Académique Documents

Professionnel Documents

Culture Documents

Decoupler

Transféré par

syedahmedsabirDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Decoupler

Transféré par

syedahmedsabirDroits d'auteur :

Formats disponibles

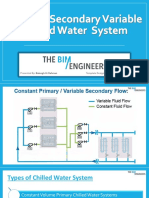

CHILLED WATER PRIMARY/SECONDARY VARIABLE FLOW SYSTEMS. Multiple chiller plants use primary/ secondary variable flow configuration.

There are two loops in this set up. One is plant side loop. It includes chillers, primary pumps and decoupler line. It makes a complete circuit. Primary pumps are low head pumps. They are selected to meet head of this circuit only. This circuit is called primary loop. Second circuit is the system loop or secondary loop. It comprises secondary pump, piping network in the building and all air side equipment. Secondary pump covers friction losses of piping system, cooling coils, control valves, all fittings and return piping up to cross over bridge. Secondary pump is variable speed pump. Primary pump is constant speed pump. When air conditioning loads in the building drops, it requires less water to meet building needs. Providing same volume of water at these conditions is wastage of pumping energy. Therefore, secondary pump varies its speed according to building requirements. Pressure differential transducer is installed at the remote leg of piping circuit. When number of control valves close due to drop in cooling demand, pressure in the pipe lines increases. Control valves on air side equipment are two way types. These reduce flow of water to the coil. Less flow to the coils increases pressure in the lines. Increased pressure is sensed by differential pressure sensor in the lines. This signal is transmitted to controller which reduces secondary pump speed to maintain required pressure differential in the lines. When flow of water in the secondary circuit increases, water flows in the crossover bridge in reverse direction. It mixes with supply water from chiller and increases supply water temperature to the cooling coils. Warmer water is unable to meet air handling unit requirement. Due to this, control valves open more under these conditions. Desirable direction in decoupler line is from primary supply to primary return. In this case primary water flow exceeds secondary water flow. When excess water is equal to a chiller capacity, one chiller is taken out of circuit or destaged. For this purpose flow meter is installed in decoupler line. For chiller staging, bidirectional flow sensor is used to ascertain direction of flow. When this sensor reads flow from secondary return to secondary supply, it starts a new chiller. It means there is more demand of cooling in the building. Size of decoupler line is kept equal to pump header size. It is long enough to minimize sharp bends before and after flow meter and water flow sensor. Diameter is kept large to minimize pressure drop through this line.

Vous aimerez peut-être aussi

- Different Control Strategies For Chiller PlantDocument19 pagesDifferent Control Strategies For Chiller PlantAnkit AbhinavPas encore d'évaluation

- Tyco Pre Action LimitsDocument13 pagesTyco Pre Action LimitsGrbayern Munchen100% (2)

- Air Curtain Guide DesignDocument8 pagesAir Curtain Guide Designanton7786Pas encore d'évaluation

- Electric Duct HeatersDocument13 pagesElectric Duct HeatersKhizerPas encore d'évaluation

- Domestic Hot Water Solutions Guide For HospitalsDocument8 pagesDomestic Hot Water Solutions Guide For HospitalsFarhang MotallebiPas encore d'évaluation

- Fire Fighting Pipe Sizing UAEDocument2 pagesFire Fighting Pipe Sizing UAEgiemy george100% (1)

- 5310 20170830 Mechanical Specification R2Document630 pages5310 20170830 Mechanical Specification R2rajatPas encore d'évaluation

- Flow Tech Louvers PDFDocument10 pagesFlow Tech Louvers PDFMoriyasuNguyenPas encore d'évaluation

- System Design Manual-DPCVDocument29 pagesSystem Design Manual-DPCVrama_easPas encore d'évaluation

- CP13 - 1999 MV and AC in BuildingDocument56 pagesCP13 - 1999 MV and AC in Buildingbozow bozowlPas encore d'évaluation

- Decoupler RecommendationsDocument1 pageDecoupler RecommendationsWaleed FathiPas encore d'évaluation

- Heat Wheel Technical HandbookDocument29 pagesHeat Wheel Technical Handbooksripriya01Pas encore d'évaluation

- Ruskin Fire DamperDocument4 pagesRuskin Fire DamperRAGANPas encore d'évaluation

