Académique Documents

Professionnel Documents

Culture Documents

Complete Book List

Transféré par

sigmasundar0 évaluation0% ont trouvé ce document utile (0 vote)

214 vues3 pagesThis document lists 53 books related to lean manufacturing and Toyota Production System principles. Some of the most frequently mentioned books discuss The Goal by Eliyahu Goldratt, Lean Thinking by James Womack and Daniel Jones, and books about Toyota's production methods including The Toyota Way, Kaizen, and TPM. The books provide guidance on topics like just-in-time production, continuous flow, mistake-proofing, visual management, and implementing lean tools on the shop floor.

Description originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document lists 53 books related to lean manufacturing and Toyota Production System principles. Some of the most frequently mentioned books discuss The Goal by Eliyahu Goldratt, Lean Thinking by James Womack and Daniel Jones, and books about Toyota's production methods including The Toyota Way, Kaizen, and TPM. The books provide guidance on topics like just-in-time production, continuous flow, mistake-proofing, visual management, and implementing lean tools on the shop floor.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

214 vues3 pagesComplete Book List

Transféré par

sigmasundarThis document lists 53 books related to lean manufacturing and Toyota Production System principles. Some of the most frequently mentioned books discuss The Goal by Eliyahu Goldratt, Lean Thinking by James Womack and Daniel Jones, and books about Toyota's production methods including The Toyota Way, Kaizen, and TPM. The books provide guidance on topics like just-in-time production, continuous flow, mistake-proofing, visual management, and implementing lean tools on the shop floor.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

S.

No Some Useful Books

1 The Goal

2 The Goal II

3 The choice

4 Production TOC way

5 Lean Thinking

6 The Gold mine

7 How toyota changed

8 The machine that changed the world

9 Latenight discussion on TOC

10 Kanban just in time at toyota

11 Toyota field book

12 Necessary but not sufficient

13 isn't it obvious

14 Just in time for Today and Tomorrow

15 Workplace management Ohno

16 Value strem Management

Velocity: Combining Lean, Six Sigma And The Theory Of

17

Constraints To Achieve Breakthrough Performance

18 Out of the crisis

19 Critical Chain

20 Lean Tools

21 Lean Tools tamil

22 Shige shingo - ZQC

23 Sayings of shingo

24 8185985006, Taiichi Ohno

How Toyota Became #1: Leadership Lessons from the

25

World's Greatest Car Company

26 Learning to See

27 Creating Continuous Flow

28 Making Materials Flow

29 Seeing the Whole

30 Creating Level Pull

31 Building a Lean Fulfillment Stream

32 Lean Lexicon

Gemba Kaizen: A Commonsense, Low-Cost Approach to

33

Management

34 Kaizen: The Key To Japan's Competitive Success

35 A Revolution in Manufacturing: The SMED System

Quick Changeover for Operators: The SMED System

36

(Shopfloor Series)

5S for Operators: 5 Pillars of the Visual Workplace (For Your

37

Organization!)

38 Standard Work for the Shopfloor (Shopfloor Series)

39 Identifying Waste on the Shopfloor (Shopfloor Series)

Mistake-Proofing for Operators: The ZQC System (Shopfloor

40

Series)

41 TPM for Every Operator (Shopfloor Series)

OEE for Operators: Overall Equipment Effectiveness

42

(Shopfloor Series)

43 Autonomous Maintenance for Operators (Shopfloor Series)

44 Pull Production for the Shopfloor (Shopfloor Series)

Cellular Manufacturing: One-Piece Flow for Workteams

45

(Shopfloor Series)

46 Kanban for the Shopfloor (Shopfloor Series)

47 Just-in-Time for Operators (Shopfloor Series)

Focused Equipment Improvement for TPM Teams (Shop

48

Floor Series)

Autonomous Maintenance in Seven Steps: Implementing

49

TPM on the Shop Floor

50 Poka-Yoke: Improving Product Quality by Preventing Defects

IMPLEMENTING TPM: THE NORTH AMERICAN

51

EXPERIENCE

TPM in Process Industries (Step-By-Step Approach to TPM

52

Implementation)

