Académique Documents

Professionnel Documents

Culture Documents

Ingersoll Rand Compressor Manual SS3L3

Transféré par

Castoriadis100%(2)100% ont trouvé ce document utile (2 votes)

4K vues36 pagesINGERSOLL-RAND. AIR COMPRESSORS CONSUMER INFORMATION SHEET Thank you for purchasing an Ingersoll-Rand product. We trust that it will offer you many years of trouble-free service. If you encounter any problems or need assistance, please refer to the infonnation provided in this sheet.

Description originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentINGERSOLL-RAND. AIR COMPRESSORS CONSUMER INFORMATION SHEET Thank you for purchasing an Ingersoll-Rand product. We trust that it will offer you many years of trouble-free service. If you encounter any problems or need assistance, please refer to the infonnation provided in this sheet.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(2)100% ont trouvé ce document utile (2 votes)

4K vues36 pagesIngersoll Rand Compressor Manual SS3L3

Transféré par

CastoriadisINGERSOLL-RAND. AIR COMPRESSORS CONSUMER INFORMATION SHEET Thank you for purchasing an Ingersoll-Rand product. We trust that it will offer you many years of trouble-free service. If you encounter any problems or need assistance, please refer to the infonnation provided in this sheet.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 36

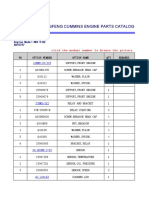

(GD) Ingersoll Rand.

SS3L3

Owner’s Manual

With Parts List

More Than Air. Answers. CCN: 22204929

inline answers: http://www.air.irco.com: REV. A

PHONE: 1-800-526-3615 OCTOBER 2002

INGERSOLL-RAND. ‘esereoa Seay Sect

—<—<—<—$—$—<—<—<—<—<— ecco

AIR COMPRESSORS Davidson, NC 28036

1-800-AIR SERV

(800-267-7378)

wow ar ingersolbrand com

CONSUMER INFORMATION SHEET

‘Thank you for purchasing an Ingersoll-Rand product. We trust that it will offer you many years of trouble-free

service. If you encounter any problems or need assistance, please refer to the information provided in this sheet.

INSTALLATION, OPERATION, MAINTENANCE & TROUBLESHOOTING ISSUES

Read the owner's manual first. Often this will clarify your understanding. If you stil have problems, please call the toll-free

hotline.

MISSING PARTS

I parts are missing call the tol free hotline. Have the serial number, part number, model number and parts lst (with missing

parts circled) handy when you call. Your parts will be shipped immediately

‘SHIPPING DAMAGE OR DEFECTIVE PARTS

Each new product is inspected and in good condition prior to shipment from the factory. If your product was received in a

‘condition that was less than satisfactory, or if you discover a defect that requires service or adjustment by qualified

Personnel, please contact your nearest authorized service representative.

DO NOT RETURN THE PRODUCT

TO YOUR RETAILER!

| NOTE REGARDING

| EXTENSION corps

| To avoid power loss and

‘overheating, use additional air

hose instead of an extensior

cord

SERVICE HOTLINE:

3 1-800-AIR SERV

5 (1-800-247-7378)

© Ingersoll-Rand Company Form SCD-846A

Printed in USA. ly 1989

GRD Ingersoll Rand.

Owner’s Manual

Installation, Operation and Maintenance

Instructions for Models SS3 and SS5

Stationary Air Compressors

IMPORTANT INFORMATION! READ AND FOLLOW THESE INSTRUCTIONS. RETAIN FOR REFERENCE.

SAFETY

DEFINITIONS,

@(QEMISHE WILL cause DEATH, SEVERE INJURY or substantial

property damage.

AWARNING CAN cause DEATH, SEVERE INJURY or substantial

property damage.

ACAUTION WILL oF CAN cause MINOR INJURY or property

damage.

GENERAL SAFETY PRECAUTIONS.

AQENIEE INTAKE AIR. Can contain carbon monoxide or other

‘contaminants. Will cause serious injury or death.

Ingersol-Rand air compressors are not designed,

intended or approved for breathing ai. Compressed

should not be used for breathing alr applications

treated in accordance with all applicable

ute

‘codes and regulations.

AWARNING HAZARDOUS VOLTAGE. Can cause serious injury

‘oF death. Disconnect power and bleed pressure

{rom tank before servicing. Lockout/Tagout

machine. Compressor must be connected to

properly grounded circu. See grounding

Instructions in manual. Do not operate compressor

Inwet conditions, Store Indoors.

MOVING PARTS. Can cause serious Injury. Do not

‘operate with guards removed. Machine may start

‘automatically. Disconnect power before servicing.

LockoutTagout machine.

HOT SURFACES. Can cause serious injury. Do not

touch, Allow to cool before servicing. Do nat touch

hot compressor or tubing.

HIGH PRESSURE AIR. Bypassing, modifying or

removing satetyrliof valves can cause serious

injury or death. Do not bypass, modity or remove

‘afetyiolief valves, Do not direct alr stream at body,

Rusted tanks can cause explosion and severe injury

‘or death. Drain tank dally or after each use. Drain

valve located at bottom of tank

RISK OF BURSTING. Use only suitable air handling

parts acceptable for pressure of not less than the

‘maximum allowable working pressure ofthe

machine,

CAUTION

CES

Your air compressor units suitable for operating air tools, caulking

duns, grease guns, sandblasters, ele. Depending on your

‘pplication, the folowing accessories may be required

© Anair pressure regulator to adjust the air pressure entering the

tol or accessory,

© An airline filter for removal of moisture and oil vapor in

compressed air.

© Anintine lubricator to prolong the Ife of ar tools

© Separate ar transformers which combine the functions of ale

reguiation andlor moisture and dirt removal.

Contact your nearest authorized dealer or call 1-800-AIR-SERV for

‘mote Information on a tools and accessories for your application,

eee ee

Ensure adequate liting equipment is available for unloading and

‘moving your unit tothe installation ste,

Note: Liting equipment must be propery rated for the

weight ofthe u

Lit the unit by the shipping skid only. Use straps to

prevent tipping.

.CAUTION Do not work on or walk under the compressor whi

itis suspended.

Before signing the delivery receipt, inspect for damage and missing

atts. If damage or missing parts are apparent, make the

‘Sppropriate notation on the delivery receipt, then sign the receipt

Immediately contact the carer for an inspection, Al material must

bbe held in the receiving location for the carrier's inspection, Delivery

receipts that have been signed without a notation of éamage or

rmissing parts are considered to be delivered “clear.” Subsequent

Claims are then considered to be concealed damage claims. Settle

{amage claims directly wth the transportation company.

Ityou discover damage after receiving the unit (concealed

‘éamage), the carrier must be notiied within 18 days of receipt and

{an inspection must be requested by telephone with confirmation in

‘iting, On conceales damage claims, the burcen of establishing

‘thatthe unit was damaged in transit reverts pack tothe claimant.

Read the unit specification label to verity itis the model ordered,

and read the motor nameplate to verity itis compatible with your

‘electrical conditions. Make sure electrical enclosures and

‘components are appropriate for your application.

© Ingersoll-Rand Company

Printed in U.S.A

Form SCD-877A

March 2002

TEEN

SELECTING A LOCATION.

GENERAL. Select a clean, dry, weighted indoor area with plenty

‘of space for proper cooling ai fiow and accessibility. Locate the unit

atleast 12 inches (30 cm) from walls, and make sure the main

ower supply s clearly dentiied and accessible.

‘TEMPERATURE. Iceal operating temperatures are between 32°F

and 100°F (0°C and 37.8°C). If tomperatures consistently érop

below 32°F (0°C), locate the unit inside a heated building. I this fs

not possible, you must protect safetyirelief valves and drain valves.

