Académique Documents

Professionnel Documents

Culture Documents

High Temperature Properties: Outokumpu Steel Grade C% N% CR% Ni% Si% Other EN Astm

Transféré par

Bibit TanjungDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

High Temperature Properties: Outokumpu Steel Grade C% N% CR% Ni% Si% Other EN Astm

Transféré par

Bibit TanjungDroits d'auteur :

Formats disponibles

High Temperature Properties

In many industrial, as well as public and domestic applications, the construction material is exposed to elevated

temperatures, sometimes in connection with a more or less aggressive environment.

Depending on the operating conditions, the demands on high temperature alloys may be as follows:

· High creep strength (and/or ductility)

· Stability of internal microstructure

· High resistance to oxidation and HT corrosion

· Good resistance to erosion-corrosion

All materials selection must be determined by the application and operating conditions in each individual case.

Outokumpu Stainless can offer a number of special HT stainless steels:

Austenitic High Temperture Grades

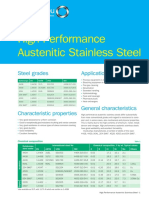

Outokumpu C% N% Cr% Ni% Si% Other EN ASTM

Steel Grade

4984 0.05 - 18.3 8.7 0.5 1.4984 304H

4878 0.05 - 17.5 9.5 0.5 Ti 1.4878 321H

153 MA™ 0.05 0.15 18.5 9.5 1.3 REM 1.4818 S30415

4828 0.04 - 20 12 2.0 1.4828

4833 0.06 - 22.5 12.5 0.5 1.4833 309S

253 MA™ 0.09 0.17 21 11 1.7 REM 1.4835 S30815

4845 0.05 - 25 20 1.0 1.4845 310S

4841 0.12 - 25 20 2.0 1.4841 314

353 MA™ 0.05 0.15 25 35 1.5 REM 1.4854 S35315

Besides the common Austenitic High Temperature Alloys above (i.e., 4948, 4878, 4828, 4833, and 4845), there are three proprietary

Outokumpu Stainless alloys: 153 MA, 253 MA, and 353 MA.

These three alloys are based on the same concept:

Improved oxidation (and thus also HT corrosion) resistance by an increased silicon content and addition of very small quantities of rare

earth metals (micro-alloying => MA).

Enhanced creep strength due to increased contents of nitrogen (and carbon for 253 MA).

In many cases, the properties of these steels have proved to be equivalent or even superior to those of grades with higher contents of

alloying elements. 153 MA is normally intended for use at somewhat lower service temperatures than the other two grades.

Ferritic High Temparature Grades

Outokumpu C% Mn% Cr% Si% Al% EN

Steel Grade

4713 0.08 0.7 6.5 0.8 0.8 1.4713

4724 0.08 0.7 13.5 1.0 1.0 1.4724

4742 0.08 0.7 18 1.3 1.0 1.4742

4762 0.08 0.7 24 1.4 1.5 1.4762

For information about our ferritic high temperature grades use this link.

© Outokumpu 2008 Site map Privacy policy Legal notice

Vous aimerez peut-être aussi

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocument12 pages253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulPas encore d'évaluation

- Austenitic High Temperature Grades DatasheetDocument12 pagesAustenitic High Temperature Grades Datasheetbiliboi5Pas encore d'évaluation

- High Temperature Austenitic Stainless SteelDocument12 pagesHigh Temperature Austenitic Stainless SteelCarlos Nombela PalaciosPas encore d'évaluation

- Austenitic High Temperature Grades Datasheet PDFDocument12 pagesAustenitic High Temperature Grades Datasheet PDFjmaf_terPas encore d'évaluation

- Ams 4928Document8 pagesAms 4928REKHA100% (3)

- Outokumpu Ultra Range DatasheetDocument16 pagesOutokumpu Ultra Range DatasheetIndraPas encore d'évaluation

- Creep and Creep-Rupture Behaviour Bainitic 2 1/4 Cr-1 Mo SteelDocument21 pagesCreep and Creep-Rupture Behaviour Bainitic 2 1/4 Cr-1 Mo SteelStephen JonesPas encore d'évaluation

