Académique Documents

Professionnel Documents

Culture Documents

Hydrometer

Transféré par

harshithagowdaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hydrometer

Transféré par

harshithagowdaDroits d'auteur :

Formats disponibles

HYDROMETER A hydrometer is an instrument used to measure the specific gravity (or relative density) of liquids; that is, the

ratio of the density of the liquid to the density of water. A hydrometer is usually made of glass and consists of a cylindrical stem and a bulb weighted with mercury or lead shot to make it float upright. The liquid to be tested is poured into a tall container, often a graduated cylinder, and the hydrometer is gently lowered into the liquid until it floats freely. The point at which the surface of the liquid touches the stem of the hydrometer is noted. Hydrometers usually contain a scale inside the stem, so that the specific gravity can be read directly. A variety of scales exist, and are used depending on the context. Hydrometers may be calibrated for different uses, such as a lactometer for measuring the density (creaminess) of milk, a saccharometer for measuring the density of sugar in a liquid, or an alcoholometer for measuring higher levels of alcohol in spirits.

LACTOMETER An instrument to find out the content of the water in the milk or to test the richness of the milk is thus termed as 'lactometers'. The lactometer works on the principle of gravity of milk. The construction of this instrument is very unique as there is long vessel test tube and meter bulb attached to it so that whenever the milk is poured into the vessel the meter bulb starts floating on it. The purity of the milk gets tested without any dilution of water content in it. These lactometers are known for precision design, accurate measurement and reliability. These lactometers are used highly at milk processing units and at dairies. Some unscrupulous milk suppliers adulterate milk with added water to increase the volume or added solids to make it look thicker. Addition of anything to milk can introduce bacteria that will make it spoil quickly. Adulteration of milk is also illegal. Here is how to test the milk to check whether it has been adulterated. The test is based on the fact that milk has a heavier weight or density (1.026 - 1.032 g/ml) compared to water (1.000 g/ml). When milk is adulterated with water or other solids are added, the density either decreases (if water is added) or increases (if solids are added). If milk fat (cream) is added to milk, the density becomes lower. The equipment used to determine milk density is called a lactometer. Most lactometers are usually marked from 0 (representing density of 1.000 g/ml) to 40 (representing density of 1.040 g/ml).

The various types of the lactometer are mercury coated lactometer which is highly acknowledged for its precision design and efficiency. The other type is the steel ball lactometer which known for its accuracy and longer working life.

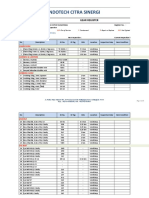

Equipment used for determination of milk density:

Mercury coated lactometer

Steel ball lactometer

Procedure: Ensure that the milk has been left to cool at room temperature for at least 30 minutes and its temperature is about 20oC. Stir the milk sample and pour it gently into a 200ml measuring cylinder (or any container deeper than the length of the lactometer). Let the lactometer sink slowly into the milk. Take the lactometer reading just above the surface of the milk. If the temperature of the milk is different from the lactometer calibration temperature (20C), then use this correction factor: For each C above the calibration temperature add 0.2 lactometer degrees (L) to the observed lactometer reading, and for each C below calibration temperature subtract 0.2 lactometer degrees (L) from the observed lactometer reading. These calculations are done on the lactometer readings i.e. 29 instead of the true density of 1.029 g/ml.

Example of how to calculate the true lactometer readings when the milk temperature differs from the lactometer calibration temperature of 20C.

Judgment: Normal milk has a density of 1.026 -1.032 g/ml (or 26 - 32 on the lactometer reading). If water has been added, the lactometer reading will be below 26. If any solid such as flour has been added, the reading will be above 32.

BUTYROMETER Butyrometers are used to determine the fat content of dairy products using the Gerber acidbutyrometry method.

Objective: The price of milk fixed on its fat content. To determine the fat level in milk by Gerber method.

