Académique Documents

Professionnel Documents

Culture Documents

Biotech Full 0

Transféré par

zeeshan225Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Biotech Full 0

Transféré par

zeeshan225Droits d'auteur :

Formats disponibles

Ashden Awards Case Study | BIOTECH India | Summary

Case study summary BIOTECH, India

2007 Ashden Award

BIOTECH is a consultancy working on the management of organic waste and the production of energy from it.

India statistics 2004/5

(UNDP)

GDP: US$736/year per person CO2 emission: 1.2 tonnes/year per person 80% of people live on less than US$2/day

Kerala is a prosperous state in South India with a growing demand for the clean and hygienic disposal of waste from homes, institutions and municipalities. BIOTECHs 2007 Ashden Award recognised its achievement in developing technologies to manage domestic and municipal organic waste at source, and produce biogas for cooking and electricity generation. Digesters prefabricated from ferro-cement and gas collectors from Fibreglass Reinforced Plastic (FRP) for quick and easy installation on site. Biogas produced from decomposition of organic waste in anaerobic conditions. In households and institutions, plants handle waste food and sometimes have toilets connected. Biogas is used for cooking, displacing about 50% of LPG use. Larger systems used at markets and municipal sites, where biogas is cleaned and then used to generate electricity for lighting. 1 m3 household plants cost about US$220, with government subsidy available of up to 60%. Average family can pay back contribution to the cost of the plant in about three years through savings in LPG use. Between 2004 and 2007, 12,000 domestic plants (serving about 48,000 people), 200 institutional plants and 19 energy-from-waste projects were installed. Plants save about 3,700 tonnes/year of CO2 in avoided LPG and diesel use. For domestic users, food waste can be disposed of easily and hygienically, with 50% LPG savings. Biogas plant effluent makes a useful fertiliser, resulting in higher food production. For markets and councils, removal of food waste reduces health risks associated with disposal onto streets. Update BIOTECH set up a roadshow, funded by the Ashden Award, which travelled around southern India, demonstrating benefits of biogas plants to a wide audience. Significant interest generated. . Further technical development, including an engine to run on 100% biogas, a dehumidifier, and heat recovery system for larger plants. Several new products launched a portable domestic plant, a pre-treatment unit and a modular plant. By 2009, 16,000 biogas plants installed: 15,700 domestic, 253 institutional and 47 municipal plants. BIOTECH was established in 1994, and provides efficient stoves and solar lighting systems as well as biogas plants. It has grown rapidly since its 2007 Award, with turnover increased from US$168,000 (2005/06) to US$565,000 (2008/09); full time staff from 42 to 140, and piece-work technicians and volunteers from 180 to 600.

44% of people lack grid electricity Location

Indian Asia Subcontinent

Before I had the plant, I had to walk for half an hour to put my waste in the corporation bin. Before, one bottle of LPG lasted 40 days, now it lasts 70. Domestic plant user

A BIOTECH domestic biogas plant

Contact BIOTECH India Mr A Saji Das biotechindia@eth.net www.biotech-india.org www.biotechin.org

info@ashdenawards.org www.ashdenawards.org/winners/biotech

Document last updated December 2009

Ashden Awards Case Study | BIOTECH, India

Case study BIOTECH, India

Background Kerala is a prosperous state in South India, with a growing middle-class population. Many family members spend part of their working lives overseas. Kerala also has a thriving tourist industry with numerous beach resorts. Leaving out waste food for animals, which works relatively well in rural areas, is simply not acceptable in this suburban environment, and there is a demand for the clean and hygienic disposal of waste for homes, institutions and municipalities. Many local panchayats (councils) operate door to door waste collection services, but animals tear open rubbish sacks to get to food waste, and create more litter. The biogas digesters developed by BIOTECH manage organic waste and wastewater at source, and produce significant amounts of clean gas for cooking and other purposes.

