Académique Documents

Professionnel Documents

Culture Documents

AMS - Bransonic Support Racks TDS

Transféré par

sshaffer_90 évaluation0% ont trouvé ce document utile (0 vote)

82 vues2 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

82 vues2 pagesAMS - Bransonic Support Racks TDS

Transféré par

sshaffer_9Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

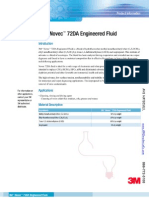

When using an ultrasonic cleaner it is important

not to place components directly on the tank

bottom. This can inhibit the ultrasonic activity

and possibly damage the unit.

Common practice is to use parts baskets to

suspend items in the solution. Baskets, how-

ever, are not practical for all cleaning applica-

tions.

The use of support racks in the bottom of the

ultrasonic cleaner tank is frequently an excel-

lent alternative. Support racks allow the total

volume of the tank to be used. They provide a

stable flat surface upon which parts, fixtures, or

containers may be placed with confidence.

Their open design with integral rubberized

“feet does not inhibit chemistry circulation or

ultrasonics and provides for positive drainage.

Additional racks are also useful as countertop

drain boards following cleaning or processing

They hold containers or components off the

table to facilitate air circulation and drying

Branson Ultrasonics Corporation

SUPPORT RACKS

for use with tabletop

ultrasonic cleaners

KEY BENEFITS

+ A complete range of sizes providing for access to

the full volume of your tank

+ Astable, flat platform for placement of items for

cleaning or processing

+ Assurance that items will not be placed on the

tank bottom potentially damaging the equipment

+ Sizes consistent with most available tabletop

ultrasonic cleaning units

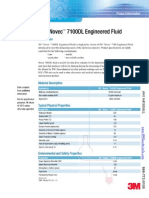

SPECIFICATIONS

Model Part Number Size Fits

SR-15 CPN-916-039 6°x5.5"x0.8" 1/2Gal Unit

SR-25 CPN-916-040 5°x9"x0.8" 3/4 Gal Unit

SR-35 CPN-916-041 58x 11"x0.8" 1 1/2 Gal Unit

SR-55 CPN-916-042 8.5"x 11" x0.8" 21/2 Gal Unit

SR-85 CPN-916-043 11" x 19"x0.8" 5 1/2 Gal Unit

+ All 300 series stainless construction for chemical

compatability

+ Electro-welded design for durability

* Bright electropolished finish for cleanliness

Prnted in USA 6/02

‘STVIISLYH SAY

WPA RAY ORR

801S-Z22-998

ranson is the induscey leader in che design,

development, manufictute, and markecing of

precision cleaning and processing equipment —the

nly company of our caliber worldwide. We are

comicted co providing solutions co the aeeds of our

cuscomess, providing che latest in technology, both in

products and processes. Our global organization

provides us wich boch che esources and the facilis to

suippore our customers on a worldwide bass,

‘With mere than 1,800 employees and 70 sles

sind service offices chroughout the world

Branson's resoures are substan. Tecbology and

manufacturing facies are in Connecticut, Michigan,

New York, Canada, Mexico, Geemaay, France,

Netherlands, Slovakia, China, Hong Kong, Malaysia,

an Japan.

Corporate History

Norman G. founded Branson

Tostruments in 1946 ia. Danbury, CT, co harness

uleeasonic energy for indvsteal purposes. The firs

produce was che Audigage ~ a nondestructive

smaceial thickness este. The company expanded in

1953 by forming Branson Cleaning Equipment

Co. w develop uleaonic deaning equipment

for emerging industrial echoologie.

Branson

In 1960 Beaeson acquired Sonic

Energy Corporation, which

designed and manufactured

the Sonifee™ cell diseuptor for

biological research, Groweh

continued withthe founding in 1963 of Branson,

Sonic Power Co. co expand the uses of high-ineensicy

Luleasonic equipmene

Global

Headquarters—

Danbury,

fh Since 1984 Branson has been among che more

Connecticut

than 50 autonomous divisions of Se. Louis-based

Emerson Electric Co,, a Fortune 100 company.

Bearson Sonic Power Co, and Beanson Cleaning

rent Co, merged in 1986 and the next yeat

combined resources in Danbury, co form Branson

Ulrasonics Corporation

In 1988, Dees Sonics (Paramoune, CA) and

Ulerasons Annemasse (Prance) were acquiced co

eohance syseems building capabilities for precision

cleaning. [a 1992, Branson acquited Vincon, Inc. ia

BRANSON ULTRASONICS CORPORATION

Rochester, NY, a manufacturer of linear and orbital

vibration welders. This facility sow produces non-

ulersonic plasis joining produces including lear

and orbital vibration welders, hot late welders, and

spin welders. The cleaning portion of Westinghouse

was acquired in 1993, bringing Magnapak

‘echnology to the precision cleaning product mix,

Ultrasonics and More

Ulerasonic energy isthe creation and

channeling of high-frequency sound waves for

indusccal purposes.

