Académique Documents

Professionnel Documents

Culture Documents

Project Opuim

Transféré par

Mallikarjun Bhogavi0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues1 pageTitre original

PROJECT OPUIM

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues1 pageProject Opuim

Transféré par

Mallikarjun BhogaviDroits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

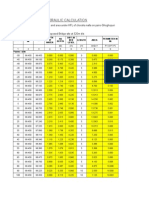

Optimization of Power Utilization in Induction Melting

Heat No: 2 Date : 04/02/2011

Time Quantity of Charge Type of charge Quality of Charge Size of Charge Percentage of rating Line current Line voltage Power status

Frequency Power Voltage R Y B

9.44am 60kg Pig Iron Piglets 74 80 78 510 510 510 410 ON

30kg R.R Sand ip medium ON

9.48am 25kg MS clean medium 74 76 90 490 490 480 400 ON

30kg Return scrap small small ON

9.53am 30kg MS clean medium 78 78 80 480 480 470 400 ON

9.59am 30kg MS clean 82 76 70 490 490 480 400 ON

10.05am 20kg R.R Sand ip medium 86 76 74 500 490 480 400 ON

10.08am 4kg carbon fine ON

10.12am 40kg CR Scrap oily small 90 78 64 490 490 480 400 ON

1kg carbon fine ON

10.15am 20kg CR Scrap oily small 90 78 64 490 490 480 400 ON

10.17am 20kg R.R Sand ip medium 90 78 68 490 490 480 400 ON

10.20am 10kg R.R Sand ip medium 90 78 68 490 490 480 400 ON

10.22am 25kg R.R Sand ip medium 92 78 68 490 490 480 400 ON

10.29am 5kg R.R Sand ip medium 92 78 68 490 490 480 400 ON

10.46am 0.25kg carbon fine ON

10.48am 6kg R.R Sand ip medium 98 78 68 480 480 480 410 ON

10.50am 0 0 0 0 0 0 410 OFF

Initial Meter Reading 3314.2 Required Temprature 1500oC

Final Meter Reading 3317.3 Final Temprature 1595oC

Meter Reading Difference 3.1 Temprature Difference 95oC

Total Time Taken 63 Minutes Total Charge Quantity 346.25kg

Total units; 3.1x80= 248 for 346.25kg

Power consumed in melting 1T Metal = 716.245kWh

1 of 1

Vous aimerez peut-être aussi

- HEAT TREATMENT Process Cycle Details SheetDocument3 pagesHEAT TREATMENT Process Cycle Details SheetPraveen NaikPas encore d'évaluation

- PricelistDocument3 pagesPricelist4 fruit companyPas encore d'évaluation

- Daily Prod Report SGB 02 - 07 - 2022Document2 pagesDaily Prod Report SGB 02 - 07 - 2022Said PrayogiPas encore d'évaluation

- Control de Materias Primas - Enero 2024Document28 pagesControl de Materias Primas - Enero 2024ftony.santosPas encore d'évaluation

- Fokus Cabang Member Ponta dan Penjualan ProdukDocument10 pagesFokus Cabang Member Ponta dan Penjualan ProdukNuur Afif KunPas encore d'évaluation

- FT Ahu-01Document8 pagesFT Ahu-01Liviu ToaderPas encore d'évaluation

- Brighto Ready Mix Price ListDocument2 pagesBrighto Ready Mix Price ListGallery ExploringPas encore d'évaluation

- Cooling Water ME Test Bulan JanuariDocument4 pagesCooling Water ME Test Bulan JanuariAnto AriPas encore d'évaluation

- Mitsui Chemicals catalyst and additive stream specificationsDocument1 pageMitsui Chemicals catalyst and additive stream specificationskara_25Pas encore d'évaluation

- Bulk Material StockDocument8 pagesBulk Material StockAshanmugam SunfacePas encore d'évaluation

- 31 - Well Control Data Sheet For Vertical Wells Wt. & Wt. MethodDocument1 page31 - Well Control Data Sheet For Vertical Wells Wt. & Wt. MethodJunaid MateenPas encore d'évaluation

- Estimted Budget For 3rd Party Testing of Material Under Quality Control Lab MHDCL Project (Per Building)Document1 pageEstimted Budget For 3rd Party Testing of Material Under Quality Control Lab MHDCL Project (Per Building)RSM UnityPas encore d'évaluation

