Académique Documents

Professionnel Documents

Culture Documents

Government of Pakistan: Pakistan Ordnance Factories Tender Enquiry

Transféré par

Amal PirzadaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Government of Pakistan: Pakistan Ordnance Factories Tender Enquiry

Transféré par

Amal PirzadaDroits d'auteur :

Formats disponibles

POF 1262 (FOREIGN SUPPLIES)

Government of Pakistan

PAKISTAN ORDNANCE FACTORIES TENDER ENQUIRY To __________________________ __________________________ Dear Sir, Reference: TENDER ENQUIRY No. 411-FP-Capt-DS-Elect (Wah) , dated 19.05.2012.

You are requested to submit sealed quotations for the item(s) noted in the Schedule to the Tender. Offers should be sent duly sealed in an envelope. Fax / E-mail offers are not acceptable. Please note the following instructions for filling the tender: 1. SUBMISSION OF TENDER 1.1 Tenders will be opened at 1200 hours on 30.06.2012 and must reach this office on or before that time. The tender received late will not be entertained. You may witness the opening of the tender if you so desire. If representative is deputed the request alongwith particulars (Copy of CNIC) of the rep be sent to this office 10 days before opening of TE. Only one tender should be included in one envelop. The outside of the envelope should be inscribed with: Tender Enquiry No. Tender to be opened on Address as follows:i) TECHNICAL OFFER (PART-I) Director Services, POFs Wah Cantt 47040 (Pakistan) Tele: +92-51-9055 21090 Fax: +92-51-9271400, 9314100 1.3 ii) COMMERCIAL OFFER (PART-II) Chairman POF Board POFs Wah Cantt 47040 (Pakistan) Fax: +92-51-9271400, 9314100 411-FP-Capt-DS-Elect (Wah), Dt:19.05.2012 30.06.2012

1.2

If envelope do not indicate reference of TEs or received late the same returned un-opened.

Page | 1

2.

GENERAL INSTRUCTIONS REGARDING PREPARATION OF QUOTATIONS 2.1 For materials, the prices should be filled in column 5 and delivery date in column 6 at Para I of the schedule to this Tender Enquiry. The undertaking should be signed at the bottom of the schedule, which shall form the Quotation. You may use a separate sheet if necessary. For Plant and Machinery, you are required to quote in two parts:Part I Technical Offer. It should exclusively give technical details and literatures / brochures of the offered plant, machinery and equipment; validity date; delivery schedule; signed undertaking given on the schedule to this Tender Enquiry. It must not indicate price, costs etc. (Addressed to Director Services) Part II Commercial Offer. It should indicate the commercial terms e.g price, terms of payment, mode of payment, mode of supply. (Address to Chairman POF Board) Each part should be placed in a separate sealed cover. The envelopes should be inscribed with: Part I Technical Quotation without price and Part II Commercial Quotation with price. 2.3 The quotation must remain valid for, at least 180 days from the date of opening of tenders. The quotation should hold good for any reduced or enhanced quantities without notice. In the event of non-acceptance of offer, no intimation will be given to the Tenders. Conditional offers or alternative offers are likely to be ignored. Quotations should be based on C&F Karachi. The consignment will be shipped preferably through Pakistan National Shipping Corporation (PNSC). In case there is no PNSC service in the country of shipping, the store may be shipped on foreign flag vessel (preferably the conference line vessel) calling at Karachi as the first port of call in the South Asia sub continent. Under no circumstances shipment will be made on INDIAN OR ISRAELI vessels are on the foreign flag vessel, calling first at any INDIAN Seaport en-route to Karachi. The freight should be indicated separately. Insurance premium should not be included in the quoted price. However, where insurance is considered necessary, advice to that effect should be given in the quotation.

2.2

2.4 2.5 2.6 2.7

Page | 2

2.8

Submission of the offer through an agent in Pakistan should be avoided. In case it is considered inevitable, the agents quotation must invariably be accompanied by the original proforma invoice from the principals / manufacturers. Country of origin and port of shipment to be stated. The offer of the principal must clearly indicate whether the rate quoted is inclusive of agents commission, and if inclusive, rate of commission included be specified. Suppliers will render necessary information regarding hazardous effects on environment, of the materials / products supplied by them, in their quotations and shipping / dispatch documents. If the requisite information is not furnished on the T.E form or offer receive is not in conformity with the requirement of the T.E such offer shall be ignored.

2.9 2.10

2.11

2.12 3.

INSPECTION 3.1 The bed test of each Genset at full load will be carried out by manufacturer in the presence of POFs Engineer (s) at the manufacturers premises. Suppliers will bear all the expenses. The final inspection and performance test of each Genset and its auxiliaries will be carried out by POFs Engineers and suppliers Engineers at site. The store will be obtained on suppliers warranty / guarantee subject to inspection on receipt. Rejected store will be removed and replaced with the acceptable store by the supplier at his own expense, within a specified time.

3.2 3.3

4.

ACCEPTANCE OF OFFERS 4.1 The right to accept or reject any offer in full or in part, without assigning any reason or to negotiate price without prejudice to the original offer is hereby reserved. PERFORMANCE BOND The successful bidder will provide performance bond at the rate of 10% of C&F value of the contract in favour of Controller of Military Account (CMA) Pakistan Ordnance Factories, Wah Cantt. The performance bond will be furnished in the form of an un-conditional bank guarantee on prescribed proforma covered by a scheduled bank in Pakistan. The performance Bond shall be furnished within 45 days from the date of opening of Letter of Credit. It shall be valid for a period

Page | 3

4.2

of three years after the date of expiry of L.C, however, it will be extendable till the expiry period of satisfactory performance of the plant. Period of performance bond would start from date of successful performance test of plant. If performance bond is not furnished, within the above mentioned prescribed time, the purchaser reserves the right to cancel the contract and has the right of risk purchase action. Performance Bond shall be released after two years satisfactory performance of the plant. 4.3 FAILURE TO SUPPLY THE STORES All deliveries must be completed by the specified date. If the failure to deliver the stores within the scheduled time should have arisen from Force Majeure, which the purchaser may admit as reasonable ground for further time, he will allow such additional time as he may consider to have been required by the circumstances of the case. Otherwise, he will be entitled, at his discretion, to cancel the contract; and/or claim liquidated damages upto 2% but not less than 1% of the contract price of the items and their quantities for each and every month or part of a month, beyond the specified delivery date, during which these may not be delivered, subject to a maximum of 10% of the total contract value or to purchase, from elsewhere, the unsupplied stores at the risk and cost of the supplier. 4.4 PAYMENT 4.4.1 Payment will normally be made by means of irrevocable letter of credit. Scheduled of payment is as under: i) ii) iii) iv) 60% Payment will be released against shipment on submission of shipping documents to the Bank. 20% Payment will be released after the successful inspection of the complete store at site in the presence of Suppliers rep. 20% Payment will be released after satisfactory performance test of each unit. In case, the delay in installation/ commissioning occurred on the part of purchaser, the balance 20% payment will be released after 30 months since receipt of store.

