Académique Documents

Professionnel Documents

Culture Documents

Microcomputer Motor Protection Relays and Monitoring Device

Transféré par

EAGLE TECHNOLOGYCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Microcomputer Motor Protection Relays and Monitoring Device

Transféré par

EAGLE TECHNOLOGYDroits d'auteur :

Formats disponibles

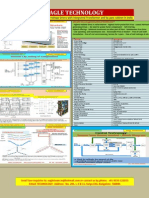

EAGLE TECHNOLOGY

http://www.eaglewanlida.com

Supplier of Magnetic Controlled Rectifier Type Static Var Compensator (MCR Type SVC), 48 Pulse MV Drives, Active Power Filter, Protection Relays and Intelligent Switchgear at reasonable price in India.

Contact us

Mr. Sunil Jha Mobile: +91-9590273474 E-mail: sunil.jha@yantrabazaar.com, jhasunil100@gmail.com SKYPE: jhasunil100 Google Talk: jhasunil00@gmail.com

To Read and Download all our Products catalogs: http://www.scribd.com/sunil_jha To Read and Download Online our MV-VFD Catalogs http://www.scribd.com/doc/63980384/MV-Drives To Watch Online Video Presentation on YouTube: http://www.youtube.com/watch?v=W2AVlS4-0SM To Read MV-VFD Presentation Online on our website: http://eaglewanlida.com/vfdpresentation.aspx To Read and Download online our relays catalog: http://www.scribd.com/doc/73143176/MMPR-620-HB-Micro-Computer-M otor-Protection-and-Monitoring-Device

Users

manual

of

MMPR-610Hb

microcomputer motor protection and monitoring device

Manufactured by ZuHai Wanlida Electric co Ltd, China.

Sole Distributor in India: EAGLE TECHNOLOGY

Prepared by Proofed by Approved by

Document No.WLD[K]-JY-222-2010 Date of publication: October 2010 Copyright: Zhuhai Wanlida Electric Co., Ltd.

Version No.:V2.02.01

Note: Our company reserves the right to modify this manual. For any inconsistency between the product and this manual, please contact us for relevant services. Technical support hotline: 0756-3395398 Fax: 0756-3395500

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Foreword

1. Model description

The structural type of the MMPR-610Hb series protection is Hb. MMPR-610Hb supports three-phase current protection, also supports two-phase current protection. When ordering, please specify.

2.

Standards referenced

General specification for static protection, security and automatic equipment, DL 478-2001 Technical code for relaying protection and security automatic equipment GB/T 14285-2006 Protective relay and automatic equipment design rules of power equipment GB50062-92

3.

Caution

Negative sequence voltage involved in this series of protection is combined with phase voltage, all of low voltage component depend on line voltage in compound voltage block, if one of the three line voltages is lower than low voltage setting, low voltage component will operates and unblock over current protection.

There are 4 standard curves of inverse protection involved in this series of protection, if the fault current is higher than 15 times of rated current, the inverse protection component as if the current is 15 times of rated current.

The appearance should be inspected before power is applied, to ensure that the panel is OK without scratch, the screws are tightened, the device is grounded firmly, all screws of plug-ins are tightened and in good contact.

When power is applied, the Run indicator on the panel should flash, digital tube displays primary measuring result in cycle, protection and measuring data are displayed on the lcd in cycle.

The terminal D25D28 are measuring circuit of 420mA DC signal, when testing, signal should be supplied by special equipment, direct apply signal of relay protection tester is prohibited(Can be selected or not).

When the device is equipped with ungrounded system, terminal D07D08 are zero sequence small current input terminal, the ac current input should be limited to within 2A, the measuring current input should be limited to 6A, pay attention to the signal input when testing to avoid large signal applied so as to avoid damage to

2

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

components. Operating circuit inside the device is only applicable to DC power supply, if AC power is used, it should be applied with rectifier and filter. It is prohibited to plug or unplug the plug-ins, in order to avoid damage to the device. It is prohibited to do digital output test when the device is running with primary equipments.

1. Product description

1.1 Scope of application

The MMPR-610Hb microcomputer motor protection applies to the protection and monitoring of medium and high-voltage motors with voltage ratings of 3kV~10kV. It can be used for the integrated protection of large and medium motors of different capacities, and also for the dual configuration of main protection and backup protection of ultra-large motors.

1.2 Function and specification 1.2.1 Protective function

Prolonged start time protection(Start Time Over) 2-section definite time limit over-current protection instantaneous over-current protection, locked rotor protection(Overcurrent) Negative sequence over-current protection(NS Overcurrent) Zero sequence over-current protection(ZS Overcurrent) Overload protection(Overload) Overheat protection(Motor Over Heat) Underload protection(Underload PROT) voltage protection Under-voltage protection, Over-voltage protection (Voltage PROT) Non-electric quantity protection2-way(Non-electric) (Can be selected or not) Logical control(Joint Trip PROT) Out-of-step protectionSynchronous motor(Out-Of-Step PROT) Asynchronous impact protectionSynchronous motor(Asynchro.Impact)

1.2.2 Auxiliary function

Under-frequency unloading (Under-frequency) Soft start function(Soft Startup) Motors normal-reverse function(Nor.Rev.Func.) Harmonic spectrum analysis Phase display Integral energy and impulse energy(Pulse energy can be selected or not) Self-checking fault alarm of device

3

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Remote calling and modification of protections settings Fault recorder(Wave Record) One or two ways programmable output of 420mA Provide ethernet print function(manual print setting value, manual/auto print reports) (Can be selected or not).

1.2.3 Monitoring function

Electric quantity remote measuring quantity voltage, current, active power, reactive power, active energy, reactive energy, power factor, grid frequency, non-electric quantity measuring(Can be selected or not), etc. Remote binary quantity: the device has 15-way binary input, in which: 12-way for external gathering, and 3-way for internal gathering.

1.2.4 Communication capability

2 standard RS485 multipoint communication ports 2 industrial ethernet ports(Can be selected or not) Supports single, dual network communication, it is fully qualified for network redundancy and backup IEC-60870-5-103 RS485 communication mode ,IEC-60870-5-104 industrial ethernet modestandard communication protocol(Can be selected or not).

1.2.5 GPS clock synchronization function(Can be selected or not)

The device is able to receive GPS clock minute synchronization (or second synchronization) through RS485 differentiate voltage, and it can be done with monitoring system to accomplish GPS precise clock synchronization.

1.2.6 Device specifications

32-bit DSP microprocessor Real-time multi-task operating system and C++ program techniques, realizing online programming Double-screen display (LCD Chinese display and nixie tube display), easy for inspection One or two ways 4~20mA DC quantity output, which can be set flexibly as any corresponding electric quantity (such as current, voltage, power, frequency, etc.) Collecting 4 ways of 4~20mA DC quantities for measurement of non-electric quantities, such as temperature, pressure, and realizing online monitoring(Can be selected or not) Having the electric energy quality analysis function and perfect harmonic analysis function Integrating perfect metering functions Excellent hardware interchangeability, easy user maintenance and reduced quantity of spare parts Protection output relays can be configured flexibly for user convenience With remote/local changeover switch and trip/closing buttons, reducing the number of elements on the board/cabinet panel and simplifying wiring

4

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Using a 6U, 19/3 standard enclosure in a rear plug-in structure; the device can be installed in site on a switchboard or combined in a centralized manner

1.2.7 Main technical specifications

Rated data DC/AC 86265V DC 220V or DC 110V Power supply: AC voltage: AC current: Frequency:

Operating voltage:

1 0 0 / V or 100V 3

5A or 1A 50Hz

Power consumption

DC circuit: 10Wnormal operation15Wprotection operation. AC voltage circuit:0.5VA/ phase AC current circuit:1VA/ phaseIn=5A0.5VA/ phaseIn=1A. Overload capability AC voltage circuit: 1.2Un, continuous operation Current measuring circuit: 1.2Un, continuous operation Protective current circuit: 2In, continuous operation 10In, allowing 10s 40In, allowing 1s Range and error of setting value Maximum range of setting value: Voltage element: 1V~120V Current element: 0.1In~20In Frequency: 45.00Hz~55.00Hz Timing element: 0.00S~100.00s Current and voltage setting value: 3% of setting value Frequency setting value: 0.02Hz Slip setting value: 5% of setting value Angle setting value: 2 Intrinsic operating time of current instantaneous over-current protection: not greater than 40ms at 1.5 times the setting value Intrinsic operating time of Difference instantaneous over-current protection: not greater than 30ms at 2 times the setting value Measuring accuracy AC current: Class 0.2 AC voltage: Class 0.2 4~20mA DC quantity input: 1%

