Académique Documents

Professionnel Documents

Culture Documents

Alloy Screw Pin Shackle G209A

Transféré par

Rony Prayitno SimeonDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Alloy Screw Pin Shackle G209A

Transféré par

Rony Prayitno SimeonDroits d'auteur :

Formats disponibles

Shackles_Metric.

fm Page 66 Wednesday, September 24, 2008 2:24 PM

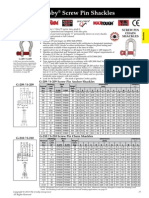

Crosby® Alloy Screw Pin Shackles

G-209A • Capacities 2 thru 21 metric tons.

• Forged Alloy Steel - Quenched and Tempered, with alloy pins.

• Working Load Limit permanently shown on every shackle.

• Hot Dip Galvanized.

• Crosby products meet or exceed all requirements of ASME B30.26

including identification, ductility, design factor, proof load and

temperature requirements. Importantly, Crosby products meet other

critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

• Shackles can be furnished proof tested with certificates to designated

Screw pin anchor shackles meet the standards, such as ABS, DNV, Lloyds, or other certification. Charges

performance requirements of Federal for proof testing and certification available when requested at the time

Specification RR-C-271D Type IVA, of order.

Grade B, Class 2, except for those

s e l k c a h S n i P w e r c S y o l l A ® y b s o r C

provisions required of the contractor.

For additional information, see page 391.

G-209A

Crosby® Alloy Screw Pin Shackles

Working Dimensions Tolerance

Nominal Load SN209AHeader Weight (mm) +/-

Size Limit G-209-A Each

(in.) (t)* Stock No. (kg) A B C D E F G H L M P C A

3/8 2 1017450 .14 16.8 11.2 36.6 9.65 26.2 23.1 45.2 63.5 6.35 51.5 9.65 3.30 1.50

7/16 2-2/3 1017472 .17 19.1 12.7 42.9 11.2 29.5 26.9 51.5 74.0 7.85 60.5 11.2 3.30 1.50

1/2 3-1/3 1017494 .29 20.6 16.0 47.8 12.7 23.3 30.2 58.5 83.5 9.65 68.5 12.7 3.30 1.50

5/8 5 1017516 .63 26.9 19.1 60.5 16.0 42.9 38.1 74.5 106 11.2 85.0 17.5 3.30 1.50

3/4 7 1017538 1.02 31.8 22.4 71.5 19.1 51.0 46.0 89.0 126 12.7 101 20.6 6.35 1.50

7/8 9-1/2 1017560 1.53 36.6 25.4 84.0 22.4 58.0 53.0 102 148 12.7 114 24.6 6.35 1.50

1 12-1/2 1017582 2.41 42.9 28.7 95.5 25.4 68.5 60.5 119 167 14.2 129 26.9 6.35 1.50

1-1/8 15 1017604 3.09 46.0 31.8 108 29.5 74.0 68.5 131 190 16.0 142 31.8 6.35 1.50

1-1/4 18 1017626 4.31 51.5 35.1 119 32.8 82.5 76.0 146 210 17.5 156 35.1 6.35 1.50

1-3/8 21 1017648 6.01 57.0 38.1 133 36.1 92.0 84.0 162 233 19.1 174 38.1 6.35 3.30

* Maximum Proof Load is 2 times the Working Load Limit (metric tons).

Minimum Ultimate Load is 4.5 times Working Load Limit based on Metric tons.

For Working Load Limit reduction due to side loading applications, see page 74.

66 Copyright © 2008 The Crosby Group, Inc.

All Rights Reserved

Vous aimerez peut-être aussi

- Drilling Fluids Processing HandbookD'EverandDrilling Fluids Processing HandbookÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Crosby ShackleDocument1 pageCrosby ShacklevrandyPas encore d'évaluation

- Aluminum Structures: A Guide to Their Specifications and DesignD'EverandAluminum Structures: A Guide to Their Specifications and DesignÉvaluation : 5 sur 5 étoiles5/5 (2)

- Angular Contact Bearing SwivelsDocument1 pageAngular Contact Bearing SwivelsmeromikhaPas encore d'évaluation

- CROSBY Shackle Anchor 1Document1 pageCROSBY Shackle Anchor 1Tapan MehtaPas encore d'évaluation

- Crossby Shackles Catalog G-2130 PDFDocument1 pageCrossby Shackles Catalog G-2130 PDFSam LowPas encore d'évaluation

