Académique Documents

Professionnel Documents

Culture Documents

Sol Ex

Transféré par

metalharleyDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sol Ex

Transféré par

metalharleyDroits d'auteur :

Formats disponibles

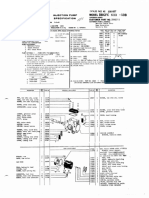

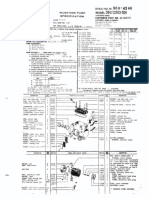

50-504-1

19 75 T E CHL IT CO .

PRINTED IN U.S.A.

I N S T R UCTION SHEET

SOLEX CARBURETOR -MODELS 30 PICT-2,-3, 34 PICT-3

1968 TO 1974 TYPE 1, 1968 TO 1971 TYPE 2

REMOVING

GENERAL EXPLODED VIEW REMOVE OIL BATH AIR CLEANER. DETACH FUEL HOSE, VACUME HOSE OF DASHPOT.

THE GENERAL D E S I G N AND PARTS SHOWN WILL VARY TO I N D IV ID U A L (WHERE APPLICABLE ), AND VACUUM HOSE. DISCONNECT AUTO-MATIC CHOKE CABLE,

UNITS COVERED ON THIS INSTRUCTION SHEET BYPASS AIR CUT OFF VALVE CABLE (WHERE APPLICABLE), AND ELLCTRO-MAGNETIC

PILOT JET CABLE. DETACH ACCELERATOR CABLE AT THROTTLE VALVE LEVER.

REMOVE TWO NUTS ON INTAKE MANIFOLD AND TAKE OFF CARBURETOR.

DISASSEMBLY

USE EXPLODED VIEW AS A GUIDE. THE NUMERICAL SEQUENCE MAY GENERALLY BE

FOLLOWED TO DISASSEMBLE UNIT FAR ENOUGH TO PERMIT CLEANING AND

INSPECTION. CAUTION: BRASS TUBE TYPE JETS ARE NOT REMOVABLE. BEFORE

REMOVING CHOKE VALVE SCREWS (11) FILE OFF PEENED END FOR EASY REMOVAL.

MARK LINKAGE RODS AND LEVERS SO THEY CAN BE RETURNED TO THE SAME

POSITIONS.

NONMENCLATUR

REF REF.

NO. NO.

