Drum Unit Memory PCB (C) (UN32) 4. Check the

E020Unable to adjust the control harness/connector between the DC Controller PCB

0241

voltage at the time of ATR (UN09/ J25) and the Drum Unit Relay PCB (C)

Sensor (C) initialization.

(UN28). 5. Replace the Drum Unit (C). 6. Replace

the DC Controller PCB (UN09)

ATR patch failed to be

created correctly or Patch

E020Sensor error

0250

High density for the target

at patch detection

1. Clean the scanners window. 2. Use your hand

to check if the shutter of the Registration Patch

Sensor Unit can be open. 3. Check if the window of

the Patch Sensor (UN43/ UN44) is soiled. 4. Check

scar on the ITB. 5. Check movement of the

Registration Shutter Solenoid (SL02). COPIER >

FUNCTION > PART-CHK > SL to move SL02 6.

Check the harness/connector between the DC

Controller PCB (UN09/J12) and the Patch Sensors

(UN43/J4007, UN44, J4006). 7.Replace the Drum

Unit (C) 8.Replace the Registration Patch Sensor

Unit 9 Replace the ITB Unit. 10. Check conduction

of the fuses (FU5, FU8) in the DC Controller PCB

(UN09). 11. Replace the Primary Transfer High

Voltage PCB (UN04) 12. Replace the Developing

High Voltage PCB (UN07) 13. Replace the Primary

Charging High Voltage PCB (UN06) 14. Replace

the Auxiliary High Voltage PCB (UN08) 15.

Replace the Replace the DC Controller PCB

(UN09)

ATR patch failed to be

created correctly or Patch

E020Sensor error

0260

High density for the target

at patch detection

1. Check the patch shape. 2. Clean the high

voltage contact point with dry wiping or air blower.

3. Check the harness/connector between the DC

Controller (UN09) and the High Voltage PCB.

Between the DC Controller PCB (UN09/ J21) and

the Primary Charging High Voltage PCB (UN06/

J441, J442) Between the DC Controller PCB

(UN09/ J21, J22) and the Developing High Voltage

PCB (UN07/ J451, J452) Between the DC

Controller PCB (UN09/ J19) and the Auxiliary High

Voltage PCB (UN08/J461, J462) Between the DC

Controller PCB (J205) and the Primary Transfer

High Voltage PCB (UN04/J1001) 4. Replace the

Drum Unit (C) 5. Replace the Registration Patch

Sensor Unit 6. Replace the ITB Unit. 7. Check

conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09). 8. Replace the Primary

17

Transfer High Voltage PCB (UN04) 9. Replace the

Developing High Voltage PCB (UN07) 10. Replace

the Primary Charging High Voltage PCB (UN06)

11. Replace the Auxiliary High Voltage PCB

(UN08) 12. Replace the DC Controller PCB (UN09)

ATR Sensor (C) error or

toner supply error

E020- The average of ATR

0290 Sensor (C) detection value

is the specified value or

lower.

1. Check if the Drum Unit (C) is installed. 2. Check

the Drum Unit Relay PCB (C) (UN28) 3. Check the

Drum Unit Memory PCB (C) (UN32) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (C)

(UN28). 5. Replace the Drum Unit (C). 6. Replace

the DC Controller PCB (UN09)

ATR Sensor (C) error or

toner supply error

E020- The average of ATR

0291 Sensor (C) detection value

is the specified value or

higher.

1. Check if the Drum Unit (C) is installed. 2. Check

the Drum Unit Relay PCB (C) (UN28) 3. Check the

Drum Unit Memory PCB (C) (UN32) 4. Check the

harness/connector between the DC Controller PCB

(UN09/ J25) and the Drum Unit Relay PCB (C)

(UN28). 5. Replace the Drum Unit (C). 6. Replace

the DC Controller PCB (UN09)

Code

Description

Remedy

ATR Sensor (C) error or toner

supply error

E020- The T/D ratio detected by the

02B0 ATR Sensor (C) (UN41) is

equal to or higher than the

specified value (high density)

1. Check if the Drum Unit (C) is installed. 2.

Check the Drum Unit Relay PCB (C) (UN28) 3.

Check the Drum Unit Memory PCB (C) (UN32) 4.

