Académique Documents

Professionnel Documents

Culture Documents

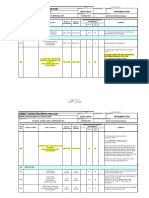

DE-102006 (Tank Data Sheet TK-107)

Transféré par

Mohammed AnwerDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DE-102006 (Tank Data Sheet TK-107)

Transféré par

Mohammed AnwerDroits d'auteur :

Formats disponibles

OPRNS

ENVIRONMENT DEVELOPMENT CO. LTD

API STANDARD 650 STORAGE TANK DATA SHEET GENERAL INFORMATION (TO BE COMPLETED BY PURCHASER)

CERT

PMT

ENGG

MZA

1. PURCHASER/AGENT ENVIRONMENT DEVELOPMENT CO. LTD ADDRESS P.O. Box 10183, Jubail Industrial City, Jubail 2, Road 274 / T-311, Kingdom of Saudi Arabia. CITY Jubail STATE ZIP CODE 31961 PHONE +966 3 367 0026 / 64 2. USER

ENVIRONMENT DEVELOPMENT CO. LTD

ISSUED FOR FINAL REVIEW

RS

3. ERECTION SITE : NAME OF PLANT LOCATION JUBAIL

300

3 3

DESCRIPTION

4. TANK NO TK-107 NOMINAL CAPACITY 5. PUMPING RATES: IN 15

m (bbl)

3/ m h (bbl/h)

NET WORKING CAP. By Vendor OUT

0

m (bbl) m3/h (bbl/h)

2.5

6. MAXIMUM OPERATING TEMPERATURE 7. PRODUCT STORED

80 (176)

0

C( F) DESIGN SPECIFIC GR. 0.9 @ 350 C 10 kPa (abs)

JO/EWO

EDCO 00081

WASTE OIL, CHEMICAL & OTHER LIQUID

DESIGN METAL TEMPERATURE 8. CORROSION ALLOWANCE: SHELL BOTTOM 9. SHELL DESIGN 10. ROOF DESIGN

-5 (23)

C( F)

VAPOR PRESSURE ROOF STRUCTURALS APPENDIX A APPENDIX F

09-20-11

DATE

NONE mm (in) NONE mm (in)

NONE mm (in) NONE mm (in)

REV. NO.

00

BASIC STANDARD 650

DISCIPLINE ENGINEER MZA DATE

Sep 2011

BASIC STANDARD 650 APPENDIX G (ALUMINIUM DOME) FRANGIBLE ROOF JOINT? YES

APPENDIX C (EXTERNAL FLOATING) NO

PROJECT ENGINEER MHN DATE

Sep 2011

CERTIFIED RS DATE

Sep 2011

11. ROOF DESIGN INFORMATION: UNIFORM LIVE LOAD PER CODE SPECIAL LOADS NONE INSULATION LOAD N/A MAXIMUM DESIGN ROOF TEMPERATURE 80 (176) GASES IN THE VAPOR SPACE 12. EARTHQUAKE DESIGN? YES NO SEISMIC USE GROUP SUG 1 MBE SITE CLASS D 13. WIND LOAD: VELOCITY

150

kPa (lb/ft ) 2 kPa (lb/ft ) 2 kPa (lb/ft ) 0 0 C( F) ROOF TIE RODS (5.10.4.5) ? Ss 0.25 S1 YES

0.1 S0

(APPENDIX E)

N/A

CONSTRUCTION AGENCY

IMPORTANCE FACTOR 1.0 MAPPED SEISMIC PARAMETERS km/h (mph ) YES

___________ DATE OPERATIONS ___________ DATE

PROVIDE INTERMEDIATE WIND GIRDER (5.9.7)? 14. ENVIRONMENTAL EFFECT MAXIMUM RAINFALL TOTAL SNOW ACCUMULATION 15. SIZE RESTRICTIONS:

___________

NO

SEE NOTE 1

mm/h (in./h ) mm (in.)

MAXIMUM DIAMETER EARTH

7.5

m ( ft )

MAXIMUM HEIGHT OTHER

m (ft )

____________

CONTROL NUMBER

BY: ____________

16. FOUNDATION TYPE: REMARKS

CONCRETE RINGWALL

_________________ DATE:

1. VENDOR TO CHECK THE REQUIREMENT OF INTERMEDIATE WIND GIRDER 2. TANK SHALL BE DESIGNED FOR ATMOSPHERIC PRESSURE CONSIDERING STATIC HEAD OF FLUID. 3. VENDOR SHALL COMPLETELY FILL IN ALL BLANK COLUMNS.