- Unilever Ecuador Weekly Inventory ReportDocument5 pagesUnilever Ecuador Weekly Inventory ReportMonica PradoPas encore d'évaluation

- FT Ahu-02Document8 pagesFT Ahu-02Liviu ToaderPas encore d'évaluation

- Conversion Factors GuideDocument2 pagesConversion Factors GuideAndri MPPas encore d'évaluation

- Peru PiranaDocument1 pagePeru PiranaCarlos A. Villanueva HilaroPas encore d'évaluation

- LVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateDocument1 pageLVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateEMTC EMTCPas encore d'évaluation

- Titanium Ti-6Al-4V Alloy DataDocument2 pagesTitanium Ti-6Al-4V Alloy DataAdriano100% (1)

- Bill of Materials: Location Owner Estimator ProjectDocument1 pageBill of Materials: Location Owner Estimator ProjectMark Roger Huberit IIPas encore d'évaluation

- House - 4th Schedule of FundingDocument1 pageHouse - 4th Schedule of FundingJessalyn Benabese AgudalPas encore d'évaluation

- Determinate Hybrid Tomato BudgetDocument14 pagesDeterminate Hybrid Tomato Budgetwalter mombePas encore d'évaluation

- Conversion FactorDocument2 pagesConversion FactorLea Gerelyn DucayPas encore d'évaluation

- PFE ChubbDocument2 pagesPFE Chubbkuya77Pas encore d'évaluation

- P.E. Grava y ArenaDocument12 pagesP.E. Grava y ArenaNelson Flores MunozPas encore d'évaluation

- Rate AnalysisDocument42 pagesRate AnalysisSwaraj BPPas encore d'évaluation

- WIP SO Fitt May'23Document16 pagesWIP SO Fitt May'23Nur MukhayanPas encore d'évaluation

- Rate Analysis - Salwade To Bharwas ChasDocument81 pagesRate Analysis - Salwade To Bharwas ChasTanmoy DhabalPas encore d'évaluation

- Type Thhn/Thwn-2: ApplicationDocument1 pageType Thhn/Thwn-2: ApplicationhanumehrotraPas encore d'évaluation

- Construction project expenses and purchasesDocument2 pagesConstruction project expenses and purchasesEsther Oilynjoy MelendrezPas encore d'évaluation

- Leyes de NewtonDocument5 pagesLeyes de NewtonLizeth Sanchez TorresPas encore d'évaluation

- BXR SeriesDocument2 pagesBXR Seriesaaron mufukPas encore d'évaluation

- Overview STG-BB Untuk KPDocument56 pagesOverview STG-BB Untuk KPJibraltar Amin SyamPas encore d'évaluation

- CONCRETE MIX DESIGN FOR BRICKSDocument2 pagesCONCRETE MIX DESIGN FOR BRICKSWaqas Muneer KhanPas encore d'évaluation

- 29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodDocument1 page29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodJunaid MateenPas encore d'évaluation

- NoteDocument3 pagesNoteניב דדושPas encore d'évaluation

- Repaso Segundo Parcial - Revisión Del IntentoDocument7 pagesRepaso Segundo Parcial - Revisión Del IntentoPablo VásquezPas encore d'évaluation

- Ipr Satu Fasa (Gilbert)Document2 pagesIpr Satu Fasa (Gilbert)ICHSAN AL SABAH LPas encore d'évaluation

- Check Valve Class 150Document1 pageCheck Valve Class 150abdo elmokademPas encore d'évaluation

- Crude TBP Country Nigeria Distillation: Akpo BlendDocument2 pagesCrude TBP Country Nigeria Distillation: Akpo Blendeke23Pas encore d'évaluation

- Masonry EstimateDocument17 pagesMasonry EstimateEvans Corp100% (1)

- Fence Park BarrierDocument1 pageFence Park BarrierRex Melchor ImperialPas encore d'évaluation

- Ruspetro PI 413 P41 05 EOWDocument15 pagesRuspetro PI 413 P41 05 EOWOleg MalkovPas encore d'évaluation

