Académique Documents

Professionnel Documents

Culture Documents

Class Outline Design Control

Transféré par

ttk_mani0 évaluation0% ont trouvé ce document utile (0 vote)

30 vues1 pageFDA expects manufacturers to control each step in any design process that produces regulated medical devices. This seminar introduces all aspects of Design Control from Design Inputs through to Design Transfer. Any change in a production process needs to include a consideration of whether the design of the device has been affected.

Description originale:

Titre original

Class Outline Design Control[1]

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentFDA expects manufacturers to control each step in any design process that produces regulated medical devices. This seminar introduces all aspects of Design Control from Design Inputs through to Design Transfer. Any change in a production process needs to include a consideration of whether the design of the device has been affected.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

30 vues1 pageClass Outline Design Control

Transféré par

ttk_maniFDA expects manufacturers to control each step in any design process that produces regulated medical devices. This seminar introduces all aspects of Design Control from Design Inputs through to Design Transfer. Any change in a production process needs to include a consideration of whether the design of the device has been affected.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

Introduction to Design Control

This seminar is specially designed to help engineers,

scientists, and managers implement Design Control as

required by 21 CFR 820.30. FDA expects manufacturers to

control each step in any design process that produces

regulated medical devices.

This seminar introduces all

aspects of design control from

Design Inputs through to Design

Transfer. Participants will come

away with an understanding of

the aspects of Design Control

that they need in order to

perform their job. They may be surprised at the reach of this portion of the CFR. Any change in

a production process needs to include a consideration of whether the design of the device has

been affected.

Who Should Attend: Engineers, scientists, and managers in product development,

production, quality, and support groups; anyone who develops or

changes product designs including the design of the manufacturing

process

Class Length: Half day

Maximum Class Size: 25

Course Prerequisites: Introduction to QSRs

Course Objectives: At the conclusion of the class,

participants will be able to answer

these questions:

• Design and development planning. At what point does Design Control start?

• Design input. What are the needs of the user? What are the needs of the patient? How

are incomplete, conflicting or ambiguous requirements to be addressed?

• Design output. How are the acceptance criteria that essential for the proper functioning

of the device identified? How does one balance the complexity of procedures needed

to control large projects with the need to keep the business viable?

• Design review. Who needs to participate in design reviews? When should they be

scheduled? What needs to be reviewed?

• Design verification. How does one match up design inputs with design outputs when the

design may have changed during the course of the project? What is the Design History

File? What training is necessary for Design Verification?

• Design validation. What is the difference between design validation and process

validation? What is the difference between design validation and design verification?

Where should design validation be documented?

• Design transfer. What procedures are necessary to document proper design transfer to

production?

• Design changes. What constitutes a design change? When during a design project

must change control be implemented?

VALIDATION & COMPLIANCE INSTITUTE

537 Fort Dearborn St.

Dearborn, MI 48124

734-274-4680

Vous aimerez peut-être aussi

- Preparing For Successful Design TransferDocument7 pagesPreparing For Successful Design TransferRahul Dhingra100% (1)

- Design & DevelopmentDocument21 pagesDesign & DevelopmentRahulPas encore d'évaluation

- Detail DesignDocument4 pagesDetail DesignPal_praveenPas encore d'évaluation

- Types of Innovation Process: by Dr. Vijay KR KhuranaDocument43 pagesTypes of Innovation Process: by Dr. Vijay KR KhuranamohitPas encore d'évaluation

- CH 5 Product DesignDocument18 pagesCH 5 Product DesignMahi VirmaniPas encore d'évaluation

- Chapter 6 Design For Quality & Product ExcellenceDocument32 pagesChapter 6 Design For Quality & Product ExcellenceKhazandra Nicole CudapasPas encore d'évaluation

- Design ReviewsDocument10 pagesDesign ReviewsMario LavalleePas encore d'évaluation

- Presented By:: Subodh Adavadkar Nishant Bhoye Shashikishor Chavan Aniket Gaikar Devendra GhudeDocument12 pagesPresented By:: Subodh Adavadkar Nishant Bhoye Shashikishor Chavan Aniket Gaikar Devendra Ghudeaniket7gPas encore d'évaluation