REVISION RECERTIFICATION

__________

DATA SHEET FOR TK-107 MIXING TANK

DWG. TYPE

PLANT NO. -

INDEX -

DRAWING NO.

SHT NO

REV NO.

DE - 102006 1 of 3 00 EDCO 00081

EDCO WASTE TREATMENT PLANT JUBAIL SAUDI ARABIA JO NO.

OPRNS

ENVIRONMENT DEVELOPMENT CO. LTD

API STANDARD 650 STORAGE TANK DATA SHEET CONSTRUCTION DETAILS (TO BE COMPLETED BY MANUFACTURER AND/OR PURCHASER)

CERT PMT

ENGG

MZA

1. MANUFACTURER ADDRESS CITY SERIAL NO. 2. FABRICATOR ADDRESS

RS

STATE

ZIP CODE

PHONE

ISSUED FOR FINAL REVIEW

CITY SERIAL NO.

STATE

ZIP CODE ASTM A 36 ASTM A 36 ASTM A 36 ASTM A 36

PHONE

DESCRIPTION

3. MATERIAL SPECIFICATIONS: SHELL ROOF BOTTOM STRUCTURALS 4. NO. OF SHELL COURSES

JO/EWO

EDCO 00081

5. PLATE WIDTHS AND THICKNESS (INCLUDING CORROSION ALLOWANCE), IN mm (in.) 1 2 3 6. TANK BOTTOM: PLATE THICKNESS SLOPE 1 IN 120 4 5 6 7 8 9

09-20-11

DATE

mm (in.)

mm/m (in/ft)

LAP

BUTT SEAMS

REV NO.

TO FROM CENTER (DRAINING TOWARDS SHELL) PER CODE YES NO

00

7. MINIMUM WIDTH AND THICKNESS OF BOTTOM ANNULAR PLATES (5.5), in mm (in.) :

DISCIPLINE ENGINEER MZA

8. ROOF-TO-SHELL DETAIL (FIGURE F-2) 9.INTERMEDIATE WIND GIRDER? 10. ROOF TYPE: YES NO SUPPORTED SLOPE OR RADIUS THICKNESS EXTERIOR?

(d), (e), (g), (h) or (i) TOP WIND GIRDER FOR USE AS WALKWAY? SELF-SUPPORTED (NOTE-2) 1:4.7 (12) mm (Deg.) mm (in.) LAP NO NO NO NO INTERIOR INTERIOR INTERIOR MATERIAL FIELD PER CODE PROPERTY OF FLOATING BUTT YES YES YES JOINT NO NOTE-3 NO NOTE-3 NO NOTE-3

DATE

Sep 2011

PROJECT ENGINEER MHN DATE RS DATE

Sep 2011 Sep 2011

11. ROOF PLATE 12. PAINT: SHELLBOTTOMSTRUCTURAL STEEL13. TANK BOTTOM COATING: 14. INSPECTION BY: 15. WELD EXAMINATION: 16. FILMS

YES

CERTIFIED

CONSTRUCTION AGENCY _________ DATE OPERATIONS _________ DATE _____________ CONTROL NUMBER

SURFACE PREPARATION UNDERSIDE YES SURFACE PREPARATION EXTERIOR? YES SPECIFICATION INTERIOR YES APPLICATION SPECIFICATION SHOP RADIOGRAPH

SUPPLEMENTARY LIQUID PENETRANT OR ULTRASONIC 17. LEAK TESTING 18. MILL TEST REPORTS: BOTTOM REQUIRED? YES PER CODE N0 STRUCTURAL SHAPES 7.5 m (ft.) HEIGHT 7 Eleventh Edition (June 2007) with Latest Addendum m (ft.) NOTE 4 ROOF PER CODE

__________

_____________________ DATE: __________

__________

PLATE 19. PURCHASERS REFERENCE DRAWING : 20. TANK SIZE: DIAMETER 21. DATE OF STANDARD 650 EDITION/REVISION REMARKS

REVISION CERTIFICATION

BY:

1. VENDOR SHALL COMPLETELY FILL IN ALL BLANK COLUMNS 2. SELF SUPPORTED CONICAL ROOF TYPE WITHOUT COLUMNS 3. FOR COATING SPECIFICATION, PLEASE REFER TO APPURTENANCE DRG. DE-102017 4. TO BE CONFIRMED BY VENDOR BASED ON NOMINAL VOLUME CALCULATION.

DATA SHEET FOR TK-107 MIXING TANK

DWG. TYPE

PLANT NO. -

INDEX -

DRAWING NO.