53 Introduction to TPM by seichi Nakajima

Vous aimerez peut-être aussi

- Technical Aspects of Supervision: The Commonwealth and International Library: Supervisory StudiesD'EverandTechnical Aspects of Supervision: The Commonwealth and International Library: Supervisory StudiesPas encore d'évaluation

- Optimizing Factory Performance: Cost-Effective Ways to Achieve Significant and Sustainable ImprovementD'EverandOptimizing Factory Performance: Cost-Effective Ways to Achieve Significant and Sustainable ImprovementPas encore d'évaluation

- Lean ManagmentDocument86 pagesLean Managmentvenkateshdavey100% (52)

- Lean Management - EnGLISHDocument416 pagesLean Management - EnGLISHLaith Abdul Rahim100% (1)

- Sanet - ST Learning Robotic Proc PDFDocument349 pagesSanet - ST Learning Robotic Proc PDFKoushik Pal67% (3)

- Interview Questions - IEDocument4 pagesInterview Questions - IEkashmiri food and culture and bunkPas encore d'évaluation

- Viva Voce Questions Cad/Cam LabDocument2 pagesViva Voce Questions Cad/Cam Labvenkatanaveen306Pas encore d'évaluation

- Six Sigma 1 Day RDocument107 pagesSix Sigma 1 Day Rguriya khanPas encore d'évaluation

- MF F418 Lean Manufacturing - AKGuptaDocument3 pagesMF F418 Lean Manufacturing - AKGuptaSAMARTH patilPas encore d'évaluation

- BCD 206 Management Decision ModelsDocument3 pagesBCD 206 Management Decision ModelsparikentysonPas encore d'évaluation

- Tutorial 1 QuestionsDocument7 pagesTutorial 1 QuestionsXuejing YangPas encore d'évaluation

- 2 Pillars of Toyota Production SystemDocument13 pages2 Pillars of Toyota Production Systemwaludde conradPas encore d'évaluation

- GBE KPO 2 001 00 Lean Basics 1Document69 pagesGBE KPO 2 001 00 Lean Basics 1anooo12Pas encore d'évaluation

- Enterprise Resource Planning by Alexis Leon MohitDocument322 pagesEnterprise Resource Planning by Alexis Leon MohitRPas encore d'évaluation

- Learning From Toyota PDFDocument36 pagesLearning From Toyota PDFMurat TerziPas encore d'évaluation

- Chapter 6 On Just-In-Time Production Leveling: 6.1 Publishing InfoDocument8 pagesChapter 6 On Just-In-Time Production Leveling: 6.1 Publishing InfoGurpreet MaanPas encore d'évaluation

- Toyota Production SystemDocument4 pagesToyota Production SystemAhmedPas encore d'évaluation

- Unit 3 TQM Tools and TechniqesiDocument2 pagesUnit 3 TQM Tools and TechniqesiSuguna PriyaPas encore d'évaluation

- Lean Transformation With VSMDocument26 pagesLean Transformation With VSMMansoor AliPas encore d'évaluation

- TQM Unitwise QuestionsDocument5 pagesTQM Unitwise QuestionssujianushPas encore d'évaluation

- Lean Manufacturing: Module-1Document36 pagesLean Manufacturing: Module-1pravit08Pas encore d'évaluation

- Lean Manufacturing FOR Competitive AdvantageDocument13 pagesLean Manufacturing FOR Competitive Advantagemicmech100% (5)

- Kanban For The Shop Floor - PPDocument2 pagesKanban For The Shop Floor - PPRachmat BoerhanPas encore d'évaluation

- WCM Unit 1Document29 pagesWCM Unit 1RAJASREE SPas encore d'évaluation

- 16 Marks TQMDocument1 page16 Marks TQMJeyaram KumarPas encore d'évaluation

- Lean Manufacturing-Case Study at MACPLDocument53 pagesLean Manufacturing-Case Study at MACPLpraful100% (1)

- Course Duration: The Course Duration Is of 40 Sessions of 60 Minutes Each. 3. Course ContentsDocument3 pagesCourse Duration: The Course Duration Is of 40 Sessions of 60 Minutes Each. 3. Course Contentschirag khokhriPas encore d'évaluation