- Procedure For Design andDocument4 pagesProcedure For Design andSharif KhanPas encore d'évaluation

- Design and Development ISODocument7 pagesDesign and Development ISObrenda smith100% (1)

- Process Designer - JDDocument9 pagesProcess Designer - JDMoataz BelkhairPas encore d'évaluation

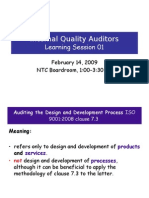

- 01 IQA Learning Session-Design and Development - February 14, 2009Document37 pages01 IQA Learning Session-Design and Development - February 14, 2009Lyne LerinPas encore d'évaluation

- Chapter Five (Managing For Product Quality)Document5 pagesChapter Five (Managing For Product Quality)Marica ShanePas encore d'évaluation

- Cbme ReportDocument38 pagesCbme ReportNessa VillaralboPas encore d'évaluation

- Design Review Procedure For Projects in Fertilizer PlantsDocument9 pagesDesign Review Procedure For Projects in Fertilizer PlantsmanuPas encore d'évaluation

- Chapter 13 - Quality by DesignDocument6 pagesChapter 13 - Quality by Designehtesham_asgharPas encore d'évaluation

- Quality Function Deployment (QFD) Quality Function DeploymentDocument5 pagesQuality Function Deployment (QFD) Quality Function DeploymentApril Rose BaquerosPas encore d'évaluation

- Concurrent EngineeringDocument13 pagesConcurrent EngineeringdressfeetPas encore d'évaluation

- CHAP1 - Product Design Theory and MethodologyDocument61 pagesCHAP1 - Product Design Theory and MethodologySeng SoonPas encore d'évaluation

- 07 Design Drawing and SafetyDocument12 pages07 Design Drawing and SafetySafikul HossainPas encore d'évaluation

- Fundamental of Eng. DesignDocument43 pagesFundamental of Eng. DesignMvelo PhungulaPas encore d'évaluation

- Quality by DesignDocument45 pagesQuality by DesignMoraxell. GGPas encore d'évaluation

- Chapter 2Document66 pagesChapter 2Tinsae LirePas encore d'évaluation

- P 830 Design DevelopmentDocument7 pagesP 830 Design DevelopmentTamara Johnson-Pariag100% (1)

- Production & Operations ManagementDocument0 pageProduction & Operations ManagementAbdul AzisPas encore d'évaluation

- Product and Process DesignDocument47 pagesProduct and Process DesignJai HindPas encore d'évaluation

- Product Design and AnalysisDocument30 pagesProduct Design and AnalysisAbhishek KumarPas encore d'évaluation

- Design For Manufacturing Questions and AnswersDocument18 pagesDesign For Manufacturing Questions and Answersyeswanth100% (2)

- Concurrent EngineeringDocument28 pagesConcurrent EngineeringAnkit SinghPas encore d'évaluation

- Om Unit - Ii MbaDocument60 pagesOm Unit - Ii MbaPrerana eclubPas encore d'évaluation

- Lecture 3 10102022 091737amDocument43 pagesLecture 3 10102022 091737amdoodhjaleybiPas encore d'évaluation

- Chapter 7 FinaceDocument43 pagesChapter 7 FinaceMiakeresuTsukamitoPas encore d'évaluation

- Ipd BnoDocument33 pagesIpd BnoluminabaPas encore d'évaluation

- Updated Quality Management PlanDocument3 pagesUpdated Quality Management PlanLok SewaPas encore d'évaluation

- Chapter 4. Quality Function DeploymentDocument35 pagesChapter 4. Quality Function DeploymentENGINEER'S MINDSPas encore d'évaluation

- Procedure For Designing and Developing ProjectDocument3 pagesProcedure For Designing and Developing ProjectMalu Paras LacsonPas encore d'évaluation

- PLCM2 1Document25 pagesPLCM2 1sayandh spPas encore d'évaluation

- Lesson 2 - PRODUCTS, PROCESS AND SCHEDULE DESIGNDocument30 pagesLesson 2 - PRODUCTS, PROCESS AND SCHEDULE DESIGNMazey AustriaPas encore d'évaluation