- Staircase Pressurization System TestingDocument5 pagesStaircase Pressurization System TestingJavedPas encore d'évaluation

- Kitchen Exhaust/Fresh Air Fan Sequence: To BMS For MonitoringDocument2 pagesKitchen Exhaust/Fresh Air Fan Sequence: To BMS For MonitoringShiyam SathiyajithPas encore d'évaluation

- Condensate Drain Calculation - Lab AHU PDFDocument1 pageCondensate Drain Calculation - Lab AHU PDFAltaf KhanPas encore d'évaluation

- تقرير تدريب صيفي لواء الدين مظفرDocument23 pagesتقرير تدريب صيفي لواء الدين مظفرlalaPas encore d'évaluation

- Hot Water Circulation Pump Sizing1Document1 pageHot Water Circulation Pump Sizing1imtiyaz94Pas encore d'évaluation

- Installation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreDocument25 pagesInstallation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreScherraine Khrys CastillonPas encore d'évaluation

- Acoustic Calculation of Ventilation SystemsDocument49 pagesAcoustic Calculation of Ventilation SystemsHari Babu DharmavarapuPas encore d'évaluation

- Double Regulating ValveDocument24 pagesDouble Regulating ValveMohamed Rady33% (3)

- A Method of Damper Control For Corridor Ventilation and Smoke ExtractionDocument15 pagesA Method of Damper Control For Corridor Ventilation and Smoke ExtractionrasheedillikkalPas encore d'évaluation

- Ventilation - Electrical Rooms PDFDocument4 pagesVentilation - Electrical Rooms PDFvalentinlupascu33Pas encore d'évaluation

- Carrier Cooling Load Hand Book-1 PDFDocument16 pagesCarrier Cooling Load Hand Book-1 PDFAsep Uhan SugandiPas encore d'évaluation

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Document5 pagesProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaPas encore d'évaluation

- MAHU Catalogue 2015Document16 pagesMAHU Catalogue 2015Ong MatPas encore d'évaluation

- Chiller PlantDocument1 pageChiller PlantSudhir KulkarniPas encore d'évaluation

- Mullti-Story Building Water Supply Pumping: Roof TanksDocument7 pagesMullti-Story Building Water Supply Pumping: Roof TanksAjay Raju.bPas encore d'évaluation

- VRF & DX Split Type ACU Testing MethodologyDocument1 pageVRF & DX Split Type ACU Testing MethodologydamianPas encore d'évaluation

- Non Pressurised Cold Water Pipe SizingDocument5 pagesNon Pressurised Cold Water Pipe SizingZiaullah BiyabaniPas encore d'évaluation

- Chilled Water Piping Systems (VPF Focus)Document48 pagesChilled Water Piping Systems (VPF Focus)albrgmail100% (1)

- Sample Pneumatic Tube SystemDocument2 pagesSample Pneumatic Tube Systemmajortay100% (1)

- Hot Water Circulating Pump Cal2Document3 pagesHot Water Circulating Pump Cal2mansidaughtPas encore d'évaluation

- NBC vs. NFPADocument12 pagesNBC vs. NFPAMGHIRBI HAYKELPas encore d'évaluation

- Water Treatment For Closed Heating and C PDFDocument112 pagesWater Treatment For Closed Heating and C PDFhans30Pas encore d'évaluation

- Design Calculation Sheet: Water Demand & Drainage FlowDocument5 pagesDesign Calculation Sheet: Water Demand & Drainage FlowAhmadPas encore d'évaluation

- Run Around Coil Loop Heat RecoveryDocument3 pagesRun Around Coil Loop Heat RecoveryesagcojrPas encore d'évaluation

- TCVN - English VersionDocument4 pagesTCVN - English Versionambition1340cnPas encore d'évaluation

- Carrier E20-II Design Software Hourly Analysis Program v4.60 Release SheetDocument2 pagesCarrier E20-II Design Software Hourly Analysis Program v4.60 Release SheetZeeshan HasanPas encore d'évaluation

- Fcu PipingDocument20 pagesFcu PipingRamadan RashadPas encore d'évaluation

- Flowtech Grilles & RegisterDocument3 pagesFlowtech Grilles & RegisterLeomark RespondePas encore d'évaluation