The technology in more detail Most domestic plants have a volume of 1 m3 and produce about 1 m3 of biogas per day, with a maximum input of 5kg solids and 20 litres organic waste water per day. The digester vessel consists of a gas holder drum, floating over a pre-cast digester tank. The digester tank is usually prefabricated from ferro-cement and sunk into the ground. The gas holder is constructed from Fibreglass Reinforced Plastic (FRP), weighed down with concrete to increase the gas pressure. The pre-cast construction makes it possible for two technicians to construct a plant in about four hours, so that two to three plants can be constructed in a day. A water seal is used in some domestic models and in all larger systems, to prevent gas leakage. BIOTECH also makes portable digesters that stand on the surface, to allow construction where excavation is impossible or undesirable - for instance where the water table is too high. The main feedstock for the plants is food waste, but cow dung needs to be used initially to provide a culture of suitable bacteria to get the digestion process started. Food waste is simply mixed with organic waste-water from the kitchen in a bucket and poured into the plant inlet, and no additional water is needed. Some plants have toilets connected as well. Biogas gradually collects in the gas holder as the waste decomposes, and a pipe is used to take it to a special biogas stove in the kitchen. A valve is used to open and shut the flow, and a regulator varies the flame. The effluent from the plants is virtually odourless and has a high content of nitrogen, phosphorous and potassium, so it can be used as a garden fertiliser.

The organisation BIOTECH was founded as a consultancy in 1994 by Mr A Saji Das, to research, develop and install renewable energy systems, in particular systems producing energy from waste. In addition to the biogas work, BIOTECH supplies improved smokeless ovens and stoves, solar lanterns and home lighting systems. BIOTECH has grown rapidly since its 2007 Ashden Award. Turnover has increased from US$168,000 (Rs 7.2 million) in 2005/06 to US$565,000 (Rs 26 million) in 2008/09. Full time staff have increased from 42 to 140, and piece-work technicians and volunteers from 180 to 600. The technology How does it work? Biogas systems take organic material into an airtight vessel, where bacteria break down the material and release biogas a mixture of mainly methane with some carbon dioxide. The biogas can be burned as a fuel and the solid residue can be used as organic compost. The biogas plants made and supplied by BIOTECH are designed to dispose of organic household and municipal waste and toilet waste. BIOTECH has developed standard plants in different sizes to serve three different market sectors: domestic (individual households), institutions (schools, hostels, hospitals, hotels) and municipal (local councils). BIOTECHs use of pre-fabricated components simplifies the construction of the plants. On-site construction takes only about four hours (instead of four days) and semi-skilled or unskilled masons can install the units easily. How much does it cost and how do users pay? US$1 = Rs 43 (Indian Rupees) [March 2007] A domestic biogas plant costs about US$220 (Rs 9,500). The national Ministry of Nonconventional Energy Sources (MNES) offers a subsidy of US$60 (Rs 2,700) for each domestic plant up to 10 m3 capacity, and the local and district panchayats provide further subsidies - typically US$60 (Rs 2,700) in urban areas and US$80 (Rs 3,500) in rural areas. The purchasers pay the remainder directly. The MNES subsidy is paid to the beneficiary through BIOTECH after a government official has inspected the plant. A typical family normally uses about 168 kg of LPG a year. Biogas replaces about 50% of this use, or about 84 kg per year, saving the family about US$53 (Rs 2,280) per year. This means that the family can pay back their contribution to the cost of the plant in about three years, and more quickly if they collect extra food waste from shops to increase their biogas production.

Ashden Awards Case Study | BIOTECH, India

The integrated waste management plant cost US$71,000 (Rs 3,000,000), of which US$2790 (Rs 120,000) came from MNES and some from the local and district panchayats. BIOTECH provides some capital, and charges an annual operating fee to run the plant. How is it manufactured, promoted and maintained? BIOTECH manufactures all the plants in its own workshops to a high standard. The details of all plants are recorded so that BIOTECH is eligible for the subsidy from MNES. BIOTECH staff visit each new customer every three months for two years in order to ensure that the plant is running smoothly. The oldest plant in use is over ten years old (2007). There have been occasional minor problems with gas pipes blocked (or chewed through by rats), water condensing in pipes, and broken tap fittings but these have been fixed quickly by BIOTECH staff. Benefits The total capacity installed by BIOTECH between 2004 and 2007 was 16,000 m3, split 81% for domestic users, 16% for institutional users, and 3% for energy-from-waste schemes. Nearly 12,000 domestic plants were installed (serving about 48,000 people), about 200 institutional plants and 19 energy-from-waste projects (with 12 further plants under construction in 2007). Environmental benefits The total rate of biogas production from all installed plants in 2007 was estimated to be about 16,000 m3/day, which replaces the equivalent of about 1,400 tonnes/year of LPG and diesel. The plants therefore directly avoid the emission of about 3,700 tonnes/year of CO2, with further savings from the reduction in methane production from the uncontrolled decomposition of waste, and from the transport of LPG. Social benefits For most domestic users, the main benefit of a BIOTECH plant is the easy, hygienic disposal of food waste and the savings made in LPG use. Operators of institutional plants are pleased with the absence of odour, which was unpleasant for both them and their neighbours. For the markets and councils, the removal of food waste and the associated public health risks is a great advantage. This is a very convenient way of disposing of waste without any headache. No smell, no mess, we are very very happy with it and we just hope that more people would go about installing this because it keeps the environment clean, and it gives us gas as well as fertiliser. Jayasri Sahadevan In homes and institutions, cooking is always started on the biogas stove. Typically, this can be used for two hours using the gas produced during the previous day, and the pot is simply moved to the LPG stove when the biogas runs out. Biogas replaces about 50% of LPG use in an average family. Institutional plants with latrines attached replace between 50 and 75% of their LPG use, because of the additional biogas production from the sewage waste. Biogas is safer than LPG for cooking, because it cannot be lit accidentally by a spark. Economic and employment benefits The effluent or residue in the biogas plant makes good fertiliser which results in higher food production. The manufacture, installation and maintenance of the biogas plants has generated a significant amount of employment: this is estimated at 13 days for each domestic plant, 55 days for each institutional plant and 80 days for each waste to energy plant.