4.4.2 All Bank charges incurred in Pakistan in connection with the establishment of L.C. will be borne by the purchaser, whereas all Bank charges incurred in connection with drawing of payment including charges for confirmation of L.C. by the advising Bank / Foreign Bank will be borne by the Supplier.

Page | 4

5.

SECURITY OF INFORMATION The tenderer and his employees must not communicate any information relating to the sale/purchase of stores under this enquiry to any person other than the manufacturer or to any press or agent not authorized in writing by POFs to receive it. Please return the schedule to the Tender duly signed by the specified date, alongwith the specifications, drawings etc. if any, enclosed herewith even if you are unable to quote.

Note:-

Offer must be according to clause 2.2 (Technical & Commercial separately). Yours faithfully,

Tele

+ 92-51-905521024 + 92-51-905521090

(TASHHIR UDDIN) DIRECTOR SERVICES Fax + 92-51-9271400 Fax + 92-51-9314100

Page | 5

POF 1262

PAKISTAN ORDNANCE FACTORIES

SCHEDULE

SCHEDULE TO TENDER NO. To be opened on 30.06.2012 1. (1) Item No. 1. FOR MATERIALS (2) Description with spec etc (3) Unit (4) Qty (Units) 01 (5) Price per unit for C&F delivery. Price in Price in figure words (6) Delivery date 411-FP-Capt-DS-Elect (Wah) Dated: 19.05.2012

Power units capacity of Nos. 7-8MW comprising2 x Gas Gensets of 3.5-4.0MW each with Heat Recovery System alongwith complete accessories, auxiliaries and installation material. For Plant & Machinery: Specification: Special Conditions: a. b. Model Evaluation Criteria

2. 3.

Attached as Annexure 1

Robust, Standard, successfully running worldwide in the same climatic conditions as in Pakistan. Following will also be consider during evaluation in addition to other technical aspects: Per MW capital cost Consumption of fuel / KWH Consumption of lube oil / KWH Parasite load Maintenance cost / KWH based on a period of 10 years operations. Quality of product i.e. proven technology world wide

Page | 6

c. d.

O & M Cost:

Operational and maintenance cost / year be provided

Installation & Installation & Commissioning will be carried out by purchaser, commissioning: under the supervision of suppliers rep. Training: The supplier will provide training to the following POFs personnel for operation, trouble shooting and maintenance/ overhauling of the plant and its auxiliaries i.e. PLC system, Engine Control System and etc. in manufacturer premises for a period of 3 4 weeks free of cost. i) Mechanical Engineer = 01 ii) Electrical Engineer = 01 iii) Electronic Engineer = 01 iv) Plant operator = 04 v) Technician = 06 i. Performance Bond period will be extended, if the downtime of plant is more than 15 days due to fault. Two years warranty/guarantee period will be started from the date of satisfactory completion of performance test of plant.

e.

f.

Warranty / Guarantee:

g.

Inspection:

Any damage / or loss to the plant and equipment procured due to faulty design, material workmanship including loss / damage to life and property shall be the responsibility of the manufacturer / supplier (s) who shall have to compensate the Purchase according to the consultation and decision of the two parties. However, the total amount of consequential damages and penalties including but not limited to liquidate damages will not exceed the sum value of the plant. Inspection of store will be carried out in the presence of suppliers rep at site.

ii.

Page | 7

h.

Acceptance Performance Test:

i)

Each Genset will run continuously for 72 hours at guaranteed output i.e. 100% load with -5% load variation at 95% availability of Gensets. This will exclude the initial trial period. In case of any specific fault for which manufacture have to call a specialist, the time taken by him in reaching the site of test shall not be counted as plant downtime. However, travel time shall not exceed 5 days. If the down time period of Gensets due to any fault exceeds the above mentioned availability percentages, excluding the downtime, if any, attributable to POF, then the performance test will be considered as unsatisfactory. In such event the supplier/manufacturer shall perform necessary repair/adjustment & new performance test will be conducted. Before putting the Genset into operation suppliers/manufactures personnel will check and ensure that all the accessories/auxiliaries, gas and oil filters etc are in good condition. POF will provide the output load (with-5% variation) for test run of each Genset. Any trip due to fluctuating load above 100% will not be considered for purposes of availability. Any tripping due to electrical load management attributable to POF, will not affect the performance test of the Gensets. If a Genset fails in the performance test due to the reasons attributable to the supplier/manufacturer, the supplier/manufacturer shall be given a period of 14 days to make the necessary adjustment/repair. After this adjustment period a repeat test shall be performed. If the supplier/manufacturer fails to conduct the repeat test within 14 days it shall be deemed to have failed. If the Gensets do not make above mentioned performance criteria further course of action will jointly be determined.

ii)

iii)

iv)

v)

vi)

Page | 8

i.

Eligibility:

i)

Manufacturers of Gas Gensets having backup/ field services setup in Pakistan are eligible to submit the offer. Company profile and details of plant / equipments in operation worldwide particularly in Pakistan are also required to be provided for evaluation. Provision of the profile, but not limited to the following information is compulsory: Name & Address of the firm / company. i) Establishment year. ii) Total Assets Details of firms capabilities, experience and performance. Particulars, organizational set-up alongwith detailed profile. Complete details and performance data of projects executed in the last five years with complete references and detail of projects in hand. Detail of relevant projects in Pakistan. Terms of after sales support covering all aspect of maintenance.

ii)

j.

Conditional offers:

Offers with conditions like availability of export permit or any other restrictions will not be accepted. Within 06 months

k. Delivery Period: 4. Undertaking:-

Should our offer be accepted, we hereby undertake to supply the stores / render the services contracted on the basis of General Conditions of Contract embodied in Form POF 1282, and to deposit the performance bond within the prescribed time, failing which it will constitute a breach of contract, and POF will have the right to purchase the stores / services elsewhere at our risk and cost. Place_____________________ Date_____________________ Signature of the Tenderer _______________ Name_____________________________ Position____________________________ Address____________________________ Income Tax G.I.R No. ________________

Page | 9

ANNEXURE 1 SPECIFICATIONS OF POWER PLANT POF WAH

Power Plant of Capacity 7-8MW, complete with heat recovery system (Annex K). Comprising of two Reciprocating Gas Engine With Generator each having capacity of 3.54MW for electric power generation along with all auxiliaries, accessories, protection equipment, plant installation accessories, synchronizing system and all related protection system. 2. Burning System Voltage Frequency Excitation System Lean Burn System 11,000 Volts 50 Hz Brushless (Digital Control)

NATURAL GAS INJECTION SYSTEM 2.1 Natural Gas pressure increasing/reducing system for both Power Plants as per requirement of Gas Genset alongwith safety valves, control valves, pressure gauges and strainers. The pressure of Natural Gas supply system available at site, varying from 1 to 4 Bar (Analysis of Natural Gas is enclosed as AnnexureA) Gas compressor(s). (Optional) Gas flow meter with totalizer for each unit. Additional one gas flow meter on main line.