RelevantInformation: Fat is the most important constituent of milk as it is used as a basis for fixing the purchase and sale price of milk. It helps to detect adulteration like watering and skimming of milk. Gerbers method commonly used in Europe and in India. Dr. N Gerber of Zurich Switzerland invented this method in the year 1892-1895. In this test H2SO4 is used to increase specific gravity of milk serum which makes greater difference between milk serum and fat globules. It also destroys stickiness of milk by dissolving all the SNF. The free fat globules rise to the surface by subsequent application of centrifugal force to this mixture and heat produced due to mixing of acid and milk, causing melting of fat. It facilitates the fat particles to come to the surface freely. The specific gravity of fat is 0.9 and that of acid milk mixtures is 1.43. This situation promotes complete separation of fat when proper centrifugal force is applied. Due to application of centrifugal force lighter substances (Butter fat) are thrown towards centre and rest of serum portion that is heavier is thrown towards the pheriphen. Addition of amyl alcohol helps for separation of fat from the milk acid mixture and also prevents the charging of fat and sugar by the H2SO4.

Material Required: iMilk ii.Sulphuric acid (sp.gr..1.82) iii.Amyl alcohol (sp. gr.0.82-0. 83)

Butyrometer Apparatus: 1. Milk sample bottle. 2.10 ml automatic tilt measure for H2SO4. 3. 1 ml automatic tilt measure for amyl alcohol. 4. 10.75 ml capacity milk pipette. 5. Dairy floating thermometer. 6. Hot water bath. 7. Gerbers centrifuge machine (1100 rpm). 8. Gerbers butyrometer plain neck with graduations from 0-10%. 9. Butyrometer stand. 10. Rubber stopper. 11. Guiding pin or key.

Procedure: 1. Put the clean and dry butyrometer in a butyrometer stand with open mouth upwards. 2. Run 10 ml of sulphuric acid with the tilt measure in the butyrometer. 3. Pipette out 10.75 ml of milk sample gently by the side of butyrometer, whose temperature is about 60-70 0 F. 4. Pour 1 ml. of amyl alcohol with tilt measure. 5. Stopper the butyrometer with the help of lock stopper using regulating pin/guiding pin. 6. The tube is well (mixed) shaken till mahogany red colour is obtained. Keep the butyrometer in

hot water bath till it attains 60-70 0 F and the butyrometer are placed in the centrifuged machine that is revolved at 1100 rpm for 4 minutes. 7. Take out the butyrometer in an upright position with the stopper end down wards. 8. Keep the butyrometer in hot water bath a 149 0 F (600 C) for some time. 9. Adjust the fat column which will appear clear and yellowish within the graduation with the help of key. 10. Note the reading. Reading should be taken from bottom of the fat column to lower border of meniscus on the scale.

Butyrometers: Milk Butyrometer 0-10% Cream Butyrometer 0-70% Cheese Butyrometer 0-40% Butter Butyrometer 0-90% Milk Powder Butyrometer 0-35% Ice Cream Butyrometer 0-20% Skim Milk Butyrometer 0.5%

REFERENCE: y y y Wikipedia Copyright 2011 Netlink Solutions (India) Ltd Milk Processing Guide Series Volume 2, FAO/TCP/KEN 6611Project. Training Program for Small-Scale Dairy Sector. Dairy Training Institute, Naivasha y Agriinfo.in@2011.

Vous aimerez peut-être aussi

- Cutting Aws C5.3 2000 R2011Document33 pagesCutting Aws C5.3 2000 R2011Serkan AkşanlıPas encore d'évaluation

- Biochemical Engineering Lab ManualDocument35 pagesBiochemical Engineering Lab ManualWazif Zakwan100% (1)

- Laboratory BalancesDocument21 pagesLaboratory BalancesAnonymous OpRuX6VPas encore d'évaluation

- Buffalo Milk Vs Cow MilkDocument3 pagesBuffalo Milk Vs Cow MilktrajrajPas encore d'évaluation

