Académique Documents

Professionnel Documents

Culture Documents

VP44 Electronic Inj Pump2

Transféré par

Elmer OngDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

VP44 Electronic Inj Pump2

Transféré par

Elmer OngDroits d'auteur :

Formats disponibles

VP44 Electronic Inj Pump

DodgeRam.org > Main > Diesel Index > ISB 24 Valve - VP44 General Information

VP44 Injector Pump System

Visit Geno's Garage

for Truck accessories.

The VP44 injection pump was introduced on the Cummins ISB as a stop gap measure to meet 1998 emissions

standards before a common rail fuel system was ready for production. For Dodge Ram pickups, the ISB engine was

used in all trucks built after January 1, 1998. A common rail system is being road tested now, and reliable rumors say

the the VP44 will be replaced by a common rail in 2003 models. For those with 1998-2002 Rams, here are some

details about the VP44 pump.

To meet environmental regulations for a variety of engine applications, Cummins designed an ECU to which they

could download different engine control programs without making any physical changes to the engine. This electronic

engine control unit (ECU) is installed in a sealed box that is mounted directly to the cylinder block of the engine. The

ECU communicates with the VP44 fuel injection pump through a high-speed 2-way CAN-BUS data-link.

There is no direct connection from the throttle to the injector pump. Inputs from engine sensors and the throttle

position are used by the ECU to determine how much fuel is injected, and when. The ECU uses sensor and throttle

position inputs to compute the appropriate "load", then the controller obtains the fueling rate information from look-up

tables, sometimes called maps, stored in ROM. From these a value is determined that represents the desired amount of

fuel to be delivered to the engine. This value is then communicated to the injector pump.

The VP44 injection pump uses a set of mechanical plungers to pressurize the fuel, and a mechanical distributor to

route the fuel to the correct injector. An electronic controller converts the fuel information sent from the ECU into

mechanical control of the fuel delivery by opening and closing fuel spill ports inside the pump mechanism. The pump

returns information to the ECU regarding its current operating state.

Bosch VP44 Injector Pump Cummins ECU

General Information from the ZEXEL site:

The VP44 systemwas developed to meet emission

standards and reduce fuel consumption. VP44 is a direct-

injection type fuel-injection system for small- to medium-

size diesel engines. To generate the high injection pressures

file:///Z:/Manuals/injection%20pumps/Vp44.htm[8/13/2010 12:41:23 AM]

VP44 Electronic Inj Pump

needed for direct-injection, The VP44 uses an internal cam

disk and radially opposed plungers to pressurize the fuel

from two directions.

The VP44 controls the injection rate and injection timing

using two electromagnetic valves. Also, the electronic

control unit is divided into two, with a compact control unit

mounted directly on the pump and a larger Engine Control

Module mounted on the engine block.

Fuel System - General Information from Cummins

The VP44 is an electronic fuel injection pump manufactured by Bosch®, that can vary fueling and injection timing

based on input from the electronic control module (ECM). This pump has its own electronic control unit, the fuel

pump control module (FPCM), which contains fueling, timing, and diagnostic data. The fuel pump control module

(FPCM) communicates with the engine controller (ECM) to obtain information on desired fueling and timing. The fuel

pump control module (FPCM) responds to the ECM's commands by consulting the fueling data and timing in its

memory and actuating the fueling and timing solenoids.

A fuel temperature sensor is located inside the VP44 pump to compensate for changes in the temperature of the fuel.

The pump also contains a speed sensor (IAT) that gives the fuel pump control module (FPCM) data on the position and

speed of the pump shaft. A reference pulse that marks top dead center (TDC) of cylinder No. 1 is sent from the ECM

once every pump revolution. By comparing this reference pulse from the ECM to the position signal from the speed

sensor (IAT), the fuel pump control module (FPCM) can reference the pump's position in relation to the engine's

position. This allows the fuel pump control module (FPCM) to adjust the pump timing to compensate for minor

position differences between the fuel pump shaft and the engine camshaft. If the difference between the pump position

and engine position becomes too great, then a fault will be logged in the fuel pump control module (FPCM).

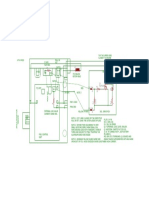

In addition to the

engine position

reference pulse, the

fuel pump control

module (FPCM) also

receives timing and

fueling commands

from the ECM. The

fuel pump control

module (FPCM)

controls the timing and

fueling through two

solenoids located in the

pump. The timing

solenoid controls the

position of a cam ring

inside the pump by

varying internal

transfer pump pressure.