The technology in more detail continued Biogas plants for schools and hostels range in capacity from about 10 m3 to 25 m3 and each serve an average of 200 people. On a larger scale, energyfrom-waste plants are installed for local councils or fish markets, and are made from one or two 25 m3 biogas digesters. In these the organic waste is broken down to a uniform size with a mechanical chopper before it is put into the digester, to speed up the digestion process. If required, water separated from the output slurry can be recycled, by mixing it with the feed material. The biogas is used in a 3 kW engine to generate electricity for lighting the market, and where possible two generators are installed to provide backup for maintenance or repair. It is essential to remove hydrogen sulphide and particulates by scrubbing and filtering the gas before it goes into the engine, to prevent corrosion. Because these plants are used in public places the generators and electrical connections must be securely housed in locked cages, accessible only to operators. BIOTECH has also installed an integrated energy from waste plant in Kadakkal Grama Panchayat, which processes nearly three tonnes of municipal solid waste per day. The waste is sorted by hand into wet waste, dry bio-degradable waste, glass, plastics and metal. The wet waste goes into a biogas plants and other materials are sold for recycling. Blood and wash water from a local abattoir is also taken to the plant, but uses a separate digester so that the bacteria become optimised for the specific waste type. Some of the biogas produced runs an incinerator for the dry bio waste, in addition to generating electricity for lighting.

Ashden Awards Case Study | BIOTECH, India

Potential for growth and replication BIOTECH plants are in demand. A pre-fabricated domestic plant can be installed within two to three days, provided that finance is available. The technology could be used in many other countries. In rapidly growing urban areas, the safe disposal of organic waste at source is important for hygiene and cleanliness, and the value of the gas produced is significant for households and institutions. However, the greater potential is possibly at the municipal level, where there are serious public health risks from large volumes of organic waste, including pollution of water supplies. To work effectively the plants need an average ambient temperature above 30C throughout the year but it is in countries with these high temperatures that the health problems from unmanaged waste are the most serious. Update: what happened next? Since its 2007 Ashden Award, BIOTECH actively promoted its biogas plants. In 2008 it used part of the Ashden Award prize fund to organise a roadshow which travelled around southern India, demonstrating the benefits of biogas plants to a wide audience. Many people have come forward for installation of plants as a result of the publicity, and because of the rising cost of alternatives. BIOTECH has also invested time and money in improving technology. It has developed an engine for its energy-from-waste plants, which can run on 100% biogas rather than 80% biogas and 20% diesel; a dehumidifier for drying the biogas before it goes into the engine; and a system for heat recovery from larger plants. Recent innovations include a portable domestic plant made from fibreglass (100 installed); an anaerobic pre-digester for waste which decomposes very slowly (eight installed); and a modular biogas plant (four installed). Although the cost of domestic plants has increased from about US$220 (Rs 9,500) to US$350 (Rs 16,000), demand is still growing. By the end of 2009, a total of 15,700 domestic plants and 253 institutional plants had been installed. The major growth has been in municipal energy-from-waste plants, where 47 are now in operation compared with 19 at the time of the 2007 Award. In total, BIOTECH has provided 16,000 biogas plants, benefitting more than 200,000 people.

One of BIOTECHs portable domestic plants.

A BIOTECH plant at a school in Trivandrum, South India.