SHT NO

REV NO.

DE - 102006 2 of 3 00 EDCO 00081

EDCO WASTE TREATMENT PLANT JUBAIL SAUDI ARABIA JO NO.

OPRNS

ENVIRONMENT DEVELOPMENT CO. LTD

API STANDARD 650 STORAGE TANK DATA SHEET APPURTENANCE (TO BE COMPLETED BY MANUFACTURER AND/OR PURCHASER)

PMT

CERT

RS

1. STAIRWAY STYLE:

CIRCULAR LADDER

STRAIGHT

ANGLE TO HORIZONTAL

DEGREES

ENGG

MZA

2. WALKWAY:

WIDTH

710 (MIN.)

mm (in.)

LENGTH

m(ft.)

3. DRAWOFF SUMP:

ISSUED FOR FINAL REVIEW

STANDARD YES QUANTITY ONE

YES (API 650)

SPECIAL RAISED MATERIAL SS FLUSH

DESCRIPTION

4. BOLTED DOOR SHEET 5. MIXER / AGITATOR : 6. INTERNAL PIPING:

NO (APPENDIX A TANKS ONLY) TYPE HORIZONTAL

SWING LINE HEATING COIL SURFACE AREA

SUCTION LINE N/A

m2 (ft2)

JOINTED

N/A

JO/EWO

EDCO 00081

7. ROOF DRAIN:

HOSE SIPHON

09-20-11

DATE

8. NO. AND SIZE OF SHELL MANHOLES 9. NO. AND SIZE OF ROOF MANHOLES

ONE (1) 24" TWO (2) 24"

REV NO.

00

10. SHELL NOZZLES (SEE FIGURES 5-7B, 5-8 AND TABLES 5-8, 5-9 AND 5-10)

DISCIPLINE ENGINEER MZA

MARK

SIZE

SGL

FLANGED DBL SPL

THREADED B C D

ORIENTATION N=0

HEIGHT FROM BOTTOM

SERVICE

DATE

Sep 2011

PROJECT ENGINEER MHN DATE Sep 2011 CERTIFIED RS DATE Sep 2011 CONSTRUCTION AGENCY ___________ DATE OPERATIONS ___________ DATE _________ CONTROL NUMBER _____________________ DATE: __________ BY: ____________ _______________

11. ROOF NOZZLES, INCLUDING VENTING CONNECTION (SEE FIGURES 5-16, 5-19 AND TABLES 5-13 AND 5-14) MARK SIZE FLANGED THREADED REINFORCEMENT ORIENTATION N=0 DISTANCE FROM CENTER SERVICE

REVISION CERTIFICATION

NOTE :

1. FOR NOZZLES AND APPURTENANCES DETAILS AND ORIENTATION REF LAYOUT OF APPURTENANCES DRG NO. DE-102017 2. VENDOR SHALL COMPLETELY FILL IN ALL BLANK COLUMNS AND PROVIDE APPURTENANCES DRG..

DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT NO REV NO.

DATA SHEET FOR TK-107 MIXING TANK

DE -102006 3 of 3 00 EDCO 00081

EDCO WASTE TREATMENT PLANT JUBAIL SAUDI ARABIA JO NO.

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Letter Giving InformationDocument1 pageThe Letter Giving Informationeduard_erjaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Environment Development Company Ltd. (Edco) : Instrument Specification Sheet - Float and Board Level IndicatorDocument1 pageEnvironment Development Company Ltd. (Edco) : Instrument Specification Sheet - Float and Board Level IndicatorMohammed AnwerPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- GE-103009, Diesel Unloading Pumps, P-201 A, BDocument4 pagesGE-103009, Diesel Unloading Pumps, P-201 A, BMohammed AnwerPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- GE-103010, Diesel Oil Transfer Pumps, P-202 A, BDocument4 pagesGE-103010, Diesel Oil Transfer Pumps, P-202 A, BMohammed Anwer100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- GE-103002, Waste Oil Transfer Pumps, P-102A&BDocument4 pagesGE-103002, Waste Oil Transfer Pumps, P-102A&BMohammed AnwerPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- SCOC 9677 2012 AramcoDocument5 pagesSCOC 9677 2012 AramcoMohammed AnwerPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- RegistrationDocument9 pagesRegistrationMohammed Anwer100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Quran Hadith ScienceDocument127 pagesQuran Hadith ScienceMohammed AnwerPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Jubail Operation and Maintenance Co (Jomel) : Vendors Registration FormDocument1 pageJubail Operation and Maintenance Co (Jomel) : Vendors Registration FormMohammed AnwerPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Mohammed Anwar Khan: Opportunity To Advance ProfessionallyDocument1 pageMohammed Anwar Khan: Opportunity To Advance ProfessionallyMohammed AnwerPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- What Is Logistcs and Supply ChainDocument11 pagesWhat Is Logistcs and Supply ChainSaadiShahwan100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Sewing 04-Needle Class 118 of Groz-Beckert For Union Special FlatseamersDocument6 pagesSewing 04-Needle Class 118 of Groz-Beckert For Union Special Flatseamersfriendztoall4351Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Muestra EstructuralDocument1 pageMuestra Estructuralsua749Pas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- TLP Solutions: Our ActivitiesDocument16 pagesTLP Solutions: Our ActivitiesFrank DrennanPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Ansaldo Steam Turbines PDFDocument8 pagesAnsaldo Steam Turbines PDFMuhamadMa'arifPas encore d'évaluation

