Académique Documents

Professionnel Documents

Culture Documents

Scantling Calc 2007

Transféré par

nourtia_nilCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Scantling Calc 2007

Transféré par

nourtia_nilDroits d'auteur :

Formats disponibles

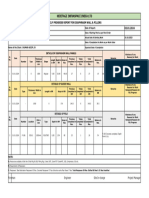

Scantling Calculation

Particulars Frame spacing a=0.5m Web frame spacing Length of ship Breadth of ship Draft Height Block coefficient Material factor for normal strength hull structure

Bottom shell plating Length coefficient Service coefficient Distribution factor CF = 1.0 Wave coefficient C0 for length L>90m for unlimited service range for midship

nf = 1.0 for Transverse framing = 0.83 for Longitudinal framing Permissible design stress perm = 230/K for L>90m

= 230/1.0 = 230 Probability factor = 1.0 for shell plating

Basic external dynamic load p0 = 2.1 X(CB+ 0.7)X C0 X Cl X f = 2.1 X(0.6 + 0.7)X 7.92 X 1X 1 = 21.62 Maximum bottom design hull girder bending stress LB = 120/k

= 120/1 = 120 Maximum design shear stress due to longitudinal hull girder bending pl

Vertical distance of the structure load centre from base line z = 3.6485 m Load on sides

External load on ships bottom

Corrosion addition tK

for thickness <10mm

The thickness of bottom plating should not be less than the greater of the two following values

Or,

So we take the thickness of our bottom plate as Flat keel plating The thickness of flat plate keel should not be less than

So we take the thickness of our flat plate keel as Bilge plating We take the thickness of our bilge plate as Side shell plating The thickness of the side shell plating should not be less than the greater of the two following values

Or, (In this case p = pS)

So we take the thickness of our side shell plating as Dimension of centre girder The depth of the centre girder should not be less than

So we take the depth of centre girder as The web thickness of the centre girder should not be less than

So we take the thickness of centre girder as Hence the dimension of the centre girder is Dimension of side girder The web thickness of the side girder should not be less than

So we take the thickness of side girder as Hence the dimension of the side girder is Thickness of floor plating The thickness of plate floors is not to be less than

So we take the thickness of floor plating as Thickness of inner bottom plating The thickness of inner bottom plating should not be less than

(In this case

So we take the thickness of inner bottom as Dimension of main frame Length of unsupported span Maximum height of curve s = 0 for L>90m Factor for curved frames for main frame

Here,

The section modulus of main frame should not be less than

(In this case

So we take the section modulus of main frame as Hence the dimension of the main frame L-section is

Dimension of web frame Web frame spacing The section modulus of web frames should not be less than

So we take the section modulus of web frame as Hence the dimension of the web frame T -section is Dimension of side stringer We take the dimension of side stringer same as that of the web frame Hence dimension of the side stringers are Dimension of deck beam Vertical distance of the load centre of the structure above base line The load on weather deck,

Length of unsupported span for beams and girders The section modulus of deck beam should not be less than

(In this case

So we take the section modulus of deck beam as Hence the dimension of the deck beam L-section is

Dimension of deck girder The section modulus of deck girder should not be less than

(In this case

So we take the section modulus of deck girder as Hence the dimension of the deck girder T-section is Dimension of deck web The section modulus of deck girder should not be less than

(In this case

So we take the section modulus of deck girder as Hence the dimension of the deck girder T-section is Thickness of deck plate The speed of ship for midship So,

Hence acceleration addition

Mean deck height Static load on cargo

So, The load on cargo deck

The plate thickness of deck plate should not be less than

So we take the thickness of deck plate as Dimension of brackets Here for bottom frames

Unsupported span The section modulus of bottom and inner bottom frames should not be less than

For flanged bracket The thickness of the bracket should not be less than

So we take the thickness of the brackets as Now

The arm length of brackets should not be less than

So we take the arm length of bracket as Dimension of longitudinals We have

Unsupported span Hence

0.783 Again

.245 Now

Here And assuming

The section modulus of bottom longitudinal should not be less than

So we take the section modulus of bottom longitudinal as Hence the dimension of the bottom longitudinal is In case of side shell Unsupported span The section modulus of side longitudinal should not be less than