5

Error of setting value:

Whole-group operation time (including relays intrinsic time):

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Power: Class 0.5 Integral energy: Class 1 (active), Class 2 (reactive) Frequency: 0.02Hz SOE resolution: 2ms Impulse width of impulse quantity: 10ms 4~20mA DC quantity output: 1% Capacity of trip/closing output contact

Can be connected to DC 250V, 8A for prolonged periods. GPS clock synchronization error clock synchronization error2ms Environmental conditions Ambient temperature: Operating-20+55 Storage-25+70, rainproof and snow-proof rooms with relative humidity not greater than 80%, ambient air free of acid, alkaline or other corrosive and explosive gas; no excitation quality is applied at the limits, the device shall not have any irreversible change; after temperature restoration, the device shall operate properly. Relative humidity: The average relative humidity of the most humid month shall not be greater than 90%, the average minimum temperature of this month not lower than 25 and there shall be no surface condensation; at the highest temperature of +40, the average maximum humidity shall not exceed 50%. Atmospheric pressure: 80kPa~110kPa (below relative altitude of 2wc)

1.2.8 Hardware structure

The device uses a 6U, 19/3 standard enclosure, with aluminum alloy casing and installed by overall embedding. The display panel is mounted in the front, and the other plug-in modules are rear mounted. From the rear view, the power, I/O, CPU and AC plug-in modules are from the left to the right.

External dimensions and boring diagram

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Structural and dimensional diagram

Boring diagram for installation

Devices fabricated on-screen steps: first release on-screen stents unfastening screws, remove the stents; installed the device on the screen from the front and push until close to the fixed plate; install the stent 2, and then stent 1, and then use fastening screw to insertion hole from rear of stent1, and then screwed into stent 2 and tighten screw; the stents from up and down are installed in the same way; use grounding screws to connect grounding line.

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

2. Function of device

2.1 Prolonged start time protection(Start Time Over)

When the maximum phase current of the motor rises from zero to above 10% of Ie (Ie is the motors rated current, the same below), the device begins to time, until the current drops to 120% of Ie, this time is known as the motors start time (as Tstart). When the start time Tstart exceeds setting value of the motors start time, the protection will operate on the trip. After the end of starting, the motors prolonged start time protection will be switched off. During the motors starting process, the mark motor starting is displayed in the lowest line on the LCD. The value of current Ia can be seen in the report during 30s of motors starting. The motor starting process is shown in Figure 2-1

120% Ie

120% Ie

10%

10%

Tstart

Tstart

Figure 2-1 Schematic diagram of motor starting process

2.2

2-section definite time limit over-current protection(Overcurrent)

The device has 2-section definite time limit over-current protection, instantaneous over-current protection and locked rotor protection, switched On/Off by control word separately, used to protect the motor from inter-phase short-circuit. Instantaneous over-current protection is provided. The instantaneous over-current protection Section I setting value 1 is input; after the end of starting, the instantaneous over-current protection Section I setting value 2 is input. Thus, mis-operation due to excessive starting current during the starting process can be avoided effectively and guarantee a high level of sensitivity during the protection operation. The locked rotor protection will be switched off automatically during the motors starting process. The operation logic diagram of the instantaneous over-current protection is shown in Figure 2-2. The operation logic diagram of the locked rotor is the same as instantaneous over-current protection.

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

IaInstantaneous

settings IbInstantaneous settings IcInstantaneous settings

Instantaneous

protection on/off

Protection output sequence

Figure 2-2 Operation logic diagram of instantaneous over-current protection 2.3 Negative sequence over-current protection(NS Overcurrent)

Where there is great asymmetry in the 3 phase currents of the motor, there will be a high negative sequence current, which will produce a current of double the line frequency in the rotor, so that the rotors additional heat increases dramatically, endangering the safe operation of the motor. The device has negative sequence definite time limit over-current protection and negative sequence inverse time limit over-current protection, providing protection to abnormal conditions, such as opposite phase, loss-of-phase, inter-turn short-circuit and serious voltage asymmetry, etc. The operation logic diagram of the negative sequence definite time limit over-current protection is shown in Figure 2-3.

Negative I2>negative sequence settings sequence over-current on/off

Protection sequence

output

Figure 2-3 Operation logic diagram of negative sequence definite time limit over-current protection

To avoid any protection mis-operation arising from the asynchronism of the 3 phases upon closing of the circuit breaker, the set delay should not be less than 0.2s. As stipulated by the IEC (IEC255-4), the following 4 standard characteristic equations of the inverse time limit component are usually used: 0.14 t p General inverse time limit: ( I / I p ) 0.02 1 13.5 t p Unusual inverse time limit: (I / I p ) 1 80 t p Extreme inverse time limit: (I / I p )2 1 120 t p Long inverse time limit: (I / I p ) 1

1 2 3 4

Where: Ip is the setting value of the negative sequence inverse time limit over-current starting current; p is the negative sequence inverse time limit over-current time constant,

9

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

within the range of 0~1s; the inverse time limit characteristic can be selected by the setting value of the negative sequence inverse time limit over-current curve (1: general inverse time limit; 2: unusual inverse time limit; 3: extreme inverse time limit; 4: long inverse time limit).

2.4

Zero sequence over-current protection(ZS Overcurrent)

The device has the zero sequence over-current protection function, selecting trip or alarm by control word. The zero sequence current I0 is from the special zero sequence transformer. For ungrounded system, if the grounding fault occurs in the system, the zero sequence current at grounding fault point is almost capacitance current, which scope value is very low. The selectivity is hardly guaranteed that using zero sequence over-current relay to protect from grounding fault. The device uploads scope value and direction of zero-sequence current by communication and low current grounding line selection is carried on by position machine. The operation logic diagram of the zero sequence over-current protection is shown in Figure 2-4.

Note: When the zero sequence over-current trip is switched on, the zero sequence

over-current alarm will be switched off automatically.

I0>zero-sequence settings

Zero-sequence over-current on/off T

Protection output sequence

Figure 2-4 Operation logic diagram of zero sequence over-current protection

2.5

Overload protection(Overload)

The device has the overload protection function, selecting trip or alarm by control word. Overload protection is blocked during motors starting process. The operation logic diagram of the overload protection is shown in Figure 2-5.

Note: When the overload trip is switched on, the overload alarm is switched off

automatically.

Ia1>overload settings Ib1>overload settings Ic1>overload settings After motors start

&

Overload protection on/off T

Protection output sequence

Figure 2-5 Operation logic diagram of overload protection

2.6

Overheat protection(Motor Over Heat)

Overheat is an important cause of motor damage, especially rotor overheat due to negative sequence current. According to the ANSI/UL 2111-2002 Safety standard for motor

10

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

overheat protection,

the judgment criterion of overheat protection operation is:

t

Where:

1

K1 ( I1 / I e ) K 2 ( I 2 / I e ) 2 1.052

2

t operating time of protection (s); 1motors overheat time constant (s), corresponding to motors overload capability; I1positive sequence component of motors actual operating current (A); I2negative sequence component of motors actual operating current (A); Ieoverheat protection starting current setting value (value of motors actual operating rated current reflected to the CT secondary side); K1motors positive sequence heating factor. During the starting process, it can be set within 0~1 with a frequency of 0.01 to evade starting. After the end of starting, it will turn to 1 automatically;

K2motors negative sequence heating factor; it can be set within 0~10 with a frequency of 0.01, usually being 6. The overheat protection has overheat alarm and overheat trip, and has separate control words for switching On/Off. The overheat alarm is an anticipating signal that can be set within 30%~100% of the trip value with a frequency of 1%. When the motor trips due to overheat, the devices output relay will remain at the closed state, and the device will radiate heat at the set radiating time constant until the motor reaches 40% of the trip value, then the output relay will return, allowing the motor to restart. When emergency starting is required, press the Reset key of the device or enter the [Signal Reset] menu for reset, so that the output relay returns.