2.2 2.3 3.

COOLING SYSTEM 3.1 Package type induced draught cooling Towers of suitable capacity for each unit designed on ambient conditions exhibited in Annexure-B and wet bulb temp 27 o C. The specifications of the treated water to be used in the cooling towers are given in Annexure-C. Cooling water circulation pumps with motor, starter and ammeter alongwith one additional pump complete as standby for each cooling tower with all accessories. Provision of low water level alarm & indicator in control room.

3.2

3.3

Page | 10

4.

LUBE OIL SYSTEM 4.1 4.2 4.3 Lube oil circulation pump for each engine. Lube oil storage tank with auto filling system of lube oil in Genset. Lube oil filling and decanting pumps for storage tank and Genset.

5.

HEAT EXCHANGERS 5.1 5.2 Heat exchanger for each unit to cool the HT/LT jacket water of Genset. Analysis of treated water, raw water and demineralised water are enclosed as Annexure- C, D & E.

6.

VENTILATION SYSTEM Complete ventilation system as per requirement of the power plant.

7.

SAFETY SYSTEM 7.1 Provide the auto purging & shut off valves on main gas line and on gas train of each Genset to cut off the complete Natural Gas supply and purge out accumulated gas from the line immediately in case of emergency. Provide manual gas control vales (Ball Valve) on main line and before and after the gas train. Natural gas leakage detection system for main engine hall with alarm and indication in control room. Provide the list of safeties installed on engine & alternator. Alarm, indication & tripping required on the following ( central control room and auxiliary panel of individual unit): Failure of cooling water pump : Indication & Alarm in the control room : -doFailure of cooling water fan High temperature of compressed : Indication and alarm in the control room and local panel. gas alarm and tripping. : Indication & Alarm in the control Cooling tower water low level room : -doFailure of ventilation system

7.2 7.3 7.4 7.5

Page | 11

7.6

Safeties for gas compressor Failure of gas compressor Inlet & outlet gas pressure (low/high) High temperature of compressed gas alarm & tripping Lube oil high Temperature : Indication & Alarm in the control room : -do-

Indication and alarm in the control room and local panel : Indication, Alarm & Tripping in the control room : -doLow lube oil level Auto purging of Natural Gas from the system in case of emergency.

7.7 8.

CO2 Fire Extinguisher system for transformer room.

AUXILIARIES 8.1 STARTING SYSTEM Battery operated system along with battery charger or air starting system. 8.2 AIR COMPRESSORS Self lubricated dry for the each plant air vessels, safety tripping alarm and 8.3 PIPING 8.4 All types of piping (seamless) upto battery limit for power plant. Pipelines from gas train to gensets and for instruments, compressed air lines should be of stainless steel material. compression air compressors of suitable capacity & pressure unit with refrigeration air dryer for instrument air alongwith valves and pressure gauges. Complete control system with indication in the control room and local panel.

CONTROL SYSTEM PLC/DCS Control System alongwith i) ii) iii) Provision of 01 PC in control room alongwith UPS, software, printer (s) for continuous fault recording system (each event recorder) and one coloured printer for printing of desired data. PLC programmer & its software. PLC trouble shooting software.

Page | 12

8.5

PROTECTION SYSTEM 8.5.1 Protection system having complete standard mechanical/electrical/ electronic protections to run the plant, parallel with the grid, with each other and with the existing POFs 11 KV generators. 8.5.2 Installation of surge/spike arrestor on each genset to absorb the surges/ spikes generated in the net work

8.6

11 KV PANELS 8.6.1 Generator panels 8.6.2 Transformer panel (Annex-G) : For each Genset : 01 No

8.7

TRANSFORMER

(Specification attached as Annexure-H)

Transformer of 750 KVA for auxiliary load. 8.8 L.T. FEEDER PANELS 8.8.1 8.8.2 380-440 volts panels for plant auxiliary & equipments. L.T. transformer panels 1600A, 65KA, Complete with all protection system. (Specification attached as Annexure-J) As per Requirement 01 No

8.9

CABLES & JOINTING MATERIAL Provision of all types of control cable (imported any European country) & HT & LT power cables (make: Pakistan Cables, Pioneer Cables, New age Cables) and jointing material for power plant.

8.10

SYNCHRONIZING SYSTEM Synchronizing system with the existing network, (National Grid & Turbo gensets) with each other for both power plants & independent operation (Island Mode)

8.11

CHIMNEY Chimneys for each genset

Page | 13

8.12

STEEL STRUCTURE FOR PLATFORMS & LADDERS Provide complete platform, stairs & ladders of each genset, and auxiliary equipment to carry out maintenance & inspection.

9.

TOOLS & TACKLES Testing kit for analyzing of jacketed water alongwith three years consumables. Complete tools and tackles kit for 60,000 running hours of Gensets and electric crane. Inspection & measuring tools/gauges Tools for routine /running maintenance of plant Complete maintenance tools including torque wrenches, hydraulic jack etc. Special tools for inspection & calibration Laptop (latest version) alongwith all accessories, Software for programming & troubleshooting of gensets Overhead electric crane of suitable capacity to lift up at least alternator = 01 Set = 01 Set = 01 Set = 01 Set = 01 Set = 01 No = 01 No = 01 No.

10.

SPARE PARTS Recommended spares upto 30,000 running hours maintenance (1st top-up overhauling) with item wise cost alongwith name and addresses of their manufacturers. Also provide the schedule of maintenance according to running hours.

11.

EMERGENCY SPARES. 11.1 ELECTRICAL / ELECTRONICS 11.2 One set of all type of module / control of cards mounted on engines and control panels. Spare diodes for excitation system. One set of bearings for generator. One set of bearings for each motor & auxiliary pump.

MECHANICAL One complete cylinder head. One Lube oil circulation pump. One HT/LT water circulation pump. One pre-heating pump.

12. 13.

Natural gas leakage detection system for genset hall. (Optional) Guarantee for provision of spares for a period of ten years.

Page | 14

14. 15.

List of fast wearing parts, routine, replacement parts with first time repair and complete overhauling showing frequency of replacement. ERECTION, INSTALLATION & COMMISSIONING Erection, installation and commissioning will be carried out by the supplier. The erection / commissioning supervision charges should be indicated separately in the quotation. 15.1 15.2 All required materials will be arranged by the supplier including supply of lube oil & jacketed water coolant for warranty period. POF will supply only Natural Gas, raw water & demineralised / soft water.

16.

INSPECTION AND PERFORMANCE TEST OF THE PLANT 16.1 The bed test of the plant at full load will be carried out by manufacturer/ supplier in the presence of POFs Engineer (s) at the manufacturers premises. Suppliers will bear all the expenses. The final inspection and performance test of plant and its auxiliaries will be carried out by POFs Engineers and suppliers Engineers at site

16.2 17.