{tom freezing,

A.CAUTION Never operate in temperatures below 20°F (6.6%)

lor above 125°F (51.0°C).

HUMID AREAS. In frequently humid areas, moisture may form in

the bare pump and produce sludge in the lubricant, causing running

parts fo wear out prematurely. Excessive moisture is especially

Tkely to occur ifthe unt is located in an unheated area that is

‘subject to large temperatura changes. Two signs of excessive

humidity are external concensation on the bare pump shen it cools

down and a “milky” appearance in petroleum compressor lubricant

‘You may be able to prevent moisture from forming inthe bare pump

by increasing ventilation, operating for longer intervals or installing

a crankcase heater kit.

NOISE CONSIDERATIONS. Consul local officials for information

regarding acceptable noise levels in your area. To reduce excessive

noise, use vibration isolator pads or intake silencers, retocate the

Unit oF construct total enclosures or baffo wall

PERMANENT MOUNTING

A.WARNING Remove the unit from the skid before mounting.

The unit must be permanently mounted. Wen mounting the unt.

bolt the feet toa frm, level foundation (euch as a concrete flea).

Do not bolt uneven feet tightly tothe foundation, as this wil cause

‘excessive sitess on the receiver tank. Use metal shims under the

“short Feet I necessary.

Typical Permanent Mounting (Customer-Supplied Hardware)

Flat Washer

318" Lag Screw

L—

tsoiator

Washer

‘shim beneath \ Flotine

'solator washer,

necessary Lag screw anchor

orconcrete

INSTALLING THE AIR INLET FILTER

A.CAUTION Do not operate the unit without the air Inlet fers).

Ihe ale around the units relatively free of art, instal the alr inet

fiter(s) atthe iniet connecton(s) atthe bare pump. I remote air

inlet piping or heavy duty fitration is required, contact your dealer

{or information,

INSTALLING DISCHARGE PIPING

itis necossary to install air discharge and condensate discharge

pining, adhere tothe following general guidelines. Contact your

‘dealer for more information

A.WARNING Do not use plastic pipe, rubber hose, or lead-in

‘soldered joints anywhere in the compressed air

system,

Ian aftercooler, check valve, block valve, or any

‘other restriction is added to the compressor

discharge, install a properly-sized ASME approved

safetyrellet valve between the compressor

discharge and the restriction.

Ifyou will be using Ingersoll-Rand synthetic

compressor lubricant, all downstream piping

material and systom components must be

compatible, Refer tothe following material

compatibility lst there are incompatible materials

present in your system, orf there are materials not

Included in the list, contact your dealer or call

1-800-AIR-SERV.

WARNING

A. CAUTION

‘Suitable:

‘ton Teton, Epoxy (Glass Filed), Ot Resistant ky, Fuorsileone,

Fliorocaroon, Plyeutic, 2-Component Uretnane, Nylon, Oslen3,

CCalcone. High ite Rubber (Buna N. NBR more man 96% Acro),

Polyurethane, Plyethylene. Epinioronyarin, Polacrylte, Melamine,

Polypropylene, Baked Phenolics Epory, Modiied Akyds

(© inccatos vacomark of DuPont Corporaton)

‘Not Recommended

‘Neoprene, Natural Rubber, SBR Rubber, Acre Paint Lacquer, Vari,

Polystyrene, PVC, ABS, Plycaroonata, Cellulose Acelate, Low Nie

Rubber (Buna N. NBR less than 26% Acryontnle), EPOM, Ethylene inv

‘Aceate, Latex, EPR, Acris, Phenony, Plysulfones, Styrene

‘eryonie (San), Buty

GENERAL REQUIREMENTS. Tho piping, fitings, recelver tank,

tc, must be certified safe for atleast the maximum working

pressure ofthe unit. Use hard-weided or threaded steel or copper

pipes and cast ron fitings that are certified safe forthe unit's

Sischarge pressure and temperature, DO NOT USE PVC PLASTIC.

Use pipe thread sealant on all threads, and make up joins tightly to

prevent air leaks,

CONDENSATE DISCHARGE PIPING. If installing a condensate

discharge ine, the piping must be atleast one size larger than the

connection, as short and direct as possible, secured tightly and

routed 1o suitable drain point. Condensate must be disposed of in

accordance with local, state, and federal laws and regulations.

NOTE All compressed alr systoms gonerate condensate

‘hich accumulates in any drain point (e.g tanks,

filters, drip logs, aftercooler, dryers). This

condensate contains lubricating oll and/or

Substances which may be regulated and must be

disposed of in accordance with local, state, and

{federal laws and regulations.

ELECTRICAL WIRING

4.WARNING Electrical installation and service should be

performed by a qualified electrician who is ferliar

‘ith all applicable local, state and federal laws and

regulations,

‘This product should be connected to a grounded,

metalic, permanent wiring system, or an

‘equipment-grounding terminal or lead on the

product

NOTE

GENERAL. The motor rating, as shown on the motor nameplate,

‘and the power supply must have compatible voltage, phase and

hertz characteristics

WIRE SIZE. The electrical wiring between the power supply anc

slectric motor varies according to motor Norsepower. Power leads

‘must be adequately sized to protect against excessive voltage drop

uring start-up, Information for selecting the proper wire size and

securing connections should be provided with the motor. I not, refer

to the National Electric Code (NEC) or applicable local, state and

federal laws and regulations. If ther electrical equipment is

connected tothe same circuit, the total electrical load must be

considered in selecting the proper wire size, DO NOT USE

UNDERSIZE WIRE,

FUSES. Refer to the National Electric Code to determine the proper

fuse or cult breaker rating required. When selecting fuses,

Femember the momentary starting current of an electic motor is

{reater than its full load current. Time-delay oF "slow-biow” fuses

fare recommenses,

SinglePhese Wing

pp Rt ee

Tal prem svt

Single phase

inctor

COMPRESSOR LUBRICATION.

‘CAUTION Do not operate without lubricant or with inadequate

lubricant. Ingersoll-Rand is not responsible for

compressor failure caused by Inadequate

lubrication.

SYNTHETIC LUBRICANT. We recommend Ingersoll-Rand

synthetic compressor lubricant from start-up, See the WARRANTY

section for extended warranty information

ALTERNATE LUBRICANTS. You may use a petroleum-based

lubricant that is premium quality, does not contain detergents,

contains only anti-rust,ant-oxidation, and ant-foam agents as

Additives, has a flashpoint of 440°F (227°C) or higher, and has an

Aautorigntion point of 850°F (343°C) or higher

See the petroleum lubricant viscosity table below. The table is

intenced as a general guide only. Heavy duty oaerating concitions

require heavier viscosities. Refer specific operating conditions to

your dealer for recommendations.

INITIAL START-UP

Follow this procedure before putting the unit into service forthe frst

4L_Set the pressure switch lover to “OFF”

Pressure Switch Lever

2. Open the sarvice valve fly to prevent air pressure from bulding in

the tank (A=Open, B=Ciosed),

Service Valve

“Temperature Around Unit] Viscosity @ 100" (376°C)] Veco Grace

e “© sus Contstoles|_Ig0___ SAE

Wabslow 44a bee | 150 2 2 0

40-00 44-257 | 500 0 | 100 2

0.125 267-510 | 750 us| 10 0

Ifyou use a petroleum-based compressor lubricant at star-up and

decide to convert to Ingersoll-Rand synthetic compressor lubricant

later on, the compressor valves must be thoroughly decarbonized

and the crankcase must be flushed befare conversion

FILLING PROCEDURES:

4, Unscrew and remove the ol il plug (A).

2. Sloniyfilthe crankcase with lubricant unt the Wricant reaches the

top thread ofthe ofl opening andthe top ofthe sight glass.