So we take the section modulus of side longitudinal as Hence the dimension of the side longitudinal is Thickness of bulkhead plating: Here We, assume So, Spacing of stiffeners Here, 4.4485m So, for bulkheads

The thickness of bulkhead plating should not be less than

So we take the thickness of transverse bulkhead as We also take the thickness of longitudinal bulkhead as Dimension of stiffeners: Here

The section modulus of stiffeners should not be less than

So we take the dimension of the stiffener as Dimension of stem The cross-sectional area of bar stem should not be less than

So we take the cross-sectional area of bar stem as Hence the dimension of bar stem as we take is Keel plate width The width of flat keel plate should not be less than

So we take the width of flat keel plate as Hence the half width of flat keel plate as we take is Shear strake width The width of shear strake should not be less than

So we take the width of shear strake as The thickness of shear strake should not be less than the greater of the following two values

Or,

So we take the thickness of the shear strake as

Vous aimerez peut-être aussi

- Final Scantling CalculationDocument15 pagesFinal Scantling CalculationAnonymous SiA1p78SUPas encore d'évaluation

- Inclining Experiment Catamaran ReportDocument24 pagesInclining Experiment Catamaran ReportFrankiePas encore d'évaluation

- Calculation (Midship) of ShipDocument24 pagesCalculation (Midship) of ShipSarath Babu S100% (7)

- Scantling Calculation 1031Document9 pagesScantling Calculation 1031ShifatMahmudRumman100% (5)

- 08 Freeboard Calculation - SC4259 101 04Document5 pages08 Freeboard Calculation - SC4259 101 04parthiv_mechmind1987Pas encore d'évaluation

- Ship Hull DesignDocument66 pagesShip Hull DesignRiyan EsapermanaPas encore d'évaluation

- Report Project (Scantling)Document19 pagesReport Project (Scantling)FrankiePas encore d'évaluation

- Rudder CalculationDocument8 pagesRudder CalculationGerard SargPas encore d'évaluation

- Scantling CalculationsDocument70 pagesScantling Calculationsjrladdu100% (4)

- SEO-Optimized Power and Speed Calculations for Basic ShipDocument92 pagesSEO-Optimized Power and Speed Calculations for Basic Shiptyagimohit228Pas encore d'évaluation

- Scantling of ShipDocument84 pagesScantling of ShipVignesh Muthusamy0% (1)

- Inclining Test Procedure-ExampleDocument28 pagesInclining Test Procedure-Exampletalabiz50% (2)

- Still Water BM and SFDocument5 pagesStill Water BM and SFpothirajkalyanPas encore d'évaluation

- ScantlingDocument39 pagesScantlingSky R100% (1)

- General ArrangementDocument33 pagesGeneral Arrangementapi-27176519100% (16)

- Freeboard CalculationDocument45 pagesFreeboard CalculationgksahaPas encore d'évaluation

- Scantling 161001223025Document8 pagesScantling 161001223025Hoang Tien Dung100% (1)

- Rudder DesignDocument11 pagesRudder Designnawan67% (3)

- Lecture NotesDocument32 pagesLecture NotesSree Harsha Penugonda100% (1)

- Methods of Longitudinal Weight DistributionDocument24 pagesMethods of Longitudinal Weight DistributionWafaà WafaPas encore d'évaluation

- Analysis and Design of Ship StructureDocument76 pagesAnalysis and Design of Ship Structureapi-26548846100% (3)

- Longitudinal Strength Calculation Report for MV. MUJUR 1Document50 pagesLongitudinal Strength Calculation Report for MV. MUJUR 1Awwalin Bocah Ilang100% (1)

- Scantling CalculationDocument19 pagesScantling CalculationBarnil Samiu100% (1)

- Scantling Calculation GuideDocument33 pagesScantling Calculation GuideDominic VillamantePas encore d'évaluation

- Calculation & Assignment of FreeboardDocument26 pagesCalculation & Assignment of Freeboardapi-26251207100% (7)