TRAINING The supplier will provide training to the following POFs personnel for operation, trouble shooting and maintenance/ overhauling of the plant and its auxiliaries i.e. PLC system, Engine Control System and etc. in manufacturer premises for a period of 3 4 weeks free of cost. i. ii. iii. iv. v. Mechanical Engineer Electrical Engineer Electronic Engineer Plant operator Technician = = = = = 01 01 01 04 06

18.

CIVIL CONSTRUCTION DRAWING OF THE BUILDING AND BLOCK DIAGRAM OF THE PLANT The size of the buildings suitable for accommodating the offered plant, service, accessories and installation block diagram should be provided with the technical offer. However, complete civil drawing of the building of power plant & foundation of genset (s) will be provided by the supplier within 30-days after the issue of letter of intent.

Page | 15

19.

PERFORMANCE BOND The successful bidder will provide performance bond at the rate of 10% of C&F value of the contract in favour of Controller of Military Account (CMA) Pakistan Ordnance Factories, Wah Cantt. The performance bond will be furnished in the form of an unconditional bank guarantee on prescribed proforma covered by a scheduled bank in Pakistan. The performance Bond shall be furnished within 45days of the date of opening of Letter of Credit. Period of performance bond would start from date of successful commissioning of plant. It shall be released after two years satisfactory performance of the plant. In case, the delay in installation/ commissioning occurred on the part of purchaser, the payment will be released after 30 months since receipt of store.

20.

WARRANTEE / GUARANTEE Performance Bond period will be extended, if the downtime of plant is more than 15 days due to fault. Two years warranty/guarantee period will be started from the date of satisfactory completion of performance test of plant. 20.1 Any damage / or loss to the plant and equipment procured due to faulty design, material workmanship including loss / damage to life and property shall be the responsibility of the manufacturer / supplier (s) who shall have to compensate the Purchase according to the consultation and decision of the two parties. However, the total amount of consequential damages and penalties including but not limited to liquidate damages will not exceed the sum value of the plant.

21.

PERFORMANCE TEST PROCEDURE vii) Each Genset will run continuously for 72 hours at guaranteed output i.e. 100% load with -5% load variation at 95% availability of Gensets. This will exclude the initial trial period. In case of any specific fault for which manufacture have to call a specialist, the time taken by him in reaching the site of test shall not be counted as plant downtime. However, travel time shall not exceed 5 days. If the down time period of Gensets due to any fault exceeds the above mentioned availability percentages, excluding the downtime, if any, attributable to POF, then the performance test will be considered as unsatisfactory. In such event the supplier/manufacturer shall perform necessary repair/adjustment & new performance test will be conducted. Before putting the Genset into operation suppliers/manufactures personnel will check and ensure that all the accessories/auxiliaries, gas and oil filters etc are in good condition.

viii)

ix)

Page | 16

x) xi) xii)

POF will provide the output load (with-5% variation) for test run of each Genset. Any trip due to fluctuating load above 100% will not be considered for purposes of availability. Any tripping due to electrical load management attributable to POF, will not affect the performance test of the Gensets. If a Genset fails in the performance test due to the reasons attributable to the supplier/manufacturer, the supplier/manufacturer shall be given a period of 14 days to make the necessary adjustment/repair. After this adjustment period a repeat test shall be performed. If the supplier/manufacturer fails to conduct the repeat test within 14 days it shall be deemed to have failed. If the Gensets do not make above mentioned performance criteria further course of action will jointly be determined.

22.

PENALTY If lube oil and fuel consumption increase with respect to specified limits by the firm on the basis of the fuel gas analysis as per Annexure-A. If any of them or both exceed the prescribed level, an equal amount will be charged by POF, on the basis of fuel, lube oil or both consumed in excess for the units generated during 24000 hours at full load guaranteed by the firm at ISO condition, using the price prevailing at the time of commissioning of the plant. If the down time of the plant is increased more than 15 days after expiry of commissioning period due to the fault, then POF will charge generation loss @ 50% of Pakistan Electric Power Company tariff

23.

UTILITIES AVAILABLE AT SITE i) ii) iii) iv) v) Power 400 Volts (+5%), 50 Hz (+1%), 3-Phase & 200 Volts (+5%), 50 Hz (+1%), single phase. Natural Gas at 0.5 to 3.5 Bar. Water for cooling towers. Raw Water Demineralized water

24.

LITERATURE / MANUALS 24.1 Installation / erection manual complete with necessary civil mechanical & electrical drawings for complete project. Operation manual for each equipment Maintenance manual for each equipment Spare parts catalogue Electrical/Electronics schematic diagrams with component values for each equipment Block diagram of the system. Trouble Shooting guide. 04 Sets

24.2 24.3 24.4 24.5 24.6 24.7

04 04 04 04

Sets Sets Sets Sets

04 Sets 04 Sets

Page | 17

25. 26.

Copy of all software i.e. operation, trouble shooting will be provided. GENERAL INFORMATION TO BE SUBMITTED WITH THE TECHNICAL OFFER Model of genset Output electrical per genset at 48 C Output electrical per genset at ISO standard Output mechanical per genset at 48 oC Output mechanical per genset at ISO standard Engine rpm Gas consumption per KWH at 48 C Minimum gas pressure required Lube oil consumption per KWH at 48 C Generation voltage Frequency Efficiency at 0.8 P.F Parasite load Top end overhauling Major overhauling Length of the complete Genset Width of the complete Genset Weight of the complete Genset Temperature of exhaust gases Analysis of exhaust gases

o o o

_____ _____ KW _____ KW _____ KW _____ KW _____ RPM _____ CuM _____ Bar _____ Litters _____ KV _____ Hz _____ % _____ KWs _____ Hours _____ Hours _____ mm _____ mm _____ KGs _____

o

____________

Steam generation rate per MW in case of waste ____________ heat recovery system installed. Pressure of steam Temp. of exhaust gases after waste heat boiler Noise level at 10 meters Any other special parameters Reference list of customers in Pakistan and Abroad. ____________ ____________ ________ dBs ____________ ____________

After sales service in Pakistan and detail of plants supplied in Pakistan and other countries. ____________ Confirmation regarding getting the export license for exporting the equipments to Pakistan. ____________

Page | 18

27.

