Académique Documents

Professionnel Documents

Culture Documents

02-Nuevo Sistema de Control Electronico

Transféré par

RodrigoCastilloAcostaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

02-Nuevo Sistema de Control Electronico

Transféré par

RodrigoCastilloAcostaDroits d'auteur :

Formats disponibles

Electronic control system redesign

Frank Tegtmeier - Electrical Engineering Terex O&K

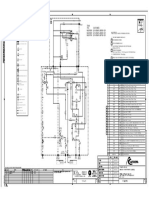

Current configuration of the control system

Board Control System

BCS

CAN Bus II

CAN Bus I

J1939

Data

Aquisition

Processor

DAP

Pump Management System

LH engine

PMS

J1939

Programmable

Logic Control

PLC

Data

Aquisition

Processor

DAP

Pump Management System

RH engine

PMS

Central Management

CMS

Goals / Advantages of the new control system

One type of controller for all automation functions

Less different parts to be kept

Reduced number of controllers in the new system

Only one programming tool for reprogramming

Controller can be programmed through BCS

Advanced trouble shooting and self diagnostic functions

New control system

BCS

CAN bus II

CAN bus I

J1939

Drive controller LH

J1939

Motion Management

Auxiliaries

Drive controller RH

New Board Control System (BCS) Hardware

Faster CPU (400 MHz)

Advanced temperatur

range (-40C - 55C)

Larger display

(12 / 800 x 600 pixel)

Additional keys and

touch screen

for better navigation

Operating system

Win XP embeded

Compact Flash card

and USB port

for software updates

Development timeline

July 2007

Software

December 2007

October 2007

3rd quarter 2008

Development

BCS

Controller

module test

Software

Development

Controller

Prototype

installation

at factory

Prototype machine

to selected client

New BCS functions

Integrated engine interface via J1939 data bus

Engine fault code information is available

All controllers can be configured and

programmed through the BCS

No additional service tool is required.

Service laptop can be connected using

wireless network access.

Service software will be identical with BCS

software

Operators and service personell will have

different access levels

Advanced fault storage / Example

Fault

code

123

Description

LH pump drive temperature

high

Alarm

condition

Temp. > 70C

for 15 sec.

Sensor

code

B1

Temp. < 65C

for 2 min.

LH pump drive

gearbox temperature

Start time and date

Machine hour at start

Duration of fault

13:27:15 15.8.2006

2340

00:15:23

Component serial

number

Time and date of

installation

xxyyzz

13:27:15 15.8.2006

Alarm limit

Time of occurrence

Related info from continuous logging

LH engine speed

LH engine load factor

Component Management Info

Fan motor

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Pump drive gearbox

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Engine coupling

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Engine

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Fan motor

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

radiator

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Fan motor

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Oil cooler

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Oil cooler

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Rotor

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Fan motor

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Swing gearbox RH

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Swing gearbox LH

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Pump drive gearbox

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Engine coupling

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

Engine

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

radiator

date of inst. : 2.2.2006

S/N: xxyyzz

oper hour: 345 h

On board documentation

On board documentation

electrical schematic

technical handbook

operator handbook

Dealer Days 06

Thank you !

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- B0700ap ADocument76 pagesB0700ap ARodrigoCastilloAcostaPas encore d'évaluation

- Casio FX-9700GH Calculator ManualDocument188 pagesCasio FX-9700GH Calculator ManualLuna StonePas encore d'évaluation

- B0700BG BDocument64 pagesB0700BG BRodrigoCastilloAcostaPas encore d'évaluation

- Parametros Nuevos Epm 7000Document3 pagesParametros Nuevos Epm 7000RodrigoCastilloAcostaPas encore d'évaluation

- B0700ap ADocument76 pagesB0700ap ARodrigoCastilloAcostaPas encore d'évaluation

- Hu2 02 0001esDocument3 pagesHu2 02 0001esRodrigoCastilloAcostaPas encore d'évaluation