2.7

Underload protection(Underload PROT)

The device has underload protection function, selecting trip or alarm by control word. Underload protection is blocked during the motors start process. The operation logic diagram of the underload protection is shown in Figure 2-6.

Note: When the underload trip is switched on, the underload alarm is switched off

automatically.

Motors start over Circuit breaker at closed position IaUnderload settings IbUnderload settings IcUnderload settings Underload on/off

& &

Protection output sequence

Figure 2-6 Operation logic diagram of underload protection

2.8 2.8.1

Voltage protection(Voltage PROT) Under-voltage protection(Undervoltage PRO) The device compares the maximum line voltage value. If it is less than the setting

11

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

value and reaches the setting delay, the protection operates on the trip. The protection is via switch position block and PT failure block. The operation logic diagram of protection is shown in Figure 2-7.

Circuit breaker at closed position

Umax<Uddy

PT failure

&

PT failure block

&

Under-voltage protection on/off

Protection output sequence

Figure 2-7 Operation logic diagram of under-voltage protection To avoid any potential protection mis-operation arising from closing of the circuit breaker, the set delay should not be less than 0.2s.

2.8.2

Over-voltage protection(Overvoltage PROT)

When any line voltage of the bus is greater than the over-voltage protection setting value, the setting delay is reached; the over-voltage protection will operate on trip. The protection is blocked at switch position. The operation logic diagram of the over-voltage protection is shown in Figure 2-8.

Circuit breaker at closed position

Umax Ugdy

&

/ Over-voltage on/off

Protection output sequence

Figure 2-8 Operation logic diagram of over-voltage protection

2.9

Logical control protection(Joint Trip PROT)

The device has the 4-way logical control protection function, switched On/Off by control word. When a control word exits, the corresponding input quantity may be used as an ordinary input.

2.10

Non-electric quantity protection(Non-electric) (Can be selected or not)

The device has the 2-way non-electric quantity protection function, switched On/Off by control word, operating on the trip.

2.11

PT failure alarm(PT Failure Alarm)

The judgment criterion of PT failure depends on the wiring mode. When the PT failure block function is switched on, if PT failure occurs, the under-voltage protection, compound voltage component and current directional component will be blocked. The judgment criterion of PT failure is as follows:

V-V wiring mode

The current value of the phase with the maximum current is less than the maximum load

12

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

current value (using the setting value of the overload current).

Maximum phase-phase voltage < 30V, and current of any phase > 0.1Ie; Negative sequence voltage > 8V

If any of the above conditions is met, the delay (settable) will report PT failure, and will return when failure disappears.

Y-Y wiring mode

The current value of the phase with the maximum current is less than the maximum load

current (using the setting value of the overload current). When |Ua+Ub+Uc| >7V, and the modulus difference between the maximum and minimum line voltage is greater than 18V, it is thought that one or two phases have PT failure; When |Ua+Ub+Uc| > 7V, and the minimum line voltage is less than 18V, used to detect 2-phase failure. When MAX{Uab, Ubc, Uca}<7V, and the current of any phase > 0.1Ie, it is regarded as PT 3-phase failure. If any of the above conditions is met, the delay (settable) will report PT failure, and will return when failure disappears.

Max{IaIbIc}<Igfh MaxU<30V Max{Ia,Ib,Ic}>0.1*Ie U2>8V V-V wiring

&

PT failure on/off

&

&

PT failure component

| U a U b U c | 7V

|MaxU-MinU|>18V

&

TPT

PT failure operation information

| U a U b U c | 7V

MinU<18V

&

&

MaxU<7V Max{Ia,Ib,Ic}>0.1*Ie

&

MaxU=Max(Uab,Ubc,Uca) MinU=Min(Uab,Ubc,Uca)

Figure 2-9 Operation logic diagram of PT failure 2.12 CT failure alarm(CT Failure Alarm)

When the CT failure block function is switched on, if CT failure occurs, the device sends alarm signal. When the current value of any phase exceeds the setting value of the overload protection current, CT failure detection will be disabled.

Protection CT 3-phase wiring

During normal operation, the sum of the 3 phase currents at any side is zero (less than

13

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

0.1Ie). In case of CT failure in any phase, the sum of the 3 phase currents is not zero (greater than 0.1Ie). To differentiate from ground fault, the following judgment is required: the 3 phase currents, the current value of the phase with the minimum current is zero (less In than 0.1Ie). The value of the phase with the maximum current is not zero (greater than 0.1Ie), and its current value is less than the setting value of the overload current.

Protection CT 2-phase wiring

The current of one phase is greater than 0.15Ie and less than the setting value of overload

current , and current of another phase is less than 0.08 Ie, then, it is judged as CT failure.

2.13

Under-frequency unloading protection(Under-frequency)

The frequency is derived from software calculation. Using the frequency of Uab, the under-frequency unloading protection is blocked by under-voltage block, under-current block or slip block, in which slip block can be switched On/Off. The operation logic of under-frequency unloading is shown in Figure 2-10.

Figure 2-10

Operation logic of under-frequency unloading

2.14

Synchronous motor protection(Synchrodyne)

Out-of-step protection(Out-Of-Step PROT)

The synchronous motor is one running at a certain speed determined by its number of

poles and AC frequency. This speed is known as the synchronous speed, which is determined by the grid frequency and number of pole pairs: Namely,

60 f (r / m i n ) P

f-grid frequency; P-number of pole pairs

The synchronous motors key function is conversion between mechanical energy and constant frequency AC power. Characteristics of synchronous motor: The speed does not vary with the load and voltage, and is related to the frequency only, featuring high stability. When the motor speed cannot reach the synchronous speed determined by the system frequency due to excessive external load or reduced load-carrying capacity arising from the motors internal fault, the synchronous motor is out of step. The judgment criterion of the synchronous motor out-of-step protection is the protection

14

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

current relative to the setting value IDZ. When the circuit breaker is closed, out-of-step occurs and the out-of-step protection setting delay is reached, the out-of-step operation will operate on the trip. In case of the current disappears, the out-of-step protection will return.

IDZ t

Figure 2-11 Schematic diagram of out-of-step oscillating current

Asynchronous impact protection(Asynchro.Impact) The asynchronous impact protection of this device is based on the reverse power protection principle. When the reverse power is greater than the setting value of asynchronous impact protection and the setting delay is reached, the asynchronous impact protection will operate. The operation logic diagram of the asynchronous impact protection is shown in Figure 2-12. The reverse power (Pn) is calculated from the protection current and voltage.

Asynchronous impact On/Off

Reverse power >asynchronous impact setting value

Protection output sequence

Figure 2-12 Operation logic diagram of asynchronous impact protection Note: synchronous motor loss-of-excitation protection

This device realizes the synchronous motors loss-of-excitation protection via the contact by which the logical control protection is connected to the loss-of-excitation relay.

2.15

Normal-reverse function of motor(Nor.Rev.Func.)

For the positive or negative rotate motor, the protection device provides positive and negative rotate function. After the normal-reverse function switched on, the device judges motors normal-reverse on binary input. Select phase changing mode of current according to on-the-spot phase changing. The device can automatically adjust the calculation of

15

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

negative sequence current and power to adapt the motors normal-reverse.Note: When the motor is at phase changing state, the motor should be off. It is regarded as the motor stops when MAX{IAIBIC}<0.1Ie, it can change phases, otherwise it will be regarded as the last state by default. 2.16 Soft starting function(Soft Startup)

The device has soft starting function, which is suitable for the self-starting control of large-scale asynchronous motor.

Circuit breaker closure & QF2 open QF2 closure r e t u r n successfully & & Send command of closing B29-B30 outputsreturn after 500ms, check QF2 position after 3s. &

Pattern 1 Current < Irqdset Former current > Irqdset Start time

Soft start on/off

QF2 failure, QF trip

Pattern 2 Current < Irqdset Former current > Irqdset Start time & &

Figure 2-13 Operation logic diagram of soft starting 2.17

Start current effective value record(MotorStart Value)

During motors start process, record the effective value of protection current Ia1 for reference of analysis of motors start process. The device records 150 effective values of protection current Ia1, which is at intervals to record for 200ms. It can be looked up in the report menu.