- AZITP-J-902-01 Rev 00 Metallic Instrument and Control CableDocument5 pagesAZITP-J-902-01 Rev 00 Metallic Instrument and Control CableVinay YadavPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Leaflets 2018 Triple Type enDocument2 pagesLeaflets 2018 Triple Type enСтефан ВасилевPas encore d'évaluation

- Mrs Comp Manual T-BTD-RMDocument98 pagesMrs Comp Manual T-BTD-RMkatepol82640% (1)

- Working Environment: Norsok StandardDocument52 pagesWorking Environment: Norsok StandardFoad MirzaiePas encore d'évaluation

- Natural Gas Cleaning and TreatmentDocument13 pagesNatural Gas Cleaning and Treatmentvamsix100% (1)

- M.tech-ECE-Embedded Systems (ES) - SEM1 Course Structure & SyllabiDocument8 pagesM.tech-ECE-Embedded Systems (ES) - SEM1 Course Structure & Syllabisatraj5Pas encore d'évaluation

- RTMST 2013Document327 pagesRTMST 2013palpandi.mPas encore d'évaluation

- Nammcesa 000014 PDFDocument3 732 pagesNammcesa 000014 PDFBasel Osama RaafatPas encore d'évaluation

- The Dieline Trend Report 2017Document21 pagesThe Dieline Trend Report 2017salahhuddeenPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Thermocouple GroundingDocument6 pagesThermocouple GroundingNAYEEMPas encore d'évaluation

- AICTE Approved Institutes Dec 19 2012Document789 pagesAICTE Approved Institutes Dec 19 2012dipakdks420Pas encore d'évaluation

- En LiNear Catlog v17 (Web)Document72 pagesEn LiNear Catlog v17 (Web)Dan RaileanPas encore d'évaluation

- Automotive Programme GDP 1617 Web VersionDocument18 pagesAutomotive Programme GDP 1617 Web VersionJPas encore d'évaluation

- White Paper Gasoline BlendingDocument12 pagesWhite Paper Gasoline BlendingHeniPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- NBR Catalogue Eng KKPCDocument2 pagesNBR Catalogue Eng KKPCChandrasekar KrishnamurthyPas encore d'évaluation

- Improvement in The Overall Efficiency of Mining Equipment PDFDocument7 pagesImprovement in The Overall Efficiency of Mining Equipment PDFAndres Mujica MorovicPas encore d'évaluation

- English Presentation .Document16 pagesEnglish Presentation .Joshua Tazeem100% (1)

- Accelerometer Based Tilt Sensor For Controlling Wheel ChairDocument23 pagesAccelerometer Based Tilt Sensor For Controlling Wheel ChairatulonwheelsPas encore d'évaluation

- 7020 - Liquid Soap ThickenerDocument2 pages7020 - Liquid Soap Thickenerzuber ahmedPas encore d'évaluation

- Fur An Flex 6 PP BrochureDocument2 pagesFur An Flex 6 PP Brochureseptimiu89Pas encore d'évaluation

- A572 50 TY1 KrakatauposcoplateASTMproductDocument1 pageA572 50 TY1 KrakatauposcoplateASTMproductSteel BridgePas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Kuka Branchenflyer Food en 140523 ScreenDocument12 pagesKuka Branchenflyer Food en 140523 ScreencabecavilPas encore d'évaluation

- Xylene SolubaleDocument4 pagesXylene Solubale6850079Pas encore d'évaluation

- Analysis of Shoe Manufacturing Factory by SimulatiDocument9 pagesAnalysis of Shoe Manufacturing Factory by SimulatiJosé Lorenzo ArtigasPas encore d'évaluation