- Crosby G-2130 Shackle Data Sheet PDFDocument1 pageCrosby G-2130 Shackle Data Sheet PDFdavidandrewleggPas encore d'évaluation

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor ShacklesRaul GutierrezPas encore d'évaluation

- CANAN Steel Deck Catalogue - 2023Document48 pagesCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- Crosby G-257 PDFDocument1 pageCrosby G-257 PDFKonstantinos SynodinosPas encore d'évaluation

- Release & Retrieve ROV Shackle With Non - Thread Bolt Release & Retrieve ROV Shackle With QUIC - Thread BoltDocument1 pageRelease & Retrieve ROV Shackle With Non - Thread Bolt Release & Retrieve ROV Shackle With QUIC - Thread BoltAugusto.FilhoPas encore d'évaluation

- Grade 100 Alloy ChainDocument1 pageGrade 100 Alloy ChainPanthPas encore d'évaluation

- cROSBY LINKSDocument1 pagecROSBY LINKSTheo van der BergPas encore d'évaluation

- Master Link A345Document1 pageMaster Link A345Hunnymijie NorPas encore d'évaluation

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor Shacklesramy abazaPas encore d'évaluation

- SCI GroovedDocument56 pagesSCI GroovedVeer GangjiPas encore d'évaluation

- NonPre Hex 8.8 Nonpreloaded88hex S275 BS5950 UK 15 - 06 - 2021Document5 pagesNonPre Hex 8.8 Nonpreloaded88hex S275 BS5950 UK 15 - 06 - 2021yasser elnessaryPas encore d'évaluation

- Dsi-Usa Dywidag Tie Rods Us 02Document12 pagesDsi-Usa Dywidag Tie Rods Us 02Hery Mardiono HeryPas encore d'évaluation

- Grooved 0910Document15 pagesGrooved 0910Juan Víctor JiménezPas encore d'évaluation

- Crosby 2130 2150Document1 pageCrosby 2130 2150Sumner TingPas encore d'évaluation

- Crosby G-209R ROV ShackleDocument1 pageCrosby G-209R ROV ShacklenatPas encore d'évaluation

- Evaluation of External Loads On Welding Neck Flanges As Per Code Case 2901Document6 pagesEvaluation of External Loads On Welding Neck Flanges As Per Code Case 2901NirmalPas encore d'évaluation

- Jaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyDocument1 pageJaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyGustavo ArancibiaPas encore d'évaluation

- G-277 Cancamo CrosbyDocument1 pageG-277 Cancamo CrosbyDavid Borja HuarachiPas encore d'évaluation

- FT Eslabon Maestro A342Document1 pageFT Eslabon Maestro A342fernando.solarPas encore d'évaluation

- HG 225Document1 pageHG 225Claudio Alvarado ArayaPas encore d'évaluation

- Crosby Bolt Type Shackles: Testing The LimitsDocument1 pageCrosby Bolt Type Shackles: Testing The LimitsStephen KokoPas encore d'évaluation

- S G209 CrosbyDocument1 pageS G209 CrosbyJS168Pas encore d'évaluation

- Catalogue - Crosby G-2130 Bolt Type Shackle PDFDocument1 pageCatalogue - Crosby G-2130 Bolt Type Shackle PDFAnindya SaputraPas encore d'évaluation

- ROV Shackle Design ManualDocument2 pagesROV Shackle Design ManualPrakash SinghPas encore d'évaluation

- Catalogo Crosby ShacklesDocument1 pageCatalogo Crosby Shacklesinternet.casa149Pas encore d'évaluation

- Sling Saver ShackleDocument1 pageSling Saver ShackleFatihTufanPas encore d'évaluation

- ShacklesDocument9 pagesShacklesMuhammad Najam AbbasPas encore d'évaluation

- UPVC Pipe DIN 8062 TdsDocument3 pagesUPVC Pipe DIN 8062 TdsAdany AdenPas encore d'évaluation

- Bolt Capacities: Grade 4.6 Bolts in S355Document3 pagesBolt Capacities: Grade 4.6 Bolts in S355Ah ChiaPas encore d'évaluation

- 45-150 Floor Deck Data SheetDocument1 page45-150 Floor Deck Data SheetAkhil VNPas encore d'évaluation

- Correction To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsDocument2 pagesCorrection To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsTimPas encore d'évaluation

- Hook Shur LocDocument1 pageHook Shur LocCall Wirvin FalcãoPas encore d'évaluation