2.18

Impulse energy/integral energy

Impulse energy(Can be selected or not) The impulse circuit of the device uses an internal power supply; passive energy impulses

are input from the outside; and accumulation of impulse energy is finished by the software.

Integral energy The software accumulates active and reactive powers into active and reactive energy in

real time.

16

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

2.19

Fault recorder(Wave Record)

See the communication coding table for the protection voltage and current waveform data collected by the recording unit.

3.

3.1

Setting of parameters and setting values of the device

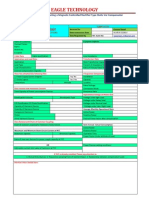

System parameters

Range Description

Parameter

Settings of setting value zone number Setting value zone number(Setting Zone

No.)

0-7

Set step:1factory default 0

Communication settings RS485 address(RS485

Address)

1-99

Set step:1factory default 1

RS485 baud rate(RS485 Baudrate) Pulse confirmation time(Pulse Input Time) IP address(IP Address) Subnet mask (Subnet

Mask)

Set step:1factory default 1

0-5

02.4KB14.8KB29.6KB319.2KB4 38.4KB5115.2KB

1-1000ms It has four sections. The range of every section is 0-255

Set step:1factory default 1

One section set step:1factory default 192.168.6.117 One section set step:1factory default 255.255.255.0 One section set step:1factory default 8.168.6.1

KW default value(KW

Default)

Setting of basic parameters(B.Parameters) Secondary value of rated current (In) ( Rating Current) PT transformation ratio(PT Ratio) CT transformation ratio(CT Ratio) CT wiring mode(CT Wiring Mode) PT wiring mode(PT Wiring Mode) Selection of harmonic monitoring

0-1 1-1500 1-5000 0-1 0-1 0-12

Set step:1factory default 0005A011A Set step:1factory default 1 Set step:1factory default 1 Set step:1factory default 0003-phase;01 2-phase Set step:1factory default 000Y-Y01V-V For harmonic calculation, select the corresponding reference quantity:

17

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010 Parameter channel(Harmonic Channel) Range Description

0exit from harmonic calculation function 1:Ia,2:Ib,3:Ic,4:I0,5:IA,6:IB,7:IC,8:Ua, 9:Ub,10:Uc,11:U0

Fault recorder(Wave Record)

1/0

1/0On/Off (factory default Off) 00Ungrounded

Neutral point grounding mode Earth

Mode

Out-of-step cycle(Out-Of-Step CY) FC block delay(FC Block Delay)

0-1

01Major grounding

It is provided in the unground method if there is no special instruction.

0.50-100.00s 0-5000ms

Set step:0.01sfactory default 10s Set step:1 ms (factory default 200ms)

D/A channel setting(D/A Setting)

Select DA1~2 to output corresponding reference quantities: 0:No D/A output 1:IA,2:IB,3:IC ,4:Ua,5:Ub,6:Uc,7:Uab,8:Ubc, 9:Uca,10:P,11:Q Voltage reference quantity:0120V responding to 4mA20mA.

DA12 channel selection

Rating 5A 0-14

Current reference quantity: 06A responding to 4mA20mA Power reference quantity:01000W responding to 4mA20mA.

Rating 1A

Current reference quantity: 01.2A responding to 4mA20mA Power reference quantity:0200W responding to 4mA20mA.

DA12 adjustment factor

0.5-1.5

Adjust D/A channel 124-20mAparameters Pulse energy setting

Pulse 1 Pulse 2 Pulse 3 Pulse 4 Positive active energy

0-4294967295 0-4294967295 0-4294967295 0-4294967295 0-4294967.29 5kWh

Set step: 1

Press confirm for reservation, and revert to last menu.

Set step:0.001

Press confirm for reservation, and revert to last

18

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010 Parameter Range Description

Positive reactive energy Negative active energy Negative reactive energy

0-4294967.29 5kvh 0-4294967.29 5kWh 0-4294967.29 5 kvh

menu.

Opening Count Clearing (Trip Times Clear) Press confirm for reservation, and revert to last menu. Channel factor setting(Channel Coef.)

Set step:0.001factory default 1

Channel data 112

0.5-5

Channel data 1-12 are corresponded to the channel factor of analog quantity 1-12.

Set step:0.001factory default 1

Channel data 1314

0.5-5

Channel data 13,14 are corresponded to channel factor of DC quantity 1,2.

3.2

Setting value list Parameter Prolonged start time(Start Time Over) Instantaneous over-current protection(Inst.PRO

Range 1/0

Description

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

Protection On/Off word

T) Locked rotor protection(Locked-r otor) Negative sequence definite time over-current(NS OC DT) Negative sequence inverse time over-current(NS OC IT) 1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

19

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Parameter Zero sequence over-current alarm(ZS OC Alarm) Zero sequence over-current trip(ZS OC Trip) Overload alarm(Overload Alarm) Overload trip(Overload Trip) Motor overheat alarm(Motor OH Alarm) Motor overheat trip(Motor OH Trip) Underload alarm(Underload Alarm) Underload trip(Underload Trip) Under voltage protection(Undervol tage PRO) Over voltage protection(Overvolt age PROT) Logic control 1 protection(Joint Trip 1) Logic control 2 protection(Joint Trip 2)

Range

Description

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

20

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Parameter Logic control 3 protection(Joint Trip 3) Logic control 4 protection(Joint Trip 4) Non-electric quantity 1 protection(Non-elec tric 1) Non-electric quantity 2 protection(Non-elec tric 2) PT failure alarm(PT Failure Alarm) PT failure block(PT Failure Lock) CT failure alarm(CT Failure Alarm) FC block alarm(FC Lock Alarm) Out-of-step protection(Out-Of-S tep PROT) Asynchronous impact protection(Asynchr o.Impact) Under-frequency unloading protection(Under-fr equency) Slip block(Slip Lock)

Range 1/0

Description

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0 1/0 1/0 1/0

1/0: On/Off (factory default Off)

1/0: On/Off (factory default Off)

1/0: On/Off (factory default Off)

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

21

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Parameter Soft start(Soft Startup) Normal-reverse function (Nor.Rev.Func.)

Range 1/0

Description

1/0: On/Off (factory default Off)

1/0

1/0: On/Off (factory default Off)

Prolonged start time protection of motor(Start Time Over)

Motor rated current(Ie) (Rated Current) Motor start time(Startup Time) 0.11.2In 0.0-1000.0s

Set step:0.01A(factory default 1.0In)

Set step:0.1s(factory default 100s)

Motors over-current protection(Overcurrent)

Current of instantaneous over-current 1 instantaneous over-current at start (Inst.PROT 1) Current of instantaneous over-current 2 instantaneous over-current after start (Inst.PROT 2) Instantaneous over-current delay(Inst.Time) Current of locked rotor protection(Locked-rotor C) Locked rotor protection delay(Locked-rotor T) 0.1-20In 0.00-100.00s

Set step:0.01A(factory default 20In)

0.1-20In

Set step:0.01A(factory default 20In)

0.1-20In

Set step:0.01A(factory default 20In)

0.00-100.00s

Set step:0.01s(factory default 100s)

Set step:0.01s(factory default 100s)

Negative sequence over-current protection(NS Overcurrent)

Negative sequence definite time limit over-current(NS

0.1-20In

Set step:0.01A(factory default 2In)

DT Current)

Negative sequence definite time limit delay(NS DT

0.20-100.00s

Set step:0.01s(factory default 100s)

Time)

22

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Parameter

Negative sequence inverse time limit curve(NS IT

Range 1-4

Description

Set step:1(factory default 1)

Curve)

Negative sequence inverse time limit constant(NS IT

0.00-1.00s

Set step:0.01s (factory default 1s)

Constant)

Inverse time limit starting current(NS IT Start C)

0.1-2In

Set step:0.01A(factory default 1In)

Zero sequence over-current protection(ZS Overcurrent)

Current of zero sequence over-current(ZS OC Value) Zero sequence over-current delay(ZS OC Time)

0.00-2.00A 0.00-100.00s

Set step:0.01A(factory default 2A)

Set step:0.01s(factory default 100s)

Overload protection(Overload)

Overload current(Overload

Current)

Overload delay(Overload

0.1-20In 0.00-100.00s

Set step:0.01A(factory default 20In)

Time)

Set step:0.01s(factory default 100s)

Overheat protection(Motor Over Heat)

Heating time constant(Heating T) Radiating time constant(Diffusion T) K1 K2 Overheat alarm coefficient(Alarm Coeff.)