The cam ring has

evenly spaced lobes

around its inner diameter. The pumping plungers ride on rollers that rotate inside this cam ring. The rollers follow the

inner diameter of the cam ring and push the pumping plungers inward whenever a cam lobe is encountered, thus

file:///Z:/Manuals/injection%20pumps/Vp44.htm[8/13/2010 12:41:23 AM]

VP44 Electronic Inj Pump

building injection pressure. By rotating the cam ring with the timing solenoid, the fuel pump control module (FPCM) is

able to advance and retard the injection timing by making the rollers contact the cam lobes either earlier or later.

The second solenoid in the pump is used to meter fuel to the injectors. The solenoid opens the fuel metering valve to

allow fuel from the supply pump to flow into the pumping chamber. Once the pumping chamber is charged with fuel,

the solenoid valve closes. This traps the fuel in the chamber and allows injection pressure to build. The fuel is routed

to the correct injector by the pump distributor. The distribution port on the distributor aligns with one of the six outlet

ports to distribute fuel to a given injector. Once the desired amount of fuel has been injected, the solenoid valve opens,

causing the pressure in the pumping chamber to bleed down, which ends injection. The cycle then begins again for the

next cylinder.

The fuel injection pump (VP44) is an electronic rotary distributor pump. The pump performs four basic functions:

1. Producing the high fuel pressure required for injection

2. Metering the exact amount of fuel for each injection cycle

3. Distributing the high-pressure, metered fuel to each cylinder at the precise time

4. Varying the timing relative to engine speed.

A cam ring with three plungers, a rotor, and an electronically controlled fueling solenoid valve is used to develop

and distribute the high pressure required for injection.

A worn or damaged internal transfer pump, plunger, or fueling valve can affect the pressure and the amount of fuel

injected, thus reducing the power from the engine. Generally, if the fuel-injection pump is injecting fuel from one

outlet, it will deliver from all outlets.

VP44 Timing Principles

Timing in the VP44 is controlled by an internal timing piston coupled to a cam ring inside the pump. The timing

piston is moved by fuel pressure. The amount of fuel pressure in the timing piston assembly housing is controlled by

an internal transfer pump and a pulsating timing solenoid valve. As the pump speed increases, the fuel pressure to the

timing piston assembly also increases.

Based on the inputs from the fuel pump control module (FPCM), the timing solenoid valve pulses to vary the

pressure to move the timing piston, which results in the cam ring moving to the desired position to achieve the

commanded timing. The more pressure created by the internal transfer pump and timing solenoid valve, the more the

timing will advance; therefore, timing range capability is increased at higher rpms.

The ISB engine is equipped with an electric-powered lift pump.

Fuel flow begins as the fuel lift pump pulls fuel from the supply

tank. This electric lift pump supplies low-pressure fuel (10 to 12

psi) to the filter head, through the filter, and then to the electronic

distributor injection pump.

The electronic distributor pump builds the high injection

pressures required for combustion and routes the fuel through

individual high-pressure fuel lines to each injector.

When the high-pressure fuel reaches the injector, the pressure

lifts the needle valve against the spring tension to let the fuel enter

the combustion chamber.

Any leakage past the needle valve enters the fuel drain manifold

in the cylinder head. The fuel in the manifold exits at the rear of

the cylinder head and is routed to the fuel tank. The fuel that is

returned from the fuel injection pump is also routed back to the

fuel tank.

What other engines use the VP44 Injection Pump?

file:///Z:/Manuals/injection%20pumps/Vp44.htm[8/13/2010 12:41:23 AM]

VP44 Electronic Inj Pump

BMW 320d

Ford Focus td

Opel dti

Saab

VAG V6 tdi

John Deere 6.8L diesel

Case tractors and construction equipment

Subject: [TD] VP44 & P7100

Date: Fri, 11 Jun 1999 08:19:36 -0700

From: Josh Berman j.e.berman@metc.cummins.com

To: TurboDiesel, cummins

> I was told the rotary pump on the ISB's does not have near the capacity of the

> older in line pumps. One cylinder versus six. Just does not have the ability

> to move as much fuel apparently.

The VP44 that we use actually has 3 pistons arranged in a radial pattern (think of the "star" logo on a line of German

luxury cars :-). BOSCH makes VP44s with different #'s of pistons, depending on how many cylinders the engine has.