- GemLock Submital Binder 1 - 2024 03 06 143033 - NtgyDocument21 pagesGemLock Submital Binder 1 - 2024 03 06 143033 - Ntgyjeferjoan.11Pas encore d'évaluation

- BS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020Document88 pagesBS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020MohMohkPas encore d'évaluation

- Forged Machinery Eye Bolts: See Application and Warning InformationDocument1 pageForged Machinery Eye Bolts: See Application and Warning InformationHasrul SunPas encore d'évaluation

- CB2 BucklingDocument2 pagesCB2 Bucklingbranka0savicPas encore d'évaluation

- CB1 Member 444Document2 pagesCB1 Member 444branka0savicPas encore d'évaluation

- Mckissick Overhaul Balls Mckissick Overhaul BallsDocument1 pageMckissick Overhaul Balls Mckissick Overhaul BallsKonstantinos SynodinosPas encore d'évaluation

- CSI Spec Fiberglass PDFDocument5 pagesCSI Spec Fiberglass PDFSubash Bastola100% (1)

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDocument1 pageScrew Pin Anchor Shackles Screw Pin Chain ShacklesJulius HendraPas encore d'évaluation

- Acero Cajon Concr CALCULOS Y PLANOSDocument178 pagesAcero Cajon Concr CALCULOS Y PLANOSESNAYDER WILMAN VASQUEZ ARMASPas encore d'évaluation

- Eye Bolt 1Document1 pageEye Bolt 1Adi SutardiPas encore d'évaluation

- Clevis Grab Hook Crosby® A338 (Grade 80)Document1 pageClevis Grab Hook Crosby® A338 (Grade 80)CROSBYPas encore d'évaluation

- Timber Truss Design: ProjectDocument8 pagesTimber Truss Design: ProjectEvello MercanoPas encore d'évaluation

- Plastic Concrete TestDocument8 pagesPlastic Concrete TestSlan ClanPas encore d'évaluation

- Elbow Dimension PDFDocument2 pagesElbow Dimension PDFquang kinhluanengineeringPas encore d'évaluation

- Dimensions of Long Radius Elbows Dimensions of Short Radius ElbowsDocument2 pagesDimensions of Long Radius Elbows Dimensions of Short Radius ElbowsDedi KartiwaPas encore d'évaluation

- 01 PDFDocument2 pages01 PDFMayur MandrekarPas encore d'évaluation

- Dimensions of Long Radius Elbows Dimensions of Short Radius ElbowsDocument2 pagesDimensions of Long Radius Elbows Dimensions of Short Radius ElbowsbenPas encore d'évaluation

- 00 PDFDocument2 pages00 PDFMayur MandrekarPas encore d'évaluation

- Elbow Dimensions PDFDocument2 pagesElbow Dimensions PDFRadhakrishna VachaPas encore d'évaluation

- 01 PDFDocument2 pages01 PDFMayur MandrekarPas encore d'évaluation

- RT Question LavenderDocument37 pagesRT Question LavenderRony Prayitno Simeon100% (1)

- Manual Mobile Crane Chapter 1Document18 pagesManual Mobile Crane Chapter 1Rony Prayitno SimeonPas encore d'évaluation

- ATTAR Hands On Intro To NDTDocument3 pagesATTAR Hands On Intro To NDTRony Prayitno Simeon0% (1)

- 2013 API U Trainer Application FillLinksDocument1 page2013 API U Trainer Application FillLinksRony Prayitno SimeonPas encore d'évaluation

- Ultrasonic Flaw Specimens KitDocument2 pagesUltrasonic Flaw Specimens KitRony Prayitno SimeonPas encore d'évaluation

- ICE Standards Information BookletDocument18 pagesICE Standards Information BookletRony Prayitno SimeonPas encore d'évaluation

- 04-Use of Optic Aids Info SheetsDocument21 pages04-Use of Optic Aids Info SheetsRony Prayitno SimeonPas encore d'évaluation

- 04-Diff Surface Conditions Info SheetsDocument14 pages04-Diff Surface Conditions Info SheetsRony Prayitno SimeonPas encore d'évaluation

- Crane Inspection EngineerDocument3 pagesCrane Inspection EngineerRony Prayitno SimeonPas encore d'évaluation

- Smart Load Brochure AbcdDocument4 pagesSmart Load Brochure AbcdRony Prayitno SimeonPas encore d'évaluation

