Académique Documents

Professionnel Documents

Culture Documents

Chock Fast

Transféré par

redsilverDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chock Fast

Transféré par

redsilverDroits d'auteur :

Formats disponibles

MARINE

EPOXY CHOCKFAST ® Orange

SYSTEMS

The Premier Chocking Compound

Technical Bulletin # 659F

Product Description

CHOCKFAST ORANGE (PR-610TCF) is a specially formulated 100% solids, two component inert filled casting compound

developed for use as a chocking or grouting material. CHOCKFAST is designed to withstand severe marine and industrial

environments involving a high degree of both physical and thermal shock. The compound is non-shrinking and has very high

impact and compressive strength.

Years of successful in-service experience have shown the use of PR-610TCF to be a far superior yet less expensive method of

establishing and permanently retaining precise equipment alignment under extreme conditions.

PR-610TCF is approved or accepted for its intended marine use by American Bureau of Shipping, Lloyd's Register, Bureau

Veritas, Det Norske Veritas, Germanischer Lloyd and most other major regulatory agencies worldwide.

Use & Benefits

CHOCKFAST ORANGE was developed as a chocking or grouting compound for use under marine main propulsion machinery in

depths of ½” to 4” (12mm to 100mm). The compound is used under diesel and gas engines, reduction gears, generators,

compressors, pumps, bearing blocks, crane rails and numerous other applications.

PR-610TCF requires no special tools or special skills as does chocking with steel. When cast, CHOCKFAST ORANGE flows

readily into the chock area filling voids and conforming to all irregularities. This eliminates the machining of base plates or

foundations for a perfectly fitted chock.

Design Considerations

For design considerations and application details please request Bulletin No. 692 for Marine and 642 for Industrial applications or

contact ITW Polymer Technologies' Engineering Services Department.

Application Instructions

Using open-cell foam damming material, build a dam

around 3 sides of the area to be chocked. Wrap the

anchor bolt with tape so the Chockfast will not stick to it,

Install a metal dam along the front of the chock

approximately ½” to ¾” (12mm to 18mm) from the

mounting flange. Seal the flange with strip caulking, or

Silicone to prevent leaks. Install foam in the overpour

area to the top of the mounting flange to prevent the

Chockfast from leaking.

Mix the Chockfast as directed on the can. See technical

Bulletin #665 to determine the proper amount of

hardener to use. Slowly pour the Chockfast into one end

of the overpour area and allow it to flow across and

under the mounting flange.

ITW POLYMER TECHNOLOGIES

130 Commerce Drive Montgomeryville, PA 18936 215-855-8450 Fax 215-855-4688

www.chockfast.com

Chockfast Orange

Bulletin No. 659F, Page 2

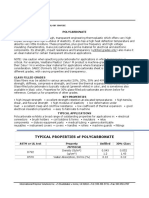

Physical Properties

COMPRESSIVE STRENGTH 19,000 psi (1,336 kg/cm2) ASTM D-695MOD

COMPRESSIVE MODULUS OF ELASTICITY 533,000 psi (37,482 kg/cm2) ASTM D-695

LINEAR SHRINKAGE 0.0002 in/in ASTM D-2566

(0.0002 mm/mm) or 0.02%

COEFFICIENT OF LINEAR THERMAL 17.1 x 10-6/F° @ 32°F to 140°F (30.8 x 10- ASTM D-696

6

EXPANSION /C@0°C to 60°C)

FLEXURAL STRENGTH 7,615 psi (575 kg/cm2) ASTM C-580

5 2

FLEXURAL MODULUS OF ELASTICITY 8.6 x 10 psi (72,880 kg/cm ) ASTM C-580

TENSILE STRENGTH 4,970 psi (349 kg/cm2) ASTM D-638

SHEAR STRENGTH 5,400 psi (380 kg/cm2) FED-STD-406

(Method 1041)

IZOD IMPACT STRENGTH 6 in.lbs/in. (0.27 N.m/cm) ASTM D-256

SHOCK RESISTANCE Pass MIL-S-901C (Navy) High Impact

Shock Test, Grade A, Type A,Class 1

THERMAL SHOCK Pass -0F to 212F (18C to ASTM D-746

100C)

