Académique Documents

Professionnel Documents

Culture Documents

A Variable Speed Pump 2012

Transféré par

Elyar AiretiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A Variable Speed Pump 2012

Transféré par

Elyar AiretiDroits d'auteur :

Formats disponibles

2012 06 03

UNIVERSITY OF WINDSOR

Department of Mechanical, Automotive and Materials Engineering

FLUID MECHANICS II (92-320)

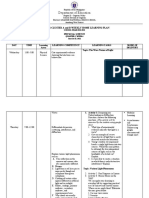

EXPERIMENT A: CENTRIFUGAL PUMP EXPERIMENT

_________________________________________________________________________________

OBJECT:

The objective is to experimentally determine the performance (head vs flowrate)

characteristic curves for a variable speed centrifugal pump and show that the Affinity Laws

of Scaling apply.

APPARATUS:

a) GUNT HM150.04 Variable Speed Centrifugal Pump Test Facility and HM150 Basic Hydraulics

Bench as illustrated below.

b) stop watch

Refer to the apparatus schematic supplied by the Graduate Assistant to identify the

1. Storage tank

2. Supply pump and ON/OFF switch

3. RPM controller

4. Test pump and ON/OFF switch

5. RPM-Watt readout and indicators

6. Inlet and outlet pressure gauges

7. Flow control valve

8. Measurement tank and volume scale

9. Drain valve

PROCEDURE:

1. Make sure that the drain valve is open and there is water in the storage tank.

2. Turn on the test pump using the test pump ON/OFF switch.

3. Make sure that the RPM-Watt Indicator is set to RPM and adjust the RPM of the test pump to

1200 RPM using the RPM controller and readout.

4. Close the flow control valve completely.

5. Read and record the values of PIN and POUT (V, Q and CQ = 0 for this case)

6. Fully open the flow control valve.

7. Close the drain valve and, using the stopwatch and measurement scale, measure the time

required to collect 20 litres of water and record these values.

8. Read and record the values of PIN and POUT.

9. Change the RPM to 1800 and repeat steps 4 to 8 inclusive.

EXP. A - CENTRIFUGAL PUMP EXPERIMENT

(Page 2 of 3)

GROUP # ________________

DATE: _____________

_________________________________________________________________________________

DATA REDUCTION:

As shown in class, a dimensional analysis of flow through a pump yields the following dimensionless

groups.

Head Coefficient = CP = P/(2D2) = f( CQ , Re, /D)

where

P = pressure difference (P2 - P1)(Pa)

= fluid density (approximately equal to1000 kg/m3in this experiment)

= pump rotor angular velocity (rad/s)

N = number of rotor revolutions per minute (RPM)

D = pump rotor diameter (taken to be 0.1m in this case)

CQ = Capacity or Flow Coefficient = Q/D3

Re = Reynolds number = D2/

/D = Relative Roughness

and

Q = volume flow capacity (m3/s) = V/t

V = volume collected (in this experiment use 20 litres = 0.02m3)

t = time to collect volume

= viscosity (Ns/m2)

= surface roughness (m)

Usually the viscous and roughness effects are negligible and CP = f( CQ)

N (RPM)

P2

(bar)

P1

(bar)

P

(Pa)

= ( P2-P1)*105

(rad/s)

= N/30

CP

V

3

(m )

=

P/(2D2)

1200

0.0

1200

0.02

1800

0.0

1800

0.02

Time

(secs)

Q

(m3/s)

= V/t

CQ

= Q/D3

0.0

0.0

0.0

0.0

EXP. A - CENTRIFUGAL PUMP EXPERIMENT

(Page 3 of 3)

GROUP # ________________

DATE: _____________

_________________________________________________________________________________

0.50

Head Coefficient, C H

0.45

0.40

0.35

RPM

0.30

0.25

1500

0.20

2000

0.15

0.10

0.05

0.00

0.0E+00 5.0E-04 1.0E-03 1.5E-03 2.0E-03 2.5E-03 3.0E-03 3.5E-03 4.0E-03

Flow Coefficient, C Q

QUESTIONS:

1.

How do your data points compare with those points from the other angular velocities?

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

2.

List two possible reasons for error in the experimental results.

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

GROUP MEMBERS:

Printed Name

Duties

Signature

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- TM - 11-5855-214-23&p - (N04596) PDFDocument65 pagesTM - 11-5855-214-23&p - (N04596) PDFtyra24Pas encore d'évaluation

- Assignment 1 DESA 1004 - Paulo Ricardo Rangel Maciel PimentaDocument4 pagesAssignment 1 DESA 1004 - Paulo Ricardo Rangel Maciel PimentaPaulo PimentaPas encore d'évaluation

- Solving The Simandoux EquationDocument15 pagesSolving The Simandoux Equationjose_rarmenta100% (1)

- The Four Ch1Document14 pagesThe Four Ch1Sisma Yoga67% (3)

- INDE 8390 L01 B1 GenIntroDocument21 pagesINDE 8390 L01 B1 GenIntroElyar AiretiPas encore d'évaluation

- Davos Manifesto 2020 Universal Purpose of CompaniesDocument2 pagesDavos Manifesto 2020 Universal Purpose of CompaniesElyar AiretiPas encore d'évaluation

- Brealey6ce Ch20 MJZDocument37 pagesBrealey6ce Ch20 MJZElyar AiretiPas encore d'évaluation

- The World Is Getting Quietly Better - WSJ-Jan-02-2019Document2 pagesThe World Is Getting Quietly Better - WSJ-Jan-02-2019Elyar AiretiPas encore d'évaluation