- The Toyota Production SystemDocument4 pagesThe Toyota Production SystemSanjay Mehrishi100% (1)

- CRO Workbook Web DoneDocument64 pagesCRO Workbook Web DoneVlad VamoșPas encore d'évaluation

- Just in TimeDocument54 pagesJust in TimeSiddhartha PaulPas encore d'évaluation

- Just in TimeDocument5 pagesJust in TimeKuljeet S GujralPas encore d'évaluation

- Pre-Training Report: (Preferably Attach An Organization Brochure)Document4 pagesPre-Training Report: (Preferably Attach An Organization Brochure)Jesus vazquezPas encore d'évaluation

- Operations and Supply Chain Managemnt DossierDocument36 pagesOperations and Supply Chain Managemnt DossierAmit KumarPas encore d'évaluation

- Lean ManufacturingDocument69 pagesLean ManufacturingVinay InavoluPas encore d'évaluation

- E-Course: Total Quality Management 2000 - SIX SIGMA & POKA-YOKEDocument22 pagesE-Course: Total Quality Management 2000 - SIX SIGMA & POKA-YOKECarlo ScodanibbioPas encore d'évaluation

- Mech VIII Sem Question BankDocument14 pagesMech VIII Sem Question BankMASTER SOURCEPas encore d'évaluation

- Clase 1Document38 pagesClase 1Gary Warthon MelendezPas encore d'évaluation

- Aiesec ColombiaDocument46 pagesAiesec ColombiaJorge SerranoPas encore d'évaluation

- 20MBA21 SyllabusDocument4 pages20MBA21 SyllabusBheemeswar ReddyPas encore d'évaluation

- TPS and Lean ProductionDocument18 pagesTPS and Lean ProductionMikey ChuaPas encore d'évaluation

- ManufacturaDocument87 pagesManufacturaMiguel Angel GarcíaPas encore d'évaluation

- (Shopfloor Series) Productivity Development Team-Cellular Manufacturing - One Piece Flow For Workteams-Productivity Press - Routledge (2018) PDFDocument87 pages(Shopfloor Series) Productivity Development Team-Cellular Manufacturing - One Piece Flow For Workteams-Productivity Press - Routledge (2018) PDFmichelle100% (3)

- Lec15 TPS Overview 2015 PDFDocument69 pagesLec15 TPS Overview 2015 PDFLuka VuleticPas encore d'évaluation

- HNDT Mba s9 13Document34 pagesHNDT Mba s9 13Shreeraj PawarPas encore d'évaluation

- MT 17 - LeanDocument48 pagesMT 17 - LeanRuíz Figueroa, Jean E.Pas encore d'évaluation

- Hpu Improvement in DV Block Line: Ganesh C, Giridharan D., and Guided by A.Venkatesan (Hod/Ap-Mech)Document11 pagesHpu Improvement in DV Block Line: Ganesh C, Giridharan D., and Guided by A.Venkatesan (Hod/Ap-Mech)theijesPas encore d'évaluation

- History of Lean Production, The Toyota Production SystemDocument2 pagesHistory of Lean Production, The Toyota Production SystemfaizanahmedilovekindPas encore d'évaluation

- Manual MboDocument56 pagesManual MboHudson AraújoPas encore d'évaluation

- History of The Kanban SystemDocument5 pagesHistory of The Kanban Systemezhila964Pas encore d'évaluation

- " '5S' Implementation in Food Industry ": Department of Mechanical EngineeringDocument39 pages" '5S' Implementation in Food Industry ": Department of Mechanical EngineeringMayur Madhukar MankarPas encore d'évaluation

- Unit - I - Introduction To Operations Management SYLLABUS: Operations Management - Nature, Importance, Historical DevelopmentDocument3 pagesUnit - I - Introduction To Operations Management SYLLABUS: Operations Management - Nature, Importance, Historical Developmentsabha5121021Pas encore d'évaluation

- Learning From ToyotaDocument36 pagesLearning From ToyotaEldori1988Pas encore d'évaluation