CCrankease capacty for te SS is one-half (0.5) ier. Crankcase

capacty for the SSS sone (1 ter.

3. Replace the ofl plug HAND TIGHT ONLY.

3. Move the pressure swich lever to “ON/AUTO". The unt will star.

44. Run the unit for 30 minutes. Ensure the service valve fs uly open

and there is no tank pressure bulé up.

A.CAUTION Unusual noise or vibration indicates a problem. Do

not continue to operate until you identity and

Correct the source ofthe problom. IF EMERGENCY

CONDITIONS ARE ENCOUNTERED, SHUT OFF THE

MAIN POWER IMMEDIATELY.

'5, After 30 minutes, close the service vive fly. The ar receiver wil fll

to cutout pressure and the motor wil stop, The unit is now ready for

Caen

GENERAL

‘Your air compressor was designed for 100% continuous duty

‘operation with the use of Ingersoll-Rand synthetic compressor

lubricant and 60% continuous duty operation withthe use of

petroleum lubricant. In other words, synthetic lubricant allows the

‘compressor to pump continuously without eyeling. Petroleum

lubricant limits the compressor to a maximum of 36 minutes of

‘pumping time per hour. The compressor should not eycie mare than

410 times per hour

NORMAL START-UP.

Sot te pressure suit lover to “OFF”

Close the service valve

‘Altach hose and accessory.

Move tho pressure switch lover to “ON/AUTO. Tho unt wil stat

‘Allow tank pressure to build. The motor wil slop when tank pressure

reaches cut-out pressure

{6._ Open the service valve. The units now roady for use

NoTE When the receiver tank pressure drops below the

factory pre-set minimum, the pressure switch resets

and restarts the unit

WHEN YOU ARE FINISHED:

Set the pressure switch lever to “OFF”

‘Close the service valve fly

Remove the ai tool or accessory

Slowly open the service valve to bleed air pressure down to 20 psig

Slowiy apen the manual drain valve a he bottom ofthe tank to

drain all condensat (water)

Close the dra valve and te service valve forthe next use

TMs

AWARNING Disconnect, lock and tag the main power supply and

release air pressure from the system before

performing maintenance.

All compressed air systems contain maintenance

parts (e.g. lubricating oll fiers, separators) which

fare periodically replaced. These used parts may be,

‘oF may contain, substances that are regulated and

‘must be disposed of in accordance with local, state,

And federal laws and regulations.

Tako note ofthe positions and locations of parts

during disassembly to make reassembly easier. The

assembly sequences and parts illustrated may dif

for your particular unit.

[Any service operations not included inthis section

should be performed by an authorized service

representative.

ROUTINE MAINTENANCE SCHEDULE

Dally orBetore —@ Check lubricant level. Fill as needed

Esch Operation @ Drain receiver tank condensate, Open the

‘manual drain valve and collect and cispose of

condensate accordingly.

© Check for unusual noise and vibration,

‘© Ensure beltguards and covers are securely in

place,

{© Ensure area around compressor is foe from

rags, tools, debris, and flammable or

explosive materials,

Woetty ‘© Inspect air fiter element, Clean or replace if

necessary,

Monthly {© Inspect for aie leaks. Squitt soapy water

around joints during comoressor operation

land watch for bubbles.

|© Check tightness of screws and bolts. Tighten

as needed

© Clean exterior.

500 ‘© Change petroleum lubricant while crankcase

‘212000° ‘© Change synthetic lubricant while crankcase is.

© Replace fter

NoTE

NOTE

NOTE

* nao

35 monthsioperating hours, whichever occurs frst.

FILTER REPLACEMENT (SS3)

41. Unscrew and remove the wing nit (8).

2. Remove the fiter cover (8), bale (C) and element (0) trom the

aso (E).

3._ Install a new element and reassemble the fier assembly.

Note “The air intake holes in the baffle and cover must be

“staggered 180". When reinstalling the assembly at

the inlet connection, ensure the intake hole in the

Cover is on the bottom to minimize the entry of

foreign matter from the ar.

FILTER REPLACEMENT (SS5)____

4. Unsore and remove the wing nut (A) securing the fiter housing (8)

toi base (C),

2. Remove te titer housing and withdraw the od fiter element (D)

Clean the element witha jet of air or vacuum.

3. Replace the ite element and housing, securing tin place wth the

wing nut previously removed.

OIL CHANGE,

4. Romove the oll drain plug (A) and allow the ibrlcat o drain into @

suitable container.

2. Replace tho ol drain plug

3. Follow the filing procedures in OPERATION section

BELT ADJUSTMENT

(CHECKING BELT TENSION Check belt tension occasionally,

especialy if looseness is suspected, A quick check to determine it

Aajustment is proper may be made by observing the slack side of

the belt for a slight bow when the unit isin operation. Ifa slight bow

Is evident, the belt is usually adjusted satstactonly

TENSIONING BELTS Belt tensioning can be achieved by loosening

the motor anchar screws, pushing the motor away from the pump,

‘and retightening the motot anchor screws, The motor can be easily

‘moved by placing a prying too! beneath it. commercially avaiable

Spreader or other belt tensioning device can also be helptul should

tensioning be necessary.

Detection innches [Win Tension (ibs) [Max. Tension (Lbs)

om 20 60

Follow the procedures outlined below to correctly set and measure

belt tension

4, Layaa straight edge across the top outer surface ofthe belt rive

from pulley to sheave.

2. Atthe center ofthe span, perpendicular tothe be, apply pressure

to the outer surface ofthe belt with a tension gauge. Force the belt

to the deflection incicated in the table at right Compare the reading

tnthe tension gauge tothe following tabe.

Ensure the pulley and sheave are properly aligned and the motor

anchor screws are adequately retightened prior to restarting the

‘compressor.

ACAUTION Improper pulleyisheave alignment and belt tension

can result in motor overioad, excessive vibration,

‘and premature belt andlor bearing fallur.

‘To provont those problems from occurring, ensure

the pulley and sheave are aligned and belt tension

is satisfactory aftr installing new belts or

tensioning existing batts.

TANK INSPECTION

‘The life ofan air receiver tank is dependent upon several factors

including, but not limited to, operating conditions, ambient

environments, and the level of maintenance. The exact effect of

these factors on tank ie is dificult to predict; therefore,

Ingersoll-Rand recommends thet you Schedule a cette tank

Inspection within the fist five years of compressor service. To

arrange @ tank inspection, contact the nearest IR Air Center or

istrbutor, or call 1-800-AIR SERV.

If the tank has not been inspected within the fist 10 years of

‘compressor service, the tank must be taken out of service unt it

hhas passed inspection. Tanks that fall to meet requirements must be

replaced

WARNING Failure to replace a rusted ar receivor tank could

result in ar receiver tank rupture or expiosion,

Which could cause substantial property damage,

‘Severe personal injury, or death. Never modify or

ropair tank. Obtain replacement from service center.

CEES

PROBLEM. POSSIBLE CAUSE POSSIBLE SOLUTION.

‘Abnormal pion, ger 4. Lubreant vscoay tos low 1. Drala existing be cant and rel wih proper hbvcant

ine” wear 2 Libres ove! to lw 2. Aas ublcat to erantcove to proper level

3. Detorgont ype avian’ being uso. 3, Drain exiting lubreant and refll wth proper ies

4 Oylinderts) or pistons) searched, worn or sored 4. Repair o” replace as eauired.

5. Exvomaly dusty etmosohare 5 Inca rote aint oiping and routo te source of ceanor

{. Worn eytinder ish ‘4. netall mor affective titration,

6, Deglaze eyinder with 180 grt ex-hone

‘A delvery raps oF 1, Clogged or dty it andor dlacharge Ine Mer. 1. Clean or replace.