1. SCREW (31)-RETAINING RING 23. PIN- FLOAT LEVER

2. RETAINING RING – COVER 24. JET - AIR CORRECTION

3 SPACER BUSH-RETAINING RING 25. JET - AUX IDLE SPEED FUEL

4. COVER -WITH SPRING AND HEATER ELEMENT 25A. VALVE - IDLE CUT OFF (30PICT-2,3)

5. PLASTIC CAP 26. PLUG - AV X. FUEL JET

6. SPRING - THROTTLE RETURN 27. JET - AUXILIARY FUEL

7. SCREW&LKWSHR(5)-UPPER BODY 28. PLUG MAIN JET

8. UPPER BODY ASSY. 29. GASKET - PLUG

9. NUT CHOKE SHAFT 30. JET-MAIN

10. OPERATING LEVER - FAST IDLE 31. AIR SCREW - BYPASS

11. SCREW (2)-CHOKE VALVE 32. O-RING-VOLUME CONTROL SCREW

12. VALVE-CHOKE 33. VALVE - BYPASS AIR CUT-OFF

13. SHAFT- CHOKE 34. PLUG - VOLUME CONTROL SCREW

14. SPACER WASHER (2) -CHOKE VALVE 35. SCREW- VOLUME CONTROL

15. SCREW (3) COVE R 36. O-RING-VOLUME CONTROL SCREW

16. COVER VACUUM DIAPHRAGM 37. COTTER PIN

17. SPRING- VACUUM DIAPHRAGM 38. WASHER (2)

18. VACUUM DIAPHRAGM - CHOKE 39. SPRING- CONNECTOR ROD

19. NEEDLE, SEAT & GASKET ASSY. 40. SCREW (4)-COVER

20. GASKET- CARBURETOR BODY 41. COVER-WITH LEVER&PIN

21. LUG-FLOAT PIN 42 DIAPHRAGM -PUMP

22. FLOAT 43. SPRING - DIAPHRAGM

44. CARBURETOR MAIN BODY ASSY'

CLEANING

CLEANING MUST BE DONE WITH CARBURETOR DISASSEMBLED. SOAK PARTS LONG

ENOUGH TO SOFTEN AND REMOVE ALL FOREIGN MATERIAL. USE A CARBURETOR CLEANING

SOLVENT. MAKE CERTAIN THE THROTTLE BODY IS FREE OF ALL HARD CARBON DEPOSITS.

WASH OFF IN SUITABLE SOLVENT. BLOW OUT ALL PASSAGES IN CAST INGS WITH

COMPRESSED AIR AND CHECK CAREFULLY TO INSURE THOROUGH CLEANING OF OBSCURE

AREAS. CAUTION: DO NOT SOAK SOLENOIDS, SWITCHES, FLOAT, OR RUBBER PARTS IN

SOLVENTS.

R E A S S E MB L Y

USING ESSENTIALLY THE REVERSE ORDER OF DISASSEMBLY GIVING SPECIAL ATTENTION

TO THE FOLLOWING SPECIAL INSTRUCTIONS.

SPECIAL I N S T R U C T I O N S

MAKE SURE ALL JET ORIFICES ARE CLEAN AND OPEN. CLEAN WITH COMPRESSED AIR. DO NOT USE

WIRES TO CHECK FOR CLOGGED ORIFICES.

WHEN INSTALLING THE PUMP DIAPHRAGM AND SPRING (43) MAKE SURE THE LARGER END OF SPRING IS

PROPERLY SEATED IN THE CARBURETOR BODY CAVITY. BE SURE TO INSTALL THE DIAPHRAGM (42)

WITH PLUNGER TOWARD PUMP COVER (41).

CHECK FOR A WORN SPOT (DEPRESSION) ON THE FLOAT LEVER WHERE IT MAKES CONTACT WITH THE

FUEL INLET NEEDLE VALVE. REPLACE FLOAT ASSEMBLY, IF NECESSARY. FLOAT ASSEMBLY-MAY BE

PURCHASED AT LOCAL VW DEALER. P/N 113-129-391 RECTANGULAR SHAPED FLOAT (22).

PROPER NEEDLE SEAT GASKET MUST BE USED FOR SPECIFIC CARBURETOR. USE THE FOLLOWING

CHART TO DETERMINE THE CORRECT GASKET.

CARBURETOR MODEL

30 PICT-2 1.0 MM .040"

30 PICT-3 1.5 MM COMBINE 1.0 AND 0.5 MM GASKETS

34 PICT-3 0.5 MM .020"

CHECK THE THERMOSTATIC SPRING IN HOUSING (ITEM #4) FOR DAMAGE. IF IT IS DISTORTED OR

"KINKED", REPLACE THE ASSEMBLY. ALSO, MAKE SURE THE ELECTRICAL HEATING ELEMENT IS NOT

BROKEN.

THIS CAN BE CHECKED WITH AN OHMMETER OR CONNECTED TO A CORRECT VOLTAGE BATTERY FOR A

FEW MINUTES TO SEE IF IT WARMS UP. (BE SURE TO GROUND THE INSIDE METAL PART OF THE

HOUSING IN ORDER TO COMPLETE THE CIRCUIT.) WHEN INSTALLING ASSEMBLY WITH SPRING AND

HEATER ELEMENT, CAREFULLY ROTATE ASSEMBLY COUNTERCLOCKWISE, BEING SURE THE HOOK ON

COIL END ENGAGES WITH THE LEVER ON CHOKE SHAFT. CONTINUE ROTATING APPROXIMATELY 1/8-

TURN MORE UNTIL INDEX MARKS ALIGN. THEN TIGHTEN SCREWS SECURELY.