Check the harness/connector between the DC

Controller PCB (UN09/ J25) and the Drum Unit

Relay PCB (C) (UN28). 5. Replace the Drum Unit

(C). 6. Replace the DC Controller PCB (UN09)

ATR Sensor (C) error or toner

supply error

Error in detected delta T/D

E020- ratio The T/D ratio detected

02B1 by the ATR Sensor (C)

(UN41) is equal to or lower

than the specified value (light

density)

Overload of the motor or motor failure 1. Check

conduction of FU9 on the DC Controller PCB

(UN09). 2. Check the harness/connector

between the DC Controller PCB (UN09/J24) and

PS08. 3. Replace the DC Controller PCB (UN09)

4. Check the Hopper Unit (C). 5. Replace the

Hopper Unit (C).

ATR Sensor (Bk) error or

toner supply error

E020- Error in detected TD ratio.

0320 The average of ATR

reference value is the

specified value or lower at the

1. Check if the Drum Unit (Bk) is installed. 2.

Check the Drum Unit Relay PCB (Bk) (UN29) 3.

Check the Drum Unit Memory PCB (Bk) (UN33)

4. Check the harness/connector between the DC

Controller PCB (UN09/ J25) and the Drum Unit

Relay PCB (Bk) (UN29). 5. Replace the Drum

18

time of ATR Sensor (Bk)

initialization.

Unit (Bk). 6. Replace the DC Controller PCB

(UN09)

ATR Sensor (Bk) error or

toner supply error

Error in detected TD ratio.

E020- The average of ATR

0330 reference value is the

specified value or higher at

the time of ATR Sensor (Bk)

initialization.

1. Check if the Drum Unit (Bk) is installed. 2.

Check the Drum Unit Relay PCB (Bk) (UN29) 3.

Check the Drum Unit Memory PCB (Bk) (UN33)

4. Check the harness/connector between the DC

Controller PCB (UN09/ J25) and the Drum Unit

Relay PCB (Bk) (UN29). 5. Replace the Drum

Unit (Bk). 6. Replace the DC Controller PCB

(UN09)

ATR Sensor (Bk) error or

toner supply error

E020Unable to adjust the control

0340

voltage at the time of ATR

Sensor (Bk) initialization.

1. Check if the Drum Unit (Bk) is installed. 2.

Check the Drum Unit Relay PCB (Bk) (UN29) 3.

Check the Drum Unit Memory PCB (Bk) (UN33)

4. Check the harness/connector between the DC

Controller PCB (UN09/ J25) and the Drum Unit

Relay PCB (Bk) (UN29). 5. Replace the Drum

Unit (Bk). 6. Replace the DC Controller PCB

(UN09)

ATR Sensor (Bk) error or

toner supply error

E020Unable to adjust the control

0341

voltage at the time of ATR

Sensor (Bk) initialization.

1. Check if the Drum Unit (Bk) is installed. 2.

Check the Drum Unit Relay PCB (Bk) (UN29) 3.

Check the Drum Unit Memory PCB (Bk) (UN33)

4. Check the harness/connector between the DC

Controller PCB (UN09/ J25) and the Drum Unit

Relay PCB (Bk) (UN29). 5. Replace the Drum

Unit (Bk). 6. Replace the DC Controller PCB

(UN09)

ATR patch failed to be

created correctly or Patch

E020Sensor error

0350

High density for the target at

patch detection

1. Clean the scanners window. 2. Use your hand

to check if the shutter of the Registration Patch

Sensor Unit can be open. 3. Check if the window

of the Patch Sensor (UN43/ UN44) is soiled. 4.

Check scar on the ITB. 5. Check movement of

the Registration Shutter Solenoid (SL02).

COPIER > FUNCTION > PART-CHK > SL to

move SL02 6. Check the harness/connector

between the DC Controller PCB (UN09/J12) and

the Patch Sensors (UN43/J4007, UN44, J4006).

7.Replace the Drum Unit (Bk) 8.Replace the

Registration Patch Sensor Unit 9 Replace the

ITB Unit. 10. Check conduction of the fuses

(FU5, FU8) in the DC Controller PCB (UN09). 11.

Replace the Primary Transfer High Voltage PCB

(UN04) 12. Replace the Developing High Voltage

PCB (UN07) 13. Replace the Primary Charging

High Voltage PCB (UN06) 14. Replace the

19

Auxiliary High Voltage PCB (UN08) 15. Replace

the Replace the DC Controller PCB (UN09)

