Académique Documents

Professionnel Documents

Culture Documents

Talk On MTS Moel For 6061T6 Al

Transféré par

b.banerjee.nz6800Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Talk On MTS Moel For 6061T6 Al

Transféré par

b.banerjee.nz6800Droits d'auteur :

Formats disponibles

A modified Follansbee-Kocks model

for 6061-T6 aluminum

Anup Bhawalkar and Biswajit Banerjee

Department of Mechanical Engineering, University of Utah

ASME Applied Mechanics and Materials Conference, 2007

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 1 / 33

Outline

1 Mechanical Behavior of 6061-T6 Aluminum

2 Models

3 Modified Follansbee-Kocks Model

4 How well does our model do?

5 Some numerical simulations

6 Summary

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 2 / 33

Mechanical Behavior of 6061-T6 Aluminum

Temperature Dependence

Strain-Rate = 0.001 /s. Strain-Rate = 1000 /s.

400 400

Flow Stress (MPa)

Flow Stress (MPa)

300 300

200 200

100 100

0 0

200 300 400 500 600 700 800 200 300 400 500 600 700 800

Temperature (K) Temperature (K)

Sigmoidal curves?

For sources of data see Anup Bhawalkar’s M.S. Thesis.

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 3 / 33

Mechanical Behavior of 6061-T6 Aluminum

Strain-Rate Dependence

Strain = 0.2; Temperature = 300K

4

10

?

Flow Stress (MPa)

Older Data

3

10

Recent Data

2

10 −5 −1 3 7 11

10 10 10 10 10

Strain Rate (/s)

High temperature data?

ForBiswajit

Anup Bhawalkar and sources of data (University

Banerjee see http://www.eng.utah.edu/

Modified

of Utah) banerjee/Papers/MTS6061T6Al.pdf/

Follansbee-Kocks Model McMat07 4 / 33

Mechanical Behavior of 6061-T6 Aluminum

Pressure Dependence

Strain Rate = 0.001/s; Plastic Strain = 0.05

500

450

Flow Stress (MPa)

300 K

400

367 K

350

422 K

300

478 K

250

200

0 100 200 300 400

Pressure (MPa)

High strain rate data?

Experimental data from Davidson, 1973

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 5 / 33

Mechanical Behavior of 6061-T6 Aluminum

Can a single flow stress model predict all these behaviors?

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 6 / 33

Models

Older Models

Steinberg, Cochran, Guinan (1980), Steinberg and Lund

(1989).

Johnson and Cook (1983, 1985), Johnson and Holmquist

(1988).

Zerilli and Armstrong (1987, 1993), Abed and Voyidajis (2005).

Different regimes need different sets of parameters.

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 7 / 33

Models

More Recent Models

Mechanical Threshold Stress Model - Follansbee and Kocks

(1988), Goto et al. (2000).

Preston, Tonks, Wallace (2003).

Physically based to some extent. May be possible to extend so

that the same parameters can be used for a large domain of

regimes.

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 8 / 33

Models

Original Follansbee-Kocks Model

µ(p, T )

σy (σe , ε̇, p, T ) = [τa + τi (ε̇, T ) + τe (σe , ε̇, T )] (1)

µ0

where

σe =an evolving internal variable that has units of stress (also called the mechanical threshold stress)

ε̇ =the strain rate

p =the pressure

T =the temperature

τa =the athermal component of the flow stress

τi =the intrinsic component of the flow stress due to barriers to thermally activated dislocation motion

τe =the component of the flow stress due to structure evolution (e.g., strain hardening)

µ =the shear modulus

µ0 =a reference shear modulus at 0 K and ambient pressure.

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 9 / 33

Models

Assumptions in Original Model

Thermally activated dislocation motion dominant and

viscous drag effects on dislocation motion are small.

This assumption restricts the model to strain rates of 104 s−1

and less.

High temperature diffusion effects (such as solute diffusion

from inside grains to grain boundaries) are absent.

This assumption limits the range of applicability of the model

to temperatures less than around 0.6 Tm . For 6061-T6

aluminum alloy this temperature is approximately 450 - 500 K.

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 10 / 33

Modified Follansbee-Kocks Model

The Modified Follansbee-Kocks Model

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 11 / 33

Modified Follansbee-Kocks Model

A Simple Modification

µ(p, T )

σy (σe , ε̇, p, T ) = [τa + τi (ε̇, T ) + τe (σe , ε̇, T )]

µ0

Since hardening is relatively small we can

Try to get the correct temperature dependence of µ and τi .

