Académique Documents

Professionnel Documents

Culture Documents

Mapping HVAC Systems For Simulation in Energyplus

Transféré par

Wenhong ZhangDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mapping HVAC Systems For Simulation in Energyplus

Transféré par

Wenhong ZhangDroits d'auteur :

Formats disponibles

1 2 3 4 5 6 7 8 9 10

MAPPING HVAC SYSTEMS FOR SIMULATION IN ENERGYPLUS Mangesh Basarkar, James O'Donnell, Philip Haves, Kevin Settlemyre and Tobias Maile Lawrence Berkeley National Laboratory, Berkeley, CA, 94720 U.S.A.

ABSTRACT

For building energy simulation tools to be accessible to designers, tool interfaces should present a conventional view of HVAC systems to the user, and then map this view to the internal data model used in the tool. The paper outlines a process that enables design engineers to create HVAC system representations using industry standard terminology and system, icon and typological representations and convert that unified representation into the format required by the whole building energy simulation tool EnergyPlus. This paper describes each stage of the conversion process, which involves transformations between the following representations: 1) engineers representation, 2) component connectivity representation, 3) representation in the internal data model used in the Simergy graphical user interface for EnergyPlus, and 4) EnergyPlus representation. The paper also describes mappings between these representations and the development of a rule-based validation and assignment framework required to implement that mapping. In addition, the paper describes the implementation of this process in Simergy.

EnergyPlus (EnergyPlus, 2012), support description at the component level. A component-level description provides much greater flexibility but requires correspondingly more input information, though this problem can be alleviated by the use of templates of standard systems as starting points for the description of non-standard systems or of variants of standard systems. Each tool has a different representation of HVAC systems as compared to standard engineering representations and translation between the two representations is not a trivial task (Bazjanac, 2001, 2008). Engineers require additional training in order to understand tool-specific terminology and modeling constructs, which has posed another challege to tool adoption. This paper describes an attempt to minimize this problem by providing a drawing environment in the Simergy (See et al., 2011) graphical user interface for EnergyPlus that allows the HVAC system to be specified in a form that resembles single line mechanical schematic diagrams. The paper then describes the sequence of transformations required to generate the corresponding input file data for EnergyPlus and the development of a rule-based validation and assignment framework necessary to implement that mapping are also discussed. In addition, a simple use case that presents the implementation of this process in the Simergy graphical user interface is described. With appropriate modification, this process is applicable to all simulation tools and would enable standardization of HVAC system representation and visualization.

INTRODUCTION

In the absence of comprehensive Graphical User Interfaces, whole building energy simulation models are difficult to create and modify (See et al., 2011). Building geometry is acknowledged to be the most time-consuming input (Bazjanac, 2001), but HVAC and control systems present the greatest level of difficulty for modelers. As a result, the cost of simulation modeling has served as a barrier to widespread use, thereby slowing the uptake of simulation tools in the design-build-commission-operate process. Some whole building simulation tools, e.g. DOE-2 (Winkelmann et al., 1993) only allow selection at the HVAC system level. This has the advantage of simple input but lacks flexibility. Other tools, e.g. IES-VE (IES, 2012), TRNSYS (TRNSYS, 2004) and

HVAC SYSTEM INPUT

To allow for industry standard HVAC system representation, a collaborative process was established through which a team of engineers and architects continuously provided practioner-focussed input for the HVAC interface layout, the icons used for screen representation, the workflow for cross referencing loops and labeling and data display formats. Through this