INSTALLING

INSTALL IN REVERSE ORDER OF REMOVING. TORQUE RETAINING NUTS TO 2.0 MKG. (14 FT LB.)

IDLING ADJUSTMENT

30 PICT-3 34 PICT-3

A. CHECK IF THE AUTOMATIC CHOKE IS FULLY OPEN.

B. TURN IDLING CONTROL SCREW (SEE EXPLODED VIEW) OUT UNTIL THERE IS CLEARANCE BETWEEN

SCREW AND FAST IDLE CAM.

C. THEN TURN IDLING CONTROL SCREW IN UNTIL IT JUST TOUCHES THE

FAST IDLE CAM.

D. FROM THIRD POSITION, TURN SCREW IN FURTHER 1/4 OF A TURN.

E. TURN VOLUME CONTROL SCREW (ITEM 535) IN SLOWLY UNTIL IT COMES TO A STOP, AND THEN TURN

IT RACK 2.5 TO 3 COMPLETE TURNS.

F. START ENGINE AND SEC IDLE SPEED (900 RPM) BY TURNING THE BYPASS SCREW (ITEM #31).

G. BY TURNING VOLUME CONTROL SCREW (ITEM #35), ADJUST TO THE HIGHEST IDLE SPEED, THEN

TURN IN UNTIL THE ENGINE SPEED DROPS BY 20-30 RPM.

H. RESET THE CORRECT IDLE SPEED BY TURNING THE BYPASS SCREW (ITEM #31).

(NOTE 30 PICT-2 USE PROCEDURE ON PAGE 2.) PAGE 1

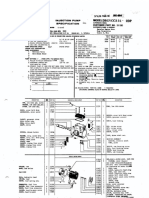

I N S T R UCTION SHEET

SOLEX CARBURETOR –MODELS – 28 PICT, -1, -2, 30 PICT -1

1961 TO 1967 TYPE 1, 1961 TO 1967 TYPE 2

REMOVING

GENERAL EXPLODED VIEW REMOVE OIL BATH AIR CLEANER. DETACH FUEL HOSE, VACUUM HOSE OF DASHPOT

THE GENERAL DESIGN AND PARTS SHOWN WILL (WHERE APPLICABLE), AND VACUUM HOSE. DISCONNECT AUTOMATIC CHOKE CARL E,

VARY TO IN D IV ID UA L UNITS C OV ER E D O N T H IS BYPASS AIR CUT-OFF VALVE CABLE (WHERE APPLICABLE), AND ELECTRO- MAGNETIC

INS TR UC T IO N PILOT JET CABLE. DETACH ACCELERATOR CABLE AT THROTTLE VALVE LEVER. REMOVE

TWO NUTS ON INTAKE MANIFOLD AND TAKE OFF CARBURETOR.

DISASSEMBLY

USE EXPLODED VIEW AS A GUIDE. THE NUMERICAL SEQUENCE MAY GENRALLY BE

FOLLOWED TO DISASSEMBLE UNIT FAR ENOUGH TO PERMIT CLEANING AND INSPECTION.

CAUTION: BRASS TUBE TYPE JETS ARE NOT REMOVABLE. WHEN NECESSARY TO REMOVE

CHOKE SHAFT, BEFORE REMOVING VACUUM DIAPHRAGM (77) FILE OFF PEENED END OF

CHOKE VALVE SCREWS FOR EASY REMOVAL. MARK LINKAGE RODS AND LEVERS SO THEY

CAN BE RETURNED TO THE SAME POSITIONS.

NOMENCLATURE

REF. REF.

NO. NO.