ENCLOSURES 1) 2) 3) 4) 5) 6) 7) 8) 9) Natural Gas Analysis Meteorological data of POFs Wah Cantt Analysis of treated water for cooling tower Raw Water Analysis Demineralise Water Analysis Transformer Panel HT 11KV Specification of 750 KVA Transformer Specification of L.T. Transformer panel Specification of waste heat recovery system - Annexure-A - Annexure-B - Annexure-C - Annexure-D - Annexure-E Annexure-G - Annexure-H - Annexure-J - Annexure-K

Page | 19

ANNEXURE-A

NATURAL GAS ANALYSIS POF WAH

Components Methane Ethane Propane I-Butane N-Butane Iso + Neo Pentane N-Pentane Nitrogen Carbon Dioxide Hexane plus higher C6++ Oxygen + Argon = = = = = = = = = = = Mol/Mol % 90.79 1.36 0.01 0.05 0.06 0.02 0.01 6.08 1.63 < 0.01 < 0.01 100% CALCULATED PARAMETERS (ASTM D 3588-91; @ 60 F/14.696 Psia/dry) Ideal gross heating value H (v, id) Real relative density d Compressibility factor z Wob index H/sqrt (d) = = = = 947.7 BTU/Cuft (real) 0.604 0.9981 1219 < 0.01 < 0.01 < 0.01 < 0.01 < 0.01 +/< 0.01 < 0.01 < 0.01 < 0.01

Note: Oil & fine sand particles are occasionally traced out in the gas.

Page | 20

ANNEXURE-B

METEOROLOGICAL DATA POF WAH

Ambient Temperature

= Max. 50oC (In June) = Min. -1oC (In January)

Humidity

= Max. 96% (In August) = Min. 17% (In June)

Rain Fall/Year Barometric Pressure Height from Sea Level

= 875.50mm of (Avg) = 710-732 mm of Hg = 510.34 Meter

Page | 21

ANNEXURE-C

ANALYSIS OF TREATED WATER FOR COOLING TOWER POF WAH

1. 2. 3. 4. 5. 6. 7. 8. 9.

Conductivity Total Hardness Total Alkalinity Chlorides Sulphates Nitrates Silica PH Value Total Dissolved Solids : : : : : : : :

500 s/cm Zero ppm 200 ppm 12 ppm 66 ppm 05 ppm 18 ppm 7.4 ppm 330 ppm

Page | 22

ANNEXURE-D RAW WATER ANALYSIS POF WAH a) b) c) d) e) f) g) h) i) j) k) l) m) Appearance Odour and taste Conductivity Ph value Total dissolved solids (TDS) Silica (SiO2) Iron (Fe) Phenolphthalein Alkalinity (P) Total Alkalinity (M) Total Hardness Alkaline Hardness Non-alkaline Hardness CATIONS a) b) c) n) Calcium (Ca+2) Magnesium (Mg+2) Sodium (Na+1) 80 ppm 15 ppm 13 ppm Clear Colourless and free from suspended matter Odourless and tasteless 460 s/cm 7.4 330 ppm 18 ppm < 0.05 ppm Nil 205 ppm as Ca Co3 265 ppm as Ca Co3 205 ppm as Ca Co3 60 ppm as Ca Co3

ANIONS a) b) c) d) Bicarbonates Chloride Sulphate Nitrate 250 11 66 <5 ppm ppm ppm ppm

Page | 23

ANNEXURE-E DEMINERALISED WATER ANALYSIS POF WAH a) b) c) d) Conductivity Ph Value Silica (SiO2) Hardness < 02 s/Cm 6.5-7.0 < 0.02 ppm Zero

Page | 24

ANNEXURE-G SPECIFICATION OF HT TRANSFORMER PANEL Metal clad sheet steel fabricated, totally enclosed. Cubicle type switchgear of floor mounting design. The switchgear shall be designed for 3 phase, 3 wire, 50 Hz, 11KV AC system and shall be supplied complete with air insulated, high conductivity hard drawn, electrolyte copper Bus Bars of adequate current carrying capacity and short circuit rating, instruments, inter connection wiring etc. and finished with two coats of antirust paint. The unit should have a rupturing capacity of 350 MVA and shall comprise of the following. Six poles fixed and moving cluster type isolating contacts giving double isolating facilities per phase. 1 set of automatic safety shutters. One suitable trolley mounted draw out type vacuum circuit breaker of adequate capacity (630 A). One circuit breaker lowering mechanism fitted with removable handle. Circuit breaker hand charging spring closing mechanism and motorized charging for 220 Volts A.C. One 30/110 Volts D.C. Shut trip coil. One emergency trip push button. One spring closing and charging mechanism. One mechanical On/Off position indicator. One 30/110 Volts DC closing mechanism. On/Off push buttons One each. 3 current transformers 400/5/5 15VA class D required for protection and metering. 96x96mm digital ampere meter reading 1000A with selectable CT ratio. 1 ammeter phase selector switches 3 ways and off. Digital over current, short circuit, earth fault relay. Operating 110V DC / 30V DC One Multicore cable and box suitable for accommodating 3 core 185mm2 PVC/XLPE cable. One designation label. One set of cable sockets. One suitably hinged instrument panel. 96x96mm digital volt meter PT ratio 11000 / 110V measuring 0-15KV

POF has the right to ask the supplier to produce any type of test certificates NOTE:from an approved laboratory and to witness the routine test of the equipment according to the relevant IEC publication

Page | 25

ANNEXURE-H TECHNICAL SPECIFICATION 750 KVA POWER TRANSFORMER

Indoor type 750KVA, 3 , 50 Hz, oil impressed natural cooled for use in an ambient temperature of 50oC, Delta star winding with neutral brought out on L.V. side, vector group Dyn 11, A dial indicating thermometer on the tank, a silica gel breather, an oil gauge with the conservator and Buchholz relay to be incorporated. TECHNICAL DATA Rated Power Voltage Ratio Full load current No. of Phases Frequency Neutral Impedance Efficiency Type of cooling Tapping of H.V. side Ambient Temperature Winding connection = 750 KVA = 11000/415-230 Volts = 39.3/1085 Amps = 3 = 50 Hz = On L.V. side = 4.5% = 98.45 at full load = Natural = +2.5% = 50 C = Dyn11

o

+5%

+7.5%

FOLLOWING STANDARD FITTINGS TO BE PROVIDED 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Oil conservator with oil level gauge. Silica gel breather. Rollers Bi-Directional. Off load tap changer. Rating and diagram name plates. Oil drain valve. Earthing terminal. Dial type thermometer. Buchholz relay. Complete termination kit both H.V. and L.V. Explosion vent.