- Assignment 5Document1 pageAssignment 5Elyar AiretiPas encore d'évaluation

- INDE 8390 L01 A1 OverviewDocument5 pagesINDE 8390 L01 A1 OverviewElyar AiretiPas encore d'évaluation

- Brealey6ce Ch19 MJZDocument26 pagesBrealey6ce Ch19 MJZElyar AiretiPas encore d'évaluation

- Mass-Spring Sys + Harmonic Mass-Spring Sys + Harmonic Mass-Spring Sys + HarmonicDocument24 pagesMass-Spring Sys + Harmonic Mass-Spring Sys + Harmonic Mass-Spring Sys + HarmonicElyar AiretiPas encore d'évaluation

- Fluid Mechanics Question BankDocument11 pagesFluid Mechanics Question BankBharath Waj100% (1)

- Wheel and Tire Inventory April 2012Document2 pagesWheel and Tire Inventory April 2012Elyar AiretiPas encore d'évaluation

- Control Theory Project WriteupDocument13 pagesControl Theory Project WriteupElyar AiretiPas encore d'évaluation

- Advising For Winter 2013Document3 pagesAdvising For Winter 2013Elyar AiretiPas encore d'évaluation

- Suspension Design AnalysisDocument8 pagesSuspension Design AnalysisPrithvish M GowdaPas encore d'évaluation

- Experiment ADocument2 pagesExperiment AElyar AiretiPas encore d'évaluation

- Unit Hydrograph DerivationDocument7 pagesUnit Hydrograph DerivationSudharsananPRSPas encore d'évaluation

- Distribution System HandbookDocument346 pagesDistribution System HandbookAyan Mandal100% (2)

- Signature RedactedDocument49 pagesSignature RedactedG Pavan KumarPas encore d'évaluation

- A Potential Attenuation Equation For Design and Analysis of Pipeline Cathodic Protection Systems With Displaced An (51300-03197-Sg)Document18 pagesA Potential Attenuation Equation For Design and Analysis of Pipeline Cathodic Protection Systems With Displaced An (51300-03197-Sg)rachedPas encore d'évaluation

- Open Stent Design: Craig Bonsignore NDC 47533 Westinghouse Drive Fremont, CA, 94566Document93 pagesOpen Stent Design: Craig Bonsignore NDC 47533 Westinghouse Drive Fremont, CA, 94566akire_aicragPas encore d'évaluation

- Physics SL Paper 3 TZ2Document20 pagesPhysics SL Paper 3 TZ2Dongjean SeoPas encore d'évaluation

- TCL Air Conditioner Service ManualDocument138 pagesTCL Air Conditioner Service ManualFabian EtcheniquePas encore d'évaluation

- E1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes TérmicasDocument3 pagesE1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes Térmicasfredy lopezPas encore d'évaluation

- Ashish PPT 2Document9 pagesAshish PPT 2Ankit JaglanPas encore d'évaluation

- Noise Margin Definition ExplainedDocument10 pagesNoise Margin Definition ExplainedAnil BhardwajPas encore d'évaluation

- Gate Solved Paper - Me: y X X X P P P P X FX A B V Ydx P y X A B V XDX P XDX PDocument33 pagesGate Solved Paper - Me: y X X X P P P P X FX A B V Ydx P y X A B V XDX P XDX PHarish Jahan MohanPas encore d'évaluation

- 2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical ApplicationsDocument6 pages2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical Applicationsultrasonic81Pas encore d'évaluation

- ELIMINATION REACTIONS: AN OVERVIEWDocument19 pagesELIMINATION REACTIONS: AN OVERVIEWSyuhadah NoordinPas encore d'évaluation

- Department of Education: Humss 12 Cluster A and B Weekly Home Learning PlanDocument3 pagesDepartment of Education: Humss 12 Cluster A and B Weekly Home Learning PlanRhomelyn AbellarPas encore d'évaluation

- Assignment 2Document2 pagesAssignment 2ue06037Pas encore d'évaluation

- Acceleration (Inclined Plane)Document5 pagesAcceleration (Inclined Plane)jambunaPas encore d'évaluation

- 176-fc4731 Fault CodeDocument3 pages176-fc4731 Fault CodeHamilton MirandaPas encore d'évaluation

- 1117 1 M-Ary Signals PART 1Document11 pages1117 1 M-Ary Signals PART 1PARKSANGWOOKPas encore d'évaluation

- The Second Term Exam of EnglishDocument2 pagesThe Second Term Exam of Englishsof chimiste100% (1)

- Bridge Design Report - Docx 150Document17 pagesBridge Design Report - Docx 150nephembaniPas encore d'évaluation

- Winitzki - Heidelberg Lectures On Advanced General Relativity 2007Document156 pagesWinitzki - Heidelberg Lectures On Advanced General Relativity 2007winitzkiPas encore d'évaluation

- Mercury Gemini Program Design Survey. NASA ERC Design Criteria Program Stability, Guidance and ControlDocument217 pagesMercury Gemini Program Design Survey. NASA ERC Design Criteria Program Stability, Guidance and ControlBob Andrepont100% (1)

- Shoot For Your Grade Lab Write UpDocument5 pagesShoot For Your Grade Lab Write Upapi-254812059Pas encore d'évaluation

- Transmision de Potencia NewDocument12 pagesTransmision de Potencia NewGustavo ArmellaPas encore d'évaluation

- Design of Masonry StructuresDocument10 pagesDesign of Masonry StructuresmuhammedPas encore d'évaluation

- Rebound Hammer Test Procedure For Concrete HardnessDocument4 pagesRebound Hammer Test Procedure For Concrete HardnessSite Engineer.2p2Pas encore d'évaluation

- Strength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07MettkDocument287 pagesStrength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07Mettkluis morales100% (2)