VIBRATION Meets MIL-STD-167

FIRE RESISTANCE Self extinguishing ASTM D-635

SPECIFIC GRAVITY 1.58

BARCOL HARDNESS 40+ fully cured - 35 minimum ASTM D-2583

Product Information

UNIT COVERAGE Small Unit: 120 cu.in (1,966 cc)

Large Unit: 260 cu.in (4,261 cc)

APPLICATION TEMPERATURE 55oF (13oC) to 95oF (35oC)

PACKAGING per Unit Small Unit: Resin (NH) - 7.2 lbs. (3.3 kg), 0.53 gal (2 L) in a 1 gal

can, Hardener (H) –0.5 lbs. (0.23 kg), 7.7 oz (0.23 L) in an 8 oz

plastic bottle

Large Unit: Resin (NH) - 14.4 lbs. (6.5 kg), 0.53 gal (2 L) in a 1 gal

can, Hardener (H) –0.99 lbs. (0.45 kg), 15.4 oz (0.23 L) in an 16 oz

plastic bottle

UNIT SHIPPING WEIGHT Small Unit: 9 lbs (4 kg) Large Unit: 17 lbs. (7.7 kg)

CURE TIME (approximate) 48 hours @ 60F (15C) 24 hours @ 70F (21C)

36 hours @ 65F (18C) 18 hours @ 80°F (26°C)

POT LIFE 30 min. @ 70F (21C)

SHELF LIFE 2 years

CLEAN UP IMPAX IXT-59 or similar epoxy solvent

Reference For design considerations and application details please request Bulletin

No. 692, 642 or contact ITW Polymer Technologies' Engineering Services

Department.

Date 08/2005

General: Every reasonable effort is made to insure the technical Suggestions concerning the use of products are not warranties. The

information and recommendations on these data pages are true and purchaser assumes the responsibility for determining suitability of

accurate to the best of our knowledge at the date of issuance. However, products and appropriate use. ITW Polymer Technologies’ sole

this information is subject to change without notice. Prior versions of this liability, for breach of warranty, negligence or otherwise, shall be the

publication are invalid with the release of this version. Products and replacement of product or refund of the purchase price, at ITW

information are intended for use by qualified applicators that have the Polymer Technologies’ election. Under no circumstances shall ITW

required background, technical knowledge, and equipment to perform said Polymer Technologies be liable for any indirect, incidental or

tasks in a satisfactory manner. Consult your local distributor for product consequential damages.

availability, additional product information, and technical support. Modification of Warranty: No distributor or sales representative has

Warranty: ITW Polymer Technologies, a division of Illinois Tool Works the authority to change the above provisions. No change in the above

Inc., warrants that its products meet their printed specifications. This is provisions will be valid unless in writing and signed by an officer or

the sole warranty. This warranty expires one year after product shipment. the Technical Director of ITW Polymer Technologies. No term of any

Warranty Claims: If any product fails to meet the above, ITW Polymer purchase order shall serve to modify any provision of this document.

Technologies will, at its option, either replace the product or refund the Mediation and Arbitration: If any dispute arises relating to products

purchase price. ITW Polymer Technologies will have no other liability for or product warranties, either the purchaser or ITW Polymer

breach of warranty, negligence, or otherwise. All warranty claims must be Technologies may a) initiate mediation under the then current Center

made in writing within one year of the date of shipment. No other claims for Public Resources (CPR) Model Procedure for Mediation of

will be considered. Business Disputes, or b) initiate a non-binding arbitration under the

Disclaimer: ITW Polymer Technologies makes no other warranty, rules of the American Arbitration Association for the resolution of

expressed or implied, and specifically disclaims any warranty of commercial disputes.

merchantability or fitness for a particular purpose.

Vous aimerez peut-être aussi

- 04 HT - Chockfast OrangeDocument2 pages04 HT - Chockfast OrangeGESTION Y CONTROL DE PROYECTOS IngeminPas encore d'évaluation

- Chockfast Orange PDFDocument2 pagesChockfast Orange PDFKaharul AfandiPas encore d'évaluation

- Product: Chocking & Anchor Bolt Setting CompoundDocument2 pagesProduct: Chocking & Anchor Bolt Setting CompoundFajri AnnamlaPas encore d'évaluation

- Prod CatalianDocument87 pagesProd Cataliananon_591741392Pas encore d'évaluation

- Chockfast Orange DataDocument2 pagesChockfast Orange DataDilnesa EjiguPas encore d'évaluation