process, several methods were identified to reduce HVAC system input time while allowing for effective manipulation of system configuration at a component level and letting users establish, edit and view HVAC controls in more intuitive ways. Visualization and editing of the system is implemented within Simergy at different levels ranging from the overall system level to aspects of different loop designs down to the individual component level. Each of the 200+ HVAC component types within EnergyPlus has an icon in Simergy, distributed across six stencils so that they are grouped in an intuitive and accessible way. The user can draw or view the air, hot water, chilled water, condenser water and mixed water loops associated with the design. In addition, sensors and controls can be incorporated into the design on a separate display layer, allowing the user to view them integrated into the loop design or to turn them off, so that a simpler view of the loop is shown. The two dimensional representations are set up to be familiar to design engineers, with the intent that they will be accessible and intuitive to a wider range of users. Another aspect of this approach is the use of HVAC system templates. Each of the HVAC system templates contains the inputs and component icons for the complete system design, so that simulations can be run just by selecting the appropriate templates. When selecting an HVAC system template, the user can visualize any or all of the air, water and condenser loops overlaid with the sensor and controls layout, including the system-level controls that determine the operation of the whole loop. The work flow in Simergy involves defining the building geometry and the thermal zones before specifying the HVAC system. The first step is to define the HVAC equipment associated with each zone air terminal units, such as VAV boxes, and/or hydronic equipment, such as fan-coil units or radiant slabs. The zone HVAC equipment components can either be selected individually or combinations of components can be imported using predefined templates. The zonelevel equipment definitions are then used to automatically generate the demand side of each air loop and parts of the demand side of each water loop. The typical starting point in the definition of the supply side of each loop is a predefined template, which can be customized by deleting or adding components using the drag-and-drop capabilities of the HVAC diagram editor. It is also possible to build up the supply side of a loop from scratch using the editor. Simergy allows users to group zones that that are served by the same air loop and have the same types of zone-level HVAC equipment. In the example presented below, one Zone HVAC Group consists of all the

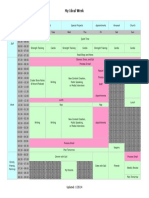

perimeter zones, which have reheat coils in their VAV terminal units and another Zone HVAC Group of core zones that have no reheat coils in their VAV boxes. This grouping minimizes the number of demand side parallel branches in the diagram, making it possible to display the whole air loop without horizontal scolling there could be tens of zones served by a single air loop but it is usually possible to aggregated them into a small number of groups, as in the example just given. This grouping facilitates automating the creation of the demand side of the air loop, speeding up the model creation process. A key part of the demand side, the Zone HVAC group, can also be set up as a template so that the user can easily incorporate different types of equipment into the Demand Side of the Air Loop. Example Figure 1A shows the screen representation of a single duct variable-air-volume (VAV) air conditioning system created in Simergy for the purposes of whole building energy simulation in EnergyPlus. A heat exchanger between the outside and exhaust air streams provides heat recovery and the dampers in the economizer modulate the ratio of the outside and recirculation air flow rates. The air is conditioned by heating and cooling coils and the conditioned air is circulated to the zones and back to the economizer by variable speed supply and return fans. EnergyPlus input files typically do not have parallel branches of the supply side of the air loop, but this generality, which is used in the water loops, has been introduced to allow for future expansion of EnergyPlus. In the example, the return air flows through a single return plenum that serves all the zones. In the diagram, the connection from each Zone HVAC Group represents multiple connections, one from each zone. Similarly, the icons for the VAV terminal units each represent multiple terminal units, one for each zone. The labels on the right hand side of the icon representing the terminal units with reheat coils are off-page references that link to the hot water loop diagram. These reheat coils appear as a Coil Group on the demand side of the hot water loop, together with other Coil Groups representing the reheat coils for zones served by other air loops.

HVAC SYSTEM TRANSFORMATION PROCESS

Figures 1A through 1D below depict the series of transformations necessary to map the engineers mental model of an HVAC system to the actual representation of that system for simulating energy use with EnergyPlus. Figure 1B shows the underlying topological representation that is stored in the drawing module and is used to generate the screen view. Note

Figure 1: Progressive transformation from an engineers representation of a single duct VAV system to an EnergyPlus representation in Simergy

that there are two connections from the outlet of the supply fan because the user drew one connection from the fan to the inlet of each air terminal for each zone group. The horizonal portion of each connection are superimposed in the screen display (Figure 1A). Figure 1C shows the representation of the same single duct VAV system in the main internal data model in Simergy (SimModel see below), where it is divided into Supply and Demand subloops. Each subloop is further decomposed, as described below, in preparation for transformation to the EnergyPlus representation, shown in Figure 1D. Splitters and Mixers In Simergy, a splitter is created automatically whenever two or more connections are made to the same outlet port; similarly, a mixer is created automatically whenever two or more connections are made to the same inlet port. However, this automatic process breaks down when a mixer would be followed immediately by a splitter. Consider the situation shown in Figure 2. 1 A 2 3 D 4 C

Simergy, provdes both levels of functionality for representing HVAC system line diagrams. Small mixer and splitter shapes can be dragged and dropped onto the screen to resolve the ambiguity described above, and there is automatic creation of splitters and mixers in non-ambiguous situations.