- BV RulesDocument14 pagesBV RulesRony Prayitno SimeonPas encore d'évaluation

- NDTDocument83 pagesNDTcanveraza3122Pas encore d'évaluation

- Journal of Atmospheric Science Research - Vol.5, Iss.4 October 2022Document54 pagesJournal of Atmospheric Science Research - Vol.5, Iss.4 October 2022Bilingual PublishingPas encore d'évaluation

- ICD10WHO2007 TnI4Document1 656 pagesICD10WHO2007 TnI4Kanok SongprapaiPas encore d'évaluation

- AcousticsDocument122 pagesAcousticsEclipse YuPas encore d'évaluation

- Morse Potential CurveDocument9 pagesMorse Potential Curvejagabandhu_patraPas encore d'évaluation

- List of Phrasal Verbs 1 ColumnDocument12 pagesList of Phrasal Verbs 1 ColumnmoiibdPas encore d'évaluation

- Pest of Field Crops and Management PracticalDocument44 pagesPest of Field Crops and Management PracticalNirmala RameshPas encore d'évaluation

- The Minimum Means of Reprisal - China's S - Jeffrey G. LewisDocument283 pagesThe Minimum Means of Reprisal - China's S - Jeffrey G. LewisrondfauxPas encore d'évaluation

- LS01 ServiceDocument53 pagesLS01 ServicehutandreiPas encore d'évaluation

- PDF of Tally ShortcutsDocument6 pagesPDF of Tally ShortcutsSuraj Mehta100% (2)

- REAL BABY FOOD: Easy All-Natural Recipes For Your Baby and Toddler by Jenna HelwigDocument8 pagesREAL BABY FOOD: Easy All-Natural Recipes For Your Baby and Toddler by Jenna HelwigHoughton Mifflin Harcourt Cookbooks50% (2)

- AstmDocument5 pagesAstmyanurarzaqaPas encore d'évaluation

- HemoptysisDocument30 pagesHemoptysisMarshall ThompsonPas encore d'évaluation

- Fire Technical Examples DIFT No 30Document27 pagesFire Technical Examples DIFT No 30Daniela HanekováPas encore d'évaluation

- Final Prmy Gr4 Math Ph1 HWSHDocument55 pagesFinal Prmy Gr4 Math Ph1 HWSHKarthik KumarPas encore d'évaluation

- Onset Hobo Trade T Cdi 5200 5400 User ManualDocument3 pagesOnset Hobo Trade T Cdi 5200 5400 User Manualpaull20020% (1)

- LavazzaDocument2 pagesLavazzajendakimPas encore d'évaluation

- Baxter - Heraeus Megafuge 1,2 - User ManualDocument13 pagesBaxter - Heraeus Megafuge 1,2 - User ManualMarcos ZanelliPas encore d'évaluation

- Alpha Sexual Power Vol 1Document95 pagesAlpha Sexual Power Vol 1Joel Lopez100% (1)

- JP Selecta IncubatorDocument5 pagesJP Selecta IncubatorAhmed AlkabodyPas encore d'évaluation

- Taylor Et Al v. Acxiom Corporation Et Al - Document No. 91Document40 pagesTaylor Et Al v. Acxiom Corporation Et Al - Document No. 91Justia.comPas encore d'évaluation

- Monitor Stryker 26 PLGDocument28 pagesMonitor Stryker 26 PLGBrandon MendozaPas encore d'évaluation

- Research Paper On Air QualityDocument4 pagesResearch Paper On Air Qualityluwahudujos3100% (1)

- Unit 1 and 2Document4 pagesUnit 1 and 2Aim Rubia100% (1)

- IIM L: 111iiiiiiiDocument54 pagesIIM L: 111iiiiiiiJavier GonzalezPas encore d'évaluation

- LRAD Datasheet 2000XDocument2 pagesLRAD Datasheet 2000XOkkar MaungPas encore d'évaluation

- Terminal Blocks: Assembled Terminal Block and SeriesDocument2 pagesTerminal Blocks: Assembled Terminal Block and SeriesQuan Nguyen ThePas encore d'évaluation

- Five Kingdom ClassificationDocument6 pagesFive Kingdom ClassificationRonnith NandyPas encore d'évaluation

- PreviewpdfDocument83 pagesPreviewpdfJohana GavilanesPas encore d'évaluation

- Nutrition Great Foods For Getting Vitamins A To K in Your DietDocument1 pageNutrition Great Foods For Getting Vitamins A To K in Your DietDhruv DuaPas encore d'évaluation

- Centrifuge ThickeningDocument8 pagesCentrifuge ThickeningenviroashPas encore d'évaluation