- Bulk Material: DIVISI. Commercial /dept WHS Sparepart & Raw MaterialDocument24 pagesBulk Material: DIVISI. Commercial /dept WHS Sparepart & Raw MaterialGentaPas encore d'évaluation

- Ship ParticularsDocument1 pageShip ParticularsEmin AbishovPas encore d'évaluation

- Bidco-COCA COLA PRICE LIST 11TH JULY 23Document2 pagesBidco-COCA COLA PRICE LIST 11TH JULY 23nicole wanjaPas encore d'évaluation

- District Office Markfed Sbs Nagar Report of Stock Position For The Month of November 2018Document8 pagesDistrict Office Markfed Sbs Nagar Report of Stock Position For The Month of November 2018nainaPas encore d'évaluation

- Inventory details reportDocument4 pagesInventory details reportRajkumar VenkatapathyPas encore d'évaluation

- Revised Reformulated Sor 2015-16 in Light of G.o.ms - NO.118Document55 pagesRevised Reformulated Sor 2015-16 in Light of G.o.ms - NO.118seshukvsPas encore d'évaluation

- Loading Catalyst by Nippon Ketjen Pertamina BalonganDocument43 pagesLoading Catalyst by Nippon Ketjen Pertamina BalonganKevin MuhammadPas encore d'évaluation

- Chemical StockDocument27 pagesChemical StockTsegaye Mokonen TsmPas encore d'évaluation

- Img NewDocument1 pageImg NewDwi Fajar SantosoPas encore d'évaluation

- Design of Precast Pier Cap - 1Document24 pagesDesign of Precast Pier Cap - 1Ankush SharmaPas encore d'évaluation

- Nameer Corporation MV Grand Royal ExpressDocument3 pagesNameer Corporation MV Grand Royal Expressfriends computerPas encore d'évaluation

- Whirlpool PDF 1.1Document2 pagesWhirlpool PDF 1.1Kip LevinePas encore d'évaluation

- Thesis DataDocument9 pagesThesis DatagskayvePas encore d'évaluation

- Ball Valve Class 300Document1 pageBall Valve Class 300abdo elmokademPas encore d'évaluation

- ROZENBERG ROMANIA AIRBOXDocument8 pagesROZENBERG ROMANIA AIRBOXLiviu ToaderPas encore d'évaluation

- ABC & Co2 MS Standard - SRI - Fire ExtinguisherDocument1 pageABC & Co2 MS Standard - SRI - Fire ExtinguisherEve MdhrPas encore d'évaluation

- Formula 6-AgDocument1 pageFormula 6-AgBernardo HoffmannPas encore d'évaluation

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryD'EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryPas encore d'évaluation

- Design in Tech Report 2016 V 03Document47 pagesDesign in Tech Report 2016 V 03Mallikarjun BhogaviPas encore d'évaluation

- Appendix Linear ProgrammingDocument44 pagesAppendix Linear Programminghksanthosh100% (2)

- LovePills by Mallikarjun BhogaviDocument40 pagesLovePills by Mallikarjun BhogaviMallikarjun BhogaviPas encore d'évaluation

- March30 Yes!+Document2 pagesMarch30 Yes!+Mallikarjun BhogaviPas encore d'évaluation

- Recruitment Summary - 7005 - PepsiCo Global New Products Manager (EMA)Document6 pagesRecruitment Summary - 7005 - PepsiCo Global New Products Manager (EMA)Mallikarjun BhogaviPas encore d'évaluation

- Reciepes DatabaseDocument7 pagesReciepes DatabaseMallikarjun BhogaviPas encore d'évaluation

- IUSServer 8 5 SP3 Admin enDocument118 pagesIUSServer 8 5 SP3 Admin enmahmoud rashedPas encore d'évaluation

- Thesis Document1Document51 pagesThesis Document1ericson acebedoPas encore d'évaluation

- Dsu Teach Camp Schedule 2023Document11 pagesDsu Teach Camp Schedule 2023api-674280680Pas encore d'évaluation

- DCV 03 hk66t102Document15 pagesDCV 03 hk66t102seaqu3stPas encore d'évaluation

- AccuracyDocument6 pagesAccuracyNEETHUPas encore d'évaluation

- Paragonimiasis - AlaboDocument12 pagesParagonimiasis - AlaboJoise Daria AlaboPas encore d'évaluation