2 leaks in sir isenarge ping 2, Check tubing and connections

3. Uoceant scanty too gn 5. Dram existing oc eant andrea win proper horcant

{4 Comoressor valves loky. broken cabonizecorleose. 4. Inepect valve, Clean or replace as required Inetal valve kt

'5 Plton rings damaged or worn (broken, rough a scfatches). 5. Install rng Kt

Excessive end gap or sie clearance 8 Acjust piston ings.

6, Plton rings not seat, are stuck in grooves or end gaps nat 7. Repairer place as eauted.

Stogoerec 8. Replace

7. Cylinders) or pistons) sesiched, worn or cored

8. Defective satotyiaintvaive.

Uni cece nat coms upto 1. Loose betvhel or motor pully, excessive end layin. Chock beltwhoa, moter pulley, erankshat,erive bolt ension

Spee

spood

a

Lubricant viscosity too high,

Improper ine vtage

Comoressor valves feaky. broken, carbonize or loose

Defective ball Bearings an eranksha’t ox motor shat

Lubrcant viscosity to Nigh

Leaking check valve or ehec« valve seat blown out

4nd aignnent Repal’ or tesace 98 requed

Drain exeting brea and refilwth proper orient

Check tine voltage an uparade nes se requled. Contact

Sloetician

Inspect bearings and replace crankshaft assembly

Drain existing Moret and ref wi proper Mbriant

FRoplace chock vaive

Relocate unt fo warmer endronment

Install erankoase eter kt

Replace

pepe

Inadequate venilaion sound bathe

Drive belts to ight or milano

Compressor valves leky. foken. catonlze oF loose.

‘irong beltwhee recon o tation

Relocate un for beta ait ow

‘jue els to proper tension and agnment

Inspect valves. Clean or replace a5 required. Install valve ki

‘Chock tor wing fer proper comecions. Reverse two

teaes on twee-phase motors.

‘Excaesve noise dung

‘Loose betwee! or motor pulley, excessive end layin

‘motor shat or loose sive bl

2, Lubveantviscsity too hgh

seeee

LWoreant ov! fa low

Compressor valves teky,ofoken, earbonlze of oose.

Carbon bull-up on tp of aston).

Defective ball bearings on cranks

Lloaking check valve or chock valves

3 blown out

(Check eltahee, motor pully, cranks, eve belt tension

fd alignment. Rapa’ or renace ae rogue

‘rain exatingbicantand ret wn proper brian,

[Ace lubricant to cranecase to prope love

Inspect valves, Clean or replace a rauites

Install ave I

Clean pisan(}-Repsl or replace requied

Inspect borings and replace eranshaft assembly i

reauires

Replace chock valve,

Excessive staring and

a

Airleaks in ar decharge ping

Pressure switch ferent too narom

Leaking check valve or chock valve soa blown out

Excossive condensate sree ant

‘Chock tubing and connacions

just pressure swien lo ncreaee diferent iferentat

‘djustmont ie provided. Install pressure such win

‘tterontalsaustment entire trent adusient

Replace check vv,

igh al consumption

Me oe Bene

ee

‘Clogged a arty it andlor lacharge Ine te.

Liuoreantisconty to om

Detergent ype tant being used

Piston singe damaged or worn (broken, rough o eratchod)

Excessive end gap or side clearance

Piston rings not seated, are stuck ingrooves or end gaps not

staggered

ylides) or pistons) ses:chod, worn a scored

Crankshaft sas worn or eranksnat scored

Worn cylinder ish

‘lean o pace.

Drain itn rca ang ret wan per ban

Drain essing Mbicant and rfl wih proper brian

Inet ing

‘Rous lta Hogs

FRopa' o” replace as eauired.

Inepect all Repair or replace 2s required.

Replace coal or cranksnat essary

PROBLEM,

POSSIBLE CAUSE

POSSIBLE SOLUTION

1. Loose belinheel or motor pulley, excessive end play in

Inotor shat or loose aie bes

1. Check beth! motor pulley, erankshat rive Bel tension

fa alignment Ropar’ or reslace as roqued

2. Comprenao" valves leaky, broken, carbonized orloose. 2. Inspec valves Clean or replace a requ

53. Carbon buleup on :p af aston). Inca valve wi.

4. Oyinders) or piston) scratched, wor or score. 3. Clean pistons) Repair or replace as required

‘5. Connecting rod piston pin erankin bearings worn or 4, Ropar ot replace as required.

Scores 5. Inspect al, Ropaic or replace as eauired.

6, Defective ball bearings on crankshat or motor shat 6. Inspect bearings and Yeplace crankshat assembly It

rected

ght foker or dim when 4. Improper line voige, 1 Checkin vltage and upgrade tes as requred. Contact,

ring 2. Wing or elecre service pane! to smal ‘section,

53, Poor conact on motor termine of starter connections. 2. Intl propery sized wre or serie oox. Contact elactican

4 improper state overload heaters. 53. Ensure good contact on moto terminals of state

'5 Poor poner regulation (unbalanced Ene) comecions

4. not proper starter ovetoae heaters. Contact lean.

5. Contact poner company.

Moisture in crankcase or 4. Dotegont ype utrioat being used 4. Drain exiting abrcant and refi wih arper horeant

ky appearance 2. Extremely ight uy eels 2. Ronni forlonges duly cytes

pvoloum lubricant using 3. Unt tected in damp of humid lection. 3. Relocat un,

Ineyindors

Motor overload ips oF Grawe 1. Lubricant seco loo hgh 4 Drain exiting lubrcant ond ell wi proper Weant

‘noosa curent 2 Improper ine vlage 2. Chock ine wetage and upgrade nes as oquled. Contact

3. Wiring or eloene service pane! to small sectncan

4 Peer coract on moto terminals of starter connections, 3. Install properly sized wire o service sox. Contact elacten

5, Improper starter overload ators, 44 Enaure good contact on motor trminal o stator

6. Peer power egulaton (unbalanced tne) camectons.

T. Drive belts to ight or misalignoc. 5. Insta proper strtor overload heaters, Contact elctclan

4, Compressor vales lay. broken carbonlzesorlcose, 6 Contac powar company,

8, Gynderta) or piston) eoratehed: worn o scored 7 Aalst bats to proper tnsion and abgnment.

40.Connocing rod, piston Snot erankpin bearings warner Inspect vavos. Clean ot replace as roquloc

‘cores Ineal vive wi

1 Detective ball beatings on erenkshatt or motor shat 9. Rena o replace as requeed

42lLoaking check valve or check valve sot tow ot

‘3-Ambiont temperature to low.

A.nepect al: Repair or replace as eared.

‘inspect seanngs and replace eraniahot assem i

44.800 motor reaties

48.Relocato unto warmer environment.

Conver to syne ubicat.

Replace

‘Wotor wi pot sat 1. lnprope ne valage 1 Check in voltage and upgrade tines a requred. Contact

2. Winng or eleetre service panel too smal Stemlan

3, Poor eonacton motor termine or starter connections, 2, Ital pope sized wire or service 20x. Conta election

4. Improper starter overload heaters. 3, Ensure good contact on motor terminals or eater

55 Bad motor onetstone

4, Inst prope starter overload heaters. Contact alain

5. Replace

Oitn sischarge air ot ubreant sco to ow 4. Drain exiting lobreant and fil wis proper hrcant

pumping} Detergent ype lusteant being used 2. Drain enatingLibicant and rfl with oroper loin

Piston singe damaged or worn (ore, rough or crached). 3. instal ring

Excessive end gay or sie clearance 4 just piston sings

Piston sings not seated, are stick n grooves or end gaps nat 8. Repair or replace as eaured

staggeree 6. Deglaze cinder with 180 grt Rox-hone.