ATR patch failed to be

created correctly or Patch

E020Sensor error

0360

High density for the target at

patch detection

1. Check the patch shape. 2. Clean the high

voltage contact point with dry wiping or air

blower. 3. Check the harness/connector between

the DC Controller (UN09) and the High Voltage

PCB. Between the DC Controller PCB (UN09/

J21) and the Primary Charging High Voltage

PCB (UN06/ J441, J442) Between the DC

Controller PCB (UN09/ J21, J22) and the

Developing High Voltage PCB (UN07/ J451,

J452) Between the DC Controller PCB (UN09/

J19) and the Auxiliary High Voltage PCB

(UN08/J461, J462) Between the DC Controller

PCB (J205) and the Primary Transfer High

Voltage PCB (UN04/J1001) 4. Replace the Drum

Unit (Bk) 5. Replace the Registration Patch

Sensor Unit 6. Replace the ITB Unit. 7. Check

conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09). 8. Replace the Primary

Transfer High Voltage PCB (UN04) 9. Replace

the Developing High Voltage PCB (UN07) 10.

Replace the Primary Charging High Voltage PCB

(UN06) 11. Replace the Auxiliary High Voltage

PCB (UN08) 12. Replace the DC Controller PCB

(UN09)

ATR Sensor (Bk) error or

toner supply error

E020The average of ATR Sensor

0390

(Bk) detection value is the

specified value or lower.

1. Check if the Drum Unit (Bk) is installed. 2.

Check the Drum Unit Relay PCB (Bk) (UN29) 3.

Check the Drum Unit Memory PCB (Bk) (UN33)

4. Check the harness/connector between the DC

Controller PCB (UN09/ J25) and the Drum Unit

Relay PCB (Bk) (UN29). 5. Replace the Drum

Unit (Bk). 6. Replace the DC Controller PCB

(UN09)

ATR Sensor (Bk) error or

toner supply error

E020The average of ATR Sensor

0391

(Bk) detection value is the

specified value or higher.

1. Check if the Drum Unit (Bk) is installed. 2.

Check the Drum Unit Relay PCB (Bk) (UN29) 3.

Check the Drum Unit Memory PCB (Bk) (UN33)

4. Check the harness/connector between the DC

Controller PCB (UN09/ J25) and the Drum Unit

Relay PCB (Bk) (UN29). 5. Replace the Drum

Unit (Bk). 6. Replace the DC Controller PCB

(UN09)

E020- ATR Sensor (Bk) error or

03B0 toner supply error

1. Check if the Drum Unit (Bk) is installed. 2.

Check the Drum Unit Relay PCB (Bk) (UN29) 3.

20

The T/D ratio detected by the

ATR Sensor (Bk) (UN42) is

equal to or higher than the

specified value (high density)

ATR Sensor (Bk) error or

toner supply error

Error in detected delta T/D

E020- ratio The T/D ratio detected

03B1 by the ATR Sensor (Bk)

(UN42) is equal to or lower

than the specified value (light

density)

Check the Drum Unit Memory PCB (Bk) (UN33)

4. Check the harness/connector between the DC

Controller PCB (UN09/ J25) and the Drum Unit

Relay PCB (Bk) (UN29). 5. Replace the Drum

Unit (Bk). 6. Replace the DC Controller PCB

(UN09)

Overload of the motor or motor failure 1. Check

conduction of FU9 on the DC Controller PCB

(UN09). 2. Check the harness/connector

between the DC Controller PCB (UN09/J26) and

PS09 3. Replace the DC Controller PCB (UN09)

4. Check the Hopper Unit (Bk). 5. Replace the

Hopper Unit (Bk).

1. Clean the scanners window. 2. Use your hand

to check if the shutter of the Registration Patch

Sensor Unit can be open. 3. Check if the window

of the Patch Sensor (UN43/ UN44) is soiled. 4.

Check scar on the ITB. 5. Check movement of

the Registration Shutter Solenoid (SL02).

COPIER > FUNCTION > PART-CHK > SL to

move SL02 6. Check the harness/connector

Abnormal Y color patch

between the DC Controller PCB (UN09/J12) and

the Patch Sensors (UN43/J4007, UN44, J4006).

E020- reading value

1050 Dark patch although setting 0 7.Replace the Drum Unit (Y) 8.Replace the

for the patch level

Registration Patch Sensor Unit 9 Replace the

ITB Unit. 10. Check conduction of the fuses

(FU5, FU8) in the DC Controller PCB (UN09). 11.