- DR Bob Jantzen's Differential GeometryDocument485 pagesDR Bob Jantzen's Differential GeometryBGMoney5134Pas encore d'évaluation

- MT8226 Block Diagram & TV Schematic DiagramsDocument12 pagesMT8226 Block Diagram & TV Schematic DiagramsVijay DanielPas encore d'évaluation

- 12 TalensDocument12 pages12 TalensConsignmenttoduatPas encore d'évaluation

- Parallel RLC Circuit Measurements and CalculationsDocument14 pagesParallel RLC Circuit Measurements and CalculationsJay BetaizarPas encore d'évaluation

- Educ 210Document2 pagesEduc 210Julie Ann CruzPas encore d'évaluation

- ElearningDocument1 488 pagesElearningsudhansu0% (1)

- Worksheet A: Teacher's Notes: Level 2 (Upper Intermediate - Advanced)Document9 pagesWorksheet A: Teacher's Notes: Level 2 (Upper Intermediate - Advanced)Elena SinisiPas encore d'évaluation

- Non-Ferrous Metal SmeltingDocument47 pagesNon-Ferrous Metal SmeltinggtdomboPas encore d'évaluation

- Well Logging Interpretation Methodology For Carbonate Formation Fracture System Properties DeterminationDocument11 pagesWell Logging Interpretation Methodology For Carbonate Formation Fracture System Properties Determinationel hadiPas encore d'évaluation

- The Kerdi Shower Book: John P. BridgeDocument7 pagesThe Kerdi Shower Book: John P. BridgeTima ShpilkerPas encore d'évaluation

- DTC CodesDocument147 pagesDTC CodesV7CT7RPas encore d'évaluation

- A Comparative Study of Engine Mounting System For NVH ImprovementDocument8 pagesA Comparative Study of Engine Mounting System For NVH ImprovementIndranil BhattacharyyaPas encore d'évaluation

- Technical Report: Design of Metal Anchors For Use in Concrete Under Seismic ActionsDocument16 pagesTechnical Report: Design of Metal Anchors For Use in Concrete Under Seismic ActionsJulioGoesPas encore d'évaluation

- HCL Sample PaperDocument32 pagesHCL Sample PaperVaishu RajanPas encore d'évaluation

- Factory Overhead - RFDDocument32 pagesFactory Overhead - RFDSamantha DionisioPas encore d'évaluation

- Hydraulic CaculationDocument66 pagesHydraulic CaculationgagajainPas encore d'évaluation

- Mastering Physics CH 14 HW College Physics I LCCCDocument24 pagesMastering Physics CH 14 HW College Physics I LCCCSamuel100% (5)

- A Dialogue On Perspectives of Biochar Applications and Its Environmental Risks PDFDocument27 pagesA Dialogue On Perspectives of Biochar Applications and Its Environmental Risks PDFMauricio BuenoPas encore d'évaluation

- Toyota G FerroDocument2 pagesToyota G FerrokrilinX0Pas encore d'évaluation

- Example of A Chronological CVDocument2 pagesExample of A Chronological CVThe University of Sussex Careers and Employability CentrePas encore d'évaluation

- Hastelloy B2 Alloy B2 UNS N10665 DIN 2.4617Document3 pagesHastelloy B2 Alloy B2 UNS N10665 DIN 2.4617SamkitPas encore d'évaluation

- Hubungan Kelimpahan Dan Keanekaragaman Fitoplankton Dengan Kelimpahan Dan Keanekaragaman Zooplankton Di Perairan Pulau Serangan, BaliDocument12 pagesHubungan Kelimpahan Dan Keanekaragaman Fitoplankton Dengan Kelimpahan Dan Keanekaragaman Zooplankton Di Perairan Pulau Serangan, BaliRirisPas encore d'évaluation

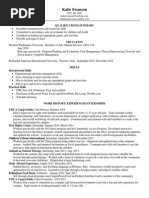

- Katie SwansonDocument1 pageKatie Swansonapi-254829665Pas encore d'évaluation

- Software House C CURE 9000 v2.90: - Security and Event Management SystemDocument5 pagesSoftware House C CURE 9000 v2.90: - Security and Event Management SystemANDRES MORAPas encore d'évaluation