Académique Documents

Professionnel Documents

Culture Documents

Alloy Steels SCM440

Transféré par

Shamik ChowdhuryDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Alloy Steels SCM440

Transféré par

Shamik ChowdhuryDroits d'auteur :

Formats disponibles

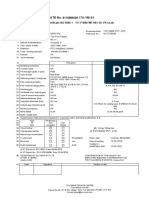

Gloria Material Technology Corp.

Alloy steels (SCM440)

Similar steels GMTC SCM440 Chemical composition (wt%) Grade SCM440 SCM440H C 0.38 0.43 0.37 0.44 Si 0.15 0.35 0.15 0.35 Mn 0.60 0.85 0.55 0.90 P Max. 0.030 Max. 0.030 S Max. 0.030 Max. 0.030 Cr 0.90 1.20 0.85 1.25 Mo 0.15 0.30 0.15 0.30 Ni Max. 0.25 Max. 0.25 Cu Max. 0.30 Max. 0.30 JIS SCM440 SAE 4140

Characteristics 1. Better tensile strength and percentage of elongation than chromium steels. 2. Combine with Cr and Mo, high hardenability, good resistance to tempered -softening. 3. Good strength and toughness Application Gearshaftscrewwinchnutbobbin

Heat Treatment 1. Annealing Heat to approx. 830, furnace cooling. 2. Normalizing : Heat to approx.830~880, air cooling. 3. Quench: (1) Heat to 840~870, oil cooling. 4. Tempering: Heat to approx. 550~650, water cooling.

GMTC

G R O U P

Mechanical properties Hardness HB Anneali Quench-Te ng mpering max.25 5 285-352 Impact Percentag Percentag Yield Tensile value e of e of area strength strength (charpy) 2 2 elongation reduction N/mm N/mm J/cm2 % >830 >980 >12 >45 >59

Hardenability Curve Temp. mm Normali 1.5 3 5 7 9 11 13 15 20 25 30 35 40 45 50 Quench HRC zing Max. 60 60 60 59 58 58 57 56 55 53 51 49 47 46 44 870 845 Min. 53 53 52 51 50 48 46 43 38 35 33 33 32 31 30 Distance from quenched end (mm)

70 60 Hardness,HRC 50 40 30 20 10 0

1.5 3 5 7 9 11 13 15 20 25 30 35 40 45 50

Distance from quenched end,mm

Availability 1. AnnealingSpheroidizing and QT condition. 2. Available size range: 660mm.

GMTC

G R O U P

Vous aimerez peut-être aussi

- Certificado 3.1 y Calibracion Termopares - TecamDocument11 pagesCertificado 3.1 y Calibracion Termopares - TecamigorPas encore d'évaluation

- Qtap 201901 0062, Pt. Wijaya Karya Rekayasa Konstruksi, 28-01-2019 PDFDocument2 pagesQtap 201901 0062, Pt. Wijaya Karya Rekayasa Konstruksi, 28-01-2019 PDFAddin Galih PrakosoPas encore d'évaluation

- Hollow Bar 304L Φ80ΧΦ50Document6 pagesHollow Bar 304L Φ80ΧΦ50Agoritsa100% (1)

- Challenges in Fabrication of 2.15Cr 1mo 0.25V ReactorsDocument56 pagesChallenges in Fabrication of 2.15Cr 1mo 0.25V Reactorsnikhileshkumar_mishr100% (1)

- DB-En 19 R-2-829 PDFDocument4 pagesDB-En 19 R-2-829 PDFashokPas encore d'évaluation

- Quality 11Smn30: Lucefin GroupDocument1 pageQuality 11Smn30: Lucefin GroupPaulo ZechinPas encore d'évaluation

- Esme TF Ger 1570527 00Document1 pageEsme TF Ger 1570527 00Fitroh MalikPas encore d'évaluation

- Supplier Comparison 0.22: Grade C % Max MN% Max S % M P % MaxDocument13 pagesSupplier Comparison 0.22: Grade C % Max MN% Max S % M P % MaxShihab Aziz0% (1)

- DIN 3015 ClampsDocument17 pagesDIN 3015 ClampsBalderas Rosas WilibaldoPas encore d'évaluation

- JCOUSER03Document1 pageJCOUSER03Neem LalPas encore d'évaluation

- Alloy Steel p22 PlatesDocument3 pagesAlloy Steel p22 PlatesMiguel PulidoPas encore d'évaluation

- 347623-Po 4503181944-Li 1Document6 pages347623-Po 4503181944-Li 1Rita WilliamsPas encore d'évaluation

- MTC 8,10Document2 pagesMTC 8,10Vu NamPas encore d'évaluation

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983Pas encore d'évaluation

- UGINEDocument1 pageUGINEjesusPas encore d'évaluation

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaPas encore d'évaluation

- Certificate FF 16662Document3 pagesCertificate FF 16662Ionela IonelaPas encore d'évaluation

- Item 13. Codo SCH-80 A234 - 783Document1 pageItem 13. Codo SCH-80 A234 - 783ELMER CHILON MINCHANPas encore d'évaluation

- Mat 3800 For Suppliers PDFDocument3 pagesMat 3800 For Suppliers PDFbaskaran ayyapparajPas encore d'évaluation

- ReferenceDocument25 pagesReference이은지Pas encore d'évaluation

- JIS To SAE Steel EquivalentsDocument2 pagesJIS To SAE Steel EquivalentsScott Kramer100% (2)