1. SCEW(3) RETAINING RING 15. SPRING - VOLUME CONTROL SCREW

2. RETAINING RING-COVER 16. JET- PILOT

3. COVER WITH SPRING AND 16A. VALVE - IDLING CUT - OFF

HEATER ELEMENT 30 PICT -1

4. SCREW & LOCKWASHER (5) 17. NUT - THROTTLE SHAFT LEVER

UPPER BODY 18. WASHER- THROTTLE SHAFT LEVER

5. UPPER BODY ASSY 19. SCREW 141 COVER

6. NEEDLE, SEAT & GASKET ASSY 20. COVER -WITH LEVER & LINKAGE

7. GASKET- CARBURETOR BODY 21 DIAPHRAGM-PUMP

8. FLOAT 22. SPRING - PUMP DIAPHRAGM

9. PIN - FLOAT LEVER 23. CARBURETOR MAIN BODY ASSY.

10. JET-.AIR CORRECTION 24. SCREW (31 -COVER

11. CARRIER – MAINJET 25. COVER - VACUUM DIAPHRAGM

12. GASKET-CARRIER 26. SPRING - VACUUM DIAPHRAGM

13. JET- MAIN 27. VACUUM DIAPHRAGM -CHOKE

14. SCREW VOLUME CONTROL

CLEANING

CLEANING MUST BE DONE WITH CARBURETOR DISASSEMBLED. SOAK PARTS LONG

ENOUGH TO SOFTEN AND REMOVE ALL FOREIGN MATERIAL. USE A CARBURETOR

CLEANING SOLVENT. MAKE CERTAIN THE THROTTLE BODY IS FREE OE ALL HARD CARBON

DEPOSITS. WASH OFF IN SUITABLE SOLVENT. BLOW OUT ALL PASSAGES IN CASTINGS

WITH COMPRESSED AIR AND CHECK CAREFULLY TO INSURE THOROUGH CLEANING OF

OBSCURE AREAS. CAUTION: DO NOT SOAK SOLENOIDS, SWITCHES, FLOAT, OR RUBBER

PARTS IN SOLVENTS.

REASSEMBLY

USING ESSENTIALLY THE REVERSE ORDER OF DISASSEMBLY GIVING SPECIAL ATTENTION

TO THE FOLLOWING SPECIAL INSTRUCTIONS.

SPECIAL INSTRUCTIONS

MAKE SURE ALL JET ORIFICES ARE CLEAN AND OPEN. CLEAN WITH COMPRESSED AIR. DO

NOT USE WIRES TO CHECK FOR CLOGGED ORIFICES.

WHEN INSTALLING THE PUMP DIAPHRAGM AND SPRING (22) MAKE SURE THE LARGER END

OF SPRING IS PROPERLY SEATED IN THE CARBURETOR BODY CAVITY. BE SURE TO

INSTALL THE DIAPHRAGM (21) WITH PLUNGER TOWARD PUMP COVER (20).

CHECK FOR A WORN SPOT (DEPRESSION) ON THE FLOAT LEVER WHERE IT MAKES

CONTACT WITH THE FUEL INLET NEEDLE VALVE. REPLACE FLOAT ASSEMBLY, IF

NECESSARY. FLOAT ASSEMBLY MAY BE PURCHASED AT LOCAL VW DEALER, P/N 111-129-

391A-ROUND SHAPED FLOAT (8).

PROPER NEEDLE SEAT GASKET MUST BE USED FOR SPECIFIC CARBURETOR. USE THE

FOLLOWING CHART TO DETERMINE THE CORRECT GASKET. CARBURETOR MODEL

28 PICT-1,2 1.0 MM .040"

30 PICT-1 1.0 MM .040"

CHECK THE THERMOSTATIC SPRING IN HOUSING (ITEM 13) FOR DAMAGE. IF IT IS

DISTORTED OR "KINKED", REPLACE THE ASSEMBLY.

ALSO, MAKE SURE THE ELECTRICAL HEATING ELEMENT 1S NOT BROKEN. THIS CAN BE

CHECKED WITH AN OHMMETER OR CONNECTED TO A CORRECT VOLTAGE BATTERY FOR A

FEW MINUTES TO SEE IF IT WARMS UP. (BE SURE TO GROUND TILE INSIDE METAL PART OF

THE HOUSING IN ORDER TO COMPLETE THE CIRCUIT.) WHEN INSTALLING ASSEMBLY WITH

SPRING AND HEATER ELEMENT, CAREFULLY ROTATE ASSEMBLY COUNTERCLOCKWISE,

BEING SURE THE HOOK ON COIL END ENGAGES WITH THE LEVER ON CHOKE SHAFT.