- High Performance Austenitic Stainless SteelDocument12 pagesHigh Performance Austenitic Stainless SteelNitin VermaPas encore d'évaluation

- Outokumpu Ultra Range DatasheetDocument16 pagesOutokumpu Ultra Range DatasheetisogulalebPas encore d'évaluation

- 253MA High Temperature Resistant TubesDocument2 pages253MA High Temperature Resistant TubesBerkan FidanPas encore d'évaluation

- Hobart MAXAL 4943 WireDocument2 pagesHobart MAXAL 4943 WirebrunizzaPas encore d'évaluation

- Ams 4965 HDocument11 pagesAms 4965 HOTK Micro-FixPas encore d'évaluation

- Ams4928v PDFDocument8 pagesAms4928v PDFNav TalukdarPas encore d'évaluation

- Welding of Ferritic Creep-Resistant SteelsDocument3 pagesWelding of Ferritic Creep-Resistant Steelssn200709Pas encore d'évaluation

- Duplex Stainless Steel - Part 1 - TWIDocument6 pagesDuplex Stainless Steel - Part 1 - TWItuanPas encore d'évaluation

- TWI Article On Super Duplex Welding - 1Document4 pagesTWI Article On Super Duplex Welding - 1kapsarcPas encore d'évaluation

- Pubs 1049240Document12 pagesPubs 1049240cooki77Pas encore d'évaluation

- Streamline Copper Tube Medical Gas Submittal Sheet 1596827Document4 pagesStreamline Copper Tube Medical Gas Submittal Sheet 1596827Harvendra SinghPas encore d'évaluation

- 468 PDFDocument4 pages468 PDFJoshua WalkerPas encore d'évaluation

- Duplex Stainless Steel SAF 2304, 2205, SAF 2507Document12 pagesDuplex Stainless Steel SAF 2304, 2205, SAF 2507Anonymous skBAwexPas encore d'évaluation

- 71IJMPERDDEC201871Document9 pages71IJMPERDDEC201871TJPRC PublicationsPas encore d'évaluation

- MaterialData - 14076 HDS H13Document2 pagesMaterialData - 14076 HDS H13Amol KulkarniPas encore d'évaluation

- Select 439tiDocument1 pageSelect 439tiHariPrasathPas encore d'évaluation

- A 391 - A 391M - 98 Qtm5ms9bmzkxts1sruqDocument6 pagesA 391 - A 391M - 98 Qtm5ms9bmzkxts1sruqClaudia Patricia Magaña RabanalesPas encore d'évaluation

- Effect of Processing Parameters On Residual StressDocument6 pagesEffect of Processing Parameters On Residual StressMassab JunaidPas encore d'évaluation

- 7 Tool Steels1Document12 pages7 Tool Steels1ontc0109Pas encore d'évaluation

- Recommended Target Analysis For Ductile IronDocument2 pagesRecommended Target Analysis For Ductile Ironarnaldorcr8646100% (2)

- T-18 - Recommended Target Analysis For Ductile IronsDocument2 pagesT-18 - Recommended Target Analysis For Ductile Ironscrazy dPas encore d'évaluation

- Blueshield LA 7018: Low-Hydrogen ElectrodeDocument2 pagesBlueshield LA 7018: Low-Hydrogen ElectrodeOPAZOSCPas encore d'évaluation

- Duplex WeldingDocument4 pagesDuplex WeldingVishal Sparkle QE3100% (1)

- Tata Steel Cutting Edges GuideDocument2 pagesTata Steel Cutting Edges GuideKen SmithPas encore d'évaluation

- StainlessSteelInStructures2012 ManninenSaynajakangasDocument16 pagesStainlessSteelInStructures2012 ManninenSaynajakangasTomás TorresPas encore d'évaluation

- Power Generation Boiler Tubes GuideDocument12 pagesPower Generation Boiler Tubes GuidewalitedisonPas encore d'évaluation