- EN 10 204 - 3.1 Quality Inspection PO.011.2022 10396282-30 21547528 2023-07-21Document1 pageEN 10 204 - 3.1 Quality Inspection PO.011.2022 10396282-30 21547528 2023-07-21Ehab Attia SelimPas encore d'évaluation

- Mechnical Property For Q235B Carbon SteelDocument3 pagesMechnical Property For Q235B Carbon SteelPritom Ahmed100% (1)

- AISI 410 Martensitic Stainless Steel: Gloria Material Technology CorpDocument1 pageAISI 410 Martensitic Stainless Steel: Gloria Material Technology CorppvdangPas encore d'évaluation

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeePas encore d'évaluation

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Pas encore d'évaluation

- Corewire Weldclad 01 PDFDocument31 pagesCorewire Weldclad 01 PDFRaviTeja BhamidiPas encore d'évaluation

- Din 17100Document4 pagesDin 17100Sheby SandyPas encore d'évaluation

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16Pas encore d'évaluation

- Material Product Data SheetDocument4 pagesMaterial Product Data SheethungPas encore d'évaluation

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaPas encore d'évaluation

- JSW Steel LTDDocument1 pageJSW Steel LTDRanjan BhatiaPas encore d'évaluation

- N.R. Engineering: Chemical AnalysisDocument4 pagesN.R. Engineering: Chemical Analysisrajesh reddyPas encore d'évaluation

- Datasheet Sandvik 6r35 enDocument7 pagesDatasheet Sandvik 6r35 enSimone FerronPas encore d'évaluation

- TATA STEEL LTD., Wire Division Technical Delivery Conditions (TDC)Document2 pagesTATA STEEL LTD., Wire Division Technical Delivery Conditions (TDC)Mayank UkaniPas encore d'évaluation

- SWRCH18ADocument2 pagesSWRCH18AHari SuthanPas encore d'évaluation

- Teava Rect 50X50X3MM PDFDocument1 pageTeava Rect 50X50X3MM PDFCiprian ShaolinPas encore d'évaluation

- Steel Grades HandbookDocument6 pagesSteel Grades Handbookbhavin178Pas encore d'évaluation

- Material Datea 2.4602Document3 pagesMaterial Datea 2.4602Charwin XiaoPas encore d'évaluation

- Equivalent Grades of Gray IronDocument2 pagesEquivalent Grades of Gray Ironsujay13780100% (1)

- 1 7335Document5 pages1 7335stamatsPas encore d'évaluation

- C43Document1 pageC43rudramansingh123Pas encore d'évaluation

- hot rolled Φ60 AISI 304L (14.230)Document3 pageshot rolled Φ60 AISI 304L (14.230)A. ΒρατσισταPas encore d'évaluation

- Certificate No. / 74 / W/ 01: Welder S Certificate ISO 9606-1 111 P BW FM1 RB T 20 PA SS, NBDocument1 pageCertificate No. / 74 / W/ 01: Welder S Certificate ISO 9606-1 111 P BW FM1 RB T 20 PA SS, NBDeepak Das100% (1)

- Schallater Gaas80 Gaa100 DownloadDocument4 pagesSchallater Gaas80 Gaa100 DownloadRakesh SrivastavaPas encore d'évaluation

- Steel Grades Gost PDFDocument5 pagesSteel Grades Gost PDFrakeshPas encore d'évaluation

- JIS C 3406 (1971) - Auto CablesDocument1 pageJIS C 3406 (1971) - Auto CablesBrandon BroPas encore d'évaluation

- Test CertificateDocument1 pageTest CertificateNithin AbrahamPas encore d'évaluation

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiPas encore d'évaluation

- Aisi 1043 Steel - Hot Rolled Bar (Uns g10430) PDFDocument1 pageAisi 1043 Steel - Hot Rolled Bar (Uns g10430) PDFfeltofsnakePas encore d'évaluation

- DIN EN ISO 9013 - Angular Deviation PDFDocument1 pageDIN EN ISO 9013 - Angular Deviation PDFflorinelvvPas encore d'évaluation

- Brass MachiningDocument68 pagesBrass MachiningVaibhav ShuklaPas encore d'évaluation

- RSP TDC For SAIL WR400 Plates-FinalDocument1 pageRSP TDC For SAIL WR400 Plates-FinalRAMAKRISHNAN R100% (1)

- Asme Section Ii A-2 Sa-815 Sa-815mDocument10 pagesAsme Section Ii A-2 Sa-815 Sa-815mdavid perezPas encore d'évaluation

- GX300CrMo15 3Document1 pageGX300CrMo15 3jdash0904Pas encore d'évaluation

- SCM 440Document2 pagesSCM 440weldmindPas encore d'évaluation

- Alloy Steels: GMTC GMTCDocument2 pagesAlloy Steels: GMTC GMTCpvdangPas encore d'évaluation

- Material 1.2767 - 45NiCrMo16Document1 pageMaterial 1.2767 - 45NiCrMo16johnnydoe90Pas encore d'évaluation

- Buderus 7225Document4 pagesBuderus 7225Ajeng GaleriPas encore d'évaluation

- Shock Resistant Tool Steel: Z Equivalent GradeDocument2 pagesShock Resistant Tool Steel: Z Equivalent GradeSubham SinhaPas encore d'évaluation