(yids) or pistons) seratched, worn or scored. 1 Dra recover ank wih mani eraln valve

‘Oitleaking tom shat 68

‘Satelit valve "pops"

Worn eytnge nish,

[Exeaseve condensate In recsve ank

Crankshaft sea worn or crankshai cored

‘logged or arty Inet andlor ascharge ine ier.

‘Compressor valvosleay. broken, carbonized or lose.

Defective safetyratit valve

“Replace sl or crankshaft assem.

Clean or pace

apt vas lean or elae a reaes

WARRANTY

Ingersoll-Rand Company warrants thatthe Equipment manufactured by it and delivered hereunder shall be free of defects in material and

workmanship for @ period of twelve (12) months from the date of placing the Equipment in operation or eighteen (18) months from the date

(of shipment, whichever shall occur firs. The foregoing warranty period shall apply fo all Equipment, except for the folowing: (A)

‘Compressors that are operated solely on Ingersoll-Rand Synthetic Compressor Lubricant will have their bare compressor warranted for

‘the earlier of twenty-four (24) months from the date of inital operation or thirty (30) months from the date of shipment. (8) Replacement

parts will be warranted for six (6) months from the date of shipment. Should any failure to conform to this Warranty be reported in writing

to the Company within said period, the Company shall tits option, correct such nonconformity by suitable repair to such Equipment, or

furnish a replacement par F.0.8, point of shipment, provided the purchaser has installed, maintained and operated such equipment in

accordance with good industry practices and has complied with speciic recommendations of the Company. Accessories or equlament

umished by the Company, but manufactured by others, shall cary whatever warranty the manufacturer conveyed to Ingersoll Rand

‘Company ane which can be passed on to the Purchaser. The Company shall not be liable for any repairs, replacements, or adjustments to

the Equipment or any costs of labor performed by the Purchaser without the Company’ prier waiten approval

The Company makes no performance warranty unless specifically stated within its proposal and the effects of corrosion, erosion anc

‘normal wear and tear are specificaly excluded from the Company's Warranty. Inthe event performance warranties are expressly included,

the Company's obligation shail be to correct in the manner and for the perio of me provided above,

‘THE COMPANY MAKES NO OTHER WARRANTY OF REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED,

EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

ARE HEREBY DISCLAIMED.

Correction by tho Company of nonconformitios, whether patent or lant, in the manner and forthe period of time provided above, shall

Constitute fultilment ofall labilties of the Company and ts Distibutors for such nancontormities with respect to or arising out of such

Equipment,

LIMITATION OF LIABILITY

‘THE REMEDIES OF THE PURCHASER SET FORTH HEREIN ARE EXCLUSIVE, AND THE TOTAL LIABILITY OF THE COMPANY, ITS

DISTRIBUTORS AND SUPPLIERS WITH RESPECT TO CONTRACT OR THE EQUIPMENT AND SERVICES FURNISHED, IN

CONNECTION WITH THE PERFORMANCE OR BREACH THEREOF, OR FROM THE MANUFACTURE, SALE, DELIVERY.

INSTALLATION, REPAIR OR TECHNICAL DIRECTION COVERED BY OR FURNISHED UNDER CONTRACT, WHETHER BASED ON

CONTRACT, WARRANTY, NEGLIGENCE, INDEMNITY, STRICT LIABILITY OR OTHERWISE SHALL NOT EXCEED THE PURCHASE

PRICE OF THE UNIT OF EQUIPMENT UPON WHICH SUCH LIABILITY IS BASED.

‘THE COMPANY, ITS DISTRIBUTORS AND ITS SUPPLIERS SHALL IN NO EVENT BE LIABLE TO THE PURCHASER, ANY

‘SUCCESSORS IN INTEREST OR ANY BENEFICIARY OR ASSIGNEE OF THE CONTRACT FOR ANY CONSEQUENTIAL, INCIDENTAL,

INDIRECT, SPECIAL OR PUNITIVE DAMAGES ARISING OUT OF THIS CONTRACT OR ANY BREACH THEREOF, OR ANY DEFECT IN,

(OR FAILURE OF, OR MALFUNCTION OF THE EQUIPMENT, WHETHER OR NOT BASED UPON LOSS OF USE, LOSS PROFITS OR

REVENUE, INTEREST, LOST GOODWILL, WORK STOPPAGE, IMPAIRMENT OF OTHER GOODS, LOSS BY REASON OF SHUTDOWN,

(OR NON-OPERATION, INCREASED EXPENSES OF OPERATION, COST OF PURCHASE OF REPLACEMENT POWER, OR CLAIMS OF

PURCHASER OR CUSTOMERS OF PURCHASER FOR SERVICE INTERRUPTION WHETHER OR NOT SUCH LOSS OR DAMAGE IS

BASED ON CONTRACT, WARRANTY, NEGLIGENCE, INDEMNITY, STRICT LIABILITY OR OTHERWISE.

Questions? Parts? Service?

1-800 AIR SERV

Visit our website:

www.air.ingersoll-rand.com

INGERSOLL-RAND.

AIR COMPRESSORS

Manual del usuario

Instrucciones de instalacién, operacién y mantenimiento

para compresores d’aire estacionarios Modelos SS3 y SS5

INFORMACION IMPORTANTE! LEA Y SIGA ESTAS INSTRUCCIONES. GUARDELAS PARA EFECTOS DE REFERENCIA

SST)

DEFINICIONES.

AE

importantes als propiedsd.

AADVERTENCIA PUEDE causar LA MUERTE, LESIONES GRAVES 0

dafios importantes ala propiedad.

‘CAUSA 0 PUEDE CAUSAR LESIONES MENORES 0

datos ala propiedad.

PRECAUCIONES GENERALES DE SEGURIDAD.

i AIRE DE ADMISION. Puede contener monéxide de

‘carbone w otros contaminantes, Puede causar

Tesiones graves o la muerte, Los compresores de

Ingersoll Rand no estén disefados, destinados

para aire respirable. No se debe usar el are

‘Comprimiso para aplicaciones de aire respirable a

manos que se trate de acuerdo con todas las

normasy reglamentos correspendientes,

AADVERTENCIA VOLTAJE PELIGROSO. Puede causat lesiones

‘graves o Ia muerte, Desconect a energiay purgue

la presion del receptaculo antes de dar

snlenimlente. BloqUearieuquetar la maquina. EL

‘compresor dobe sor conectado a un crite

‘debidamente conectado a tierra, Vea las

Imstrucclones de conexion a tera en el manual, No

‘opere el compresor en condiciones himedas.

‘Almacene dentro.

PARTES MOVILES. Puade causar lesiones graves,

No opere la méquina si se ha retro el protector.

La maquina puede empezar a funcionar

‘automaticamente,-Desconecta Ia enorgia ante de

Garle servicio a la maquina, Bloquearfetiquetarla

maquina

'SUPERFICIE CALIENTE. Puede causar lesiones

‘raves. No tocar. je que se nite antes de dar

Serviclo. No toque el compresor ola tuboria

callonte

[AIRE DE ALTA PRESION La derivacion,

modificacién oretir de las valvulae de

‘Sequridadialvio puede causarlesiones graves ola

muerte, No derive, modiique ortire las valvulas

‘de seguridadilivio, No apunte el uj d

personas. Receptaculos oxidados pueden causs

tina explosida ylesiones graves ola muarte. Oran

‘lrecopticulo dariamonte 0 después cada uso,

‘Valvula de drenajeubicado al fondo det

receptacul.