- Air-490-6, (c-d) Ar-490-6, (e-f) Ar-490-9, (g-h) Ar/H2-490-6, (i-j) Ar/H2-490-9. 14Document21 pagesAir-490-6, (c-d) Ar-490-6, (e-f) Ar-490-9, (g-h) Ar/H2-490-6, (i-j) Ar/H2-490-9. 14John WaitPas encore d'évaluation

- P 36 Material 15NiCuMoNb5-6-4Document13 pagesP 36 Material 15NiCuMoNb5-6-4Mudassar Iqbal100% (1)

- ASTM A536 Grade 80-55-06 (2021 - 03 - 22 20 - 48 - 50 UTC)Document2 pagesASTM A536 Grade 80-55-06 (2021 - 03 - 22 20 - 48 - 50 UTC)Milton Pereira JúniorPas encore d'évaluation

- Metaroll TMT Rebar Delivers 15-20% Cost SavingsDocument4 pagesMetaroll TMT Rebar Delivers 15-20% Cost Savingsrohit6varma-4Pas encore d'évaluation

- BM Europe Expansion Joints Technical CalculationDocument9 pagesBM Europe Expansion Joints Technical CalculationsahirprojectsPas encore d'évaluation

- Creep-Resistant Steels - TWI PDFDocument6 pagesCreep-Resistant Steels - TWI PDFFarid Ahmed KhwajaPas encore d'évaluation

- Creep-Resistant Steels - TWIDocument6 pagesCreep-Resistant Steels - TWIJlkKumarPas encore d'évaluation

- Duplex SSDocument12 pagesDuplex SSTushar PatilPas encore d'évaluation

- Titanium Properties GuideDocument2 pagesTitanium Properties GuideAbhishek JhaPas encore d'évaluation

- 5 - Duplex Stainless Steels and Nickel AlloysDocument44 pages5 - Duplex Stainless Steels and Nickel AlloysdennykvgPas encore d'évaluation

- Ams4943l 2020Document8 pagesAms4943l 2020BauyrzhanPas encore d'évaluation

- ENB 04 0553 Rev B Bearing Materials Technical InformationDocument4 pagesENB 04 0553 Rev B Bearing Materials Technical Informationmanasha majhiPas encore d'évaluation

- Austenitic Standard GradesDocument6 pagesAustenitic Standard Gradesfierro44Pas encore d'évaluation

- Metcoloy 5 PDFDocument5 pagesMetcoloy 5 PDFSos de HoyosPas encore d'évaluation

- AMS4930LDocument8 pagesAMS4930Lremaja1249Pas encore d'évaluation

- Developments in Gas Turbine MaterialsDocument39 pagesDevelopments in Gas Turbine MaterialsGrk GuptaPas encore d'évaluation

- Mueller PDFDocument16 pagesMueller PDFMechanical EngineerPas encore d'évaluation

- Outokumpu Ultra Alloy 825 DatasheetDocument4 pagesOutokumpu Ultra Alloy 825 DatasheetIris RamirezPas encore d'évaluation

- 17 4 PHDocument2 pages17 4 PHzaranrajputPas encore d'évaluation

- A 789 - A 789M - 04 Qtc4os9bnzg5tqDocument4 pagesA 789 - A 789M - 04 Qtc4os9bnzg5tqAhmad HajeerPas encore d'évaluation

- Aerospace Material Specification: AMS5709 REV. HDocument6 pagesAerospace Material Specification: AMS5709 REV. Hfelipe jurema100% (1)

- ALLOY 800 800H 800AT Data Sheet: GENERAL PROPERTIESDocument6 pagesALLOY 800 800H 800AT Data Sheet: GENERAL PROPERTIESCarlos Anibal OrtizPas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesD'EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesPas encore d'évaluation

- Direct Extraction of Copper From Copper Sulfide Minerals Using Deep Eutectic SolventsDocument3 pagesDirect Extraction of Copper From Copper Sulfide Minerals Using Deep Eutectic SolventsFloren Ardila AlvaradoPas encore d'évaluation

- Section II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 45Document1 pageSection II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 45洛霖Pas encore d'évaluation