Add a viscous terms that can account for viscous drag.

Include a modification for overdriven shocks a la

Preston-Tonks-Wallace.

to get

(" # )

min µ

for T < Tm

τv + (τa + τi + τe ) , σys

σy = µ0 (2)

µv ε̇ for T ≥ Tm

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 12 / 33

Modified Follansbee-Kocks Model

A Model for the Shear Modulus

Temperature dependence from Nadal and LePoac (2003) and

pressure dependence from Burakovsky and Preston (2005).

"( !)

1 ∂µ a1 a2 a3

µ(p, T ) = µ0 + p 1/3

+ 2/3 + (1 − Tb)+

J (T , ζ)

b ∂p η η η (3)

ρ i

k T

CM b

ρ (6π 2 )2/3 2 b T

η := ; C := f ; T :=

ρ0 3 Tm

" #

1 + 1/ζ

T , ζ) := 1 + exp −

J (b for b

T ∈ [0, 1 + ζ] .

1 + ζ/(1 − b T)

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 13 / 33

Modified Follansbee-Kocks Model

A Model for the Melt Temperature

The Burakovsky-Greeff-Preston model (2003):

( ! !)

1 1 2Γ2 1 1

Tm (ρ) = Tm0 η 1/3 exp 6Γ1 1/3

− 1/3 + q − q . (4)

ρ ρ q ρ0 ρ

0

ρ

η :=

ρ0

1 Γ1 Γ2

Γ(ρ) = + +

2 ρ1/3 ρq

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 14 / 33

Modified Follansbee-Kocks Model

Model Checks

Shear Modulus Melt Temperature

50 6000

Recent data

40 η=1.05 5000

Shear Modulus (GPa)

4000

30

Tm (K)

3000

20

2000

10 η=0.95 1000 Older data

0 0

0 0.2 0.4 0.6 0.8 1 0 25 50 75 100 125 150

T/Tm Pressure (GPa)

Models do reasonably well.

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 15 / 33

Modified Follansbee-Kocks Model

A Model for τi

Use a quadratic model to allow for rapid decrease in τi at high

temperatures:

!1/qi 2 1/pi

kb T

ε̇0i

τi = σi 1 − ln . (5)

3

g0i b µ(p, T ) ε̇

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 16 / 33

Modified Follansbee-Kocks Model

Fit Parameters for τi

0.05

σi = 375 MPa, g = 0.61

0.045 0i

0.04

95%

0.035 Confidence

Interval

pi

0.03

y = (σy / µ)

0.025

0.02

0.015

0.01

0.005

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

x = [(kbT/ µ b3) ln(ε0i/ ε)]1/qi

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 17 / 33

Modified Follansbee-Kocks Model

A Model for the Viscous Drag

Use ideas from Kumar and Kumble (1969) and Frost and Ashby

(1971).

2 B

τv = √ ε̇ (6)

3 ρm b 2

Need to find drag coefficient B and the density of mobile

dislocations ρm .

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 18 / 33

Modified Follansbee-Kocks Model

The Drag Coefficient

Assume that

B = Be + Bp

where Be = electron drag, Bp = phonon drag. Neglect Be for

temperatures greater than 50 K.

λp q

B ≈ λp Bp = hEi (7)

10 cs

where q = cross-section of dislocation core, cs = shear wave

speed, and ! ! 1/3

3 kb T ρ θD h c̄ 3ρ

hEi = D3 ; θD =

M T kb 4πM

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 19 / 33

Modified Follansbee-Kocks Model

Mobile Dislocation Density

Use simple model developed by Estrin and Kubin (1986) ?

!

dρm M1 ρf I3 √

= 2 − I2 (ε̇, T ) ρm − ρf

dεp b ρm b

(8)

dρf I3 √

= I2 (ε̇, T ) ρm + ρf − A4 (ε̇, T ) ρf

dεp b

Stiff differential equations!

A model that works for our purposes is

ρm ≈ ρm0 (1 + Tb)m . (9)

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 20 / 33

Modified Follansbee-Kocks Model

Check Viscous Drag Model

5

10

0

10

900 K

300 K

τv (MPa)

−5

10

50 K

−10

10

−15

10

−5 −3 −1 1 3 5

10 10 10 10 10 10

Strain Rate (s−1)

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 21 / 33

How well does our model do?