- Lean Basics: Training ScriptDocument34 pagesLean Basics: Training ScriptmagudeeshPas encore d'évaluation

- Vs M PresentationDocument73 pagesVs M PresentationMaiPas encore d'évaluation

- Value Stream Mapping: Bill Paolucci Ipfw March 17, 2009Document73 pagesValue Stream Mapping: Bill Paolucci Ipfw March 17, 2009AkPas encore d'évaluation

- VSM 1hr PresentationDocument25 pagesVSM 1hr PresentationGilson VieiraPas encore d'évaluation

- Toyota Production System (TPS) : BY: Prashant ThakurDocument51 pagesToyota Production System (TPS) : BY: Prashant ThakurCarbon Nano TubePas encore d'évaluation

- Lean Construction 3 InokumaDocument21 pagesLean Construction 3 Inokumainitiative1972Pas encore d'évaluation

- Toyota Production SystemDocument21 pagesToyota Production SystemSanjeev88% (8)

- Reducing Production Cost Whilst Increasing Efficiency With Toyota Production SystemDocument31 pagesReducing Production Cost Whilst Increasing Efficiency With Toyota Production Systemspitraberg98% (44)

- Introduction To WeldingDocument8 pagesIntroduction To WeldingsigmasundarPas encore d'évaluation

- Developing Delivering: Locally. GloballyDocument21 pagesDeveloping Delivering: Locally. GloballysigmasundarPas encore d'évaluation

- MMZG 522 Total Quality Management: Rajiv Gupta BITS Pilani August 2014Document48 pagesMMZG 522 Total Quality Management: Rajiv Gupta BITS Pilani August 2014sigmasundarPas encore d'évaluation

- TPM Score Criteria WorksheetDocument2 pagesTPM Score Criteria WorksheetsigmasundarPas encore d'évaluation

- Downtime Analysis: SER 076 Issue2Document3 pagesDowntime Analysis: SER 076 Issue2sigmasundarPas encore d'évaluation

- Regcorr 5Document20 pagesRegcorr 5sigmasundarPas encore d'évaluation

- Section 1: Make Allowances For ItDocument28 pagesSection 1: Make Allowances For ItsigmasundarPas encore d'évaluation

- Process Capability Overview-TamilDocument2 pagesProcess Capability Overview-TamilsigmasundarPas encore d'évaluation

- Industrial Statistics (2Ws02) : TeachersDocument3 pagesIndustrial Statistics (2Ws02) : TeacherssigmasundarPas encore d'évaluation

- Graduate Lectures and Problems in Quality Control and Engineering Statistics: Theory and MethodsDocument4 pagesGraduate Lectures and Problems in Quality Control and Engineering Statistics: Theory and MethodssigmasundarPas encore d'évaluation

- Quantitative Quality Management Through Defect Prediction and Statistical Process ControlDocument6 pagesQuantitative Quality Management Through Defect Prediction and Statistical Process ControlsigmasundarPas encore d'évaluation

- ISE 542 Production Planning and Control: Due Date: March 2, SundayDocument2 pagesISE 542 Production Planning and Control: Due Date: March 2, SundaysigmasundarPas encore d'évaluation

- ExergyDocument64 pagesExergyAndree RosalesPas encore d'évaluation

- Schedule: STSCI 5010 STSCI 5010Document1 pageSchedule: STSCI 5010 STSCI 5010sqrrlPas encore d'évaluation

- Data 3Document1 pageData 3mahendra.8.giarPas encore d'évaluation

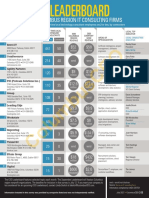

- Columbus CEO Leaderboard - IT Consulting FirmsDocument1 pageColumbus CEO Leaderboard - IT Consulting FirmsDispatch MagazinesPas encore d'évaluation

- ISTQB CTFL-AT Sample-Exam-Answers v1.3Document25 pagesISTQB CTFL-AT Sample-Exam-Answers v1.3j65wfePas encore d'évaluation