CONTINUE ROTATING APPROXIMATELY 1/8-TURN MORE UNTIL INDEX MARKS ALIGN. THEN

TIGHTEN SCREWS SECURELY.

INSTALLING

INSTALL IN REVERSE ORDER OF REMOVING. TORQUE RETAINING NUTS TO 2.0 MKG. (14 FT

LB.)

IDLING ADJUSTMENT

28 PICT,-I,-2. 30 PICT-1,-2.

A. WARM UP ENGINE; CHECK IF THE AUTOMATIC CHOKE 15 FULLY OPEN.

8. SET IDLING SPEED TO 850 RPM WITH THE IDLING CONTROL SCREW. (SEE EXPLODED

VIEW)

C. TURN VOLUME CONTROL SCREW (ITEM #14) TO RIGHT UNTIL SPEED STARTS TO DROP.

D. FROM THIS POSITION, TURN VOLUME CONTROL SCREW (ITEM #14) TO THE LEFT UNTIL

ENGINE RUNS FASTEST.

E. IF NECESSARY, REGULATE THE ENGINE SPEED (800-900 RPM) AGAIN, WITH THE IDLING

CONTROL SCREW.

PAGE 2

Vous aimerez peut-être aussi

- Manual Carburador BBD 1 1/2Document3 pagesManual Carburador BBD 1 1/2wolgfag uviedoPas encore d'évaluation

- AISAN Carb DiagramDocument2 pagesAISAN Carb DiagramSolomon XI100% (1)

- Operator and Organizational Maintenance Manual Pistol, Caliber .45, Automatic, M1911A1Document47 pagesOperator and Organizational Maintenance Manual Pistol, Caliber .45, Automatic, M1911A1C.A. MonroePas encore d'évaluation

- EF Repair en TextDocument124 pagesEF Repair en Textronat88080Pas encore d'évaluation

- Customer Part No. 4514954: Injection Pump Specification Model Ik) DelDocument2 pagesCustomer Part No. 4514954: Injection Pump Specification Model Ik) DeldieselmotorsbogotasasPas encore d'évaluation

- A Study of Gyrator Circuits PDFDocument106 pagesA Study of Gyrator Circuits PDFNadeeka PereraPas encore d'évaluation

- 6N330 (0CH10-M26102)Document343 pages6N330 (0CH10-M26102)Agung Hidayatullah100% (3)

- Manual Eléctrico Mahindra Scorpions 2.2Document134 pagesManual Eléctrico Mahindra Scorpions 2.2Juan Francisco Hidalgo SabagPas encore d'évaluation

- 08 Kobelco MARK 8 Mechatron Control SistemDocument45 pages08 Kobelco MARK 8 Mechatron Control SistemNadiel Aceto 46100% (1)

- DBGFC 633 - 5DB: ModelDocument2 pagesDBGFC 633 - 5DB: Modeljohnny sabinPas encore d'évaluation

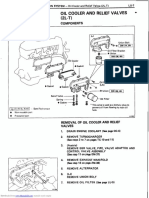

- !3imzy: Oil Cooler and Relief ValvesDocument6 pages!3imzy: Oil Cooler and Relief ValvesDavid QuispePas encore d'évaluation

- Electro-Hdraulic Diagram HARI ANAND STEERINGDocument5 pagesElectro-Hdraulic Diagram HARI ANAND STEERINGmelissaPas encore d'évaluation

- Secondary Valve Body - '97 - '98 Models: Disassembly/Inspection/ReassemblyDocument1 pageSecondary Valve Body - '97 - '98 Models: Disassembly/Inspection/ReassemblysoftallPas encore d'évaluation

- Air Compressor Duraflo596Document40 pagesAir Compressor Duraflo596Davies EmmanuelPas encore d'évaluation