- Regulation DD-9.0: Drainage: 9.1 Domestic Drainage 9.2 Water Supply 9.3 Rainwater Drainage 9.4 A/C DrainDocument10 pagesRegulation DD-9.0: Drainage: 9.1 Domestic Drainage 9.2 Water Supply 9.3 Rainwater Drainage 9.4 A/C DrainSarathPas encore d'évaluation

- As 2419 1 2005 Fire Hydrant Installations System Design Installation and Commissioning PDFDocument9 pagesAs 2419 1 2005 Fire Hydrant Installations System Design Installation and Commissioning PDFtamago_fuji100% (1)

- AHU Design GuideDocument37 pagesAHU Design Guidesachin100% (1)

- Ashrae Design Manual For Smoke ControlDocument6 pagesAshrae Design Manual For Smoke Controlist93993100% (2)

- BS 7562 5 IrrigationDocument32 pagesBS 7562 5 IrrigationSana UllahPas encore d'évaluation

- Evoflat HandbookDocument72 pagesEvoflat HandbookanescuveronicaPas encore d'évaluation

- Master Clock SystemDocument4 pagesMaster Clock SystemAli SaifPas encore d'évaluation

- Test Procedures AIR BALANCEDocument1 pageTest Procedures AIR BALANCEhabebePas encore d'évaluation

- Elite Software: Fire Hydraulic Calculation ProgramDocument48 pagesElite Software: Fire Hydraulic Calculation ProgramKhaled HelmyPas encore d'évaluation

- Systemair CatalogueDocument21 pagesSystemair CataloguePARVEZ AMEENPas encore d'évaluation

- PPR Pipe Insulation GraphDocument10 pagesPPR Pipe Insulation GraphJonPas encore d'évaluation

- FAHU SubmittalDocument62 pagesFAHU SubmittalEngr.MmosaadPas encore d'évaluation

- Air Distribution Engg GuideDocument8 pagesAir Distribution Engg GuideNiong DavidPas encore d'évaluation

- Car Parks Presentation FlaktWoodsDocument87 pagesCar Parks Presentation FlaktWoodsChidi Henry100% (1)

- Buffer Tank Hydraulic SeparatorDocument4 pagesBuffer Tank Hydraulic SeparatorJohn MorePas encore d'évaluation

- Water Distribution: Cross Connection Control Water ConservationDocument10 pagesWater Distribution: Cross Connection Control Water ConservationOwolabi RuthPas encore d'évaluation

- HVAC Primary Secondary Variable Pump Chilled Water System 1671810474Document35 pagesHVAC Primary Secondary Variable Pump Chilled Water System 1671810474Robby Renz100% (1)

- Constant Volume - Constant Speed. Chilled Water Systems. Chillers Pumps & PiDocument3 pagesConstant Volume - Constant Speed. Chilled Water Systems. Chillers Pumps & PiMohamed AdelPas encore d'évaluation

- Hydropneumatic Schemematics331 380Document2 pagesHydropneumatic Schemematics331 380wnewell1Pas encore d'évaluation

- Building Management SystemsDocument48 pagesBuilding Management Systemsapi-19789368100% (4)

- Armstrong HSC 60hz PressureRangeDocument2 pagesArmstrong HSC 60hz PressureRangesyedahmedsabirPas encore d'évaluation

- Neptune Benson ANTI VORTEX PLATES Tech DataDocument1 pageNeptune Benson ANTI VORTEX PLATES Tech DatasyedahmedsabirPas encore d'évaluation

- Sl. No. Area Floor Flat Description Rent House Hold Items Description Contact No. Date of Availability RemarksDocument1 pageSl. No. Area Floor Flat Description Rent House Hold Items Description Contact No. Date of Availability RemarkssyedahmedsabirPas encore d'évaluation

- Flat Searching OptionDocument1 pageFlat Searching OptionsyedahmedsabirPas encore d'évaluation

- Project Time ManagementDocument29 pagesProject Time ManagementsyedahmedsabirPas encore d'évaluation

- Chiller Pump ConnectionsDocument8 pagesChiller Pump Connectionsfactor_VIIIPas encore d'évaluation

- Enfinity Water Source Heat Pumps: Small Capacity Horizontal Ceiling-Mounted ModelsDocument4 pagesEnfinity Water Source Heat Pumps: Small Capacity Horizontal Ceiling-Mounted ModelsHector LuisPas encore d'évaluation