Replace the Primary Transfer High Voltage PCB

(UN04) 12. Replace the Developing High Voltage

PCB (UN07) 13. Replace the Primary Charging

High Voltage PCB (UN06) 14. Replace the

Auxiliary High Voltage PCB (UN08) 15. Replace

the Replace the DC Controller PCB (UN09)

1. Check the patch shape. 2. Clean the high

voltage contact point with dry wiping or air

blower. 3. Check the harness/connector between

the DC Controller (UN09) and the High Voltage

Abnormal Y color patch

PCB. Between the DC Controller PCB (UN09/

E020- reading value

J21) and the Primary Charging High Voltage

1060 Light patch although setting 7

PCB (UN06/ J441, J442) Between the DC

for patch level

Controller PCB (UN09/ J21, J22) and the

Developing High Voltage PCB (UN07/ J451,

J452) Between the DC Controller PCB (UN09/

J19) and the Auxiliary High Voltage PCB

21

(UN08/J461, J462) Between the DC Controller

PCB (J205) and the Primary Transfer High

Voltage PCB (UN04/J1001) 4. Replace the Drum

Unit (Y) 5. Replace the Registration Patch

Sensor Unit 6. Replace the ITB Unit. 7. Check

conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09). 8. Replace the Primary

Transfer High Voltage PCB (UN04) 9. Replace

the Developing High Voltage PCB (UN07) 10.

Replace the Primary Charging High Voltage PCB

(UN06) 11. Replace the Auxiliary High Voltage

PCB (UN08) 12. Replace the DC Controller PCB

(UN09)

1. Clean the scanners window. 2. Use your hand

to check if the shutter of the Registration Patch

Sensor Unit can be open. 3. Check if the window

of the Patch Sensor (UN43/ UN44) is soiled. 4.

Check scar on the ITB. 5. Check movement of

the Registration Shutter Solenoid (SL02).

COPIER > FUNCTION > PART-CHK > SL to

move SL02 6. Check the harness/connector

Abnormal M color patch

between the DC Controller PCB (UN09/J12) and

the Patch Sensors (UN43/J4007, UN44, J4006).

E020- reading value

1150 Dark patch although setting 0 7.Replace the Drum Unit (M) 8.Replace the

for the patch level

Registration Patch Sensor Unit 9 Replace the

ITB Unit. 10. Check conduction of the fuses

(FU5, FU8) in the DC Controller PCB (UN09). 11.

Replace the Primary Transfer High Voltage PCB

(UN04) 12. Replace the Developing High Voltage

PCB (UN07) 13. Replace the Primary Charging

High Voltage PCB (UN06) 14. Replace the

Auxiliary High Voltage PCB (UN08) 15. Replace

the Replace the DC Controller PCB (UN09)

Code

Description

Remedy

1. Check the patch shape. 2. Clean the high

voltage contact point with dry wiping or air

blower. 3. Check the harness/connector between

Abnormal M color patch

the DC Controller (UN09) and the High Voltage

reading value

PCB. Between the DC Controller PCB (UN09/

E020- Light patch although setting 7

J21) and the Primary Charging High Voltage

1160 for patch level (unable to fit in

PCB (UN06/ J441, J442) Between the DC

the target between 550 and

Controller PCB (UN09/ J21, J22) and the

640)

Developing High Voltage PCB (UN07/ J451,

J452) Between the DC Controller PCB (UN09/

J19) and the Auxiliary High Voltage PCB

22

(UN08/J461, J462) Between the DC Controller

PCB (J205) and the Primary Transfer High

Voltage PCB (UN04/J1001) 4. Replace the Drum

Unit (M) 5. Replace the Registration Patch

Sensor Unit 6. Replace the ITB Unit. 7. Check

conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09). 8. Replace the Primary

Transfer High Voltage PCB (UN04) 9. Replace

the Developing High Voltage PCB (UN07) 10.

Replace the Primary Charging High Voltage PCB

(UN06) 11. Replace the Auxiliary High Voltage

PCB (UN08) 12. Replace the DC Controller PCB

(UN09)

1. Clean the scanners window. 2. Use your hand

to check if the shutter of the Registration Patch

Sensor Unit can be open. 3. Check if the window

of the Patch Sensor (UN43/ UN44) is soiled. 4.

Check scar on the ITB. 5. Check movement of

the Registration Shutter Solenoid (SL02).

COPIER > FUNCTION > PART-CHK > SL to

move SL02 6. Check the harness/connector

Abnormal C color patch

between the DC Controller PCB (UN09/J12) and

the Patch Sensors (UN43/J4007, UN44, J4006).

E020- reading value

1250 Dark patch although setting 0 7.Replace the Drum Unit (C) 8.Replace the

for the patch level

Registration Patch Sensor Unit 9 Replace the

ITB Unit. 10. Check conduction of the fuses

(FU5, FU8) in the DC Controller PCB (UN09). 11.