- ASL RB L3C 8991 2712 00 CamionDocument202 pagesASL RB L3C 8991 2712 00 CamionjuangomezsanPas encore d'évaluation

- Installation Information Series PAVC 33/38/65/100: Variable Displacement Piston PumpsDocument9 pagesInstallation Information Series PAVC 33/38/65/100: Variable Displacement Piston PumpsJeisson RodriguezPas encore d'évaluation

- Pumps: Section XX - Page 1 Prodem M. Devooght September 1997Document31 pagesPumps: Section XX - Page 1 Prodem M. Devooght September 1997Reza SaeePas encore d'évaluation

- DuraFlo 596 (SD-01-670)Document20 pagesDuraFlo 596 (SD-01-670)emmanuelPas encore d'évaluation

- 00775Document2 pages00775johnny sabinPas encore d'évaluation

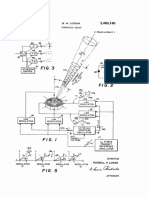

- Aug. 5, 1969 R. H. Logan 3,460,140: Filed June 29, 1967 2 Sheets-Sheet LDocument6 pagesAug. 5, 1969 R. H. Logan 3,460,140: Filed June 29, 1967 2 Sheets-Sheet LDaniela ScobarPas encore d'évaluation

- Dbgvcc431-: Ca-Ialog Pagt No: S 0 - 2 3 5 3Document2 pagesDbgvcc431-: Ca-Ialog Pagt No: S 0 - 2 3 5 3dieselmotorsbogotasasPas encore d'évaluation

- Pumf SpecificationDocument2 pagesPumf SpecificationdieselmotorsbogotasasPas encore d'évaluation

- Catalqg PAGE NO:'!$o@: 1., Njectlon LinesDocument2 pagesCatalqg PAGE NO:'!$o@: 1., Njectlon Linesjohnny sabinPas encore d'évaluation

- 1986-1986 XJ Wiring DiagramsDocument18 pages1986-1986 XJ Wiring DiagramsRichard EckerlePas encore d'évaluation

- Clutch Switch: ComponentsDocument4 pagesClutch Switch: Componentsahmed nourPas encore d'évaluation

- Spring: DlscrnpllowDocument2 pagesSpring: DlscrnpllowMiguel RojasPas encore d'évaluation

- Power Tools General CatalogDocument96 pagesPower Tools General CatalogKarin AndersonPas encore d'évaluation

- 78AC6y6NJKvRJuXAcMcmqw2Document1 page78AC6y6NJKvRJuXAcMcmqw2Quality AviationPas encore d'évaluation

- WipeprDocument1 pageWipeprIcaro FerreiraPas encore d'évaluation

- Catalog Page No 6 00 - 631 - Customer Part No. 4028125Document2 pagesCatalog Page No 6 00 - 631 - Customer Part No. 4028125Eduardo David Castillo QuijandriaPas encore d'évaluation

- Peterbilt 387 EWDDocument59 pagesPeterbilt 387 EWDmichael fawleyPas encore d'évaluation

- SK29863Document73 pagesSK29863gigo_dream100% (2)

- ALLMAND Night-Lite PRO II Parts ManualDocument93 pagesALLMAND Night-Lite PRO II Parts ManualBodega 3001Pas encore d'évaluation

- M O-352 4all: Mobel Ex-Kmx43Document2 pagesM O-352 4all: Mobel Ex-Kmx43johnny sabinPas encore d'évaluation

- Arbus 2000-850 USADocument76 pagesArbus 2000-850 USAdanielPas encore d'évaluation

- Ac 24Document2 pagesAc 24Tung NguyenPas encore d'évaluation

- Modeldbgfc 633-2Dh: Lnjectlon PLJNFP Specification / - / Customer Part No - at 22'+90 TDocument2 pagesModeldbgfc 633-2Dh: Lnjectlon PLJNFP Specification / - / Customer Part No - at 22'+90 Tjohnny sabinPas encore d'évaluation