I collect from the shop, I get some food waste or vegetable waste. I fill the drum and by morning I have half a drum of gas and it lasts for four hours. P. Narayanan Potti:

Contact details Mr A Saji Das BIOTECH PB No 520 MP Appan Road Vazhuthacadu Thycaud PO Thiruvananthapuram Kerala South India 695 014 biotechindia@eth.net www.biotech-India.org www.biotechin.org

Biogas digester tamks are pre-fabricated from ferrocement.

This report is based on information provided to the Ashden Awards judges by IDEI, and findings from visits by members of the judging team to see its work in India. The Ashden Awards have taken all reasonable care to ensure that the information contained in this report is full and accurate. However, no warranty or representation is given by The Ashden Awards that the information contained in this report is free from errors or inaccuracies. To the extent permitted by applicable laws, The Ashden Awards accept no liability for any direct, indirect or consequential damages however caused resulting from reliance on the information contained in this report.

Written: June 2007 Update: October 2009

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 924S 3Document12 pages924S 3Faisal KhokharPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- 924S 3Document12 pages924S 3Faisal KhokharPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Integrating Sequence PDFDocument195 pagesIntegrating Sequence PDFzeeshan225Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Seis Strat Notes 2009 PDFDocument95 pagesSeis Strat Notes 2009 PDFzeeshan225Pas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Ebook - RP PDFDocument240 pagesEbook - RP PDFzeeshan225Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Ashbaugh Thesis NUMERICAL AND ANALYTICAL MODELS OF SECONDARY MIGRATION FAULTSDocument121 pagesAshbaugh Thesis NUMERICAL AND ANALYTICAL MODELS OF SECONDARY MIGRATION FAULTSzeeshan225Pas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Characterization and Properties of Petroleum FractionsDocument421 pagesCharacterization and Properties of Petroleum Fractionsmoveee291% (22)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Practical Aspects of AVO Modeling - Li.downton - Xu.leadingedgeDocument14 pagesPractical Aspects of AVO Modeling - Li.downton - Xu.leadingedgeMahmoud EloribiPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- PDFDocument52 pagesPDF828391Pas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- PDFDocument52 pagesPDF828391Pas encore d'évaluation

- The Complete Professional, All Skills You NeedDocument192 pagesThe Complete Professional, All Skills You NeedQaseem Shams Nazari100% (2)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Scorpio SeisDocument11 pagesScorpio Seiszeeshan225Pas encore d'évaluation

- ChronostratChart2013 01 PDFDocument1 pageChronostratChart2013 01 PDFFeli MonnomPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Rock Physics Cambrige PDFDocument10 pagesRock Physics Cambrige PDFzeeshan225Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- R5000Platform PDFDocument1 pageR5000Platform PDFzeeshan225Pas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Well Tie, Fluid Substitution and AVO modelling-White-Simm-Xu PDFDocument11 pagesWell Tie, Fluid Substitution and AVO modelling-White-Simm-Xu PDFzeeshan225Pas encore d'évaluation

- A Comparison of Rock Physics Models For Fluid Substitution PDFDocument9 pagesA Comparison of Rock Physics Models For Fluid Substitution PDFzeeshan225Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Scientific Method of ResearchDocument9 pagesScientific Method of Researchzeeshan225Pas encore d'évaluation

- Avo TheoryDocument84 pagesAvo Theoryzeeshan225Pas encore d'évaluation

- MDT - Job Plan - InterpretationDocument7 pagesMDT - Job Plan - Interpretationzeeshan225Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Inversion of PP and Ps Data in Strata PDFDocument29 pagesInversion of PP and Ps Data in Strata PDFzeeshan225Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- MARD-SNV Case Study PDFDocument4 pagesMARD-SNV Case Study PDFzeeshan225Pas encore d'évaluation

- Biotech Full 0Document4 pagesBiotech Full 0zeeshan225Pas encore d'évaluation

- DrillingDocument15 pagesDrillingzeeshan225Pas encore d'évaluation

- GEO594/GLE594: Seismic Refraction HomeworkDocument2 pagesGEO594/GLE594: Seismic Refraction Homeworkzeeshan225Pas encore d'évaluation

- (Master Thesis) Potential of Agent-Based Models For Resilience Assessments of Energy SystemsDocument105 pages(Master Thesis) Potential of Agent-Based Models For Resilience Assessments of Energy SystemsPauloBaffaPas encore d'évaluation

- EdExcel A Level Chemistry Unit 2 Paper Jan 2002Document9 pagesEdExcel A Level Chemistry Unit 2 Paper Jan 2002Ruwan BandaraPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- BSB DB Operation ManualDocument15 pagesBSB DB Operation ManualEris Osman RifkiPas encore d'évaluation