Replace the Primary Transfer High Voltage PCB

(UN04) 12. Replace the Developing High Voltage

PCB (UN07) 13. Replace the Primary Charging

High Voltage PCB (UN06) 14. Replace the

Auxiliary High Voltage PCB (UN08) 15. Replace

the Replace the DC Controller PCB (UN09)

1. Check the patch shape. 2. Clean the high

voltage contact point with dry wiping or air

blower. 3. Check the harness/connector between

Abnormal C color patch

the DC Controller (UN09) and the High Voltage

reading value

PCB. Between the DC Controller PCB (UN09/

E020- Light patch although setting 7 J21) and the Primary Charging High Voltage

1260 for patch level (unable to fit in PCB (UN06/ J441, J442) Between the DC

the target between 550 and

Controller PCB (UN09/ J21, J22) and the

640)

Developing High Voltage PCB (UN07/ J451,

J452) Between the DC Controller PCB (UN09/

J19) and the Auxiliary High Voltage PCB

(UN08/J461, J462) Between the DC Controller

23

PCB (J205) and the Primary Transfer High

Voltage PCB (UN04/J1001) 4. Replace the Drum

Unit (C) 5. Replace the Registration Patch

Sensor Unit 6. Replace the ITB Unit. 7. Check

conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09). 8. Replace the Primary

Transfer High Voltage PCB (UN04) 9. Replace

the Developing High Voltage PCB (UN07) 10.

Replace the Primary Charging High Voltage PCB

(UN06) 11. Replace the Auxiliary High Voltage

PCB (UN08) 12. Replace the DC Controller PCB

(UN09)

1. Clean the scanners window. 2. Use your hand

to check if the shutter of the Registration Patch

Sensor Unit can be open. 3. Check if the window

of the Patch Sensor (UN43/ UN44) is soiled. 4.

Check scar on the ITB. 5. Check movement of

the Registration Shutter Solenoid (SL02).

COPIER > FUNCTION > PART-CHK > SL to

move SL02 6. Check the harness/connector

Abnormal Bk color patch

between the DC Controller PCB (UN09/J12) and

the Patch Sensors (UN43/J4007, UN44, J4006).

E020- reading value

1350 Dark patch although setting 0 7.Replace the Drum Unit (Bk) 8.Replace the

for the patch level

Registration Patch Sensor Unit 9 Replace the

ITB Unit. 10. Check conduction of the fuses

(FU5, FU8) in the DC Controller PCB (UN09). 11.

Replace the Primary Transfer High Voltage PCB

(UN04) 12. Replace the Developing High Voltage

PCB (UN07) 13. Replace the Primary Charging

High Voltage PCB (UN06) 14. Replace the

Auxiliary High Voltage PCB (UN08) 15. Replace

the Replace the DC Controller PCB (UN09)

1. Check the patch shape. 2. Clean the high

voltage contact point with dry wiping or air

blower. 3. Check the harness/connector between

the DC Controller (UN09) and the High Voltage

PCB. Between the DC Controller PCB (UN09/

Abnormal Bk color patch

J21) and the Primary Charging High Voltage

E020- reading value

PCB (UN06/ J441, J442) Between the DC

1360 Light patch although setting 7

Controller PCB (UN09/ J21, J22) and the

for patch level

Developing High Voltage PCB (UN07/ J451,

J452) Between the DC Controller PCB (UN09/

J19) and the Auxiliary High Voltage PCB

(UN08/J461, J462) Between the DC Controller

PCB (J205) and the Primary Transfer High

24

Voltage PCB (UN04/J1001) 4. Replace the Drum

Unit (Bk) 5. Replace the Registration Patch

Sensor Unit 6. Replace the ITB Unit. 7. Check

conduction of the fuses (FU5, FU8) in the DC

Controller PCB (UN09). 8. Replace the Primary

Transfer High Voltage PCB (UN04) 9. Replace

the Developing High Voltage PCB (UN07) 10.

Replace the Primary Charging High Voltage PCB

(UN06) 11. Replace the Auxiliary High Voltage

PCB (UN08) 12. Replace the DC Controller PCB

(UN09)

Possible cause is overload or rotation failure of

the motor due to an electrical trouble 1. Check

the Main Drive Unit (turn the unit by hand to see

if it rotates) Replace the Main Drive Unit when

the unit failed to rotate When the unit rotates 2.

CL Developing Motor startup

Check failure of the harness between the

error

Developing Motor (M03/J6026) and the DC

E021- After 700 msec since the

Controller PCB (UN09/J210W) (trapped cable,

0001 startup, the speed failed to be

open circuit, connector disconnection) 3. Check

OK for 500 consecutive

conduction of the fuse (FU7) in the DC Controller

msec.