Page | 26

Annexure-J L.T. TRANSFORMER PANELS Sheet steel, industrial cubicle pattern, indoor type floor mounting, phase, 4-wire, 50-Hz 400-600 Volts, comprising of: (a) (b) (c) (d) I-Sheet steel floor mounting cubicle structure. I-3 Phase set of H.D.H.C. copper Busbars of 1600 Amps rating. I-Half sized neutral bar. 1600A rating, Air Circuit breaker, drawout type manually operated: (e) (f) Overload/short circuit releases, 900-1600A & 6-12KA Rated breaking Capacity = 65 KA Rated making capacity = 90 KA Shunt trip coil = 30 V D.C 3-

4-current transformers, dry type resin cast insulated: Rated 1600/5A Class of accuracy CI, I Rated Burden-10VA Saturation factor-not less than 5

(g) (h) (i) (j) (k) (l) (m)

Digital volt meter 96x96mm square shaped flush mounted suitable for connection to current transformer 1600/5A. Ammeter Scale = 0-1600

I-Ammeter sector switch, Name plate marked Red-Yellow-Blue-out of balance / neutral-off. Digital ampere meter 96x96mm square shaped, flush mounted. Voltmeter Scale 0-600 Volts Voltmeter selector switch Name plate marked RY-YB-BR and "Off" Digital Over current / short circuit / earth fault relay. 1/2

Page | 27

Rated 5A with Over current relay setting Short Circuit relay setting Earth fault relay setting Time setting (n)

= = = =

0-50-200%. 200-800% 10-40% 0-3 sec at 10 times current setting.

2-Indicating lamps for ON and OFF indication of breaker. Control fuzes for auxiliaries rated 4 Amps

(o)

1-Set of cable box with seven glands for the incoming cable 7x500mm P.V.C. as given. The panel detailed above would be complete with internal wiring inter-connections, cable sockets, foundation bolts, etc., but would exclude compound for the cable boxes.

(p)

Provision for a shutter to be made in panel to cover the opening in the event of A.C.B. being removed for maintenance.

2/3

Page | 28

ANNEXURE-K

SPECIFICATION OF WASTE HEAT RECOVERY SYSTEM POF WAH

Waste Heat recovery system required for heat recovery from flue gases of existing Wartsila Gas Genset (5 x 2 MW, current load of 7-8MW), and power plant to be procured comprising of Gas Genset (2 x 4 MW), fired on Natural Gas. Details are as under: WASTE HEAT BOILER Complete waste heat boiler of suitable capacity at a pressure of 08-Bar alongwith all accessories, auxiliaries and control system. 1. 1.1 1.2 1.3 2. 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 DETAIL OF EQUIPMENT / ACCESSORIES & AUXILIARIES Waste Heat Boiler of suitable capacity Control Panel Mode of Operation ACCESSORIES Feed water Tank with De-aerator Blow down tank Feed water pump (elect) Feed water pump (Turbo) Lift pump Sodium Sulphite dozing unit PO4 dozing unit PIPES, FITTINGS & VALVES Pipe, Pipe Fittings, control valves, non-return valves and safety valves of suitable size/quantity for: - Heat recovery system. - For connecting the existing steam network 01 01 02 01 02 02 02 Set " " " " " " 01 No. 01 " Auto/manual

2.9

Control System must be of the latest version make USA/ 01 " European/ Japanese

1/3

Page | 29

3. 3.1

FUEL Exhaust gas quantity generated from combined flue gases of existing Wartsila Gas Genset (5 x 2 MW, current load of 7-8MW), and power plant to be procured comprising of Gas Genset (2 x 4 MW), fired on Natural Gas. EXHAUST SYSTEM Exhaust gas ducting (from gensets to proposed waste heat boiler) Insulation of Exhaust gas ducting & pipelines Exhaust gas stack Motorized damper control system through PLC with the provision of manual control system, for exhaust gases of each Genset and main duct, alongwith safety relief valve to protect the Gensets and boiler. 01 01 01 01 Set

4. 4.1 4.2 4.3 4.4

5. 5.1 5.2 5.3 5.4 6. 6.1 6.2 6.3 7. 7.1

STEEL STRUCTURE Steel Steel Steel Steel structure structure structure structure for for for for auxiliary equipments exhaust duct supports piping supports plate form and ladder 01 01 01 01 Set

FLOW METERS (DIGITAL TYPE) Steam Flow Meter Flue Gas Flow Meter Feed Water Flow Meter SPARE PARTS Two years recommended spares with cost of each spare alongwith firms complete addresses and a guarantee for provision/supply of the required spare for at least a period of the 10-years. TOOLS & TACKLES Complete tool and tackles kits for maintenance of boiler including tube expanders, flexible shaft alongwith pneumatic motor. 2/3

Page | 30

01 No. 01 01

8. 8.1

9. 9.1 9.2

DOCUMENTATION IN ENGLISH VERSION Four sets of each of the following: Operation Manual Maintenance Manual, Including Complete Trouble Shooting Instructions. Electrical Mechanical Control System Complete Installation and erection drawings. Schematic diagrams alongwith components values, detailed circuit diagrams of PCBs alongwith trouble shooting procedures. Recommended spares parts list.

9.3 9.4 9.5

10. 10.1 10.2 10.3 10.4 10.5

DOCUMENTS REQUIRED FOR REGISTRATION OF BOILER AS PER BOILER ACT Boiler manufacturing drawing duly attested by 3rd party. Stress relieving certificates. X-Ray and Ultra Sound Certificate. Inspection Certificates Comprising of Hydraulic Test. Material Testing Certificate.

PAKISTAN

Page | 31

Vous aimerez peut-être aussi

- Projest Report On 4 Week Industrial Training at 66kv Substation (MES) (Bathinda)Document70 pagesProjest Report On 4 Week Industrial Training at 66kv Substation (MES) (Bathinda)ਮਨਪ੍ਰੀਤ ਸਿੰਘ ਸ਼ੇਰਗਿੱਲ100% (1)

- VC 100-BU Voltage Regulator Operating InstructionsDocument34 pagesVC 100-BU Voltage Regulator Operating InstructionsshanthikumaravelPas encore d'évaluation

- EnglishDocument144 pagesEnglishmxnoxn100% (1)

- TE No. 0394-SJL-LP-51Document6 pagesTE No. 0394-SJL-LP-51Khalil AsgharPas encore d'évaluation

- POF Tender for Indigenous SuppliesDocument6 pagesPOF Tender for Indigenous SuppliesKashanPas encore d'évaluation

- POF Tender for Indigenous SuppliesDocument7 pagesPOF Tender for Indigenous SuppliesKashanPas encore d'évaluation

- T.E.No.0266-LP-SJL-53Document6 pagesT.E.No.0266-LP-SJL-53Irfan AhmedPas encore d'évaluation

- Detailed Experiment by RCDocument7 pagesDetailed Experiment by RCastc.rawalpindiPas encore d'évaluation

- 0306 SJL FP&LP 41Document8 pages0306 SJL FP&LP 41Rizwan RathorPas encore d'évaluation

- GPETRO Scope TenderDocument202 pagesGPETRO Scope Tendersudipta_kolPas encore d'évaluation

- Government of Pakistan Pakistan Ordnance Factories Tender EnquiryDocument6 pagesGovernment of Pakistan Pakistan Ordnance Factories Tender EnquiryRawal Chemical ComplexPas encore d'évaluation

- 5 Tonne Single Girder Electric Operated Overhead CraneDocument8 pages5 Tonne Single Girder Electric Operated Overhead CranesauravPas encore d'évaluation