The pistons ride inside a cam ring (think of a doughnut with a lumpy hole). As the pump shaft rotates, the pistons

rotate inside the cam ring, and the ramps on the cam ring press the pistons inward, pressurizing the fuel (which is then

directed through the fueling solenoid and distributor which sends the fuel to the correct cylinder). The P7100 can pump

a lot of fuel: it went to 230 HP on the B-Series automotive engine, 325 on the C-Series automotive engine, even higher

on the marine versions. Currently, the highest rating we sell the ISB (and thus the VP44) at is 275 HP. That rating is

restricted to RVs and fire trucks. I don't think the VP44 is max'd out at 275 HP, but I honestly don't know what its

limit is. -Josh B.

TOP HOME

file:///Z:/Manuals/injection%20pumps/Vp44.htm[8/13/2010 12:41:23 AM]

Vous aimerez peut-être aussi

- Bosch CP3 OperationDocument6 pagesBosch CP3 OperationGianfranco Danna Gálvez100% (2)

- Vp44 Fuel System IssuesDocument9 pagesVp44 Fuel System IssuesBoryana Tomova100% (1)

- Vp44 Pump Detail SchematicDocument7 pagesVp44 Pump Detail Schematicvinod7mungroo75% (8)

- Diesel Common Rail Injection Electronic Components ExplainedD'EverandDiesel Common Rail Injection Electronic Components ExplainedÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- Troubleshooting VP30 Fuel Injection PumpDocument7 pagesTroubleshooting VP30 Fuel Injection PumpDat100% (3)

- C Rail Bosch Textbook HMCDocument41 pagesC Rail Bosch Textbook HMCThuyết Rau Má100% (3)

- Service Manual: Pub. No. EE14E-11130Document39 pagesService Manual: Pub. No. EE14E-11130Marcelo Diesel81% (16)

- WHAT TELLS BOSCH VP 30/44 "BRAINDocument8 pagesWHAT TELLS BOSCH VP 30/44 "BRAINDonald Harris100% (12)

- Diy VP44 Repair PDFDocument1 pageDiy VP44 Repair PDFOvidio Rios67% (3)

- 0302 Delphi CRDi FinalDocument88 pages0302 Delphi CRDi Finalgabrielportres100% (6)

- VP44 Service ManualDocument39 pagesVP44 Service Manualhelder100% (5)

- Study a Fuel Injection Pump and Injector by DismantlingDocument4 pagesStudy a Fuel Injection Pump and Injector by Dismantlingdhirendra singh50% (2)

- Bosch VP44 Info & InstallationDocument4 pagesBosch VP44 Info & InstallationbenjiPas encore d'évaluation

- TF Bosch VP44 Fuel Pump (Ver1)Document43 pagesTF Bosch VP44 Fuel Pump (Ver1)Carlos A Romero92% (37)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualD'EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualÉvaluation : 2.5 sur 5 étoiles2.5/5 (2)

- Bosch Injector Part CatalogDocument36 pagesBosch Injector Part Catalog金盧德100% (1)

- EDC Pump Testing ProceduresDocument8 pagesEDC Pump Testing ProceduresCadet Raparivo100% (7)

- Mechanics of A Diesel Fuel Injection System PDFDocument8 pagesMechanics of A Diesel Fuel Injection System PDFguswerino24Pas encore d'évaluation

- Denso CR - Hp2 NissanDocument31 pagesDenso CR - Hp2 NissanMarcelo Diesel86% (7)

- VP44 Inspection PointsDocument32 pagesVP44 Inspection PointsJacq Cancontrol100% (18)

- Bosch Pressure SensorsDocument5 pagesBosch Pressure SensorsCatalin NiculescuPas encore d'évaluation

- Diagnose The Vp44 Fuel System - Diesel BombersDocument10 pagesDiagnose The Vp44 Fuel System - Diesel Bombersesyjam50% (2)

- Repair Guide For Denso Common Rail Injector RepairDocument22 pagesRepair Guide For Denso Common Rail Injector Repairrafael100% (1)

- Expert Insights on Bosch Diesel Fuel Injection PumpsDocument134 pagesExpert Insights on Bosch Diesel Fuel Injection Pumpsivcretni100% (3)

- Common Rail Direct Injection System ExplainedDocument13 pagesCommon Rail Direct Injection System ExplainedDejan Matic67% (3)

- Denso Ecd-VDocument118 pagesDenso Ecd-VIongornistu100% (5)

- Repair VP 44 PumpDocument11 pagesRepair VP 44 Pumpmuhamed95% (20)

- Bosch Pump Rotari PDFDocument41 pagesBosch Pump Rotari PDFDiat BenhillPas encore d'évaluation

- 57 Bosch Pumpe VP 44 Psg5Document2 pages57 Bosch Pumpe VP 44 Psg5dra6an100% (1)