Figure 3: The particular case where the flows from two components, A and B, are mixed and then split before entering components C and D. SimModel The Simulation Domain Model, or SimModel, is a new XML-based schema that supports Simergy and is described in more detail by ODonnell et al. (2011). SimModel is largely a union of the IFC data schema (BuildingSMART, 2012) and the EnergyPlus input data model, and was created in order to support interoperability between various building energy simulation tools. It was developed to enable future versions of Simergy to support other simulation programs, including Radiance (Radiance, 2011) and Modelica-based tools (Modelica, 2012). SimModel includes a class definition for Systems. Class SimSystem includes THE Type definitions HVACAir, HVACHotWater, HVACChilledWater AND HVACCondenser to define each of the mechanical fluid loops in EnergyPlus. Each Type includes further definitions for various associated SubTypes. For example, the SimSystem type HVACAir has associated Sub-Types that include Supply and Demand. Each Sub-Type is identified as a sub-system that is part of the system HVACAir. The type HVACAir also contains other related sub-types that further classify Supply as SupplySideSupplyPath, SupplySideReturnPath, and Outside Air AND further classify Demand as DemanSideSupplyPath, DemandSideZoneHVAC And DemandSideReturnPath. The System/Type/Sub-Type categorisation ensures that each component in the air loop can be assigned to either a Supply or Demand sub-system and then further assigned to appropriate sub-systems, such as SupplySideSupplyPath or SupplySideReturnPath, based on the framework and rules described in the next

Figure 2: The general case in which outlets on two components, A and B, are connected to inlets on two other components, C and D. In the absence of drawing icons that represent splitters and mixers, the user would have to draw the four connections shown in the figure in order to indicate that the outlet of A is connected to the inlets to C and D and that the outlet of B is also connected to the inlets to C and D. This configuration is not equivalent to the configuration shown in Figure 3 unless the ratio of the flow rates in connections 1 and 3 is specified to be the same as the ratio of the flow rates in connections 2 and 4. The solution adopted in Simergy is to have splitter and mixer icons available in the drawing palate so that the configuration shown in Figure 3 can be created explicitly. The use of explicit splitter and mixer objects is not required where the configuration is unambiguous, i.e. where a mixer is not followed immediately by a mixer, in order to make the drawing process faster. Another use of these splitter and mixer icons is to control the layout of the drawing in cases where the automatic routing does not produce the desired appearance.

section. The dotted lines in Figure 1C depict each of these assignments for the example single duct VAV system air loop. The topological grouping down to the lowest level facilitates transformation to the EnergyPlus representation depicted in Figure 1D, prior to generation of the EnergyPlus input file. The decomposition of HVAC loops into Supply and Demand subloops, and the further decomposition into Branches and Zone Air Paths, is fundamental in EnergyPlus but this decomposition is not required for inherrently modular tools such as TRNSYS and Modelic-based tools. In such cases, the input file only requires information about the components and their immediate connections to adjacent components, making the translation from the SimModel representation to the simulation engine representation relatively simple and straightforward. The HVAC System Mapping Framework for Assignment and Validation section describes in more detail the framework that supports the transformation from the drawing model (Figure 1B) to the SimModel representation (Figure 1C) and sets up the transformation from the SimModel representation to the EnergyPlus representation (Figure 1D). The HVAC System Visualization section gives a brief overiew of the features in Simergy that aid the representation of an engineering design drawing on the screen.

with the constraints on HVAC loop topology in EnergyPlus and with EnergyPlus requirements regarding the number and location of critical components. These include: No more than one set of parallel branches on either the supply side or the demand side of a water loop