- Refractometer Calibration, Use and Maintenance PDFDocument5 pagesRefractometer Calibration, Use and Maintenance PDFValentina GonzálezPas encore d'évaluation

- IpqcDocument37 pagesIpqcAjitha AzhakesanPas encore d'évaluation

- FST - 223Document92 pagesFST - 223Karthikeyan BalakrishnanPas encore d'évaluation

- Principle of Wet DigestionDocument3 pagesPrinciple of Wet Digestionmati abbasiPas encore d'évaluation

- 2022-23 Lecture Food AdditivesDocument28 pages2022-23 Lecture Food AdditivesStudent 365Pas encore d'évaluation

- Selected Procedures For VolumetricDocument136 pagesSelected Procedures For Volumetricmilalex1aPas encore d'évaluation

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofhgagPas encore d'évaluation

- MP AES Instruction ManualDocument4 pagesMP AES Instruction ManualAnom Sigit SuryawanPas encore d'évaluation

- Determination of TurbidityDocument12 pagesDetermination of TurbidityAkash SahuPas encore d'évaluation

- Lacto MeterDocument17 pagesLacto MeterSaddam Hussain75% (4)

- GS Ep Tec 260 enDocument61 pagesGS Ep Tec 260 enCesarPas encore d'évaluation

- Application of Refractive IndexDocument5 pagesApplication of Refractive IndexFatima GulPas encore d'évaluation

- Lecture On Heat Transfer and Conduction in Industrial PharmacyDocument17 pagesLecture On Heat Transfer and Conduction in Industrial PharmacyHaroon Rahim100% (2)

- FermenterDocument19 pagesFermenterIshtiaque HossainPas encore d'évaluation

- Riboflavin PDFDocument5 pagesRiboflavin PDFArya Firsty SarungalloPas encore d'évaluation

- Lactometer TestDocument11 pagesLactometer TestRanjan PalPas encore d'évaluation

- Manufacturing of Sweetened Condensed MilkDocument6 pagesManufacturing of Sweetened Condensed Milksree anugraphics100% (1)

- Increasing Market Penetration: Institut Teknologi Bandung - MBA Marketing ManagementDocument17 pagesIncreasing Market Penetration: Institut Teknologi Bandung - MBA Marketing ManagementChethana Jayarathna0% (1)

- Practical Manual of Extrusion Technology FST-608 (Dr. Faiz)Document16 pagesPractical Manual of Extrusion Technology FST-608 (Dr. Faiz)Ayesha SafdarPas encore d'évaluation

- Experiment - Calibration of An Electrical BalanceDocument5 pagesExperiment - Calibration of An Electrical BalanceDolce Ncube100% (1)

- 6 - Toxicants Formed During ProcessingDocument45 pages6 - Toxicants Formed During Processingismailmannur100% (1)

- GlasswareDocument54 pagesGlasswareSwagath NPas encore d'évaluation

- The Philippine Women'S University Biochemistry Laboratory Experiment/sDocument4 pagesThe Philippine Women'S University Biochemistry Laboratory Experiment/sskyler andradaPas encore d'évaluation

- Calibration of Volumetric GlasswareDocument3 pagesCalibration of Volumetric Glasswareak_thimiriPas encore d'évaluation

- Osmotic Dehydration QuizDocument7 pagesOsmotic Dehydration QuizTamizh TamizhPas encore d'évaluation

- Verification of Pipette CalibrationDocument2 pagesVerification of Pipette CalibrationNathan ParsonsPas encore d'évaluation

- Detergents For Dairy FarmDocument41 pagesDetergents For Dairy FarmumeshPas encore d'évaluation

- Dietary Assessment Food RecordDocument9 pagesDietary Assessment Food RecordErfiFauziyaPas encore d'évaluation

- Tests To Detect Adulteration in MilkDocument5 pagesTests To Detect Adulteration in MilkezhilnarasuPas encore d'évaluation

- AZG 3 - Moisture Analysis - PPTDocument21 pagesAZG 3 - Moisture Analysis - PPTAs Syaffa Amalia100% (1)