- Project Closure ReportDocument19 pagesProject Closure ReportChaitanya MalhotraPas encore d'évaluation

- Chapter Three Design of The Operation SystemDocument80 pagesChapter Three Design of The Operation Systemhabtamu tadessePas encore d'évaluation

- Product Development Through CimDocument57 pagesProduct Development Through CimShalom HailePas encore d'évaluation

- Product Development CycleDocument61 pagesProduct Development CycleISHANPas encore d'évaluation

- Concurent Engineering CH 1Document11 pagesConcurent Engineering CH 1kuba DefaruPas encore d'évaluation

- Piping EngineersDocument19 pagesPiping EngineersYuliyan StoyanovPas encore d'évaluation

- TQM Chapter 4 Process FocusDocument37 pagesTQM Chapter 4 Process Focusreyeselis0823Pas encore d'évaluation

- Chapter Three Design of The Operation SystemDocument79 pagesChapter Three Design of The Operation SystemEyob FekaduPas encore d'évaluation

- Design Documentation L4Document27 pagesDesign Documentation L4KOFI BROWNPas encore d'évaluation

- Product Design and Development: by Prashanth.P Lecturer - I.E.M S.I.TDocument57 pagesProduct Design and Development: by Prashanth.P Lecturer - I.E.M S.I.TKumar AbhishekPas encore d'évaluation

- Design Mee2008 VusDocument42 pagesDesign Mee2008 VusRajesh RJPas encore d'évaluation

- V&V White PaperDocument12 pagesV&V White PaperRichard CarsonPas encore d'évaluation

- Presentation New Product Design 3Document39 pagesPresentation New Product Design 3priyaa03Pas encore d'évaluation

- CEPOA-7.3-1 Design Quality ManagementDocument18 pagesCEPOA-7.3-1 Design Quality ManagementTanmay Kumar100% (1)

- ME3013 Chap 5Document7 pagesME3013 Chap 5pavetran raviPas encore d'évaluation

- QAP 4.0 - Design Control - Rev B (G) PDFDocument13 pagesQAP 4.0 - Design Control - Rev B (G) PDFPrakash TiwariPas encore d'évaluation

- Module 7 Construction Project Quality ManagementDocument27 pagesModule 7 Construction Project Quality ManagementOkita SoujiPas encore d'évaluation

- Quality & Product ExcellenceDocument104 pagesQuality & Product ExcellenceAbhishek SrivastavaPas encore d'évaluation

- Concurrent EngineeringDocument37 pagesConcurrent EngineeringPramod GowdaPas encore d'évaluation

- Design For Manufacturability PDFDocument4 pagesDesign For Manufacturability PDFCarlos Andrés Pérez EstradaPas encore d'évaluation

- UAE HC Annual Report 2011Document40 pagesUAE HC Annual Report 2011ttk_maniPas encore d'évaluation

- Hazard Analysis Critical Control Points (HACCP) - Principle 1: Conduct A Hazard AnalysisDocument9 pagesHazard Analysis Critical Control Points (HACCP) - Principle 1: Conduct A Hazard Analysisttk_maniPas encore d'évaluation

- The Design of Hazard Analysis Critical Control Point (HACCP) Plan For Biscuit PlantDocument7 pagesThe Design of Hazard Analysis Critical Control Point (HACCP) Plan For Biscuit Plantttk_maniPas encore d'évaluation

- Stabilizer PDFDocument8 pagesStabilizer PDFttk_maniPas encore d'évaluation

- Milk ProcesScan Datasheet - GBDocument2 pagesMilk ProcesScan Datasheet - GBttk_maniPas encore d'évaluation

- Using The Childrens Play Therapy Instrument CPTIDocument12 pagesUsing The Childrens Play Therapy Instrument CPTIFernando Hilario VillapecellínPas encore d'évaluation

- Free End SaddleDocument5 pagesFree End SaddleAdry AnnaPas encore d'évaluation

- Treatment Project Vat - Visual Action TherapyDocument22 pagesTreatment Project Vat - Visual Action Therapyapi-257850539100% (1)