RIESGO DE EXPLOSION. Utlice solamente pezas,

‘de manipulacion de are adecusdas que sean

ceptable para presiones no menores ala preston

maxima de trabajo admistble de la maquina,

A\PRECAUCION

APRECAUCION

‘CAUSA la MUERTE, LESIONES GRAVES 0 danos

ANE

‘Su compresor de are esta adecuado para la operactén de herramientas

reumatioa,pistolns de caleftoer,pistoles engresadoras, chorresdoras

Ge arena, etc. Se necestan los siguienlos aecesorios segin la

‘pleacion:

(© Un regulacor de la presi de aire para ajustar la presion de ale

© Un to de la linea de aire para eliminar la humesed y el vapor de

aceite del are comprimigo,

© Un tubricacor en linea para prolongar la vida de las hersamientas

© Transtormadiores de alre separados combinando las funciones de

regulacion desire yo Ia elimiacion ce a humedad y sucsedac

Comuniquese con su representante autorizado 0 lame al

1-800-AIR-SERV para informaciones acicionales de las herramle

eumdticas 108 Accesorios de aplicaciones inivduns

Paar

‘Asogirese de que existan equipos de carga adecuados para descargar

Y wasladar su compresor al site de instalacién

NoTA Et equlpo de carga debe estar calibrado

‘adeevadamente para el peso del comprosor.

Levanto ol compresor sélo por los patinos de

‘embarque. Ulicecintas para prevenir

‘Sereumbamionte,

ALPRECAUCION No trabsje ni transite bajo ol comprosor mientras

‘se encuentra suspondido.

[Antes ce fmar el reco de entrega, asegiress de que haya piezas cue

falton 9 que estén dafiadas. Sihay euidencia de dafios o de que faltan

Dlezas, haga la anotacin respectiva en el recibo de entega y hiega,

Firmelo. Comuniquese inmedtatamonto con el ranspartsta para quo

realice una Inspeccion. Todo el material se debe mantener en el lugar

{e recepcion para la Inspeccién del tansportsta, Los reebos de

fntrega firmados que no tienen anoiacion de dafos 0 piezas faanies

‘considaran como prueba do una entraga “sin problomas” Guaiquler

eclamo posterior se consideraré como demanda por datos ocultos.

Ligue evalquier demanda por dios conta empresa de anspor,

SI descubre algin dato después de recibir el ompresor (dafo coulo),

ebe notfear al ransporsta dentro de un plazo de 15 clas despues cel

Feelbo y solar por telefono una inspeceion una confimcion por

{carte En las éemandas por dafios ccutos, a responsabilidad de

tslablecer que el compresor se dari durante el transporte recoe en la

persona que hace el reclamo.

Lea la placa de identiieacion del compresor para verifier que

corresponde al modelo solictado y lea la placa del motor para verifcar

‘ue ex compatible con sus conaiiones eléctrieas. Aseguress de que las

a)a8 componentes electrics sean los adecuados.

© Ingersoll-Rand Company

Prins in U.S.A,

Form ScO-877

marzo de 2000

‘SELECCION DE UNA UBICACION,

GENERALIDADES, Seleccione un ares inlror bien iuminaca con

bastante espacio para permitr una venison, accosilicad y un jo

de air ce enfiamiento adecuados. Ubigue el compresor a una distancia

{e por lo manos 12 pulgadas (30 cin) de las paredes y asogirese co

‘que [a alimentacién principal est claramenta identficaca y accesible

TEMPERATURA. Las tomporaturas de oporacionidcalos fuctdan

{nize los 32°F y los 100°F (0°C y 37.8°C). Silas temperaturas bajan

Sistomaticamente a menos de 32°F (0°C),ubique fa unidad dentro ée un

‘ciicio calentado. Sino es posible, se dobe proteger las valvulas de

‘esahogolsegurdec y do drenaje conra el congelamiono.

APRECAUCION Nohhage funcionar el compresor a tomporaturas

Inforioras ¢ 15°F (26,1°C) 0 superiors alos 125°F

(100).

AREAS HUMEDAS. En areas frecuentemente humedas, 9 puade

‘2cumular humecad en la bombs y produce sedimentos en el ubricante

Esto causara ol desgaste prematuro de is piezas movies. El exoes0

de humedad tone muchas probabiidaces de produce si el compresor

fsa ubicado en un area sin calefaccion sujet a grandes cambias de

Temperatura, Dos signos de exceso de humedad son la condensacion

‘exlema en el compresor cuando este se entra y una apatiencia

“Iochosa" dol ltrleante do petréco. Evite quo se acumulo numodac on

la bomba aumortanco la venlacion, operando la maquina durante

periodos mas prolongados oinstalendo calefaciores en el crt.

CONSIDERAGIONES SOBRE EL RUIDO. Consule 9 las

autoridades locales sobre los nivelesaceptables de rulco en su area,

Para reducir el exceso de ido, use slenciadores en la acmision 0

‘almahaailasaislantes dele vibracion,ubique el compresor en oto luga

‘© construya recints totalmente corrados 0 paredes acustcas,

INSTALACION PERMANENTE

AADVERTENCIA. Antes del montae, retire el compr

patines.

Elcompresor debe ser montaco permanentemente. Empeme o!

‘compresor a una Sase nivelada y firme (por ejemplo, un piso de

‘conorota) No priate excesivamente las patae deenvaladae ala base,

Yya que esto causa un exceso de tension sobre el tanque receptor. i es

necesato, use cusas de metal Bajo Ias patas mas cor,

de os

Montaje permanente tipico (ferreteria suministrada por el cliente)

‘Aranda plana

Tirafondo de 38°

Arandela

el aislador

Curia debajo Lina del piso

Vous aimerez peut-être aussi

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- BW 120-4 English Service TrainingDocument107 pagesBW 120-4 English Service Trainingmauriciolapierre100% (3)

- BopDocument22 pagesBopŞadCherietŞık100% (2)

- High Tech For Highest Pressures: The BOGE SRHV 470-10 Booster.Document2 pagesHigh Tech For Highest Pressures: The BOGE SRHV 470-10 Booster.Air Repair, LLCPas encore d'évaluation

- Yamaha Fazer 1000 Service Manual PartsDocument74 pagesYamaha Fazer 1000 Service Manual PartsIgor MajksnerPas encore d'évaluation

- O MM 8060 Series Iveco MotorsDocument79 pagesO MM 8060 Series Iveco Motorsfishhunter18100% (3)

- REV207 Applications Type of CompressorsDocument86 pagesREV207 Applications Type of CompressorsDaniel Arbeláez100% (1)

- 16S251 Gear Box Kerax DXIDocument140 pages16S251 Gear Box Kerax DXImliugong100% (4)

- Instruction of Ingersoll-Rand Air CompressorDocument18 pagesInstruction of Ingersoll-Rand Air Compressorconimec100% (1)

- BD480 Onwards APF156 875Document28 pagesBD480 Onwards APF156 875jackyt09Pas encore d'évaluation

- Dec40 - User Service Rev5-0Document42 pagesDec40 - User Service Rev5-0Racob FherdzPas encore d'évaluation

- 4B3.9G2 So10737Document72 pages4B3.9G2 So10737Alexis SanchezPas encore d'évaluation

- Air Control 3 Dynamic: ManualDocument53 pagesAir Control 3 Dynamic: ManualmadiPas encore d'évaluation

- Lista de Peças GA75L-110 VSD+Document392 pagesLista de Peças GA75L-110 VSD+GustavoPas encore d'évaluation

- Volvo D13H Shop Armed Vol1Document33 pagesVolvo D13H Shop Armed Vol1Roberth SanchezPas encore d'évaluation

- CD7-60 Year 2003Document96 pagesCD7-60 Year 2003Serrefriair Garcia RefriPas encore d'évaluation

- 0574 8231 35Document2 pages0574 8231 35UbanAirlangga100% (1)

- MAN B&W Diesel Operating InstructionsDocument366 pagesMAN B&W Diesel Operating Instructionspostolache marius100% (3)