SYSTEM MAPPING FRAMEWORK FOR VALIDATION AND ASSIGNMENT

To enable the transformations from the representation in Figure 1B to that in Figure 1D described earlier, a comprehensive assignment and validation framework was created for implementation in Simergy. This framework includes the creation of assignment and validation rules in a spreadsheet based format. The spreadsheet rules are then converted to XML and applied during run time using functions that help traverse and check loop topology for engineering accuracy, completeness and consistency. Validation The validation rules serve two purposes, the first of which is to check the connections between components to confirm that the outlets of each component are connected to inlets on other components of the same fluid type, e.g. air to air, not air to water. (In general, these constraints are first enforced by the drawing process in Simergy.) The second set of rules is EnergyPlus-specific and ensures that the user-created air and water loops comply

Fans must be on the supply side of the air loop An economizer must have an outside air damper and a recirculation air damper and may have an exhaust damper A primary-secondary water loop must have either a loop pump or a set of branch pumps on the supply (primary) side and on the demand (secondary) side of the loop. These rules are a combination of engineering requirements that are enforced by EnergyPlus and limitations on the possible configurations required to make the numerical solution more tractable. An example of a screen generated in the validation process is shown in Figure 4. In this example, the user has constructed an air loop with two Zone HVAC Groups and then initiated the validation process for that loop. Errors are displayed both as descriptive text and graphically on the drawing tab (yellow triangles containing exclamation points). For the purpose of this demonstration, a dual duct air terminal was used within a single duct system - an engineering, non-EnergyPlusspecific check. In addition, the supply fan did not have an availability schedule specified, as required for EnergyPlus. Both errors are reported by the program. When a user requests validation of the air loop, or a validation event is launched before simulation, any errors encountered are delivered as either 'warnings', 'severe errors' or 'fatal errors' with each level determining what the outcome of the validation function is. If a fatal error is encountered, the validation engine will stop at that point until the user corrects the particular error. In case of 'warnings' or 'severe errors', the engine will continue processing and provide a complete list at the end of a validation run. Assignment The validation rules are closely linked to the process of analysing the topology of the loop in order to assign components to branches and branches to paths and subloops required to transform the system diagram drawn by the user into the SimModel representation and then into the EnergyPlus representation.

Figure 4: Validation example

DISCUSSION AND CONCLUSION

The visualization, assignment and validation frameworks in Simergy significantly simplify the creation of HVAC systems for the purposes of whole building energy simulation. Use of industry standard visual representations and automating the transformation to the representation required for simulation is projected to reduce significantly the time involved in setting up simulation runs and, ultimately, to improve the design of buildings. As the explicit modeling and simulation of HVAC systems at the component level becomes more common and the variety of user interfaces increases, either for EnergyPlus or for different simulation engines, it is becoming increasingly desirable for these interface to present an engineering-oriented, tool-neutral system representation to minimize the tool-specific training required for new users and to facilitate the use of multiple tools by a single user in order to address different modeling needs or the preference of different design teams for different simulation tools. In addition, in the absence of a standardized approach, it is extremely difficult for one modeler to reproduce the work of another (Bazjanac et al., 2011).

ACKNOWLEDGMENT

This work was supported by the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Building Technology, State and Community Programs of the U.S. Department of Energy under Contract No. DE-AC02-05CH11231 and by the California Energy Commission PIER Buildings program, Infosys Technologies Ltd. and the U.S. Department of Energy Technology Commercialization Fund.

REFERENCES

Bazjanac, V., 2001. Acquisition of Building Geometry in the Simulation of Energy Performance, in: Building Simulation 2001, 7th International IBPSA Conference, Rio De Janeiro. International Building Performance Simulation Association, Rio de Janiero. Bazjanac, V., 2008. IFC BIM-Based Methodology for Semi-Automated Building Energy Performance Simulation, in: 25th International Workshop by CIB W78 Computer Integrated Construction: Improving the Management of Construction Projects Through IT Adoption, Santiago De Chile, July 15 to 17, 2008. Bazjanac, V., Maile, T., ODonnell, J., Rose, C., Mrazovic, N., 2011. Data Enviroments and