- Denso Fuel Injection Pump HP3 5 - L200 - 2.5DI-D MitsubishiDocument51 pagesDenso Fuel Injection Pump HP3 5 - L200 - 2.5DI-D MitsubishiJohnny Chia90% (10)

- Diy Vp44 RepairDocument1 pageDiy Vp44 RepairOvidio RiosPas encore d'évaluation

- Control Unit 118 Pin NISSAN Bosch VP 44 Pump InstallationDocument3 pagesControl Unit 118 Pin NISSAN Bosch VP 44 Pump InstallationAlberto Abarca100% (2)

- Heui PPT 9-2010Document59 pagesHeui PPT 9-2010Alexis Luco Rojo100% (4)

- Bomba Vp44Document30 pagesBomba Vp44jimmy_huamancayo67% (6)

- Common Rail Diesel Injection (Done)Document14 pagesCommon Rail Diesel Injection (Done)Dejan MaticPas encore d'évaluation

- Diagnose and Repair Compression Ignition Engine Management SystemsDocument60 pagesDiagnose and Repair Compression Ignition Engine Management Systemslittleprayerbyjacks100% (1)

- Common Rail Diesel Injection System ExplainedDocument13 pagesCommon Rail Diesel Injection System ExplainedDejan Matic100% (1)

- Common Rail Injector Test PointsDocument5 pagesCommon Rail Injector Test Pointsreza jangiPas encore d'évaluation

- Denso CR - HP3 NissanDocument14 pagesDenso CR - HP3 NissanHerbert Sanchez75% (4)

- NEC Article 250Document42 pagesNEC Article 250unknown_3100% (1)

- Delphi Katalog Duesen PDFDocument373 pagesDelphi Katalog Duesen PDFDavid Lincoln83% (6)

- THKDocument1 901 pagesTHKapi-26356646Pas encore d'évaluation

- Injection PumpDocument3 pagesInjection PumpAbdallah MansourPas encore d'évaluation

- Oem Components For VRZ Type Injection PumpsDocument3 pagesOem Components For VRZ Type Injection PumpsMoaed KanbarPas encore d'évaluation

- VP44 Service Manualpdf PDF FreeDocument39 pagesVP44 Service Manualpdf PDF FreeTin Doan dinhPas encore d'évaluation

- Installation & Timing of the VP44 Fuel Injection PumpDocument6 pagesInstallation & Timing of the VP44 Fuel Injection PumpAlberto AbarcaPas encore d'évaluation

- Vp30 ChecksDocument4 pagesVp30 ChecksSaid TouhamiPas encore d'évaluation

- NGD 0605 S enDocument154 pagesNGD 0605 S enJuan José Rodriguez100% (15)

- Fit For The Future:: Everything For Diesel ServiceDocument68 pagesFit For The Future:: Everything For Diesel Servicemihai37100% (2)

- Sip TrainingDocument96 pagesSip Trainingronics123Pas encore d'évaluation

- Dicor EngineDocument8 pagesDicor Enginepkhurana22Pas encore d'évaluation

- Facilities Assignment 1-2-2015Document2 pagesFacilities Assignment 1-2-2015Xnort G. Xwest0% (1)

- HeuiDocument54 pagesHeuiCM Inversiones Chile100% (2)

- Bilstein SZ SL Sls 2010Document16 pagesBilstein SZ SL Sls 2010Wimin HungPas encore d'évaluation

- ASTM D 1510 - 02 Carbon Black-Iodine Adsorption NumberDocument7 pagesASTM D 1510 - 02 Carbon Black-Iodine Adsorption Numberalin2005100% (1)

- 2.fuel Inj Compresion IgnitionDocument19 pages2.fuel Inj Compresion IgnitionJo VialPas encore d'évaluation

- Unit II - Electronically Controlled Fuel InjectionDocument38 pagesUnit II - Electronically Controlled Fuel InjectiondrkbalaPas encore d'évaluation

- Gasoline electronic Direct Injection SystemDocument34 pagesGasoline electronic Direct Injection Systemloganathanpalani100% (1)

- Gasoline electronic Direct Injection SystemsDocument35 pagesGasoline electronic Direct Injection SystemsatulsemiloPas encore d'évaluation

- Fuel injection systems explainedDocument4 pagesFuel injection systems explainedanon_122284601Pas encore d'évaluation

- 1 Gasoline Electronic Direct Injection System1Document40 pages1 Gasoline Electronic Direct Injection System1EZHILARASAN RPas encore d'évaluation