1.0-1000.0s 0.10-10.00 0-1 0-10 50.00-100.00%

Set step:0.1s(factory default 100s)

Set step:0.01(factory default 10) Set step:0.01(factory default 1) Set step:0.01s(factory default 6) Set step:0.01%( factory default 80%)

Underload protection(Underload PROT)

Underload current(Underload C) Underload delay(Underload Time)

012In 0.50-100.00s

Set step:0.01A(factory default 0.1In)

Set step:0.01s(factory default 100s)

Voltage protection(Voltage PROT)

Under-voltage setting value(Undervolt. Value) Under-voltage

1.00-100.00V 0.20-100.00s

Set step:0.01V(factory default 90V) Note: set by inter-phase voltage Set step:0.01s(factory default 100s)

23

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Parameter

delay(Undervolt. Time) Over-voltage setting value(Overvolt. Value) Over-voltage delay(Overvolt. Time)

Range

Description

100.00-120.00V 0.00-100.00s

Set step:0.01V(factory default 120V) Note: set by inter-phase voltage Set step:0.01s(factory default 100s)

Logical control protection(Joint Trip PROT)

Logical control 1 delay(JointTrip 1 Time) Logical control 2 delay(JointTrip 2 Time) Logical control 3 delay(JointTrip 3 Time) Logical control 4 delay(JointTrip 4 Time) Non-electric quantity 1 setting value (Non-elec.1 Value) Non-electric quantity 1 delay(Non-elec.1 Time) Non-electric quantity 2 setting value(Non-elec.2 Value) Non-electric quantity 2 delay(Non-elec.2 Time) PT failure delay(PT

0.00-100.00s 0.00-100.00s 0.00-100.00s 0.00-100.00s

Set step:0.01s(factory default 0s) Set step:0.01s(factory default 0s) Set step:0.01s(factory default 0s) Set step:0.01s(factory default 0s)

Non-electric quantity protection(Non-electric)

4.00-20.00mA 0.00-100.00s 4.00-20.00mA 0.00-100.00s

Set step:0.01mA(factory default 20mA) Set step:0.01s(factory default 0s) Set step:0.01mA(factory default 20mA) Set step:0.01s(factory default 0s)

Failure and FC block(PT/CT&FC Lock)

Failure Time) CT failure delay(CT Failure Time) FC breaking current(FC Current)

Out-of-step protection current(Out-Of-Step C) Out-of-step protection delay(Out-Of-Step Time) Setting value of asynchronous impact(Asynchr.Impact) Asynchronous impact delay(Asynchr.Imp.Time)

0.50-10.00s 0.50-10.00s 0.1-20In

Set step:0.01s(factory default 10s) Set step:0.01s(factory default 10s) Set step:0.01A(factory default 20In)

Synchronizer protection(Synchrodyne)

0.1-20In 1.00-100.00s

Set step:0.01A(factory default 20In)

Set step:0.01s(factory default 100s)

1.01000.0W

Set step:0.1W(factory default 1000W)

0.00-100.00s

Set step:0.01s(factory default 100s)

Under-frequency unloading(Under-frequency)

Under-frequency 45.00-50.00Hz

Set step:0.01Hz(factory default 48Hz)

24

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Parameter unloading setting value(Under-freq.Value) Under-frequency unloading delay setting value (Under-freq.Time) Under-frequency unloading low current block setting value(Low Current Lock) Under-frequency unloading under-voltage block setting value (Undervolt. Lock) Under-frequency unloading slip block setting value (df/dt Lock)

Range

Description

0.50-100.00s

Set step:0.01s(factory default 100s)

0.2-5A

Set step:0.01A(factory default In)

60.00-90.00V

Set step:0.01V(factory default 90V)

0.5-8.00Hz/s

Set step:0.01Hz/s(factory default 1Hz/s)

Soft starting function(Soft Startup)

Soft start current(Starting Current) Soft start method(Starting Mode) 0.5-20A 1-2

Set step:0.01A(factory default 20A)

Select method 1 or 2

Motors normal-reverse function( Nor.Rev.Func.)

Current commutating 1AB commutating2BC commutating3

method (Commutation Mode)

1-3

CA commutating Set step:1(factory default 1)

25

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

4. Description of binary output and analog quantity input,

4.1 Monitoring of analog quantities

Analog quantities can be monitored under the [Protection Data Display], [Measured Data Display] and [Impulse Energy] menus in the [State Display] menu, press the , keys to flip over. The factory precision of the device has been calibrated. The protection current is calibrated at double the rated current and the measuring current at a single rated current. The list is as follows:

Note: for protection CT 3-phase, PT Y-Y wiring; due to the under-frequency unloading

protection of this device, the frequency display is put in the protection data. Analog quantity Analog quantity name Test method terminal

Terminals D01,D02 Protective Phase A current (Ia) Protective Phase B current (Ib) Protective Phase C current (Ic) Zero sequence current at high voltage side (I0) Measured Phase A current (IA) Measured Phase B current (IB) Measured Phase C current (IC) Phase A voltage (Ua) System frequency F Phase B voltage (Ub) Phase C voltage (Uc) Zero sequence voltage Add double the rating, displayed deviation not exceeding 1% Add double the rating, displayed deviation not exceeding 1% Add double the rating, displayed deviation not exceeding 1% Add 1A, displayed deviation not exceeding 0.2% Add a single rating, displayed deviation not exceeding 0.2% Add a single rating, displayed deviation not exceeding 0.2% Add a single rating, displayed deviation not exceeding 0.2% Add 50V, displayed deviation not exceeding 0.5% Add 50V 50Hz, displayed deviation not exceeding 0.02Hz Add 50V, displayed deviation not exceeding 0.5% Add 50V, displayed deviation not exceeding 0.5% Add 50V, displayed deviation not exceeding 0.5% Add 10mA, displayed deviation not exceeding 3% Add 10mA, displayed deviation not

Terminals D03,D04

Terminals D05,D06

Terminals D07,D08

Terminals D09,D10

Terminals D11,D12

Terminals D13,D14

Terminals D15,D16 Terminals D15,D16 Terminals D17,D18 Terminals D19,D20

Terminals D21,D22

(U0) 420mA DC Input 1 420mA DC Input 2

Terminals D25,D26 Terminals D27,D28

26

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Analog quantity terminal

Analog quantity name

Test method exceeding 3%

Terminals D09D10

D13,D14 add current by polarityD15,D16 D17,D18D19,D20 add voltage by polarity

Terminals D09,D10 3-phase active power

Add a single rating to current and 100V to line voltage Alter phase angle, displayed power deviation not exceeding 0.5%

D13,D14 add current by polarityD15,D16 D17,D18D19,D20 add voltage by polarity

Terminals C12 and 3-phase reactive power

Add a single rating to current and 100V to line voltage Alter phase angle, displayed power deviation not exceeding 2%

C16(common terminal of

impulse +24V) Terminals C13 and

Impulse 1MC1

Connect each point once, add 1 to the count

C16(common terminal of

impulse +24V) Terminals C14 and

Impulse 2MC2

Connect each point once, add 1 to the count

C16(common terminal of

impulse +24V) Terminals C15 and

Impulse 3MC3

Connect each point once, add 1 to the count

C16(common terminal of

impulse +24V)

Impulse 4MC4

Connect each point once, add 1 to the count

4.2

Monitoring of binary input

Binary input can be monitored under the [Binary input] menu in the [State Display] menu,

press the , keys to flip over.