- Part Catalog MEDocument184 pagesPart Catalog MEAkhmad ShofiPas encore d'évaluation

- Power ToolsDocument100 pagesPower ToolsKinastryan Jita KrodaPas encore d'évaluation

- D-2300 IUU Lao Rcy, C T: 7 BATE@ 1a26m66Document2 pagesD-2300 IUU Lao Rcy, C T: 7 BATE@ 1a26m66dieselmotorsbogotasasPas encore d'évaluation

- 4CHE3 Parts Catalog PDFDocument75 pages4CHE3 Parts Catalog PDFokta bedjo100% (1)

- Uenr0231uenr0231 PDocument32 pagesUenr0231uenr0231 PMax Will Carrasco SantiPas encore d'évaluation

- RC2 Series Screw Compressor Maintenance ManualDocument122 pagesRC2 Series Screw Compressor Maintenance ManualDennis Arhin100% (1)

- Fpg18Fb Manual Oil Return Kit (826-1517) Installation InstructionsDocument1 pageFpg18Fb Manual Oil Return Kit (826-1517) Installation InstructionsServicios y Repuestos Jeremy Azhael 2320 C.APas encore d'évaluation

- 6 Ayl - WetDocument149 pages6 Ayl - WetValerie EkkyPas encore d'évaluation

- Modeil Dbgvcc631-2Dli: Catilog Page No: 500-905Document2 pagesModeil Dbgvcc631-2Dli: Catilog Page No: 500-905dieselmotorsbogotasasPas encore d'évaluation

- Skyjack 6832 RTDocument33 pagesSkyjack 6832 RTRob Nash100% (1)

- Parts Manual Yanmar S165R 1Document93 pagesParts Manual Yanmar S165R 1hastaPas encore d'évaluation

- DB28251PC36 3: (Customer Part No. 2215011177Document3 pagesDB28251PC36 3: (Customer Part No. 2215011177Ventas R11Pas encore d'évaluation

- Doc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetDocument4 pagesDoc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetHoomanrrPas encore d'évaluation

- 1966 Comet Falcon Fairlane Mustang Manual-751-775Document25 pages1966 Comet Falcon Fairlane Mustang Manual-751-775shitPas encore d'évaluation

- IW11 Gearbox Dismantling Output Sleeve InstructionsDocument5 pagesIW11 Gearbox Dismantling Output Sleeve InstructionsChakravarthi NagaPas encore d'évaluation

- CR 5080 - Circuito Elétrico - Midrange PDFDocument75 pagesCR 5080 - Circuito Elétrico - Midrange PDFRenato AssisPas encore d'évaluation

- Embrague PDFDocument3 pagesEmbrague PDFSergio Manuel Ovando ChaconPas encore d'évaluation

- SC5357Document3 pagesSC5357tzPas encore d'évaluation

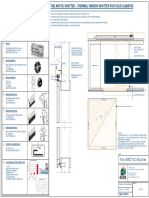

- The Arctic Shutter - Thermal Window Shutter For Cold ClimatesDocument1 pageThe Arctic Shutter - Thermal Window Shutter For Cold ClimatesKhanh DamPas encore d'évaluation

- Apollo Program: Final Flight Evaluation ReportDocument126 pagesApollo Program: Final Flight Evaluation Reportkawisoc177Pas encore d'évaluation

- Modeldeigfc: Catalog PAGE NO: 50@ 5Document2 pagesModeldeigfc: Catalog PAGE NO: 50@ 5johnny sabinPas encore d'évaluation

- Operator'S Manual: 725re 2-Cycle Gas Trimmer / EdgerDocument28 pagesOperator'S Manual: 725re 2-Cycle Gas Trimmer / EdgerJonPas encore d'évaluation

- Operating The DC-3Document265 pagesOperating The DC-3tumbPas encore d'évaluation

- Hedge Trimmer Hedge Trimmer Hedge Trimmer Hedge Trimmer: HHH25D HHH25SDocument81 pagesHedge Trimmer Hedge Trimmer Hedge Trimmer Hedge Trimmer: HHH25D HHH25Scarlos100% (2)