- Original Operating Manual - SCC Compressors: Version 1.0 E - 28.05.2017Document104 pagesOriginal Operating Manual - SCC Compressors: Version 1.0 E - 28.05.2017lucasPas encore d'évaluation

- Sample FEA ReportDocument13 pagesSample FEA ReportMario Tirabassi100% (1)

- Spare Parts List R135-180 TZDocument72 pagesSpare Parts List R135-180 TZrenatocamaram0% (1)

- Atlas Copco GA 7+,11,15 VSDDocument188 pagesAtlas Copco GA 7+,11,15 VSDFactoria Santa Isolina100% (1)

- Screw Compressors: Model: VE22-10BDocument30 pagesScrew Compressors: Model: VE22-10BVoştinar IoanPas encore d'évaluation

- Characterization of METHOCEL Cellulose Ethers by Aqueous SEC With Multiple DetectorsDocument11 pagesCharacterization of METHOCEL Cellulose Ethers by Aqueous SEC With Multiple DetectorsCastoriadisPas encore d'évaluation

- Booste - KK - N 501 1 - 2169 - 30281-02 - 02EDocument53 pagesBooste - KK - N 501 1 - 2169 - 30281-02 - 02Ecancan25Pas encore d'évaluation

- High Pressure Air CompressorDocument132 pagesHigh Pressure Air Compressorngphuc6806Pas encore d'évaluation

- Tank Operating Manual Rev 3 PDFDocument54 pagesTank Operating Manual Rev 3 PDFCastoriadisPas encore d'évaluation

- Zick AnalysisDocument12 pagesZick AnalysisrksahayPas encore d'évaluation

- Zick AnalysisDocument12 pagesZick AnalysisrksahayPas encore d'évaluation

- E 50 Parts ManualDocument13 pagesE 50 Parts Manualsteve@air-innovations.co.zaPas encore d'évaluation

- Saddle AnalysisDocument17 pagesSaddle AnalysisAntonio Perez ZornozaPas encore d'évaluation

- BoomDocument59 pagesBoomAnonymous iu95trpxN100% (1)

- Atlas Copco Bedieiningshandleiding GA-75-90-110 21711600Document153 pagesAtlas Copco Bedieiningshandleiding GA-75-90-110 21711600arun kumarPas encore d'évaluation

- GAVSDs - Atlas Copco - Launch New ProductDocument23 pagesGAVSDs - Atlas Copco - Launch New ProductquocthaitnPas encore d'évaluation

- 1.A Type of Condenser Combines The Functions of Condenser and Cooling Tower Is CalledDocument500 pages1.A Type of Condenser Combines The Functions of Condenser and Cooling Tower Is CalledChristopher Lennon Dela CruzPas encore d'évaluation

- CE CF - English PDFDocument8 pagesCE CF - English PDFm.b.homsy100% (1)

- Introduction To Vibration & Pulsation in Reciprocating Compressors (Beta)Document28 pagesIntroduction To Vibration & Pulsation in Reciprocating Compressors (Beta)FabbroxPas encore d'évaluation

- Crowd Cylinder Assembly, Double Acting, 750-Series, 753-Series, 755-Series - 19-388,19-389,19-390Document5 pagesCrowd Cylinder Assembly, Double Acting, 750-Series, 753-Series, 755-Series - 19-388,19-389,19-390ws253294388Pas encore d'évaluation

- SSR20-25 Operators Manual APDD 688B Jun98Document41 pagesSSR20-25 Operators Manual APDD 688B Jun98Diego TravezanutoPas encore d'évaluation

- Airtelligence 2.0 Modbus Anbindung enDocument9 pagesAirtelligence 2.0 Modbus Anbindung enPiotrPas encore d'évaluation

- Norton Abbrasives CatalogDocument212 pagesNorton Abbrasives CatalogCastoriadisPas encore d'évaluation

- ZT 250 FaltanteDocument170 pagesZT 250 FaltanteParis AnabelPas encore d'évaluation

- Atlas Copco Neos Xchange KitsDocument17 pagesAtlas Copco Neos Xchange KitsahmedalgaloPas encore d'évaluation

- Compressor ManualDocument172 pagesCompressor Manualtalabira100% (1)

- Tilaa Asme BPVC 2015: ASME Boiler & Pressure Vessel Code 2015Document2 pagesTilaa Asme BPVC 2015: ASME Boiler & Pressure Vessel Code 2015CastoriadisPas encore d'évaluation

- Tank Vessel HandbookDocument76 pagesTank Vessel HandbooklsgmzPas encore d'évaluation

- GR 110,132,160,200 Instruction Book From SN AIF 078406 20147600Document43 pagesGR 110,132,160,200 Instruction Book From SN AIF 078406 20147600Muhammad Hardius100% (1)

- Aib Ga30-55cDocument42 pagesAib Ga30-55cJose CoelhoPas encore d'évaluation

- SX Series Kaeser CompressorDocument16 pagesSX Series Kaeser CompressorarieprachmanPas encore d'évaluation

- Unifi 40 HPDocument33 pagesUnifi 40 HPFernando Guaman Remache100% (1)

- ZR 315 VSDDocument154 pagesZR 315 VSDLIDAIRPas encore d'évaluation

- Atlasga18 37vsdmanual 2 PDFDocument128 pagesAtlasga18 37vsdmanual 2 PDFJoseph Ilagan100% (1)

- Solenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Document2 pagesSolenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Ramius HamdaniPas encore d'évaluation

- D Operation ManualDocument136 pagesD Operation ManualJorge Lazarte MPas encore d'évaluation

- Astm A285 Grade CDocument3 pagesAstm A285 Grade CCastoriadisPas encore d'évaluation

- Xe-70M Rotary Compressor ControllerDocument3 pagesXe-70M Rotary Compressor Controllerleonardo salesPas encore d'évaluation

- SR Mam 860 ManualDocument24 pagesSR Mam 860 ManualGrmaye AsfawPas encore d'évaluation

- ZH 6000-10000 MK 4 İnst BookDocument90 pagesZH 6000-10000 MK 4 İnst BookESRAPas encore d'évaluation

- Ga37 Api 544978Document322 pagesGa37 Api 544978Franck ChampionPas encore d'évaluation

- Product Catalog 6-25-20Document62 pagesProduct Catalog 6-25-20ahmed hafezPas encore d'évaluation

- Riveted Joints ASME IDocument7 pagesRiveted Joints ASME ICastoriadisPas encore d'évaluation

- PartsDiagram KZ650SR D1 D2Document90 pagesPartsDiagram KZ650SR D1 D2Eduardo Alvarez100% (1)

- Kaeser TG TH TI Series - Dryer ManualDocument40 pagesKaeser TG TH TI Series - Dryer ManualBrandi HillPas encore d'évaluation

- Compressor Ingersool PDFDocument52 pagesCompressor Ingersool PDFFabripreta Santos100% (1)

- Almig Flex GB Web 1 2Document8 pagesAlmig Flex GB Web 1 2sebastianPas encore d'évaluation

- IRN 15 18.5 KW (20 25 HP) IRN 22 30 KW (30 40 HP) : Operation and Maintenance ManualDocument172 pagesIRN 15 18.5 KW (20 25 HP) IRN 22 30 KW (30 40 HP) : Operation and Maintenance ManualNikolay VelchevPas encore d'évaluation

- GD Compressor ManualDocument51 pagesGD Compressor Manualnzj564nxgfPas encore d'évaluation

- 7 - 7005 - 10 - USE Sigma Control BasicDocument36 pages7 - 7005 - 10 - USE Sigma Control BasicWilliam BeadenkopfPas encore d'évaluation

- Guide to Danfoss Capacity Regulators for Refrigeration and Air Conditioning SystemsDocument20 pagesGuide to Danfoss Capacity Regulators for Refrigeration and Air Conditioning Systemsdanyelstoica0% (1)