Binary input terminal B01

Binary input name Common terminal of binary input Should be connected to

Test method External power supply of 220V or 110V DC can be applied, connect the negative terminal to terminal B01,

27

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

DC220V or DC110V negative terminal of external power supply B02 B03 B04 B05 B06 B07 B08 B09 B10 B11 B12 B13 Binary input in operation circuit Circuit breaker position(Breaker) Carriage operation position(Trolley Run) Carriage test position(Trolley Test) Ground knife position(Earth Switch) Spring is not energized(Spring) Logical control 1(Joint Trip 1) Logical control 2(Joint Trip 2) Logical control 3(Joint Trip 3) Logical control 4(Joint Trip 4) QF2 contact(QF2 Node) Motors normal-reverse(Nor.Rev.Func.) Binary input 12(Input 12) Binary input by manual trip(Manual Trip) Binary input by manual closing(Manual Close) Operation circuit(Operate CIR) B14 Positive terminal of internal 24V power supply

positive terminal to terminal B02B13, in [Binary input] menu in the [State Display], the status of binary input can be seen. The device also has a 24V DC supply, if it is used, terminal B14 can be connected to terminal B02 B13, in [Binary input] menu in the [State Display], the status of binary input can be seen. The binary input input by manual trip, input by manual closing, operating circuit is gathered from operating circuit , which can monitor the state of operating circuit. In the test, negative controlling power is connected to terminal A19(-WC), and positive controlling power to A15 manual closing input A17 , manual trip input . Manual closing/ manual trip state can be seen in theinput quantitymenu. The positive controlling power to is trip connected to terminal A20+WC, negative controlling power position monitoring terminal A13 or closing position monitoring terminal A14. Open/closing state of operating circuit can be seen in the input quantitymenu. Please note about the binary input voltage upon ordering, it is set to DC220V by default.

4.3

Monitoring of binary output

Binary output can be monitored under the [Binary output] menu, press the , keys

28

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

to flip over.

Binary output terminals B15-B16 B17-B18 B19-B20 B21-B22 B23-B24 B25-B26 B27-B28 B29-B30 B31-B32Common open B32-B33 B34-B35Common open B35-B36 A22-A23 A22-A24

Binary output name Device Failure Trip Signal Alarm Signal Output 4 Output 5 PROT Output 1 PROT Output 2 Softstart Output

Test method

Select open and close menu, use +, - key to operate and test the corresponding terminals. B31-B32 and B34-B35 are common open terminals that should close.

Output 9

Output 10

Remote Close Remote Trip

29

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

5. Operation instructions

5.1 Control panel of device

128*64 matrix LCD (The LCD will go off after a period of absence of keyboard operation; the LCD will be illuminated automatically when any key is pressed or in case of protection trip or alarm.) Signal indicator: operation, communication, operation, alarm, reclosure, fault (of the device) Circuit breaker state indication: indicating the current state of the circuit breaker (Open, Close position indication) Remote/local selection signal, local opening/closing button Key pad: , , , , Cancel, -, +, Enter, Revert The 6-bit nixie tube displays the primary measured values in real time: IA, IB, IC, Uab, Ubc, Uca, P, Q, Cos. (Please set the PT, CT transformation ratios properly in the System Parameters menu). The maximum display range of the power on the nixie tube is: 99999.

Note: Measurement IA: AA, measurement IB: bA, measurement IC: CA, voltage Uab: AbkV, voltage Ubc: bCkV, voltage Uca: CAkV, active power: PkW, reactive power:

qkvar, power factor: H 5.2 Instructions for use of key pad and LCD display During the devices normal operation, it will display the measuring current, voltage, power, time and operation state of motor (indicating motors normal-reverse) in cycle. Press the Enter key to enter the main menu, which is a multi-level tree menu. Press the

30

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

, keys to move the cursor to the desired entry, press the Enter key to enter this entry, and press the Cancel key to return to the next higher level of screen. If this screen is still a menu, continue to press the , key to select the desired entry, press the Enter key to enter the next level of screen, and press the Cancel key to return to the next higher level of menu. If there is no menu screen, be sure to press the Cancel key to return to the next higher level of menu. The main menu is shown at the center of the following figure, with the corresponding submenus on both sides. The main interface displays the primary operating parameters in turn. The maximum displayed value of the primary is 6000.0A. For systems with a rated current of 5A, the set CT transformation ratio shall not exceed 2000. If the primary power is greater than 1000kW, the display unit is MW, otherwise is kW. 1. State Display Protection data Measuring data Binary input Pulse Energy Phase Angle Harmonic Data DC Input Data Trip Times 2. Signal Revert Enter 3. Report Display Trip Report Binary Report Event Report MotorStart Value 4. Output Test Device Failure Trip Signal Alarm signal Output 4 Output 5 PROT Output 1 PROT Output 2 Softstart Output Output 9 Output 10 Remote Close Remote Trip Operate All 5. Parameters Setting Zone No. Comm. Setting B.Parameters D/A Setting Pulse Energy Trip Times Clear D/A setting Impulse energy setting 8. Input Password Type:MxPR-610Hb Ver V.. Date:20-- XXXCRC:

31

Main menu 1. State Display 2. Signal Revert 3. Report Display 4. Output Test 5. SYS Parameters 6. Setting Value 7. Clock Setting 8. Password 9. Version Info.

6. SettingsNote 3 Protection On/Off Note: See protection setting table for detailed setting menus. 7. Clock setting Date-- Time::

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Note 1Only the motors protective and monitoring device has this item. Note 2The system parameters such as basic parameters, output matrix and D/A

settings are variable with the different devices. See the device description.

Note 3The setting menu is shown in the device description. State Display

The [State Display] menu contains 8 submenus, including protection data, measuring

data, binary input, impulse energy, angle display, harmonic data, DC measurement and trip statistics. It is described as follows: 1.1Protection data Ia.A Ib.A Ic.A Uab.V Ubc.V Uca.V I1.A I2.A I0. A U1.V U2.V U0.V Pn.W F.Hz I0js.A U0js.V 1.2 Measuring data IA.A IB.A IC.A Ua.V Ub.V Uc.V P .W Q .var Cos.

Protection current Bus line voltage Positive sequence current of protection Negative sequence current of protection Zero sequence current of high-voltage side analog Positive sequence voltage Negative sequence voltage Zero sequence voltageanalog Reverse power Frequency Zero sequence currentcalculation value Zero sequence voltagecalculation value

Measuring current

Bus phase voltageno display in VV wiring mode Active power Reactive power Power factor

32

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

At Closed, circuit breaker is at closed position; at Open, circuit breaker is at open position. Binary input Breaker Trolley Run: Trolley Test: Earth Switch: Spring: Joint Trip 1 Joint Trip 2 Joint Trip 3 Joint Trip 4 Description varies with model, see corresponding terminal diagram for details fixed position. When Closed, trolley at operating position When Closed, trolley at test position When Closed, trolley at closed position When Closed, energy storage not completed Note The position The of the circuit breaker relates to protection logic, with

Note: In the standard configurations, the input circuit has the connection to an

external 220VDC control power supply. When no DC control power supply or control system is available on site, but a 110VDC control power supply is available, a 110VDC control power supply may be used for direct connection through local hardware adjustment, or the 24V power supply of the device may be used as the input power supply (when the input common terminal is +24V, terminal number: B14, Terminal B01 is kept float). However, this must be specified upon ordering. Pulse Energy MC1 MC2 MC3 MC4 kWh kvh kWh kvh Phase Angle Ua 0 0 0 0 0 Ub Uc Ia Ib Ic IA IB IC

Externalimpulseenergyinput counting(4-way)

Accumulation of the devices real-time active and reactive calculations overtime, + forpositivedirection, -fornegative direction

Phase angle relativeto Ua,Uaas0 bydefault.When wiring method is VV itdisplays linevoltagesrelativeto Uab, the same as follows ,

Phase angleofprotection currentrelativeto Ua

Phase angleofmeasuring currentrelativeto Ua

33

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Harmonic I2 % I3 % I4 % I5 % I11 %

2~11st harmonics forwhich analog channelshavebeen selected in system

DC Input DC1mA DC2mA

External DCinput4~20mA(2-way)

Trip statistics Total: times

Signal revert

In the [Signal Revert] menu, press the Enter key, the signal relay and the Operation

indicator on the panel will be reset.