- Colgate Marketing ReportDocument16 pagesColgate Marketing ReportRaja GuruPas encore d'évaluation

- BiotechnologyDocument39 pagesBiotechnologyChrystal Kyla SalengaPas encore d'évaluation

- Top 10 Ranking Universities in West Africa 2022Document1 pageTop 10 Ranking Universities in West Africa 2022Bright OtcherePas encore d'évaluation

- Climbing Training Log - TemplateDocument19 pagesClimbing Training Log - TemplateKam Iqar ZePas encore d'évaluation

- The Adult Psychodiagnostic Chart 2012 1.7 PDFDocument3 pagesThe Adult Psychodiagnostic Chart 2012 1.7 PDFMF LeblancPas encore d'évaluation

- Checking Vital SighnDocument14 pagesChecking Vital SighnAdimas AnggaraPas encore d'évaluation

- PSC Question BankDocument9 pagesPSC Question BankFaisal qblp100% (29)

- Action Plan GPPDocument3 pagesAction Plan GPPMa Rk AntonioPas encore d'évaluation

- Todentj 9 250 PDFDocument7 pagesTodentj 9 250 PDFRSU DUTA MULYAPas encore d'évaluation

- Psychology of ProcrastinationDocument7 pagesPsychology of ProcrastinationPauline Wallin100% (2)

- Raynaud Syndrome Brochure-1 1Document2 pagesRaynaud Syndrome Brochure-1 1api-340995574Pas encore d'évaluation

- Hygienic Design Food IndustryDocument19 pagesHygienic Design Food IndustryLinaArev H100% (1)

- Hearing Handicap Inventory For The Elderly (HHIE)Document5 pagesHearing Handicap Inventory For The Elderly (HHIE)Is GutiérrezPas encore d'évaluation

- PQC-POL002 Qualification Guide For CertOH and iCertOH v1.0Document25 pagesPQC-POL002 Qualification Guide For CertOH and iCertOH v1.0Nathan MwewaPas encore d'évaluation

- Coca Cola Fairlife CaseDocument4 pagesCoca Cola Fairlife Caseapi-315994561Pas encore d'évaluation

- Effectiveness of Maitland vs. Mulligan Mobilization Techniques in (Ingles)Document4 pagesEffectiveness of Maitland vs. Mulligan Mobilization Techniques in (Ingles)mauricio castroPas encore d'évaluation

- Selective, Differential, & Enriched Media Lab ChartDocument2 pagesSelective, Differential, & Enriched Media Lab ChartFrankiesgirl6yr100% (6)

- Mapeh 2ND QDocument5 pagesMapeh 2ND QMaxicris SlowerPas encore d'évaluation

- Invenia ABUS USA Brochure Feb2016Document14 pagesInvenia ABUS USA Brochure Feb2016Asim AliPas encore d'évaluation

- Trasturel 440mg Anti CancerDocument3 pagesTrasturel 440mg Anti CancerRadhika ChandranPas encore d'évaluation

- Latin Eugenics in Comparative PerspectiveDocument356 pagesLatin Eugenics in Comparative PerspectivemafePas encore d'évaluation

- Med Tech LawsDocument78 pagesMed Tech LawsMarie LlanesPas encore d'évaluation

- Promoting Smart Farming, Eco-Friendly and Innovative Technologies For Sustainable Coconut DevelopmentDocument4 pagesPromoting Smart Farming, Eco-Friendly and Innovative Technologies For Sustainable Coconut DevelopmentMuhammad Maulana Sidik0% (1)

- Task 1 FinalDocument4 pagesTask 1 FinalAlᎥyⱥภPas encore d'évaluation

- Periodontal AbscessDocument27 pagesPeriodontal AbscessAhmed Tawfig GamalPas encore d'évaluation

- Export of SpicesDocument57 pagesExport of SpicesJunaid MultaniPas encore d'évaluation

- Neurobiologic Theories and PsychopharmacologyDocument2 pagesNeurobiologic Theories and Psychopharmacologymyer pasandalanPas encore d'évaluation