- Tamil Nadu Electricity BoardDocument5 pagesTamil Nadu Electricity BoardDeepak KumarPas encore d'évaluation

- Nalco 8100005766Document4 pagesNalco 8100005766Amarendra PattnaikPas encore d'évaluation

- Visakhapatnam PDFDocument23 pagesVisakhapatnam PDFD.D.SharmaPas encore d'évaluation

- RFP for Supply of Track Assembly for T-72 TanksDocument4 pagesRFP for Supply of Track Assembly for T-72 TanksPunj CorpPas encore d'évaluation

- HTLT TenderDocument74 pagesHTLT TenderRamesh AnanthanarayananPas encore d'évaluation

- Tech Specficiation LED Flood LightDocument16 pagesTech Specficiation LED Flood LightAnant NimjePas encore d'évaluation

- Tender NO.13-Supply, Installation, - Commissioning and Testing of Diesel Generator 100 KW-Technical BidDocument16 pagesTender NO.13-Supply, Installation, - Commissioning and Testing of Diesel Generator 100 KW-Technical BidAbdul MoezPas encore d'évaluation

- Check List For Commercial Terms: CL-E-R02-07-08-2020Document3 pagesCheck List For Commercial Terms: CL-E-R02-07-08-2020rafikul123Pas encore d'évaluation

- 01 Balance Work of 6 Roomed Additional Accommodation at High School Achabal AccommodationDocument6 pages01 Balance Work of 6 Roomed Additional Accommodation at High School Achabal AccommodationShabir TrambooPas encore d'évaluation

- C VDocument32 pagesC VASHISH CHAURASIAPas encore d'évaluation

- MSA Speed Boats Oct 2023Document7 pagesMSA Speed Boats Oct 2023seasonalexportpkPas encore d'évaluation

- 1547720046 (1)Document23 pages1547720046 (1)yawar ayub MughalPas encore d'évaluation

- Construction of Badminton Court Near MDC.: WWW - Iimk.ac - inDocument54 pagesConstruction of Badminton Court Near MDC.: WWW - Iimk.ac - inBhisham DevPas encore d'évaluation

- University of Wah Wah Engineering College Assignment # 06Document11 pagesUniversity of Wah Wah Engineering College Assignment # 06HAMZA KHANPas encore d'évaluation

- Table Cover Linen.Document11 pagesTable Cover Linen.Muhammad HanirPas encore d'évaluation

- Pakistan International Airlines: REF: PIACL/1.5-AC/2020Document4 pagesPakistan International Airlines: REF: PIACL/1.5-AC/2020Roma KhanPas encore d'évaluation

- Only For Oem/ Authorized Dealers/Open MarketDocument4 pagesOnly For Oem/ Authorized Dealers/Open MarketBhupender SinghPas encore d'évaluation

- My HW Tender No. 25)Document9 pagesMy HW Tender No. 25)Taha MuhammadPas encore d'évaluation

- Phone + 91 040 24220765 FAX: +91 040 24220765Document7 pagesPhone + 91 040 24220765 FAX: +91 040 24220765Suresh KumarPas encore d'évaluation

- Tendernotice - 1 - 2021-07-24T144150.183Document4 pagesTendernotice - 1 - 2021-07-24T144150.183Bhupender SinghPas encore d'évaluation

- DTU Tender for Biomethanation ProjectDocument21 pagesDTU Tender for Biomethanation ProjectAjay Iyer100% (1)

- Ctorarde: Armament Research Development EstablishmentDocument7 pagesCtorarde: Armament Research Development EstablishmentGautam RanganPas encore d'évaluation

- 44pia1110 2610Document4 pages44pia1110 2610Mustafa ChowdriPas encore d'évaluation

- RFP-SBD - Kpra - CirDocument18 pagesRFP-SBD - Kpra - CirNasir MasoodPas encore d'évaluation

- Ogdcl Eor TendersDocument47 pagesOgdcl Eor TendersgregPas encore d'évaluation

- 9 Terms and ConditionsDocument5 pages9 Terms and ConditionsManoj PatelPas encore d'évaluation

- Prices in INRDocument8 pagesPrices in INRRafea SalemPas encore d'évaluation

- Tender Document RO PlantDocument8 pagesTender Document RO PlantCareers SSPPas encore d'évaluation

- Tender Doc RFQ 2223 00128 FDocument6 pagesTender Doc RFQ 2223 00128 Fxovor75189Pas encore d'évaluation

- Limited Tender EnquiryDocument8 pagesLimited Tender EnquirysheriefmuhammedPas encore d'évaluation

- EAST CENTRAL RAILWAY Office of The Controller of Stores, Hajipur/Patna.Document21 pagesEAST CENTRAL RAILWAY Office of The Controller of Stores, Hajipur/Patna.Angela SanchezPas encore d'évaluation

- 0707 FDocument45 pages0707 FAnis BadshahPas encore d'évaluation

- Tender Ups Batteries - 2019-20Document21 pagesTender Ups Batteries - 2019-20Abhishek GadhwalPas encore d'évaluation

- National Institute of Fashion Technology, KolkataDocument9 pagesNational Institute of Fashion Technology, KolkatagbaludbPas encore d'évaluation

- Communication Network CentreDocument15 pagesCommunication Network Centreanuradha03Pas encore d'évaluation

- UntikdkDocument20 pagesUntikdkLikho GPas encore d'évaluation

- PGIMER Mortuary Upgradation TenderDocument38 pagesPGIMER Mortuary Upgradation TenderPhotostat CenterPas encore d'évaluation

- OCPPGEMATC_88e26027-700a-4702-87ce1713251728198_DYCLMOPUR_HQMCDocument10 pagesOCPPGEMATC_88e26027-700a-4702-87ce1713251728198_DYCLMOPUR_HQMCshivshetty.97Pas encore d'évaluation

- IIT Tender Equipment ChamberDocument6 pagesIIT Tender Equipment ChamberRaju PatilPas encore d'évaluation

- Special Conditions_Volleyball _Tech SpfnDocument8 pagesSpecial Conditions_Volleyball _Tech SpfnHQ NC 2Pas encore d'évaluation

- Pakistan Telecommunication Company Limited: Tender Notice TENDER NO. NTR-I/Tech-Pesh/100KVA-Transformers-NOD/2019-20/06Document7 pagesPakistan Telecommunication Company Limited: Tender Notice TENDER NO. NTR-I/Tech-Pesh/100KVA-Transformers-NOD/2019-20/06Riaz AhmadPas encore d'évaluation

- Pakistan Telecommunication Company Limited: Tender Notice TENDER NO. NTR-I/Tech-Pesh/100KVA-Transformers-NOD/2019-20/06Document7 pagesPakistan Telecommunication Company Limited: Tender Notice TENDER NO. NTR-I/Tech-Pesh/100KVA-Transformers-NOD/2019-20/06Riaz AhmadPas encore d'évaluation