- bài thầy đứcDocument23 pagesbài thầy đứcnguyenductai.lop93.lhpPas encore d'évaluation

- 1300 Series Electronic Engine Training Notes SummaryDocument40 pages1300 Series Electronic Engine Training Notes SummaryIbra KribaaPas encore d'évaluation

- Saa6d140e-3 Shop ManualDocument18 pagesSaa6d140e-3 Shop Manualjannievanstaden783Pas encore d'évaluation

- SSP 020 Common - RailDocument30 pagesSSP 020 Common - Railvenkateshyadav2116Pas encore d'évaluation

- Electronic Fuel Injection System: Damian CastelinoDocument23 pagesElectronic Fuel Injection System: Damian CastelinoRamjiPas encore d'évaluation

- General 04 Fixed Flow Pump To Three TanksDocument13 pagesGeneral 04 Fixed Flow Pump To Three TanksjpalauguillemPas encore d'évaluation

- Scramjet EngineDocument2 pagesScramjet EngineSãröj ShâhPas encore d'évaluation

- SUBstation Equipmens TLDocument12 pagesSUBstation Equipmens TLJecer Casipong NuruddinPas encore d'évaluation

- Database Classification TypesDocument10 pagesDatabase Classification TypesBhiea Mische MatilacPas encore d'évaluation

- Sem 2Document128 pagesSem 2Agustin A.Pas encore d'évaluation

- Pumps - IntroductionDocument31 pagesPumps - IntroductionSuresh Thangarajan100% (1)

- Classification of Differential Equations For Finding Their SolutionsDocument2 pagesClassification of Differential Equations For Finding Their SolutionsakhileshPas encore d'évaluation

- Camshaft Test SheetDocument4 pagesCamshaft Test SheetsughieantoPas encore d'évaluation

- Toyo ML210 thread cutting gear assembly drawingsDocument12 pagesToyo ML210 thread cutting gear assembly drawingsiril anwarPas encore d'évaluation

- Linear Thermal Expansion of Solid Materials With A Vitreous Silica DilatometerDocument7 pagesLinear Thermal Expansion of Solid Materials With A Vitreous Silica Dilatometerluis_may22Pas encore d'évaluation

- MSYS-1 0 11-ChangesDocument3 pagesMSYS-1 0 11-ChangesCyril BerthelotPas encore d'évaluation

- 2.6 Rational Functions Asymptotes TutorialDocument30 pages2.6 Rational Functions Asymptotes TutorialAljun Aldava BadePas encore d'évaluation

- Power Cable Installation ManualDocument50 pagesPower Cable Installation ManualAnn DodsonPas encore d'évaluation

- Notes Measures of Variation Range and Interquartile RangeDocument11 pagesNotes Measures of Variation Range and Interquartile RangedburrisPas encore d'évaluation

- Instrument Resume OIL and GAS.Document3 pagesInstrument Resume OIL and GAS.RTI PLACEMENT CELLPas encore d'évaluation

- Green Synthesis of Zinc Oxide Nanoparticles: Elizabeth Varghese and Mary GeorgeDocument8 pagesGreen Synthesis of Zinc Oxide Nanoparticles: Elizabeth Varghese and Mary GeorgesstephonrenatoPas encore d'évaluation

- SERVICE MANUAL CRAWLER EXCAVATOR R210LC-7Document1 pageSERVICE MANUAL CRAWLER EXCAVATOR R210LC-7DmitryPas encore d'évaluation

- Reliability EngineeringDocument9 pagesReliability Engineeringnvaradharajan1971Pas encore d'évaluation

- 08 Candelaria Punta Del Cobre IOCG Deposits PDFDocument27 pages08 Candelaria Punta Del Cobre IOCG Deposits PDFDiego Morales DíazPas encore d'évaluation

- Indian Standards List As On Jan2009Document216 pagesIndian Standards List As On Jan2009Vasudeva Pavan VemuriPas encore d'évaluation

- Mathematics of Finance: Simple and Compound Interest FormulasDocument11 pagesMathematics of Finance: Simple and Compound Interest FormulasAshekin MahadiPas encore d'évaluation

- Climate Change: The Fork at The End of NowDocument28 pagesClimate Change: The Fork at The End of NowMomentum Press100% (1)

- VLSI Design: Introduction & Motivation Introduction & MotivationDocument33 pagesVLSI Design: Introduction & Motivation Introduction & MotivationPriyanka SharmaPas encore d'évaluation

- M.E. Comm. SystemsDocument105 pagesM.E. Comm. SystemsShobana SPas encore d'évaluation