Report Display

The [Report Display] menu includes 4 submenus, including trip report, remote signal

report, event report and clear report. Event recording includes: device self-check fault, device setting value modification, system parameter modification and setting zone number modification, etc. Trip report can be recorded for the last 50 events, remote signal report for 100, event report for 30 at most. Beyond this, the latest report will overwrite the earliest one. Press the Enter key to enter the corresponding [To view xx report, please enter report number: 00 ] menu, and enter any figure within storage volume, press the Enter key to display the contents of that report. The screen is as follows:

Report No. 20--

Report No. of this report Year, month, day, hour, minute, second and millisecond when it took place Description of reports contents

Press key to see the specific operation value. Press and keys to flip over. Operation values

34

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Ia = A Ib = A Ic = A Uab = V Ubc = V Uca = V I1 = A I2 = A I0 = A U1 = V U2 = V U0 = V Ua = V Ub = V Uc = V I0js = A U0js = V Pn = W DC1 = mA DC2 = mA F = Hz

Protection current

Bus line voltage

Positive sequence, negative sequence, zero sequence of protection current Zero sequence is as analog.

Positive sequence voltage Negative sequence voltage Zero sequence voltage Bus phase voltage

Zero sequence current calculation value at high-voltage side

Zero sequence voltage calculation value Reverse power Non-electric quantity DC Frequency

Output test

After entering the [Output Test] menu, the correct password is required to enter the

[Output Test] menu. It displays the following: 4Output test Device Failure Trip Signal Alarm signal Output 4 Output 5 PROT Output 1 PROT Output 2 Softstart Output Output 9 Output 10 Remote Close

Device Failure

Press Enter key

Press Cancel key

On

Off

(Note: After signal relay closed, press the Revert key or enter theSignal revert Operate all relays menu, press Enter to make the signal relay reverted. When the test is performed on the 6 protection outputs, the starting relay will be in the Closed state automatically. The +, - keys are used for switching between the Close/Open control.)

35

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

System parameters After entering the [System Parameters] menu, the correct password is required to

enter the [System Parameters] menu. It displays the following:

5Parameters Setting Zone No. Comm. Setting B.Parameters D/A Setting Pulse Energy Trip Times Clear

Setting zone number setting: range 00~07. Communication setting

Com. Setting RS485 Address RS485 Baudrate Pulse Input Time ms IP Address . . . Subnet Mask . . . KW Default . . .

Communication address of device 0199

00 2.4KB 4.8KB 9.6KB 19.2KB 01 02 03 0438.4KB05115.2KB Confirmation time of 4-way impulse energy, >10ms, < impulse width of kilowatt-hour meter

For Ethernet communication

36

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Setting of basic parameters (see the description of the protection device for basic parameters)

B.Parameters Rating Current PT Ratio CT Ratio CT Wiring Mode PT Wiring Mode Harmonic Channel

Setting the CT secondary current rating 00 1A015A Setting the PT transformation ratio 11500 Setting the CT transformation ratio 15000

Setting the CT secondary wiring mode 00 3-phase012-phase Setting the PT secondary wiring mode 00YY 01VV Setting analog quantity channels 0~12 for harmonic monitoring, select 0 to exit from the harmonic calculation function.

D/A setting

The device has two 4~20mA outputs. The DA1~DA2 adjustment factor is used to adjust the accuracy of the channel output. The DA1~DA2 channel selection is used to select the corresponding analog quantity channel (see the description of the protection device for specific reference quantities). In the accuracy test, make sure the field ground is in good contact; otherwise the accuracy might be affected.

Impulse energy setting

Energy base numbers can be set, including Impulse 1, Impulse 2, Impulse 3, Impulse

4, positive active energy, positive reactive energy, negative active energy and negative reactive energy.

Clear trip count

It is used to clear the trip count.

Settings

After entering the password, you can enter the [Settings] menu. See the settings

description of the protection device for the detailed description.

Clock setting

A battery-back real-time clock is provided in the device, which can perform time

adjust remotely via the communication network or in-site time adjust in the [Time Setting] menu.

37

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

7. Clock setting Date20 Time

Enter this menu and press the Enter key, the clock will stop refreshing and a cursor will appear. Move the cursor to the desired position for modification by pressing the , keys, modify to the desired value with the +, - keys. Press the Enter key to complete setting. If the Cancel key is pressed, the setting will be cancelled and the screen continues to refresh the clock.

Password

The [Password] menu is used to modify the password for entry into the Settings,

System parameters and Output Test submenus. The initial password is provided by the factory. The universal password is 1000. Input Password 0 0 0 0

Move the cursor to the desired position for modification by pressing the , keys, modify to the desired password with the +, - keys. Press the Enter key to enter the new password setting menu as above; press the Cancel key to cancel the setting.

GPS clock synchronization

The GPS clock synchronization signal is input as rs485 differential voltage, the

device is able to receive GPS clock minute synchronization (or second synchronization). If there is GPS signal, there will be otherwise wont. The principle of GPS clock synchronization: The second pulse or minute pulse act with the monitoring system, the time base with second precision is sent by monitoring system, when the GPS second differential signal arrives, the time base is unified and the milliseconds are cleared. and flashing on the bottom of cycle menu;

Version Info

In the main menu, after entering the [9. Version Info] menu, the model, software

version No. and date of the device will be displayed. Note: For a corresponding nonstandard model, the devices displayed model does not have to be changed.

38

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

6. Check of protection function

6.1

Check of prolonged start time protection(Start Time Over)

Wire as Figure 6-1, switch on the prolonged start time protection. Set motors rated current and starting time according to motors nameplate parameters or real measuring value. The current >1.2Ieis input, when the motors starting time is exceeded, the protection will operate. The terminals B17-B18, B25-B26, B27-B28 should be shorted.

MMPR-610Hb Ia Ib Ic Ia (Ib ,Ic ) D01 A01 D03 D05 A02 D02(D04,D06)

Figure 6-1 6.2 Check of 2-section over-current protection(Overcurrent)

Wire as Figure 6-1, switch on instantaneous over-current protection. The current 1 of instantaneous over-current (at starting) and current 2 of instantaneous over-current (after starting) are be set separately. If the fault current is input at starting time or after starting time, the protection will operate. The terminals B17-B18, B25-B26, B27-B28 should be shorted. Switch on FC block alarm, 50ms is added up to instantaneous over-current protection delay at this moment. When the fault current exceeds FC breaking current, (the current setting value should be greater than over-current setting value), FC block instantaneous over-current protection will operate. Locked time can be set in the system parameters.

Power supply

Locked rotor protection is provided after starting, which checking way is the same as instantaneous over-current after starting. Setting value of instantaneous over-current (A) Instantaneous over-current delay (s) Current 1 of instantaneous over-current at time(A)

39

1.2 Ie 10

2 Ie 5

5 Ie 2

10 Ie 1

starting

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Current

of

instantaneous over-current after starting time (A) Instantaneous over-current time (s) 6.3 Check of negative sequence over-current protection(NS Overcurrent) Negative sequence current is derived from protection current calculation. Wire as Figure 6-1. 6.3.1 Negative sequence over-current definite time limit(NS OC DT) Switch on negative sequence over-current definite time limit protection, inputting currents of 3-phase in negative sequence mode. See the following table and set, measuring operation current value for record. Setting value of negative sequence current (A) Negative current delay (s) Negative current (A) Negative 6.3.2 sequence Negative sequence over-current inverse time limit(NS OC IT) current operation time (s) Switch on negative sequence over-current inverse time limit, select one curve in inverse time limit modes01 Standard inverse time limit02 Unusual inverse time limit 03 Extreme inverse time limit Long inverse time limit the time constant Tp of inverse 04 , time limit is set as 0.50s and the current Ip of inverse time limit is set as 5A. See the following table and set. When over-current inverse time limit protection operates, the measuring terminals B17-18, B25-26, B27-B28 should be shorted. Curve type Operation value of inverse time limit 01Standard inverse time limit Reference operation time 5.105s 3.15s 2.140s 2Ip(A) 3Ip(A) 5Ip(A) sequence operation value sequence 0.2 Ie 10 0.4 Ie 5 0.6 Ie 2 0.8 Ie 1

40

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Ip=5Ap=0.5s 02Unusual inverse time limit Ip=5Ap=0.5s 03Extreme inverse time limit Ip=5Ap=0.5s 04Long inverse time limit Ip=5Ap=0.5s

Actual operation time Reference operation time Actual operation time Reference operation time Actual operation time Reference operation time Actual operation time 60.000s s 30.000 15.000s 13.333s 5.000s 1.667s 6.750s 3.375s 1.688s

6.4

Check of zero sequence over-current protection(ZS Overcurrent) Zero sequence over-current protection can select trip or alarm. When zero

sequence over-current protection trip is switched on, the alarm will be switched off automatically. Wire as Figure 6-2.