- Analisis Kualitas Lulusan Program Studi Teknik Industri Terhadap Kepuasan Pengguna Menggunakan Metode Servqual PDFDocument8 pagesAnalisis Kualitas Lulusan Program Studi Teknik Industri Terhadap Kepuasan Pengguna Menggunakan Metode Servqual PDFAndri ApriansahPas encore d'évaluation

- Introduction To Systems Analysis and DesignDocument50 pagesIntroduction To Systems Analysis and DesignafzhussainPas encore d'évaluation

- The Description Logic Handbook Theory, Implementation and ApplicationsDocument6 pagesThe Description Logic Handbook Theory, Implementation and ApplicationsAnuj MorePas encore d'évaluation

- Robotic Control Using Fuzzy Logic - Seminar Report, PPT, PDF For ElectricalDocument4 pagesRobotic Control Using Fuzzy Logic - Seminar Report, PPT, PDF For Electricalمعراج الرحمانPas encore d'évaluation

- CS 1351 Artificial Intelligence 1Document5 pagesCS 1351 Artificial Intelligence 1Mary JansiPas encore d'évaluation

- SAFe Foundations (v4.0.6)Document33 pagesSAFe Foundations (v4.0.6)PoltakJeffersonPandianganPas encore d'évaluation

- Software Testing Materials PDFDocument160 pagesSoftware Testing Materials PDFKshitij PatilPas encore d'évaluation

- Summary of Theory CH 13 - Week 12Document5 pagesSummary of Theory CH 13 - Week 12Salsa ArdilaPas encore d'évaluation

- 1 Introduction To Machine LearningDocument20 pages1 Introduction To Machine LearningRajvir SinghPas encore d'évaluation

- Assignment 03Document2 pagesAssignment 03Ng KeithPas encore d'évaluation

- Sysml PapyrusDocument6 pagesSysml PapyrusDuygu ErsolPas encore d'évaluation

- Important Instructions To Examiners:: (Any 4 Categories: 1 Mark Per Category)Document26 pagesImportant Instructions To Examiners:: (Any 4 Categories: 1 Mark Per Category)Prathmesh GuravPas encore d'évaluation

- Gentopia: A Platform For Collaborative and Customizable ALMsDocument6 pagesGentopia: A Platform For Collaborative and Customizable ALMsMy SocialPas encore d'évaluation

- SQA AssignmentDocument15 pagesSQA Assignmentshawal aliPas encore d'évaluation

- Step by Step - Guide - Line - UAT - ERPDocument4 pagesStep by Step - Guide - Line - UAT - ERPHtun Lin100% (1)

- 基于递归神经网络的语音识别快速解码算法Document8 pages基于递归神经网络的语音识别快速解码算法wei fengPas encore d'évaluation

- V Model SE PDFDocument38 pagesV Model SE PDFduy nguyễn lê thếPas encore d'évaluation

- Unit 15 - Week 11: Assignment 11Document4 pagesUnit 15 - Week 11: Assignment 11Debraj ChatterjeePas encore d'évaluation

- Diagnosis of Coal Scraper Conveyor Based On Fuzzy FaultDocument4 pagesDiagnosis of Coal Scraper Conveyor Based On Fuzzy FaulthieuhuechPas encore d'évaluation

- Integrating Machine Learning and Optimization To Boost Decision Making Ferdinando FiorettoDocument8 pagesIntegrating Machine Learning and Optimization To Boost Decision Making Ferdinando FiorettoRafik CherniPas encore d'évaluation

- Syllabus - System Analysis and DesignDocument4 pagesSyllabus - System Analysis and Designkriz anthony zuniega100% (1)

- Business Intelligence NotesDocument88 pagesBusiness Intelligence NotesManjit SinghPas encore d'évaluation

- CPM Pert ExampleDocument22 pagesCPM Pert ExampleRoyPas encore d'évaluation

- Lectura 2ptoextraDocument6 pagesLectura 2ptoextraCarmen Angelina Garcia CerrudPas encore d'évaluation

- Operations Management - AssignmentDocument6 pagesOperations Management - AssignmentPrashant ThakarePas encore d'évaluation