- Data Sheet Mortero (Grout) Epóxico Chockfast Red PDFDocument2 pagesData Sheet Mortero (Grout) Epóxico Chockfast Red PDFDaniel Puello RodeloPas encore d'évaluation

- Datasheet Chockfast RedDocument2 pagesDatasheet Chockfast RedAlexander0% (1)

- 3H Bio Ultimax 1500 Dielectric Hyd Fluid ISO 22 32 46 68Document2 pages3H Bio Ultimax 1500 Dielectric Hyd Fluid ISO 22 32 46 68Massimiliano VolaPas encore d'évaluation

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzePas encore d'évaluation

- Macropoxy 646 SEDocument4 pagesMacropoxy 646 SESleyda MunozPas encore d'évaluation

- Braycote 631 RPDocument2 pagesBraycote 631 RPResistenciaDisidentePas encore d'évaluation

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraPas encore d'évaluation

- Corropipe IIPWDocument2 pagesCorropipe IIPWhuicholePas encore d'évaluation

- VpCI 389Document2 pagesVpCI 389Harshad DholariyaPas encore d'évaluation

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02Pas encore d'évaluation

- Raychem Shrink SleevesDocument12 pagesRaychem Shrink SleevesislamakthamPas encore d'évaluation

- Styrolution PS 1290/1291: General Purpose Polystyrene (GPPS)Document2 pagesStyrolution PS 1290/1291: General Purpose Polystyrene (GPPS)DiegoTierradentroPas encore d'évaluation

- Duraplate Uhs EnglishDocument4 pagesDuraplate Uhs EnglishLuis JaraPas encore d'évaluation

- Carboguard 891 Product Data SheetDocument4 pagesCarboguard 891 Product Data SheetPrakashPas encore d'évaluation

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthPas encore d'évaluation

- 226NDocument2 pages226NUmaibalanPas encore d'évaluation

- Shell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsMiguel ArizaPas encore d'évaluation

- 659E Chockfast OrangeDocument2 pages659E Chockfast OrangedavalgonzalezPas encore d'évaluation

- Dupont Styrofoam Brand Highload 40, 60 and 100 Xps Foam InsulationDocument4 pagesDupont Styrofoam Brand Highload 40, 60 and 100 Xps Foam InsulationAhmed AbdelazizPas encore d'évaluation

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanPas encore d'évaluation

- Shell Gadus S4 OGT Open Gear GreaseDocument2 pagesShell Gadus S4 OGT Open Gear GreaseMuhammad SaputraPas encore d'évaluation

- WD-40 Multi-Use Product: Technical Data SheetDocument3 pagesWD-40 Multi-Use Product: Technical Data SheetKatsukiDaito100% (1)

- Synthetic Gear Oil Data SheetDocument2 pagesSynthetic Gear Oil Data SheetDiegoPas encore d'évaluation

- Five Star Rapid Epoxy GroutDocument2 pagesFive Star Rapid Epoxy GroutJohnprasannaPas encore d'évaluation

- Envirolube XE Extreme TDS 190828 203810Document1 pageEnvirolube XE Extreme TDS 190828 203810Don HowardPas encore d'évaluation

- Hi-Tech Bush SpecsDocument4 pagesHi-Tech Bush SpecsRony MartínezPas encore d'évaluation

- HD6200B/HD6600B High Density Polyethylene Resin Product DescriptionDocument1 pageHD6200B/HD6600B High Density Polyethylene Resin Product DescriptionRizaldi Nur Imani100% (1)

- Premium Zinc-Rich Coating Protects Metal SurfacesDocument2 pagesPremium Zinc-Rich Coating Protects Metal SurfacesJORGE HOLGUINPas encore d'évaluation

- Nukote XT Plus TdsDocument4 pagesNukote XT Plus TdsAnsar AliPas encore d'évaluation

- Acrylic Not Recc For ChlorinatedDocument2 pagesAcrylic Not Recc For ChlorinatedoktavPas encore d'évaluation

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraPas encore d'évaluation

- NATURAL RUBBER LINING TECH DATADocument2 pagesNATURAL RUBBER LINING TECH DATASantosh JayasavalPas encore d'évaluation

- Garlock Gasket Tech Manual GSK3 1 EmpaquetaduraDocument57 pagesGarlock Gasket Tech Manual GSK3 1 EmpaquetaduraJavier AndrésPas encore d'évaluation