- AWS Code LibraryDocument2 pagesAWS Code Libraryyoonchankim0911Pas encore d'évaluation

- ESAB MMA Consumable July07-2 PDFDocument64 pagesESAB MMA Consumable July07-2 PDFvtbkPas encore d'évaluation

- Electrodes For GMAWDocument1 pageElectrodes For GMAWkapsarcPas encore d'évaluation

- 5a - Welding Metallurgy of Carbon SteelDocument16 pages5a - Welding Metallurgy of Carbon SteelAziful AiemanPas encore d'évaluation

- Chapter 1Document12 pagesChapter 1Oscar Espinosa BonillaPas encore d'évaluation

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisPas encore d'évaluation

- PIPA Hitam Welded Medium SNI SCH 40Document1 pagePIPA Hitam Welded Medium SNI SCH 40Harta Dwi AsmanaPas encore d'évaluation

- Brosure Gridswitch MK 1.1Document1 pageBrosure Gridswitch MK 1.1Anwar regarPas encore d'évaluation

- Equivalent MaterialDocument1 pageEquivalent Materialmuhammadf SardarPas encore d'évaluation

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocument2 pagesThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezPas encore d'évaluation

- Afrox 308L (-196) electrode for cryogenic applicationsDocument4 pagesAfrox 308L (-196) electrode for cryogenic applicationsBranko FerenčakPas encore d'évaluation

- Design Knowledge MaterialDocument75 pagesDesign Knowledge MaterialAkin ErsozPas encore d'évaluation

- Conversion table of EN - Materials vs. US Materials (assorted by ASTM NoDocument1 pageConversion table of EN - Materials vs. US Materials (assorted by ASTM NoNattapong PongbootPas encore d'évaluation

- Steel Colour Code PDFDocument1 pageSteel Colour Code PDFJuan ZamoraPas encore d'évaluation

- Effect of 0.5Wt% CR Addition On The Mechanical Properties and Microstructure of Heat Treated Plain Carbon Low Alloy SteelDocument5 pagesEffect of 0.5Wt% CR Addition On The Mechanical Properties and Microstructure of Heat Treated Plain Carbon Low Alloy SteelhburitiPas encore d'évaluation

- List of Stainless Steel and Nickel Alloy Welding ElectrodesDocument3 pagesList of Stainless Steel and Nickel Alloy Welding ElectrodesFernando RomeroPas encore d'évaluation

- General Casting ToleranceDocument2 pagesGeneral Casting ToleranceMuhammad M ElhafidPas encore d'évaluation

- Galvanising ProcessDocument13 pagesGalvanising ProcesschepurthiPas encore d'évaluation

- Daily Assignment Sheet-1-245 PDFDocument3 pagesDaily Assignment Sheet-1-245 PDFKúmár ẞíjéñdräPas encore d'évaluation

- Weldability 2Document56 pagesWeldability 2vivek bhangalePas encore d'évaluation

- Electrode Selection Excel SheetDocument1 pageElectrode Selection Excel Sheetchandrakit047Pas encore d'évaluation

- Detailed Guide Indian Iron Ore DepositsDocument42 pagesDetailed Guide Indian Iron Ore Depositsdrrcc0761Pas encore d'évaluation

- Stacking Fault Energies of Seven Commercial Austenitic Stainless SteelsDocument7 pagesStacking Fault Energies of Seven Commercial Austenitic Stainless SteelsADRIANOPas encore d'évaluation

- Stainless Steel Welding Consumables GuideDocument3 pagesStainless Steel Welding Consumables GuideBranko FerenčakPas encore d'évaluation

- Copia de METODOS PREPARACION ESTANDAR PLASMADocument5 pagesCopia de METODOS PREPARACION ESTANDAR PLASMAjorgePas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To Informationamit2688Pas encore d'évaluation

- Equations To Be BalancedDocument10 pagesEquations To Be BalancedDesmond Dujon HenryPas encore d'évaluation

- DEMO-ASME Filler Metals DatabaseDocument6 pagesDEMO-ASME Filler Metals DatabaseadammzjinPas encore d'évaluation