Processing in Sem-Automated Simulation with EnergyPlus, in: CIB W078-W102: 28th International Conference. CIB, Sophia Antipolis, France. EnergyPlus, 2012. EnergyPlus Energy Simulation Software [WWW Document]. http://apps1.eere.energy.gov/buildings/energyp lus/. Modelica, 2012. Modelica and the Modelica Association Modelica Association [WWW Document]. https://www.modelica.org/. URL https://www.modelica.org/ ODonnell, J.T., See, R., Rose, C., Maile, T., Bazjanac, V., Haves, P., 2011. SimModel: A domain data model for whole building energy

simulation, in: IBPSA Building Simulation 2011. Sydney, Australia. IBPSA, Sydney, Australia. Radiance, 2011. Radiance Homepage [WWW Document]. http://radsite.lbl.gov/radiance/. See, R., Haves, P., Sreekanthan, P., Basarkar, M., ODonnell, J., Settlemyre, K., 2011. Development of a user interface for the EnergyPlus whole building energy simulation program, in: IBPSA Building Simulation 2011. Sydney, Australia. IBPSA, Sydney, Australia. Winkelmann, F.C., Buhl, W.F., Birdsall, B., Ercem, A.E., Ellington, K.L., 1993. DOE-2 Supplement, Version 2.1E, ( No. LBL-34947).

SimBuild 2012 I or we, the author(s) of the submitted paper, have read the following Copyright Transfer and Disclaimer, and agree to them by submitting the submitted paper. (1) The author(s) affirm that the paper has not been published elsewhere and, if the paper is accepted, will not be published elsewhere prior to SimBuild 2012. (2) If the paper is accepted, the author(s) will automatically grant to IBPSA-USA a nonexclusive, royaltyfree, perpetual, worldwide, irrevocable, sub-licensable, and transferable license to publish the paper (in unmodified form) in any fashion (including but not limited to inclusion in the SimBuild 2012 CD proceedings, via electronic means such as the world wide web, and inclusion in future compilations of papers). This "nonexclusive" license means that the author(s) are not restricted as to future use of the material except that exclusive rights cannot be granted to another. (3) The author(s) affirm that they have the right to grant the license specified in (2), that is, publication by IBPSA-USA or its licensees will not be in conflict with copyright or other restrictions. (4) The author(s) acknowledge that acceptance of the paper does not imply IBPSA-USA's endorsement of or agreement with the ideas presented. Under no circumstances shall IBPSA-USA be liable for any damages resulting from use information included in the paper.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- ASV Posi-Track PT-80 Track Loader Parts Catalogue Manual PDFDocument14 pagesASV Posi-Track PT-80 Track Loader Parts Catalogue Manual PDFfisekkkdPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- 7 Strategies For Developing Your Own Curriculum As A New TeacherDocument5 pages7 Strategies For Developing Your Own Curriculum As A New TeacherKhusnul KhotimahPas encore d'évaluation

- CONSTRUCTION OF INTERNAL ROADS & INFRASTRUCTURE WORKS FOR SECTOR EAST 25, PHASE 2, ABU DHABI - DELAY EVENT IMPACT CALCULATIONSDocument10 pagesCONSTRUCTION OF INTERNAL ROADS & INFRASTRUCTURE WORKS FOR SECTOR EAST 25, PHASE 2, ABU DHABI - DELAY EVENT IMPACT CALCULATIONS143Pas encore d'évaluation

- Parts Catalog TT75, TT55 NEW HOLLANDDocument360 pagesParts Catalog TT75, TT55 NEW HOLLANDrogerio97% (35)

- Master Plumber Exam Coverage (Philippines)Document4 pagesMaster Plumber Exam Coverage (Philippines)Eugene Micarandayo100% (3)

- Small HVAC System GuideDocument96 pagesSmall HVAC System GuideMalcolm ChanPas encore d'évaluation

- J) Method Statement For Discharge of Stormwater and Rain WaterDocument4 pagesJ) Method Statement For Discharge of Stormwater and Rain WaterLee Tin YanPas encore d'évaluation