- Taiba Engineering Consultants (TEC MEP Institute) HVAC - 1. - Load CalculationDocument1 pageTaiba Engineering Consultants (TEC MEP Institute) HVAC - 1. - Load CalculationMaaz Uddin SiddiquiPas encore d'évaluation

- Aedgze K12 2018 20180201Document226 pagesAedgze K12 2018 20180201Terra ConsulPas encore d'évaluation

- (26-6-1) NPTEL - CryocoolersDocument36 pages(26-6-1) NPTEL - CryocoolerspraphultmenonPas encore d'évaluation

- Troubleshooting Refr SystemsDocument12 pagesTroubleshooting Refr SystemsDnyanesh BodrePas encore d'évaluation

- Carel Controler PDFDocument80 pagesCarel Controler PDFGinguba100% (1)

- SPACE PLANNING From Time Saver Standards For Architectural DesignDocument6 pagesSPACE PLANNING From Time Saver Standards For Architectural DesignJan Genesis RectoPas encore d'évaluation

- VRF SpecDocument9 pagesVRF Specmannu11Pas encore d'évaluation

- Seminar On AC SystemDocument33 pagesSeminar On AC SystemJagadish SahuPas encore d'évaluation

- MCCPK StatusDocument21 pagesMCCPK Statusrafi ud dinPas encore d'évaluation

- Radiator Connection MethodsDocument1 pageRadiator Connection Methodsgox458Pas encore d'évaluation

- Hvac Design Manual: First EditionDocument124 pagesHvac Design Manual: First EditionNathan Tom100% (7)

- COMPRESSOR OdtDocument2 pagesCOMPRESSOR OdtPradeep SukumaranPas encore d'évaluation

- Time ScheduleDocument2 pagesTime SchedulesigitbambangPas encore d'évaluation

- NA14631A - CristopiaDocument3 pagesNA14631A - CristopiaVietHienPas encore d'évaluation

- Fgas Refrigerant CalculatorDocument10 pagesFgas Refrigerant CalculatorKumar sssssPas encore d'évaluation

- Lennox Strategos DataDocument1 pageLennox Strategos DataDaniel CastroPas encore d'évaluation

- Boq VRFDocument3 pagesBoq VRFPatrick Lincuna50% (2)

- Popsicle Machine Price Sheet2Document12 pagesPopsicle Machine Price Sheet2Ramy ChaconPas encore d'évaluation

- Ventilation System Comparison - Constant Air Volume (CAV) and Variable Air Volume (VAV)Document15 pagesVentilation System Comparison - Constant Air Volume (CAV) and Variable Air Volume (VAV)ankurPas encore d'évaluation

- How Home Thermostats WorkDocument8 pagesHow Home Thermostats WorknafeesPas encore d'évaluation

- Overall Mechanical Discipline Checklist With Lessons Learned Added 7-19-2012Document5 pagesOverall Mechanical Discipline Checklist With Lessons Learned Added 7-19-2012dhanu_lagwankarPas encore d'évaluation

- Hvac Contents HVAC Selection MatrixDocument11 pagesHvac Contents HVAC Selection Matrixricha-BPas encore d'évaluation

- Rancang Bangun Simulator Trouble Shooting Sistem Kelistrikan Ac MobilDocument14 pagesRancang Bangun Simulator Trouble Shooting Sistem Kelistrikan Ac MobilJm'kosongtujuh RudiPas encore d'évaluation

- Amana Gph13 Service Manual InstallationDocument43 pagesAmana Gph13 Service Manual Installationmazda8616Pas encore d'évaluation

- V RF DirectoryDocument103 pagesV RF Directoryjd_tan_29Pas encore d'évaluation

- Ventilation System (Fresh & Exhaust Air) - : Exchanging of Air Within Space and OutsideDocument5 pagesVentilation System (Fresh & Exhaust Air) - : Exchanging of Air Within Space and Outsidesunil_v5Pas encore d'évaluation

- Tropical Design: Passive CoolingDocument6 pagesTropical Design: Passive CoolingISABELLE MAXINE MANTOPas encore d'évaluation

- PCK, PHK Packaged Unit IO ManualDocument15 pagesPCK, PHK Packaged Unit IO ManualChad HensonPas encore d'évaluation

- York TS CondenserDocument16 pagesYork TS Condenserrbooth80Pas encore d'évaluation