How well does our model do ?

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 22 / 33

How well does our model do?

Temperature Dependence

Strain-Rate = 0.001 /s. Strain-Rate = 1000 /s.

ε = 0.001 s−1 εp = 0.02 ε = 1000 s−1 εp = 0.10

500 600

450

500

400

350

400

300

σy (MPa)

σy (MPa)

250 300

200

200

150

100

100

50

0 0

0 0.2 0.4 0.6 0.8 1 0 0.2 0.4 0.6 0.8 1

T/Tm T/Tm

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 23 / 33

How well does our model do?

Strain Rate Dependence

4

10

σy (MPa)

3

10

2

10 −5 −1 3 7 11

10 10 10 10 10

−1

ε (s )

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 24 / 33

How well does our model do?

Pressure Dependence

500

450

400

Flow Stress (MPa)

350

300

250

200

0 100 200 300 400

Pressure (MPa)

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 25 / 33

Some numerical simulations

Numerical validation of the model

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 26 / 33

Some numerical simulations

Flyer Plate Impact

Evacuated Target

chamber

Target Specimen

Gas gun

Direction of

flyer plate

VISAR

Free Surface with

mirror finish

Flyer Plate

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 27 / 33

Some numerical simulations

Flyer Plate Simulations

hi = 1.879 mm, ht = 3.124 mm, hi = 1.600 mm, ht = 3.073 mm,

v0 = 270 m/s. v0 = 265 m/s.

300 300

Expt. Data

Exp. Data

Simulation

250 FEM 250

Free Surface Velocity (m/s)

Free Surface velocity (m/s)

200 200

150 MPM 150

100 100

50 50

0 0

−0.2 0 0.2 0.4 0.6 0.8 1 1.2 1.4 −0.5 0 0.5 1 1.5 2

Time (µ sec) Time (µ sec)

Experimental data from Isbell (2005).

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 28 / 33

Some numerical simulations

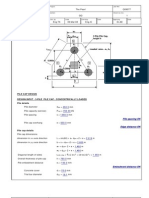

Taylor Impact Tests

11111111111

00000000000

00000000000

11111111111

Xf

00000000000

11111111111

00000000000

11111111111

00000000000

11111111111

00000000000

11111111111

00000000000

11111111111

Centroid

00000000000

11111111111

L af

00000000000

11111111111

00000000000

11111111111

C 11111111111

00000000000

xf 11111111111

00000000000 Lf

00000000000

11111111111

00000000000

11111111111

00000000000

11111111111

Af

00000000000

11111111111

00000000000

11111111111

C Wf 00000000000

11111111111

00000000000

11111111111

yf

0.2 L 0 00000000000

11111111111

00000000000

11111111111

00000000000

11111111111

00000000000

11111111111

00000000000

11111111111

00000000000

11111111111 X

Df

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 29 / 33

Some numerical simulations

Comparison of Metrics

Final Length Mushroom Diameter

1 2.4

0.9 2.2

0.8 2

Simulated Df/D0

0

X=Y

Simulated L /L

f

0.7 1.8

0.6 1.6

0.5 1.4

0.4 X=Y 1.2

0.3 1

0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.2 1.4 1.6 1.8 2 2.2

Experimental Lf/L0 Experimental Df/D0

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 30 / 33

Some numerical simulations

Comparison of Profiles

l0 = 30.00 mm, l0 = 6.00 mm, l0 l0 = 30.00 mm, d0 = 6.00 mm,

= 358 m/s, T0 = 295 K v0 = 194 m/s, T0 = 635 K

40 30

Expt. Expt.

MTS MTS

35

25

30

20

25

mm

mm

20 15

15

10

10

5

5

0 0

−15 −10 −5 0 5 10 15 −15 −10 −5 0 5 10 15

mm mm

Experimental data from Gust (1982).

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 31 / 33

Summary

Summary

Improved high temperature prediction.

Improved strain rate dependence at high rates.

Pressure dependence cannot be solely from shear modulus.

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 32 / 33

Appendix For Further Reading

For Further Reading I

B. Banerjee and A. Bhawalkar.

An extended Mechanical Threshold Stress plasticity model:

modeling 6061-T6 aluminum alloy.

under review, 2007.