- HONEYWELLDocument1 pageHONEYWELLRodrigoCastilloAcostaPas encore d'évaluation

- SRM 6000Document2 pagesSRM 6000RodrigoCastilloAcostaPas encore d'évaluation

- B0700ay BDocument44 pagesB0700ay BRodrigoCastilloAcostaPas encore d'évaluation

- Sick 518Document1 pageSick 518RodrigoCastilloAcostaPas encore d'évaluation

- Sick ReflexDocument1 pageSick ReflexRodrigoCastilloAcostaPas encore d'évaluation

- 554-45-Hoja 1 de 2Document1 page554-45-Hoja 1 de 2RodrigoCastilloAcostaPas encore d'évaluation

- B0700ax BDocument38 pagesB0700ax BRodrigoCastilloAcostaPas encore d'évaluation

- Radio ControlDocument1 pageRadio ControlRodrigoCastilloAcostaPas encore d'évaluation

- Release NotesDocument13 pagesRelease NotesRodrigoCastilloAcostaPas encore d'évaluation

- Compare HoperDocument1 pageCompare HoperRodrigoCastilloAcostaPas encore d'évaluation

- Parametros Nuevos Epm 7000Document3 pagesParametros Nuevos Epm 7000RodrigoCastilloAcostaPas encore d'évaluation

- ContentsDocument3 pagesContentsRodrigoCastilloAcostaPas encore d'évaluation

- Read MeDocument1 pageRead MeRodrigoCastilloAcostaPas encore d'évaluation

- EnerVista UR Setup - Data Loggmotor2 Cv17Document33 pagesEnerVista UR Setup - Data Loggmotor2 Cv17RodrigoCastilloAcostaPas encore d'évaluation

- LicenceDocument2 pagesLicenceRodrigoCastilloAcostaPas encore d'évaluation

- Tp0274 Mme 002 1 - Parte41 (Semaforos Descarga Chancador)Document2 pagesTp0274 Mme 002 1 - Parte41 (Semaforos Descarga Chancador)RodrigoCastilloAcostaPas encore d'évaluation

- 554-43-Hoja 1 de 2Document1 page554-43-Hoja 1 de 2RodrigoCastilloAcostaPas encore d'évaluation

- FS8W CutsheetsDocument8 pagesFS8W CutsheetsRodrigoCastilloAcostaPas encore d'évaluation

- User Manual EN PDFDocument604 pagesUser Manual EN PDFAnonymous zQ8BonPas encore d'évaluation

- Certified: Detail BDocument1 pageCertified: Detail BRodrigoCastilloAcostaPas encore d'évaluation

- Certified: Detail BDocument1 pageCertified: Detail BRodrigoCastilloAcostaPas encore d'évaluation

- PLC-SPS Technical HandbookDocument30 pagesPLC-SPS Technical HandbookRodrigoCastilloAcostaPas encore d'évaluation

- 2 EquipmentList MV MCCDocument6 pages2 EquipmentList MV MCCRodrigoCastilloAcostaPas encore d'évaluation

- Programacion Calentadores Programacion Calentadores Cleaver-Brooks Cleaver-BrooksDocument2 pagesProgramacion Calentadores Programacion Calentadores Cleaver-Brooks Cleaver-BrooksRodrigoCastilloAcostaPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Logic Chapter 1 SyllogismDocument17 pagesLogic Chapter 1 SyllogismNISHITA ACHREKARPas encore d'évaluation

- 3 772Document61 pages3 772D MNCPas encore d'évaluation

- Class and ObjectsDocument15 pagesClass and ObjectsIwan SaputraPas encore d'évaluation

- Grade 11 SEM: Markscheme Examiners ReportDocument29 pagesGrade 11 SEM: Markscheme Examiners ReportDr. Love TrivediPas encore d'évaluation

- Information Data and ProcessingDocument10 pagesInformation Data and ProcessingarshdeepsinghdhingraPas encore d'évaluation

- Survey CE1011Document34 pagesSurvey CE1011san htet aung100% (3)

- Physics As Level Book (2022-2023)Document492 pagesPhysics As Level Book (2022-2023)AMNA MOAZZAMPas encore d'évaluation