- 1 Chilling and FreezingDocument29 pages1 Chilling and FreezingPrakash Singh100% (1)

- Standard Operating Procedure: Title: Water Baths, Operation, Maintenance ApprovalsDocument2 pagesStandard Operating Procedure: Title: Water Baths, Operation, Maintenance ApprovalsFanny Aulia PratamaPas encore d'évaluation

- Lab Report 1Document8 pagesLab Report 1Farzana NenaPas encore d'évaluation

- Report BacteriaDocument11 pagesReport BacteriaSuzeanni JalilPas encore d'évaluation

- Sterilization of Milk 1Document30 pagesSterilization of Milk 1Diona mariyaPas encore d'évaluation

- Water Activity and Food StabilityDocument15 pagesWater Activity and Food Stabilityanur3a31Pas encore d'évaluation

- SterilizationDocument16 pagesSterilizationYagnesh ChainyPas encore d'évaluation

- PE Lab ManualDocument88 pagesPE Lab ManualVarun kariyaPas encore d'évaluation

- FOODCHEM EXP 6 EnzymeDocument10 pagesFOODCHEM EXP 6 EnzymesitinurhanizaPas encore d'évaluation

- Experiment: 5 Immobilization of α-amylase enzyme by gel entrapmentDocument5 pagesExperiment: 5 Immobilization of α-amylase enzyme by gel entrapmentNur amirahPas encore d'évaluation

- Introduction To HACCP Plan For MayonnaiseDocument8 pagesIntroduction To HACCP Plan For Mayonnaiseshaimamoh225279Pas encore d'évaluation

- Title Calibration of Volumetrik GlasswareDocument3 pagesTitle Calibration of Volumetrik GlasswareNadirah PeacePas encore d'évaluation

- SDS PageDocument5 pagesSDS Pagestevensb055Pas encore d'évaluation

- Calibration of Volumetric Laboratory ApparatusDocument25 pagesCalibration of Volumetric Laboratory ApparatusPatricia Dionne NUnEZPas encore d'évaluation

- AoacDocument11 pagesAoacIshwar ChandraPas encore d'évaluation

- Gas - Liquid ChromatographyDocument14 pagesGas - Liquid ChromatographySELVI APas encore d'évaluation

- Practical Manual: Food Adulteration Prof J.N. SenguptaDocument10 pagesPractical Manual: Food Adulteration Prof J.N. SenguptajnsenguptaPas encore d'évaluation

- Boley - 1980 - Determination of Foods Synthetic Colours Using HPLCDocument11 pagesBoley - 1980 - Determination of Foods Synthetic Colours Using HPLCrnd labPas encore d'évaluation

- Serial Dilution ProtocolsDocument5 pagesSerial Dilution ProtocolsYugendra Babu K100% (1)

- Widal TestDocument11 pagesWidal TestlialestariPas encore d'évaluation

- Exp 4 Complete - BLANCHINGDocument12 pagesExp 4 Complete - BLANCHINGLiyana HalimPas encore d'évaluation

- P Hmeter Operating ProcedureDocument5 pagesP Hmeter Operating ProcedureJan Leo Camba DinglasaPas encore d'évaluation

- Dairy Lab Mannual CompleteDocument40 pagesDairy Lab Mannual CompleteZarakhankhan KhanPas encore d'évaluation

- Bioinstrumentation Lab ManualDocument19 pagesBioinstrumentation Lab ManualRitayan DeyPas encore d'évaluation

- Recommended Laboratory Analytical Procedures For DDGSDocument4 pagesRecommended Laboratory Analytical Procedures For DDGSAulia VellaraniPas encore d'évaluation

- Titration LabDocument3 pagesTitration LabResonationPas encore d'évaluation

- Metodos de Analisis de Leches - EngDocument9 pagesMetodos de Analisis de Leches - EngCesar2875Pas encore d'évaluation