- Net Metering and Utility Interconnection: Bill Brooks Brooks EngineeringDocument55 pagesNet Metering and Utility Interconnection: Bill Brooks Brooks EngineeringGerardoAlainLoredoMoyedaPas encore d'évaluation

- Chapter 1 IntroductionDocument5 pagesChapter 1 IntroductionStudy MailPas encore d'évaluation

- (1 - 02) Capacitors Type EX-7L Single-Phase UnitsDocument4 pages(1 - 02) Capacitors Type EX-7L Single-Phase UnitsDaniela Emilia Insuaste CorreaPas encore d'évaluation

- Mechanical SealDocument20 pagesMechanical Sealparchure123100% (3)

- 3-Guidelines For Design - Pumped Storage HydroDocument25 pages3-Guidelines For Design - Pumped Storage HydroAdhe Suhe Notsue0% (1)

- NNPCDocument21 pagesNNPCtsar_philip2010100% (1)

- Neutral Position in DCVDocument6 pagesNeutral Position in DCVAimee SpearsPas encore d'évaluation

- Presentation On Solar R and D and MarketingDocument35 pagesPresentation On Solar R and D and MarketingSteeson MathewPas encore d'évaluation

- Silicone InsulatorsDocument13 pagesSilicone InsulatorsmadaoPas encore d'évaluation

- Global Suppliers Directory - BioInt92Document11 pagesGlobal Suppliers Directory - BioInt92George SheytanovPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Transformers - General InformationDocument4 pagesTransformers - General InformationGalco IndustrialPas encore d'évaluation

- Overview On Fuel CellsDocument6 pagesOverview On Fuel CellsCarol BrigagãoPas encore d'évaluation

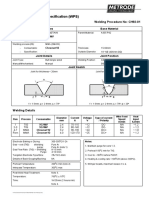

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenPas encore d'évaluation

- Electrical Energy Panorama PDFDocument40 pagesElectrical Energy Panorama PDFShihabudin QolyubiPas encore d'évaluation

- Design AuditsDocument35 pagesDesign AuditsMariyam Hasan100% (2)

- Soal Excel TerakhirDocument63 pagesSoal Excel TerakhirAndika njayPas encore d'évaluation

- Wind Energy - An IntroductionDocument5 pagesWind Energy - An IntroductionShailendra PratapPas encore d'évaluation

- Tork 1100seriesDocument2 pagesTork 1100seriesjpcc1986100% (1)

- Presented By: Anurag Prasad ROLL NO.:00720703416 Branch: Civil (4 Year) Conducted By: Mrs. Mimansa Babbar Subject: Green BuildingDocument42 pagesPresented By: Anurag Prasad ROLL NO.:00720703416 Branch: Civil (4 Year) Conducted By: Mrs. Mimansa Babbar Subject: Green BuildingANURAGPas encore d'évaluation

- SanjuDocument23 pagesSanjuAnbarasan MuthaiahPas encore d'évaluation

- Transformer ProtectionDocument23 pagesTransformer Protectionsubbu2051100% (2)

- Calpeda Pump N SeriesDocument3 pagesCalpeda Pump N Seriesgentleman457Pas encore d'évaluation

- Hvac Install ChecklistDocument4 pagesHvac Install Checklistadnyat0% (1)

- AC Transit Engages With SunPower To Save $5 Million Over The Next 25 YearsDocument2 pagesAC Transit Engages With SunPower To Save $5 Million Over The Next 25 YearssiddPas encore d'évaluation

- Experiment No: - 05 Aim: - Study of Solar Photovoltaic SystemDocument9 pagesExperiment No: - 05 Aim: - Study of Solar Photovoltaic SystemMir Aqueel AliPas encore d'évaluation

- Solar Analysis: Prepared For: Prepared byDocument10 pagesSolar Analysis: Prepared For: Prepared byCesarPas encore d'évaluation

- Summer Internship ReportDocument19 pagesSummer Internship Reportmalikavita731Pas encore d'évaluation

- Guidelines for Chemical Process Quantitative Risk AnalysisD'EverandGuidelines for Chemical Process Quantitative Risk AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookD'EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookPas encore d'évaluation

- Nuclear Energy in the 21st Century: World Nuclear University PressD'EverandNuclear Energy in the 21st Century: World Nuclear University PressÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Process Plant Equipment: Operation, Control, and ReliabilityD'EverandProcess Plant Equipment: Operation, Control, and ReliabilityÉvaluation : 5 sur 5 étoiles5/5 (1)