PCB (UN09) When the fuse is not blown out 4-1.

Replace the Developing Motor (M03) 5-1.

Replace the DC Controller PCB (UN09). When

the fuse is blown out 4-2. Replace the DC

Controller PCB (UN09).

CL Developing Motor lock

detection

E021Since the startup, the FG

0003

signal failed to be turned ON

for 300msec.

Possible cause is overload or rotation failure of

the motor due to an electrical trouble 1. Check

the Main Drive Unit (turn the unit by hand to see

if it rotates) Replace the Main Drive Unit when

the unit failed to rotate When the unit rotates 2.

Check failure of the harness between the

Developing Motor (M03/J6026) and the DC

Controller PCB (UN09/J210W) (trapped cable,

open circuit, connector disconnection) 3. Check

conduction of the fuse (FU7) in the DC Controller

PCB (UN09) When the fuse is not blown out 4-1.

Replace the Developing Motor (M03) 5-1.

Replace the DC Controller PCB (UN09). When

the fuse is blown out 4-2. Replace the DC

Controller PCB (UN09).

Developing screw rotation

E021- detection

0020 Error in the difference

between the maximum and

Possible cause: The screw is not rotating due to

failure in the coupling between the main body

and the Developing Assembly, or the value of

ATR Sensor (Y) (UN39) failed to be read due to

25

the minimum of ATR Sensor

(Y) detection value.

an electrical trouble. 1. Remove the Drum Unit

(Y) and check no damage. (Replace the Drum

Unit (Y) if defective) 2. Lift the pressure lever

after the Drum Unit (Y) is pushed all the way in.

3. Check failure of the harness between the

Drum Unit (Y) and the DC Controller PCB

(UN09/J25) (trapped cable, open circuit,

connector disconnection) 4.Check the Drum Unit

Relay PCB (Y) (UN26) (Soil/ deformation/

damage) 5. Check the Drum Unit Memory PCB

(M) (UN30) (Soil/ damage) 6.Replace the Drum

Unit (Y) 7. Replace the DC Controller PCB

(UN09). 8. Replace the Main Drive Unit

Developing screw rotation

detection

E021- Error in the difference

0120 between the maximum and

the minimum of ATR Sensor

(M) detection value.

Possible cause: The screw is not rotating due to

failure in the coupling between the main body

and the Developing Assembly, or the value of

ATR Sensor (M) (UN40) failed to be read due to

an electrical trouble. 1. Remove the Drum Unit

(M) and check no damage. (Replace the Drum

Unit (M) if defective) 2. Lift the pressure lever

after the Drum Unit (M) is pushed all the way in.

3. Check failure of the harness between the

Drum Unit (M) and the DC Controller PCB

(UN09/J25) (trapped cable, open circuit,

connector disconnection) 4.Check the Drum Unit

Relay PCB (M) (UN27) (Soil/ deformation/

damage) 5. Check the Drum Unit Memory PCB

(M) (UN31) (Soil/ damage) 6.Replace the Drum

Unit (M) 7. Replace the DC Controller PCB

(UN09). 8. Replace the Main Drive Unit

Developing screw rotation

detection

E021- Error in the difference

0220 between the maximum and

the minimum of ATR Sensor

(C) detection value.

Possible cause: The screw is not rotating due to

failure in the coupling between the main body

and the Developing Assembly, or the value of

ATR Sensor (C)(UN41) failed to be read due to

an electrical trouble. 1. Remove the Drum Unit

(C) and check no damage. (Replace the Drum

Unit (C) if defective) 2. Lift the pressure lever

after the Drum Unit (C) is pushed all the way in.

3.Check failure of the harness between the Drum

Unit (C) and the DC Controller PCB (UN09/J25)

(trapped cable, open circuit, connector

disconnection) 4.Check the Drum Unit Relay

PCB (C) (UN28) (Soil/ deformation/ damage)

5.Check the Drum Unit Memory PCB (C) (UN32)

(Soil/ damage) 6.Replace the Drum Unit (C). 7.

26

Replace the DC Controller PCB (UN09). 8.

Replace the Main Drive Unit

Developing screw rotation

detection

E021- Error in the difference

0320 between the maximum and

the minimum of ATR Sensor

(Bk) detection value.