MMPR-610Hb

I0

D07 A01

Power supply

A02 I0 D08

Figure 6-2 See the following table and set, measuring the operation current value for record. If the zero sequence over-current protection operates, the measuring terminals B17-18, B25-26, B27-B28 should be shorted. If zero sequence over-current alarm is provided, the measuring terminals B19-B20 should be shorted. Setting value of zero sequence current A) Setting value of zero sequence current delay 0.20 5 0.50 3 1.00 2 1.50 1

41

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

s Operation value (A) Operation times 6.5 Check of overload protection(Overload) Overload protection uses the maximum current of phase for judgment. Trip or alarm can be selected. Wire as Figure 6-1, switch on overload trip. When the overload trip is switched on, the alarm is switched off automatically. See the following table and set, measure operation current value and keep a record in the table. When the overload alarm operates, the measuring terminals B19-20 should be shorted. When the overload trip operates, the measuring terminals B17-B18, B25-26, B27-B28 should be shorted. Setting overload (A) Overload delay (s) Overload value (A) Overload time (s) 6.6 Check of overheat protection(Motor Over Heat) Wire as Figure 6-1, switching on overheat protection, the other protections are switched off. The motor starting time is set as 5s and set K1=1.0K2=0; The heating time constant is set according to the following table. Input the current showed in the following tableIe is the rated current, and then record the operation time. If it operates correctly, the measuring terminals B17-B18, B25-26, B27-B28 should be shorted, and the operation time should accord with the calculation value derived from overheating judgment criterion. Overheating alarm time = Trip output time Overheating alarm factor. When overheating alarm operates, the measuring terminals B19-B20 should be shorted. Input current value

Heating constant

value

of

5 10

10 5

15 2

20 1

operation operation

1.5Ie

2Ie

4Ie

6Ie

100 1000 6.7 Check of underload protection (Underload PROT) Wire as Figure 6-3, and switch on the underload protection, imitating the state of circuit breaker closing. Input starting current >0.1Ie and imitate motor start. After starting time, the motor is put into the operation state. Reduce the fault current and make it be less

42

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

than the setting value of underload, the underload protection will operate. The underload protection can be switched On/Off on alarm or trip. When it operates on the trip, the measuring terminals B17-B18, B25-26, B27-B28 should be shorted; When it operates on the alarm, the measuring terminals B19-B20 should be shorted.

MMPR-610Hb Ia(Ib,Ic) Ia(Ib,Ic) D01(D03,D05) A01 D02(D04,D06)

Power supply

B01

Auxiliary contact of breaker

A02 B02

Figure 6-3 6.8 6.8.1 Check of voltage protection(Voltage PROT) Check of under-voltage protection(Undervoltage PRO) Under-voltage protection uses the maximum line voltage for judgment. In case of PT failure, the under-voltage protection will be blocked. Wire as Figure 6-4, and switch on under-voltage protection, PT failure and PT failure block are switched on.

MMPR-610Hb Ua(Ub,Uc) Ua(Ub,Uc) D15(D17,D19) A01 D16(D18,D20)

Power supply

B01

Auxiliary contact of breaker

A02 B02

Figure 6-4 See the following table and set, measuring the operation voltage value for record. When the under-voltage operates, the measuring terminals B17-B18, B25-B26, B27-B28 should be shorted. When PT failure occurs, the under-voltage will be blocked. Setting value of delay under-voltage (V) Under-voltage (s) 95 10 90 5 85 2 80 1

43

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Operation Operation

value time

of of

under-voltage (V) under-voltage (s) 6.8.2 Check of over-voltage protection(Overvoltage PROT) Over-voltage protection uses the maximum line voltage for judgment. Wire as Figure 6-4, and switch on the under-voltage protection. See the following table and set, measuring the operation voltage value for record. When the over-voltage operates, the measuring terminals B17-B18, B25-B26, B27-B28 should be shorted. Setting value of delay over-voltage (V) Over-voltage (s) Over-voltage operation value (V) Over-voltage operation time (s) 6.9 Check of logic control protection(Joint Trip PROT) Switch on all the logic control protection, the delay is set as 0s. Terminal B01 is connected to negative pole of DC220V, and terminals B07, B08, B09, B10 is connected to the positive pole of DC220V separately, then the logic control protection will operate separately. The measuring terminals B17-18, B25-26, B27-28 should be shorted. 6.10 Check of non-electric quantity protection(Non-electric) Wire as Figure 6-5, and switch on non-electric quantity protection. Take non-electric quantity 1 protection for example. 105 10 110 5 115 2 120 1

MMPR-610Hb

DCSIn+

D25

A01

Power supply

DCSIn-

D26

A02

Figure 6-5

44

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

See the following table and set, measuring the DC operation value and keep a record in the table. When the protection operates, the measuring terminals B17-18, B25-26, B27-28 should be shorted. Setting non-electric (mA) Non-electric delay (s) Non-electric Non-electric quantity quantity 1 1 operation value (mA) operation time (s) 6.11 PT/CT failure Currents of 3 phases are wired as Figure 6-1, imitate all kinds of CT failure, the device will send alarm signal, the measuring terminals B19-B20 should be shorted. Voltages of 3 phases are wired as Figure 6-4, imitate all kinds of PT failure, the device will send alarm signal, the measuring terminals B19-B20 should be shorted. 6.12 6.13.1 Check of synchronous motor protection(Synchrodyne) Check of out-of-step protection(Out-Of-Step PROT) Wire as Figure 6-3, switch on out-of-step protection, imitating circuit breaker closing state. Input impulse current and set the setting value according to the following table. Measure the operation delay for record. When the out-of-step protection operates, the measuring terminals B17-18, B25-26, B27-28 should be shorted. Setting value of out-of-step current A Setting value of out-of-step delay s Out-of-step operation delays 6.13.2 Check of asynchronous impact protection(Asynchro.Impact) Wire as the testing power method, switch on the asynchronous impact protection. The asynchronous impact delay is set as 1s. See the following table and set, measuring the operation delay value for record. When the asynchronous impact protection operates,

45

value quantity quantity

of 1 1 5 10 15 18

10

1.2 Ie

2 Ie

3 Ie

4 Ie

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

the measuring terminals B17-18, B25-26, B27-28 should be shorted. Setting value of asynchronous impact W Setting value of asynchronous impact delay s Asynchronous impact operation delays 6.13 Check of under frequency unloading protection(Under-frequency) The frequency of under frequency unloading protection is derived from measuring frequency of voltage Uab. To prevent the load feedback, the frequency slip block (On/Off) and low current block can be used. To prevent fast voltage drop from mis-operation of frequency protection, under-frequency unloading protection has under-voltage block. Wire as Figure 6-6, switch on under-frequency unloading protection. The slip block is provided when measuring the slip frequency. Switch off the slip block when measuring frequency operation value, operation delay, so as not to affect the operation accuracy. 10 5 2 1 10 50 100 150

MMPR-610Hb Ia Ia Ua(Ub) Ua(Ub) D01 A01 D02 D15(D18) A02 D16(D17)

Figure 6-6 See the following table and set, measuring the operation value for record. When the under-frequency unloading protection operates, the measuring terminals B25-B26, B27-B28 should be shorted. Setting Setting Setting value value value of of of B17-18,

Power supply

under-frequency (Hz) under-current (A) under-voltage (V) Setting value of slip block (Hz/s)

49.5 0.5 10 3

49 0.5 20 4

48.5 1 30 5

48 1 60 7

46

Users manual of MMPR-610Hb microcomputer motor protection and monitoring device WLD[K]-JY-222-2010

Setting delay (s) Operation Operation Slip (Hz/s) 6.14

value

of 0.5 1 2 3

under-frequency operation value time of of

under-frequency (Hz) under-frequency (s) block value

Normal-reverse function(Nor.Rev.Func.) Switch on the normal-reverse function. Input DC220- at binary input terminal B01 and