- Pds CPD Sikadur55SLV UsDocument2 pagesPds CPD Sikadur55SLV UsMikePas encore d'évaluation

- TDS For Rubber Lining 1056HTDocument2 pagesTDS For Rubber Lining 1056HTYao WangPas encore d'évaluation

- SPECSPEADM5370Document1 pageSPECSPEADM5370nicolas yoris marcogliesePas encore d'évaluation

- Covalence HTLP80Document2 pagesCovalence HTLP80Jèfrì PìnémPas encore d'évaluation

- Bio-Containers - Single Use Frozen Storage Solution - FREEZE-PAK Charter MedicalDocument2 pagesBio-Containers - Single Use Frozen Storage Solution - FREEZE-PAK Charter MedicalCampaign MediaPas encore d'évaluation

- Exceed™ XP 6056ML: Performance PolymerDocument2 pagesExceed™ XP 6056ML: Performance PolymerkjmontilPas encore d'évaluation

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisPas encore d'évaluation

- Exelene Hdpe 5100MDocument1 pageExelene Hdpe 5100MAndres Quiroga JuarezPas encore d'évaluation

- Tyfo SCH-41 Composite: Using Tyfo S EpoxyDocument2 pagesTyfo SCH-41 Composite: Using Tyfo S EpoxyJonAthan LimPas encore d'évaluation

- Polibrid 705: Technical DataDocument2 pagesPolibrid 705: Technical DataSky MoonPas encore d'évaluation

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaPas encore d'évaluation

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMAPas encore d'évaluation

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanPas encore d'évaluation

- EcoShield VpCI 380Document2 pagesEcoShield VpCI 380dalt.guniPas encore d'évaluation

- FS 600 Data SheetDocument1 pageFS 600 Data SheetNguyen Hong67% (3)

- PS 14 Anchor Bolt TolerancesDocument4 pagesPS 14 Anchor Bolt TolerancesjebrijaPas encore d'évaluation

- Chock FastDocument25 pagesChock FastBrajko NikolaPas encore d'évaluation

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaPas encore d'évaluation

- Nukote Har: DescriptionDocument4 pagesNukote Har: DescriptionMarco Dos Santos NevesPas encore d'évaluation

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Geotextiles and Geomembranes HandbookD'EverandGeotextiles and Geomembranes HandbookT.S. IngoldÉvaluation : 5 sur 5 étoiles5/5 (1)

- GD&T StandardDocument100 pagesGD&T StandardsudhirPas encore d'évaluation

- MSC.266 (84) Special Purpose Ships Code 2008Document21 pagesMSC.266 (84) Special Purpose Ships Code 2008anthonyegrayPas encore d'évaluation

- Anti-Corruption, Grievance Redressal and Whistleblower Protection Act, 2010.Document31 pagesAnti-Corruption, Grievance Redressal and Whistleblower Protection Act, 2010.Jayesh BhedaPas encore d'évaluation

- Pro Eng - ModulesDocument2 pagesPro Eng - ModulesredsilverPas encore d'évaluation

- 156 Comandos para Windows XPDocument9 pages156 Comandos para Windows XPleoword100% (10)

- WarshipsDocument9 pagesWarshipsredsilverPas encore d'évaluation

- Pro E Wildfire Platform SupportDocument9 pagesPro E Wildfire Platform SupportredsilverPas encore d'évaluation

- Star Party EtiquetteDocument5 pagesStar Party EtiquetteredsilverPas encore d'évaluation

- Sheet Metal HintsDocument26 pagesSheet Metal Hintsneeraj kumarPas encore d'évaluation

- Czarina T. Malvar v. Kraft Food Philippines, Inc.Document1 pageCzarina T. Malvar v. Kraft Food Philippines, Inc.MarrielDeTorresPas encore d'évaluation

- St. Lukes Vs TorresDocument2 pagesSt. Lukes Vs TorresLorenzo Marvin Reyes100% (1)

- Toll Manufacturing Transactions Trade Secret and IDocument7 pagesToll Manufacturing Transactions Trade Secret and IClyde Louis Oliver-LinagPas encore d'évaluation

- SEAFDEC Ruling Reaffirms International Agency's Immunity from Labor CasesDocument3 pagesSEAFDEC Ruling Reaffirms International Agency's Immunity from Labor CasesJennyPas encore d'évaluation