Possible cause: The screw is not rotating due to

failure in the coupling between the main body

and the Developing Assembly, or the value of

ATR Sensor (Bk) (UN42) failed to be read due to

an electrical trouble 1. Remove the Drum Unit

(Bk) and check no damage. (Replace the Drum

Unit (Bk) if defective) 2. Lift the pressure lever

after the Drum Unit (Bk) is pushed all the way in.

3. Check failure of the harness between the

Drum Unit (Bk) and the DC Controller PCB

(UN09/J25) (trapped cable, open circuit,

connector disconnection) 4.Check the Drum Unit

Relay PCB (Bk) (UN29) (Soil/ deformation/

damage) 5. Check the Drum Unit Memory PCB

(Bk) (UN33) (Soil/ damage) 6.Replace the Drum

Unit (Bk). 7. Replace the DC Controller PCB

(UN09). 8. Replace the Main Drive Unit

Error in the Shutter Motor or the Laser Shutter

Sensor 1.COPIER > FUNCTION > PART-CHK >

MTR; move M05 When it works 2-1. Check the

Error in detection of abnormal harness between the DC Controller (UN09/ J11)

opening/closing of the Laser and the Laser Shutter Sensor (PS05) 3-1. Check

Shutter

condition of the Laser Shutter 4-1. Check the

Laser Shutter Sensor (PS05) in the Main Drive 5E022- At the Dustproof Shutter

1. Replace the Main Drive When it does not work

0000 open/close control, the

sensor fails to detect although 2-2. Check the harness between the DC

the specified time has

Controller (UN09/ J31) and the Developing

passed.

Disengagement Motor (M05) 3-2. Check

conduction of the fuse (FU6) in the DC Controller

(UN09) 4-2. Replace the Laser Shutter Motor

(M05) 5-2. Replace the Main Drive

Toner Supply Motor (Y) lock

E025- detection

0000 Failed to detect rotation after

turning ON the motor.

Possible cause: overload with the motor or motor

failure 1. Check conduction with FU2 on the DC

Controller PCB (UN09) 2. Check the

harness/connector between the DC Controller

PCB (UN09/ J23) and PS06. 3. Replace the DC

Controller PCB (UN09) Check the harness

toward the sensor 4. Check the Hopper Unit (Y)

5. Replace the Hopper Unit (Y).

Toner Container Motor (Y)

Overload of the motor or motor failure 1. Check if

E025lock detection

the Toner Bottle (Y) is installed 2. Check the

0010

Error in the current value after harness/connector between the DC Controller

27

turning ON the motor.

PCB (UN09) and the Toner Container Motor (Y)

(M07) 3. Check conduction of FU1 in the DC

Controller PCB (UN09) 4. Replace the DC

Controller PCB (UN09) 5. Replace the Hopper

Unit (Y)

Detection of short-circuit with

Toner Container Motor

(Y)FET

E025Error in element in the DC

1.Replace the DC Controller PCB (UN09)

0020

Controller PCB Error in the

current value after turning

OFF the motor.

Code

Description

Remedy

Detection of short-circuit

with Toner Container

Motor (Y) GND

E025After turning ON the

0030

motor, the current value

is a certain value or

lower.

Short-circuit failure of the Toner Bottle Motor or error

in element in the DC Controller PCB 1. Check the

harness between the DC Controller (UN09/J23) and

the Toner Container Motor (Y) (M07) 2. Replace the

DC Controller PCB (UN09) 3. Replace the Hopper Unit

(Y)

Toner Supply Motor (M)

lock detection

The Rotation Sensor

E025does not detect rotation

0100

although 5 sec has

passed since the motor

was turned ON

Overload of the motor or motor failure 1. Check

conduction with FU2 on the DC Controller PCB

(UN09) 2. Check the harness/connector between the

DC Controller PCB (UN09/J24) and PS07. 3. Replace

the DC Controller PCB (UN09) 4. Check the Hopper

Unit (M). 5. Replace the Hopper Unit (M).

Toner Container Motor

(M) lock detection

E025Error in the current

0110

value after turning ON

the motor.

Overload of the motor or motor failure 1. Check if the

Toner Bottle (M) is installed 2. Check the

harness/connector between the DC Controller PCB

(UN09) and the Toner Container Motor (M) (M09) 3.

Check conduction of FU1 in the DC Controller PCB

(UN09) 4. Replace the DC Controller PCB (UN09) 5.

Replace the Hopper Unit (M)

Detection of short-circuit

with Toner Container

Motor (M)FET

Error in element in the DC Controller PCB 1.Replace

E025Error in element in the

the DC Controller PCB (UN09)

0120

DC Controller PCB Error

in the current value after

turning OFF the motor.