- Edelbrock 1406 InstallDocument4 pagesEdelbrock 1406 Installtmosley66Pas encore d'évaluation

- Ic Engine Lab ManualDocument80 pagesIc Engine Lab ManualMuhammadKhizarSiddiquePas encore d'évaluation

- C-172 Seaplane Checklist (Floats) N98637: External: Inside Aircraft: Start - UpDocument1 pageC-172 Seaplane Checklist (Floats) N98637: External: Inside Aircraft: Start - UpalphaPas encore d'évaluation

- Johnson - Evinrude 1990-2001 Service Manual PDFDocument552 pagesJohnson - Evinrude 1990-2001 Service Manual PDFDavid Valls73% (73)

- Zenith Carburetor Model 29 Service ManualDocument11 pagesZenith Carburetor Model 29 Service ManualMatt FerdockPas encore d'évaluation

- HKS700E: Installation Instructions ManualDocument25 pagesHKS700E: Installation Instructions ManualCristhian342Pas encore d'évaluation

- Chapter 1 IntroductionDocument19 pagesChapter 1 IntroductionIslam El Sibaie100% (1)

- Honda XR250 R XR 250 Owners Maintenance ManualDocument88 pagesHonda XR250 R XR 250 Owners Maintenance Manualcrawdoogie100% (2)

- Manuale Honda f510Document251 pagesManuale Honda f510eddiePas encore d'évaluation

- Injectcarbps 5coverhaulmanualDocument151 pagesInjectcarbps 5coverhaulmanualWilfredo Díaz GonzalezPas encore d'évaluation

- Lista de Chequeo 172 NDocument4 pagesLista de Chequeo 172 NJorge Heli Garzon MarinPas encore d'évaluation

- Manual Motor Crrcpro26iDocument8 pagesManual Motor Crrcpro26ieduardo_albornoz_5Pas encore d'évaluation

- Briggs Operators Manual PDFDocument100 pagesBriggs Operators Manual PDFGaborPas encore d'évaluation

- MH VerkstadshandbokDocument92 pagesMH VerkstadshandbokSeby SebiPas encore d'évaluation

- IMPCO Master Parts Catalog Jan 2013 HiResDocument620 pagesIMPCO Master Parts Catalog Jan 2013 HiResingemexPas encore d'évaluation

- Decision Making FlyingDocument14 pagesDecision Making Flyinghil12345Pas encore d'évaluation

- CBX Eng 1Document78 pagesCBX Eng 1ЮрийPas encore d'évaluation

- Suzuki Shugun PDFDocument69 pagesSuzuki Shugun PDFPrashanthKumar33% (3)

- Honda HR21 5Document40 pagesHonda HR21 5Ferenc Norbert100% (1)

- The Cause and Effect of Poor Atomization in The Auxiliary En-GineDocument35 pagesThe Cause and Effect of Poor Atomization in The Auxiliary En-GineJay-r VillanuevaPas encore d'évaluation

- Jet KayakDocument114 pagesJet KayakBill PelkaPas encore d'évaluation

- 10653282-Polaris Download 1996 1997 1998 Snowmobile Service Manual RepairDocument831 pages10653282-Polaris Download 1996 1997 1998 Snowmobile Service Manual RepairRay J Krause95% (19)

- Piper Inspection Report PDFDocument5 pagesPiper Inspection Report PDFsujinlong100% (4)

- BMW n54 Can Dme Code ListDocument8 pagesBMW n54 Can Dme Code ListSimple GameplayPas encore d'évaluation

- Quadrajet TuningDocument10 pagesQuadrajet Tuningjet406100% (1)

- PPL Aircraft Technical Knowledge SyllabusDocument8 pagesPPL Aircraft Technical Knowledge SyllabusDhruv JoshiPas encore d'évaluation

- LEV80 Manual PDFDocument20 pagesLEV80 Manual PDFLee McDermottPas encore d'évaluation