- Labor Relations Cases, Philippine JurisprudenceDocument4 pagesLabor Relations Cases, Philippine JurisprudenceSummerBridgePas encore d'évaluation

- ArbitralityDocument4 pagesArbitralityDonaPas encore d'évaluation

- HSBC Labor Union vs HSBC labor disputeDocument13 pagesHSBC Labor Union vs HSBC labor disputeSophiaFrancescaEspinosaPas encore d'évaluation

- JurisdictionDocument46 pagesJurisdictionAdv Sanjit Kumar NaskarPas encore d'évaluation

- 51.producers Bank of The Philippines vs. NLRCDocument3 pages51.producers Bank of The Philippines vs. NLRCnathPas encore d'évaluation

- Pag-Asa Steel Works wage increase disputeDocument20 pagesPag-Asa Steel Works wage increase disputeammePas encore d'évaluation

- 27 Principles of Negotiating: Basics To Keep in MindDocument3 pages27 Principles of Negotiating: Basics To Keep in MindTarlan FisherPas encore d'évaluation

- Bedan Review April 2016Document280 pagesBedan Review April 2016Pan CorreoPas encore d'évaluation

- Court examines power of courts to entertain Section 9 applications after constitution of arbitral tribunalDocument38 pagesCourt examines power of courts to entertain Section 9 applications after constitution of arbitral tribunalVALATHOTTIC KUTTAPATA SAJIPas encore d'évaluation

- Texas Lawyers Creed PosterDocument1 pageTexas Lawyers Creed PosterRon HunterPas encore d'évaluation

- Summary of The Amar Constructions Vs CPWD CaseDocument6 pagesSummary of The Amar Constructions Vs CPWD CasebalacenaPas encore d'évaluation

- Non Disclosure Agreement TemplateDocument6 pagesNon Disclosure Agreement TemplateVivek Singh100% (3)

- 22 Toyota Motor Phil. Corp. Assoc v. NLRCDocument3 pages22 Toyota Motor Phil. Corp. Assoc v. NLRCAnniee PauloPas encore d'évaluation

- Dealer Consortium Agreement PDFDocument5 pagesDealer Consortium Agreement PDFandi1030% (1)

- MAGSAYSAY vs. MICHAEL PADERES ATRAJEDocument8 pagesMAGSAYSAY vs. MICHAEL PADERES ATRAJEAldos Medina Jr.Pas encore d'évaluation

- PORTABLE-Equipment Policy ClauseDocument5 pagesPORTABLE-Equipment Policy ClauseRoy Bhardwaj100% (1)

- Dynamic Business Law 4th Edition Ebook PDF VersionDocument61 pagesDynamic Business Law 4th Edition Ebook PDF Versionlois.sansom461100% (40)

- Haresh Advani of Mumbai Vs Suraj Jagtiani On 24 AprilDocument9 pagesHaresh Advani of Mumbai Vs Suraj Jagtiani On 24 AprilDeepak SharmaPas encore d'évaluation

- SMART COMMUNICATIONS CaseDocument8 pagesSMART COMMUNICATIONS CaseBernice joyce OliverosPas encore d'évaluation

- Asdem London Laytime and Demurrage Brochure 2018-08-13Document4 pagesAsdem London Laytime and Demurrage Brochure 2018-08-13Khaddou KarimPas encore d'évaluation

- Amazon Arbitration DemandDocument46 pagesAmazon Arbitration DemandGeekWire100% (1)

- Domain Name Dispute (WIPO AMC Decision) - Patek Philippe S.A. v. Think Secure Labs, Raymond Pestalozzi (2010)Document5 pagesDomain Name Dispute (WIPO AMC Decision) - Patek Philippe S.A. v. Think Secure Labs, Raymond Pestalozzi (2010)MaxDolotovPas encore d'évaluation

- Completed Russia Partial Scholarship Application Form-1Document3 pagesCompleted Russia Partial Scholarship Application Form-1TofaraPas encore d'évaluation

- How A Bill Becomes A LawDocument11 pagesHow A Bill Becomes A Law1222Pas encore d'évaluation

- Cls Rio LVSB Mumbai PDFDocument36 pagesCls Rio LVSB Mumbai PDFYann JustsuPas encore d'évaluation

- 2016 Harmonius JLegal Soc StuDocument16 pages2016 Harmonius JLegal Soc StuQuynh Nguyen Vu ThuyPas encore d'évaluation