A. Bhawalkar,

The Mechanical Threshold Stress Plasticity Model for 6061-T6

aluminum alloy and its numerical validation

M.S. Thesis, University of Utah, 2006.

Anup Bhawalkar and Biswajit Banerjee (University

Modified

of Utah)

Follansbee-Kocks Model McMat07 33 / 33

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Sloping Tank PressureDocument2 pagesSloping Tank Pressureb.banerjee.nz6800Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Recursive Cell Method For PBX 9501Document40 pagesRecursive Cell Method For PBX 9501b.banerjee.nz6800Pas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- ThermoElasticity NotesDocument25 pagesThermoElasticity Notesb.banerjee.nz6800100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Simulation of Mock PBXDocument18 pagesSimulation of Mock PBXb.banerjee.nz6800Pas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Useful Results in Continuum MechanicsDocument5 pagesUseful Results in Continuum Mechanicsb.banerjee.nz6800Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Validation of Plasticity ModelsDocument24 pagesValidation of Plasticity Modelsb.banerjee.nz6800Pas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Thermoplasticity Notes (Incomplete)Document43 pagesThermoplasticity Notes (Incomplete)b.banerjee.nz6800Pas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- MTS Model 4340 SteelDocument36 pagesMTS Model 4340 Steelb.banerjee.nz680075% (4)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Large Deformation Plasticity and MPM (Working Paper)Document42 pagesLarge Deformation Plasticity and MPM (Working Paper)b.banerjee.nz6800Pas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Manufactured SolutionsDocument3 pagesManufactured Solutionsb.banerjee.nz6800Pas encore d'évaluation

- Generalized Method of Cells For PBX 9501Document32 pagesGeneralized Method of Cells For PBX 9501b.banerjee.nz6800Pas encore d'évaluation

- Fragmentation With The Material Point MethodDocument6 pagesFragmentation With The Material Point Methodb.banerjee.nz6800100% (2)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Micromechanics of PBX 9501Document33 pagesMicromechanics of PBX 9501b.banerjee.nz6800Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Fluid Structure InteractionDocument21 pagesFluid Structure Interactionb.banerjee.nz6800100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Em2004 Paper270Document15 pagesEm2004 Paper270b.banerjee.nz6800Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Micromechanics-Based Determination of Effective Elastic Properties of Polymer Bonded ExplosivesDocument9 pagesMicromechanics-Based Determination of Effective Elastic Properties of Polymer Bonded Explosivesb.banerjee.nz6800Pas encore d'évaluation

- Exact Relations For CompositesDocument17 pagesExact Relations For Compositesb.banerjee.nz6800Pas encore d'évaluation

- Biswajit Banerjee - An Evaluation of Plastic Flow Stress Models For The Simulation of High-Temperature and High-Strain-Rate Deformation of MetalsDocument53 pagesBiswajit Banerjee - An Evaluation of Plastic Flow Stress Models For The Simulation of High-Temperature and High-Strain-Rate Deformation of MetalsCola7890Pas encore d'évaluation

- Em 2002 PaperDocument7 pagesEm 2002 Paperb.banerjee.nz6800Pas encore d'évaluation

- MTS6061 T6 AlDocument37 pagesMTS6061 T6 Alb.banerjee.nz6800Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Impact TestsDocument23 pagesImpact Testsb.banerjee.nz6800Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- MPM Validation: Sphere-Cylinder Impact: Medium Resolution SimulationsDocument22 pagesMPM Validation: Sphere-Cylinder Impact: Medium Resolution Simulationsb.banerjee.nz6800Pas encore d'évaluation

- Edexcel M3 NotesDocument44 pagesEdexcel M3 NotesNani AhmedPas encore d'évaluation

- Ultrasonic Testing HandbookDocument89 pagesUltrasonic Testing HandbookSucipta Pratama100% (9)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- NPTELDocument48 pagesNPTELLuma BlossomsPas encore d'évaluation

- Lifting Lug DesignDocument18 pagesLifting Lug DesignRui Salvador0% (1)

- Hydraulics and Irrigation Engineering Lab ManualDocument43 pagesHydraulics and Irrigation Engineering Lab ManualMuhammad Faisal AsifPas encore d'évaluation