Wich precision cleaning and processing,

tlteasonic energy i applied co liquid, where

cavitation cesults. Cavitation, the formation and

collapse of chousands of vacuum bubbles, creates a

highly effective scrubbing of both exposed and

hidden surfaces, The use of ulteasonics achieves

higher quality, and move consistent cleaning of pares

foc greater productivity,

In precision processing, new equipment

and chemistries ate being added co address

environmental concerns and che need co meet

increasingly stringenc cleaning. specifications. New

entally-frierlly degreaser lines have been

developed, as have higher-fequency ultrasonics for

submnicron particles. Work in the processing areas of

degassing, cell discupcion

cenhancemenc have been particularly sucessful

Resources

and chemical reaction

‘To ensure corporate growth, Branson emphasizes

the development of new cechnology. This focus i

evident in the full Research and Development

department at our worldwide headquarters,

supported by advanced engineering centers in Asia

Pacific, Europe, and North America, Many patents

have been awarded ehcough the research efforts in

Engineering and the Applications Laboratories.

In che fully-equipped Cleaning Applications

Laboratory, customers’ requirements for new

processes are met. Branson's technical expertise also

4 thared through seminars offered at headquarters,

regional caters, o in the customer’ fii.

41 Eagle Road, Danbury, CT 06813-1961 * (203) 796-0339 * (800) 732-9262 « FAX (203) 796-2240 + www:Bransonic.com

Beamon SE Asa Beason Eeope Branson Jape

Hong Keng Dictaenbch, Geemany Tako, Japan

© Beamon Ulrasonin Corporation 2002

Branton Canada

Markham, Onerio

Isston de Meco

None Lire, Mesice

Primed in S.A, 7102

‘STVIISLYH SAY

801LS-ZL2-998

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- AMS - SQL - Refrigerant Ref TableDocument6 pagesAMS - SQL - Refrigerant Ref Tablesshaffer_9Pas encore d'évaluation

- AMS - 3M - Fluorinert FC-3283Document4 pagesAMS - 3M - Fluorinert FC-3283sshaffer_9Pas encore d'évaluation

- AMS - Bransonic General BrochureDocument8 pagesAMS - Bransonic General Brochuresshaffer_9Pas encore d'évaluation

- AMS - SQL - CFC Naming ConventionDocument10 pagesAMS - SQL - CFC Naming Conventionsshaffer_9Pas encore d'évaluation

- AMS - 3M - Fluorinert FC-3284Document4 pagesAMS - 3M - Fluorinert FC-3284sshaffer_9Pas encore d'évaluation

- Ams - 3M - PF-5060Document4 pagesAms - 3M - PF-5060sshaffer_9Pas encore d'évaluation

- AMS - 3M - Cool Under FireDocument8 pagesAMS - 3M - Cool Under Firesshaffer_9Pas encore d'évaluation

- AMS - 3M - Boiling Enhancement CoatingDocument2 pagesAMS - 3M - Boiling Enhancement Coatingsshaffer_9Pas encore d'évaluation

- AMS - 3M - Fluorinert FC-70Document4 pagesAMS - 3M - Fluorinert FC-70sshaffer_9Pas encore d'évaluation

- Ams - 3M - PF-5060-DLDocument6 pagesAms - 3M - PF-5060-DLsshaffer_9Pas encore d'évaluation

- Ams - 3M - PF-5070Document4 pagesAms - 3M - PF-5070sshaffer_9Pas encore d'évaluation

- AMS - 3M - Novec 7000Document6 pagesAMS - 3M - Novec 7000sshaffer_9Pas encore d'évaluation

- AMS - 3M - Novec 7100DLDocument4 pagesAMS - 3M - Novec 7100DLsshaffer_9Pas encore d'évaluation

- Data Sheet HFE-7300Document4 pagesData Sheet HFE-7300sshaffer_9Pas encore d'évaluation

- AMS - Chemicals LRS FormulaDocument1 pageAMS - Chemicals LRS Formulasshaffer_9Pas encore d'évaluation

- AMS - Branson - B252R TDSDocument2 pagesAMS - Branson - B252R TDSsshaffer_9Pas encore d'évaluation

- AMS - Branson - B252R TDSDocument2 pagesAMS - Branson - B252R TDSsshaffer_9Pas encore d'évaluation

- Ams - 3M - TDS Hfe-72daDocument4 pagesAms - 3M - TDS Hfe-72dasshaffer_9Pas encore d'évaluation

- AMS - Branson - CH Tanks TDSDocument2 pagesAMS - Branson - CH Tanks TDSsshaffer_9Pas encore d'évaluation

- AMS - VaporWorks - Rework 2011Document14 pagesAMS - VaporWorks - Rework 2011sshaffer_9Pas encore d'évaluation

- AMS - Branson - OMNI 2000 1012 TDSDocument2 pagesAMS - Branson - OMNI 2000 1012 TDSsshaffer_9Pas encore d'évaluation

- AMS - Branson - OMNI 2000 1620 1620RI TDSDocument2 pagesAMS - Branson - OMNI 2000 1620 1620RI TDSsshaffer_9Pas encore d'évaluation

- AMS - Branson - S-8500 Generator TDSDocument2 pagesAMS - Branson - S-8500 Generator TDSsshaffer_9Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)