- Materials Required: HydrometerDocument34 pagesMaterials Required: HydrometerNavPas encore d'évaluation

- L3 Physicochemical Testing 1Document24 pagesL3 Physicochemical Testing 1muniba tariqPas encore d'évaluation

- ExerciseDocument10 pagesExerciseNguyen Mai QuynhPas encore d'évaluation

- Catalog ITEM - Pdf4a3667894b315Document552 pagesCatalog ITEM - Pdf4a3667894b315Domokos LeventePas encore d'évaluation

- Tridium Europe DatasheetDocument2 pagesTridium Europe DatasheetHoàngTrầnPas encore d'évaluation

- Comparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterDocument4 pagesComparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterSurendar KesavanPas encore d'évaluation

- Class 12 Physics Mcqs Chapter: 6 Electromagnetic Induction: AnswerDocument12 pagesClass 12 Physics Mcqs Chapter: 6 Electromagnetic Induction: AnswerDiksha TPas encore d'évaluation

- Maximus MHX DatasheetDocument5 pagesMaximus MHX Datasheetjulya julyaPas encore d'évaluation

- April 7-9 2022-WPS OfficeDocument3 pagesApril 7-9 2022-WPS OfficeAllen AntolinPas encore d'évaluation

- Sources of LawDocument27 pagesSources of LawIshita AgarwalPas encore d'évaluation

- Project Report: MES Dental College and HospitalDocument28 pagesProject Report: MES Dental College and HospitalAnurtha AnuPas encore d'évaluation

- Detail Project Report: (Heidelberg Cement Group)Document42 pagesDetail Project Report: (Heidelberg Cement Group)saravananPas encore d'évaluation

- Conventional and Box-Shaped Piled RaftsDocument6 pagesConventional and Box-Shaped Piled RaftsAdrian VechiuPas encore d'évaluation

- Renaissance QuestionsDocument3 pagesRenaissance QuestionsHezel Escora NavalesPas encore d'évaluation

- MPDFDocument10 pagesMPDFshanmuganathan716Pas encore d'évaluation

- A.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskDocument28 pagesA.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskArul brittoPas encore d'évaluation

- Oracle Pac 2nd KeyDocument48 pagesOracle Pac 2nd KeyKrishna Kumar GuptaPas encore d'évaluation

- ESQLDocument2 pagesESQLajay110125_kumarPas encore d'évaluation

- Kelley DavisDocument3 pagesKelley Davisapi-626701108Pas encore d'évaluation

- Q3 - Summative Test2 - Statprob 2022 2023Document2 pagesQ3 - Summative Test2 - Statprob 2022 2023Christian Lloyd ReandinoPas encore d'évaluation

- Lab Science of Materis ReportDocument22 pagesLab Science of Materis ReportKarl ToddPas encore d'évaluation

- 01 AirCircuitBreakers LV10 102021 EN 202111301146249676Document136 pages01 AirCircuitBreakers LV10 102021 EN 202111301146249676bkPas encore d'évaluation

- COCapplication08rev Working SampleDocument34 pagesCOCapplication08rev Working SampleTanya HerreraPas encore d'évaluation

- Inspection List For Electrical PortableDocument25 pagesInspection List For Electrical PortableArif FuadiantoPas encore d'évaluation

- Literature Review Is The Backbone of ResearchDocument7 pagesLiterature Review Is The Backbone of Researchafmzweybsyajeq100% (1)

- Project TitleDocument2 pagesProject TitleVISHAL S. VPas encore d'évaluation

- Discussion 2: OOA: Case Study Robot in MazeDocument17 pagesDiscussion 2: OOA: Case Study Robot in MazeArmmetPas encore d'évaluation

- Universal Human Values NotesDocument13 pagesUniversal Human Values NotesS RamPas encore d'évaluation

- Science 8: Learning Activity SheetDocument9 pagesScience 8: Learning Activity SheetVan Amiel CovitaPas encore d'évaluation