- MomDocument61 pagesMomMOAZPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Classical Mechanics of Non-Conservative SystemsDocument5 pagesThe Classical Mechanics of Non-Conservative Systemshmalikn7581Pas encore d'évaluation

- Bharathi Connection Design (22.5 X 56)Document22 pagesBharathi Connection Design (22.5 X 56)Chandrasekhar ReddyPas encore d'évaluation

- (Ebook - English) Gaussian Inc, Exploring Chemistry With Electronic Structure MethodsDocument335 pages(Ebook - English) Gaussian Inc, Exploring Chemistry With Electronic Structure Methodsthiagocpimentel12100% (1)

- P-Delta Analysis Column ForcesDocument9 pagesP-Delta Analysis Column ForcesMauricio CatunaPas encore d'évaluation

- PHYSICS - VOL 1 UNIT 1 KEY CONCEPTSDocument135 pagesPHYSICS - VOL 1 UNIT 1 KEY CONCEPTSUma Maheswari100% (1)

- Kinematics Practice Problems SolvedDocument3 pagesKinematics Practice Problems SolvedAbhinandan KumarPas encore d'évaluation

- Light PPT 120108205852 Phpapp01Document13 pagesLight PPT 120108205852 Phpapp01padmja4purohit100% (1)

- Module 11A.1.2 L2 2016-08-12Document84 pagesModule 11A.1.2 L2 2016-08-12Abdul Aziz KhanPas encore d'évaluation

- Rotational Mechanics Course on Unacademy Free Learning PlatformDocument10 pagesRotational Mechanics Course on Unacademy Free Learning PlatformEkta ManglaniPas encore d'évaluation

- Oscillations, Waves and OpticsDocument25 pagesOscillations, Waves and OpticsTushar GhoshPas encore d'évaluation

- 3.electric Charges Forces and FieldstheoryDocument25 pages3.electric Charges Forces and FieldstheoryGomes Ribeiro100% (1)

- Pile Cap Design 1Document6 pagesPile Cap Design 1kjpatel2100% (2)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Torsion Design of BeamDocument14 pagesTorsion Design of Beamyyanan_11180% (1)

- Machine Elements Design GuideDocument38 pagesMachine Elements Design GuideFajar ZulfikarPas encore d'évaluation

- CHANGES BETWEEN IS 1893 PART 1 EDITIONSDocument15 pagesCHANGES BETWEEN IS 1893 PART 1 EDITIONSMohdDanishPas encore d'évaluation

- Amplitude - PhaseDocument6 pagesAmplitude - Phasemuhammad awaisPas encore d'évaluation

- Physics 01-02 Displacement and VectorsDocument2 pagesPhysics 01-02 Displacement and VectorsAnonymous FDewQQkx3VPas encore d'évaluation

- Rheology and Soil Mechanics RH Ologie Et M Canique Des Sols Symposium Grenoble April 1-8-1964 Symposium Grenoble 1er 8 Avril 1964Document518 pagesRheology and Soil Mechanics RH Ologie Et M Canique Des Sols Symposium Grenoble April 1-8-1964 Symposium Grenoble 1er 8 Avril 1964Jasmin AgriPas encore d'évaluation

- Design of Cyclone and Study of Its Performance Parameters: Research PaperDocument6 pagesDesign of Cyclone and Study of Its Performance Parameters: Research PaperManish VankudrePas encore d'évaluation

- Ryu Et Al (2008) Capacity Curves, 14WCEE PDFDocument8 pagesRyu Et Al (2008) Capacity Curves, 14WCEE PDFsekkeiPas encore d'évaluation

- Uncertainties in Modelling Undrained Shear Strength of Clays Using Critical State Soil Mechanics and SHANSEP - P - 2018Document11 pagesUncertainties in Modelling Undrained Shear Strength of Clays Using Critical State Soil Mechanics and SHANSEP - P - 2018Halil Can EryasarPas encore d'évaluation

- T-1-2 WT Subsonic Wind Tunnel CapabilitiesDocument2 pagesT-1-2 WT Subsonic Wind Tunnel CapabilitieszoranmiskovicPas encore d'évaluation

- Fluid Mechanics-Fluid Dynamics PDFDocument3 pagesFluid Mechanics-Fluid Dynamics PDFCristian OmacPas encore d'évaluation

- Exam PaperDocument4 pagesExam PaperSaad MehmoodPas encore d'évaluation