- Delivery Schedule Payment Term Earnest Money/Security Money ClauseDocument8 pagesDelivery Schedule Payment Term Earnest Money/Security Money ClauseRuna BosuPas encore d'évaluation

- Transport Costing in KSRTCDocument4 pagesTransport Costing in KSRTCJaved ShaikhPas encore d'évaluation

- Alagappa University, Karaikudi: "Tender Ref - NoDocument6 pagesAlagappa University, Karaikudi: "Tender Ref - NoSam PeterPas encore d'évaluation

- Tender For The Supply and Delivery of Numerical Protection RelayDocument20 pagesTender For The Supply and Delivery of Numerical Protection RelayCm Tham (Facebook)Pas encore d'évaluation

- Enquiry Letter: by Regd. Post With AckDocument6 pagesEnquiry Letter: by Regd. Post With AckYuvan PrakashPas encore d'évaluation

- Hindustan ShipyardDocument16 pagesHindustan ShipyardSales Saraswati CablesPas encore d'évaluation

- General Terms and Conditions of The TenderDocument23 pagesGeneral Terms and Conditions of The TenderSrimathi RajamaniPas encore d'évaluation

- Adampur TenderDocument3 pagesAdampur TenderJaswinder SinghPas encore d'évaluation

- Protection Revision Notes OverviewDocument2 pagesProtection Revision Notes OverviewAmal PirzadaPas encore d'évaluation

- Cs 2Document3 pagesCs 2Amal PirzadaPas encore d'évaluation

- Variable Speed Drives EEEN-30039 Course SpecificationDocument26 pagesVariable Speed Drives EEEN-30039 Course SpecificationAmal PirzadaPas encore d'évaluation

- DraftDocument14 pagesDraftAmal PirzadaPas encore d'évaluation

- 2007 q4Document7 pages2007 q4Amal PirzadaPas encore d'évaluation

- Iec 61000-4-8-2009Document70 pagesIec 61000-4-8-2009Venkataramanan SPas encore d'évaluation

- Field Installation and IP 16-13-1 Testing of Electrical EquipmentDocument8 pagesField Installation and IP 16-13-1 Testing of Electrical EquipmentOrlando E Cabrera RojasPas encore d'évaluation

- Project Report Everest Power Pvt. LTD: (100 MW) Hydro-Electric Power Project Malana-2 Kullu, Himachal PradeshDocument44 pagesProject Report Everest Power Pvt. LTD: (100 MW) Hydro-Electric Power Project Malana-2 Kullu, Himachal PradeshmohitbiuPas encore d'évaluation

- DBR BTG ElectricalDocument67 pagesDBR BTG ElectricalParmeshwar Nath TripathiPas encore d'évaluation

- MotorPact CatalogueDocument84 pagesMotorPact CatalogueHung Cuong PhamPas encore d'évaluation

- Commissioning Tests for IDMT RelayDocument6 pagesCommissioning Tests for IDMT RelayVishal PatelPas encore d'évaluation

- New Report ON GSSDocument40 pagesNew Report ON GSSPadmakshiPas encore d'évaluation

- Data Sheet 7KM2112-0BA00-3AA0: ModelDocument8 pagesData Sheet 7KM2112-0BA00-3AA0: ModelClaudiu VlasceanuPas encore d'évaluation

- ABBACUS Metal Enclosed Capacitor Bank Technical SpecificationsDocument22 pagesABBACUS Metal Enclosed Capacitor Bank Technical SpecificationsGlenys MuñozPas encore d'évaluation

- High Set 1 (Is-HS1) & High Set 2 (Is-HS2) and Its Calculation - Electrical ConceptsDocument5 pagesHigh Set 1 (Is-HS1) & High Set 2 (Is-HS2) and Its Calculation - Electrical ConceptsAdam AbrahamPas encore d'évaluation

- SUBSTATIONDocument22 pagesSUBSTATIONAmrit Aggarwal100% (1)

- Principles of Overvoltage Protection and Insulation Coordination of Lines and Substations of PSE S.A.Document42 pagesPrinciples of Overvoltage Protection and Insulation Coordination of Lines and Substations of PSE S.A.Ayanangshu ChakrabartyPas encore d'évaluation

- Current Monitoring HandbookDocument39 pagesCurrent Monitoring HandbookmarquezgaunaPas encore d'évaluation

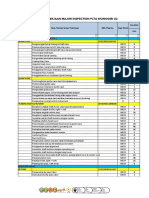

- RFQ JASA MAJOR INSPECTION PLTA WONOGIRI UNIT 2 - Untuk Penawaran Ke Vendor GeneratorDocument6 pagesRFQ JASA MAJOR INSPECTION PLTA WONOGIRI UNIT 2 - Untuk Penawaran Ke Vendor GeneratorEliyanto E BudiartoPas encore d'évaluation

- 7SR242 - Duobias Complete Technical ManualDocument292 pages7SR242 - Duobias Complete Technical ManualVishwanath TodurkarPas encore d'évaluation

- E-201 - One Line Electrical DiagramsDocument4 pagesE-201 - One Line Electrical DiagramsLAYTHMUNAFPas encore d'évaluation

- BS 00089-2-1990 (2000) en 60051-2-1989 (Iec 51-2-1984)Document18 pagesBS 00089-2-1990 (2000) en 60051-2-1989 (Iec 51-2-1984)clivePas encore d'évaluation

- Selecting CT ClassDocument4 pagesSelecting CT ClassdskymaximusPas encore d'évaluation

- TOL3Cab Three-Phase Thermal Overload Protection For Cables: 1MRS752328-MUMDocument23 pagesTOL3Cab Three-Phase Thermal Overload Protection For Cables: 1MRS752328-MUMrajeshPas encore d'évaluation

- Substation EquipmentsDocument62 pagesSubstation Equipmentskarikalan1100% (5)

- InternDocument69 pagesInternAMRUTHA VARSHINIPas encore d'évaluation

- Bus Duct WetownDocument24 pagesBus Duct WetownGiancarloEle100% (1)

- What Is The Difference Between 0.2 and 0.2S Class CT - QuoraDocument3 pagesWhat Is The Difference Between 0.2 and 0.2S Class CT - QuoraAnil MarturiPas encore d'évaluation

- Magneto-Optic Current TransformerDocument20 pagesMagneto-Optic Current TransformerSalil Kumar Gautam100% (1)

- NPAG CompleteDocument792 pagesNPAG CompleteTEMIDAYOPas encore d'évaluation

- 316Z-GREB-SP-E-82EN003-SIGNED.B - LV SWGR & MCC - Spec PDFDocument33 pages316Z-GREB-SP-E-82EN003-SIGNED.B - LV SWGR & MCC - Spec PDFMahmoud ChihebPas encore d'évaluation

- Spec of 11 KV Series Trip Metering Panel With VCBDocument21 pagesSpec of 11 KV Series Trip Metering Panel With VCBRakih SajidPas encore d'évaluation