- PCS-9881 Ethernet Switch Instruction Manual: NR Electric Co., LTDDocument41 pagesPCS-9881 Ethernet Switch Instruction Manual: NR Electric Co., LTDRicchie Gotama SihitePas encore d'évaluation

- Cennamo - Intransitivity, Object Marking and Event StructureDocument16 pagesCennamo - Intransitivity, Object Marking and Event StructureAugusto PérezPas encore d'évaluation

- 3013 Thule Atlantis 780Document2 pages3013 Thule Atlantis 780Duarte MartinsPas encore d'évaluation

- 10023890ifu Cedia Csa Low Range DXC 700 Au enDocument4 pages10023890ifu Cedia Csa Low Range DXC 700 Au enRodas GetachewPas encore d'évaluation

- Kolkata and North-East Centre at Tezpur: Indian Statistical InstituteDocument1 pageKolkata and North-East Centre at Tezpur: Indian Statistical InstitutePoonam NaiduPas encore d'évaluation

- Math Academy AppDocument4 pagesMath Academy Appkisame1357Pas encore d'évaluation

- HD 70 CDocument101 pagesHD 70 CPhamVanGiangPas encore d'évaluation

- Calculations QuestionssDocument42 pagesCalculations QuestionssAlluringcharmsPas encore d'évaluation

- Apm 2014Document9 pagesApm 2014bubushtarPas encore d'évaluation

- Communication ManagementDocument20 pagesCommunication Managementmandalapu_devi5240Pas encore d'évaluation

- Maya Dynamics Basics:: MEL and ExpressionDocument33 pagesMaya Dynamics Basics:: MEL and ExpressionNguyễn HuỳnhPas encore d'évaluation

- L28-32H GenSet TierII PDFDocument824 pagesL28-32H GenSet TierII PDFHelder Pinto100% (1)

- Lampiran Uji Komparasi Ganda ScheffeDocument2 pagesLampiran Uji Komparasi Ganda ScheffeAhmad Safi'iPas encore d'évaluation

- EVADTS - 6-1 - 04 June 2009Document232 pagesEVADTS - 6-1 - 04 June 2009Carlos TejedaPas encore d'évaluation

- BasCal (1st Long Exam Reviewer)Document23 pagesBasCal (1st Long Exam Reviewer)Ethan Erika BionaPas encore d'évaluation

- Sony HCD Zx30avDocument80 pagesSony HCD Zx30avrrobles8777Pas encore d'évaluation

- FREE EthnicKnittingBookPattern HeadbandDocument4 pagesFREE EthnicKnittingBookPattern HeadbandriyuuhiPas encore d'évaluation

- LuK Tractor Diagnosis LQDocument20 pagesLuK Tractor Diagnosis LQZam BiloiuPas encore d'évaluation

- Celonis Configuration Store Setup Guide 1.6Document11 pagesCelonis Configuration Store Setup Guide 1.6Venugopal JujhavarappuPas encore d'évaluation

- Notes of CH 6 Animal Tissues Class 9th ScienceDocument11 pagesNotes of CH 6 Animal Tissues Class 9th ScienceSingh JPas encore d'évaluation

- DDP400 Open-Frame and U-Chassis :: ROAL Living EnergyDocument12 pagesDDP400 Open-Frame and U-Chassis :: ROAL Living EnergyroalscribdPas encore d'évaluation

- EECS4421Z: Introduction To Robotics Sample Exam QuestionsDocument7 pagesEECS4421Z: Introduction To Robotics Sample Exam QuestionsMooeez BellaaminePas encore d'évaluation

- R134a HXWC Series Water Cooled Screw Flooded Chillers Cooling Capacity 200 To 740 Tons 703 To 2603 KW Products That Perform PDFDocument16 pagesR134a HXWC Series Water Cooled Screw Flooded Chillers Cooling Capacity 200 To 740 Tons 703 To 2603 KW Products That Perform PDFmohamad chaudhariPas encore d'évaluation