28

Detection of short-circuit

with Toner Container

Motor (M) GND

E025After turning ON the

0130

motor, the current value

is a certain value or

lower.

Short-circuit failure of the Toner Bottle Motor or error

in element in the DC Controller PCB 1. Check the

harness between the DC Controller (UN09/J24) and

the Toner Container Motor (M) (M09) 2. Replace the

DC Controller PCB (UN09) 3. Replace the Hopper Unit

(M)

Toner Supply Motor (C)

lock detection

After turning ON the

E025- motor, the rotation

0200 sensor does not detect

although a specified

period of time has

passed.

Overload of the motor or motor failure 1. Check

conduction of FU9 on the DC Controller PCB (UN09).

2. Check the harness/connector between the DC

Controller PCB (UN09/J24) and PS08. 3. Replace the

DC Controller PCB (UN09) 4. Check the Hopper Unit

(C). 5. Replace the Hopper Unit (C).

Toner Container Motor

(C) lock detection

E025Error in the current

0210

value after turning ON

the motor.

Overload of the motor or motor failure 1. Check if the

Toner Bottle (C) is installed 2. Check the

harness/connector between the DC Controller PCB

(UN09) and the Toner Container Motor (C) (M11) 3.

Check conduction of FU3 in the DC Controller PCB

(UN09) 4. Replace the DC Controller PCB (UN09) 5.

Replace the Hopper Unit (C)

Detection of short-circuit

with Toner Container

Motor (C)FET

Error in element in the DC Controller PCB 1.Replace

E025Error in element in the

the DC Controller PCB (UN09)

0220

DC Controller PCB Error

in the current value after

turning OFF the motor.

Detection of short-circuit

with Toner Container

Motor (C) GND

E025After turning ON the

0230

motor, the current value

is a certain value or

lower.

Short-circuit failure of the Toner Bottle Motor or error

in element in the DC Controller PCB 1. Check the

harness between the DC Controller (UN09/J24) and

the Toner Container Motor (C) (M11) 2. Replace the

DC Controller PCB (UN09) 3. Replace the Hopper Unit

(C)

Toner Supply Motor (Bk)

lock detection

The Rotation Sensor

E025does not detect rotation

0300

although 5 sec has

passed since the motor

was turned ON

Overload of the motor or motor failure 1. Check

conduction of FU9 on the DC Controller PCB (UN09).

2. Check the harness/connector between the DC

Controller PCB (UN09/J26) and PS09 3. Replace the

DC Controller PCB (UN09) 4. Check the Hopper Unit

(Bk). 5. Replace the Hopper Unit (Bk).

29

Toner Container Motor

(Bk) lock detection

E025Error in the current

0310

value after turning ON

the motor.

Overload of the motor or motor failure 1. Check if the

Toner Bottle (Bk) is installed 2. Check the

harness/connector between the DC Controller PCB

(UN09) and the B Toner Container Motor (Bk)(M13) 3.

Check conduction of FU3 in the DC Controller PCB

(UN09) 4. Replace the DC Controller PCB (UN09) 5.

Replace the Hopper Unit (Bk)

Detection of short-circuit

with Toner Container

Motor (Bk)FET

Error in element in the DC Controller PCB 1.Replace

E025Error in element in the

the DC Controller PCB (UN09)

0320

DC Controller PCB Error

in the current value after

turning OFF the motor.

Detection of short-circuit

with Toner Container

Motor (Bk) GND

E025After turning ON the

0330

motor, the current value

is a certain value or

lower

Short-circuit failure of the Toner Bottle Motor or error

in element in the DC Controller PCB 1. Check the

harness between the DC Controller (UN09/J26) and

the Toner Container Motor (Bk) (M13) 2. Replace the

DC Controller PCB (UN09) 3. Replace the Hopper Unit

(Bk)

ASSIST Counter failed

to work

E032Detection of short-circuit Check the cable (to see if its disconnected)

0001

with the Count Pulse

Signal

Error in Lift Motor or Lifter Sensor 1. While Cassette 1

is removed, turn ON the power and then insert

Cassette 1. When there is operation sound of the

motor 1-1. Check the harness/connector between the

DC Controller (UN09/J13) and the Cassette 1 Lifter

Sensor (PS12) 2-1. Check if the Cassette 1 Lifter

Sensor (PS12) is installed. 3-1. Extend the Sensor

Cassette 1 Lifter error

Flag of the Cassette 1 Lifter Sensor (PS12) by approx.