- Almig Blue S+Document2 pagesAlmig Blue S+indikumaPas encore d'évaluation

- EDE99N - Parts List 13-20-502 v02 - 2010-12-19 - SN S350021Document50 pagesEDE99N - Parts List 13-20-502 v02 - 2010-12-19 - SN S350021mantenimiento pierrotPas encore d'évaluation

- CPA Triplex H EN 1Document20 pagesCPA Triplex H EN 1Nguyễn Tấn KhiêmPas encore d'évaluation

- DTE BrochureDocument8 pagesDTE BrochureAnwar SaeedPas encore d'évaluation

- Start C PDFDocument16 pagesStart C PDFRomanCHubaPas encore d'évaluation

- Manual ALUP FU EmotronDocument88 pagesManual ALUP FU EmotronfacebookszitykaPas encore d'évaluation

- 20142400Document40 pages20142400Max BibikovPas encore d'évaluation

- Ga 5 - 11 Ga 5-15 VSD 2935 0875 44Document16 pagesGa 5 - 11 Ga 5-15 VSD 2935 0875 44elavayenPas encore d'évaluation

- Part ListDocument196 pagesPart ListHfksosnaaoPas encore d'évaluation

- Hes 1250 2015Document74 pagesHes 1250 2015SAUL OSPINOPas encore d'évaluation

- Compresores QuincyDocument220 pagesCompresores QuincyDeibyAguilarPas encore d'évaluation

- Atlas Copco GA 15 To GA 30 Part List 20 21Document2 pagesAtlas Copco GA 15 To GA 30 Part List 20 21RICHARDPas encore d'évaluation

- Ed 1 XAS H 150-175JD 2001-02Document39 pagesEd 1 XAS H 150-175JD 2001-02Victor Ortega SamPas encore d'évaluation

- DENAIR Oil-Free Air Compressor PDFDocument8 pagesDENAIR Oil-Free Air Compressor PDFagasmekatron100% (1)

- Alup Cross Referance FileDocument23 pagesAlup Cross Referance FileFranPas encore d'évaluation

- Oil Less Mtoii Single Stage Manual If3266Document93 pagesOil Less Mtoii Single Stage Manual If3266andsanleaPas encore d'évaluation

- Model NYD Direct Drive Model NYB Belt Drive: Installation, Operation and Maintenance ManualDocument8 pagesModel NYD Direct Drive Model NYB Belt Drive: Installation, Operation and Maintenance Manualanilr008Pas encore d'évaluation

- FRP Tanks: Case HistoryDocument2 pagesFRP Tanks: Case HistoryCastoriadisPas encore d'évaluation

- AGF SAND MEDIA FILTER GUIDEDocument16 pagesAGF SAND MEDIA FILTER GUIDECastoriadisPas encore d'évaluation

- Quick Guides - Pressure Vessel EngineeringDocument6 pagesQuick Guides - Pressure Vessel EngineeringCastoriadisPas encore d'évaluation

- Dio 1000 v5.01x en FullDocument102 pagesDio 1000 v5.01x en FullCastoriadisPas encore d'évaluation

- Kao R.stresses in Spherica - mar.1973.JSRDocument4 pagesKao R.stresses in Spherica - mar.1973.JSRCastoriadisPas encore d'évaluation

- EPOCH4manual PDFDocument164 pagesEPOCH4manual PDFCastoriadisPas encore d'évaluation

- Ansul Bladder Tank Fill and Maintenance Manual PDFDocument17 pagesAnsul Bladder Tank Fill and Maintenance Manual PDFCastoriadis0% (1)

- Novatek Metermatic Water Softener 51877 EnglishDocument12 pagesNovatek Metermatic Water Softener 51877 EnglishCastoriadisPas encore d'évaluation

- 138CurvedThicknessBlocks797 PDFDocument3 pages138CurvedThicknessBlocks797 PDFCastoriadisPas encore d'évaluation

- Mod6 PDFDocument29 pagesMod6 PDFsalman1566Pas encore d'évaluation

- Kunkle300 PDFDocument6 pagesKunkle300 PDFCastoriadisPas encore d'évaluation

- SectionV 2015changes1Document4 pagesSectionV 2015changes1Ahmed Ben NoumaPas encore d'évaluation

- Vertical CompressDocument47 pagesVertical CompressAskar InanPas encore d'évaluation

- CBLE Boiler BookDocument66 pagesCBLE Boiler BookEdgar SaldañaPas encore d'évaluation

- Dio 1000 v5.01x en FullDocument102 pagesDio 1000 v5.01x en FullCastoriadisPas encore d'évaluation

- Load and Resist FactorDocument5 pagesLoad and Resist FactorGustavo Alva100% (1)

- Asme Code Changes: 2015 EDITIONDocument19 pagesAsme Code Changes: 2015 EDITIONInnocent RabiosaPas encore d'évaluation

- Quizix q5000 Series Precision Pumps ManualDocument162 pagesQuizix q5000 Series Precision Pumps ManualFrancyPas encore d'évaluation

- Parts Manual For Susie's Craftsman 18 HP OHV Riding MowerDocument27 pagesParts Manual For Susie's Craftsman 18 HP OHV Riding MowermojarramanPas encore d'évaluation

- Assembly of Gearbox No.4028, 1613Document33 pagesAssembly of Gearbox No.4028, 1613Ahil KhanPas encore d'évaluation

- Series N Hydro Pneumatic Press Cylinder PDFDocument11 pagesSeries N Hydro Pneumatic Press Cylinder PDFranjith sanPas encore d'évaluation

- V-ACT D16E Brochure 22 A 100 3523 - 2007-07Document2 pagesV-ACT D16E Brochure 22 A 100 3523 - 2007-07Rolando Mancilla FloresPas encore d'évaluation

- Magnum Dxi13 Rocker and Valve AdjustmentDocument24 pagesMagnum Dxi13 Rocker and Valve AdjustmentFranky FernandezPas encore d'évaluation

- Radial Piston Pumps Technical Specifications and DimensionsDocument3 pagesRadial Piston Pumps Technical Specifications and DimensionsmdkhandavePas encore d'évaluation

- ME8781 Mechatronics Lab Manual - Experiments on Hydraulic and Pneumatic CircuitsDocument49 pagesME8781 Mechatronics Lab Manual - Experiments on Hydraulic and Pneumatic Circuitsusiaf007100% (1)

- 303-01c Engine - V8 (4V)Document94 pages303-01c Engine - V8 (4V)Darren APas encore d'évaluation

- Energy Lab Manual CompleteDocument54 pagesEnergy Lab Manual CompleteChaithra RPas encore d'évaluation

- BCM - Mechanical UNIT IV NOTESDocument22 pagesBCM - Mechanical UNIT IV NOTESKARTHICK MPas encore d'évaluation

- Range Rover Manual Brakes PDFDocument78 pagesRange Rover Manual Brakes PDFPablo Pacheco Reyes100% (1)

- 1 ADocument8 pages1 ApedroPas encore d'évaluation

- Ring(s), Piston - Engine Block - 2.7L DOHC Engine - Engine - Dodge Journey Service & Repair Manual - DodgiaDocument1 pageRing(s), Piston - Engine Block - 2.7L DOHC Engine - Engine - Dodge Journey Service & Repair Manual - DodgiaCaballitofelizPas encore d'évaluation

- Cast vs Forged Pistons: Which is BetterDocument4 pagesCast vs Forged Pistons: Which is BetterDebasis SoorPas encore d'évaluation

- Mechanotechnology n3 August Question Paper 2021Document10 pagesMechanotechnology n3 August Question Paper 2021t trivaPas encore d'évaluation