- Dse7110 Mkii Dse7120 Mkii Operator ManualDocument100 pagesDse7110 Mkii Dse7120 Mkii Operator Manualseanfsmyth100% (1)

- Co-Ordinated By: DR Parul Presented By: DR GurneetDocument45 pagesCo-Ordinated By: DR Parul Presented By: DR Gurneetreenujohney100% (2)

- An Object Oriented Database For Managing Building Components and MetadataDocument9 pagesAn Object Oriented Database For Managing Building Components and MetadataWenhong ZhangPas encore d'évaluation

- Building Energy Use and Control Problems Defining The ConnectionDocument8 pagesBuilding Energy Use and Control Problems Defining The ConnectionWenhong ZhangPas encore d'évaluation

- An Object Oriented Database For Managing Building Components and MetadataDocument9 pagesAn Object Oriented Database For Managing Building Components and MetadataWenhong ZhangPas encore d'évaluation

- Fans and AHUs WebsiteDocument50 pagesFans and AHUs WebsiteWenhong ZhangPas encore d'évaluation

- Stock PartDocument20 pagesStock PartGReyPas encore d'évaluation

- Export Promotion Councils - Final UpdatedDocument14 pagesExport Promotion Councils - Final UpdatedUtkarsh SaxenaPas encore d'évaluation

- B2BDocument31 pagesB2BAjay MaheskaPas encore d'évaluation

- Diligence International Group Understands MexicoDocument2 pagesDiligence International Group Understands MexicoPR.comPas encore d'évaluation

- Gas Range: Defsgg 24 SsDocument20 pagesGas Range: Defsgg 24 Ssfaker fake fakersonPas encore d'évaluation

- Unit 8 #10 Doppler - Effect - PPTDocument13 pagesUnit 8 #10 Doppler - Effect - PPTPrasanta NaskarPas encore d'évaluation

- Reaction Paper The Flight From ConversationDocument4 pagesReaction Paper The Flight From ConversationJoe NasalitaPas encore d'évaluation

- Nested Group PowerShellDocument3 pagesNested Group PowerShellNeha SinghPas encore d'évaluation

- Occupant Manikin Introduction: 95th Percentile Male Driver ModelDocument9 pagesOccupant Manikin Introduction: 95th Percentile Male Driver ModelarstjunkPas encore d'évaluation

- DBX DriveRack PA 2 BrochureDocument2 pagesDBX DriveRack PA 2 BrochureSound Technology LtdPas encore d'évaluation

- 29 KprogDocument582 pages29 KprogMike MorrowPas encore d'évaluation

- The Contemporary WorldDocument9 pagesThe Contemporary WorldDennis RaymundoPas encore d'évaluation

- Sound level meter covers noise applicationsDocument2 pagesSound level meter covers noise applicationsAbigail DextrePas encore d'évaluation

- Ordinary Portland Cement, 33 Grade - Specification: Indian StandardDocument12 pagesOrdinary Portland Cement, 33 Grade - Specification: Indian StandardAmbrishPas encore d'évaluation

- 2007 Output Stops RemovedDocument45 pages2007 Output Stops RemovedAisyah DzulqaidahPas encore d'évaluation

- How To Use AZUpDocument1 pageHow To Use AZUpjovicasPas encore d'évaluation

- 220 KV GSS, HeerapuraDocument56 pages220 KV GSS, Heerapurapikeshjain33% (3)

- Model Manajemen Rantai Pasok Industri Perikanan Tangkap Berkelanjutan Di Propinsi MalukuDocument12 pagesModel Manajemen Rantai Pasok Industri Perikanan Tangkap Berkelanjutan Di Propinsi MalukuEmanuellaPas encore d'évaluation

- Gfps System Specification PVC C Metric en PDFDocument24 pagesGfps System Specification PVC C Metric en PDFMohammed sabatinPas encore d'évaluation

- My Ideal Week PDFDocument1 pageMy Ideal Week PDFAnonymous QE45TVC9e3Pas encore d'évaluation

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiPas encore d'évaluation

- MARSIC300 trainingDocument31 pagesMARSIC300 trainingDenys Podlevskykh100% (1)