- Freeboard CalculationDocument11 pagesFreeboard CalculationAhmad Riadus100% (2)

- Stability StandardDocument78 pagesStability StandardJORGE ARTURO TORIBIO HUERTAPas encore d'évaluation

- Parametric Modelling of Hull Form For Ship Optimization: Filipa Marques SanchesDocument106 pagesParametric Modelling of Hull Form For Ship Optimization: Filipa Marques SanchesTarafder Md ShahjadaPas encore d'évaluation

- AASHTO LRFD 2012 BridgeDesignSpecifications 6th Ed (US)Document126 pagesAASHTO LRFD 2012 BridgeDesignSpecifications 6th Ed (US)Jessie F. SermanPas encore d'évaluation

- PDFDocument6 pagesPDFdeepak16051988Pas encore d'évaluation

- FreeboardDocument12 pagesFreeboardRodneyPas encore d'évaluation

- Rules and Regulations For The Construction and Classification of Inland Waterways Ships - 1997Document21 pagesRules and Regulations For The Construction and Classification of Inland Waterways Ships - 1997suresh kumarPas encore d'évaluation

- Holtrop & Mennen - An Approximate Power Prediction MethodDocument6 pagesHoltrop & Mennen - An Approximate Power Prediction Methodjimmyy90100% (2)

- Scantling Calculation Design CheckDocument6 pagesScantling Calculation Design CheckShyamshesha GiriPas encore d'évaluation

- ShipConstructor Training OutlineDocument9 pagesShipConstructor Training OutlineluyogyiPas encore d'évaluation

- Series 60Document318 pagesSeries 60Mahdi100% (2)

- Naval Architecture Equation Summary SheetDocument11 pagesNaval Architecture Equation Summary SheetAnonymous JSHUTpPas encore d'évaluation

- BOLLARD PULL TRIAL CODE FOR TUGS WITH STEERPROP PROPULSORSDocument12 pagesBOLLARD PULL TRIAL CODE FOR TUGS WITH STEERPROP PROPULSORSKimcuong LePas encore d'évaluation

- MV LaviniaDocument227 pagesMV LaviniaDominic VillamantePas encore d'évaluation

- Shell Plate Guide for Ship DesignersDocument45 pagesShell Plate Guide for Ship DesignersRed Ignacio100% (6)

- FPPT_AEW before travelDocument5 pagesFPPT_AEW before travelYe Win ThantPas encore d'évaluation

- Ship Design Reference GuideDocument5 pagesShip Design Reference Guidepraveench1888Pas encore d'évaluation

- A Guide to Ship Repair Estimates in Man-hoursD'EverandA Guide to Ship Repair Estimates in Man-hoursÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Commercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysD'EverandCommercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Ships & Shipbuilders: Pioneers of Design and ConstructionD'EverandShips & Shipbuilders: Pioneers of Design and ConstructionPas encore d'évaluation

- Marine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsD'EverandMarine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- A Boat Builder's Guide to Hull Design and Construction - A Collection of Historical Articles on the Form and Function of Various Hull TypesD'EverandA Boat Builder's Guide to Hull Design and Construction - A Collection of Historical Articles on the Form and Function of Various Hull TypesPas encore d'évaluation

- Beginner's Guide To Fabric PaintingDocument38 pagesBeginner's Guide To Fabric Paintingsydneypsd100% (9)

- Dakater Bhaipo by Shirshendu MukhapadhayayDocument22 pagesDakater Bhaipo by Shirshendu Mukhapadhayaynourtia_nilPas encore d'évaluation

- Uponyas Ponchok by Bani BasuDocument129 pagesUponyas Ponchok by Bani Basunourtia_nilPas encore d'évaluation

- Morison EquationDocument8 pagesMorison Equationmailnewaz96770% (1)

- Gss DraftDocument178 pagesGss DraftzexonsmartPas encore d'évaluation

- William FroudeDocument2 pagesWilliam Froudenourtia_nilPas encore d'évaluation

- William FroudeDocument2 pagesWilliam Froudenourtia_nilPas encore d'évaluation

- Savitsky Brown 76Document20 pagesSavitsky Brown 76yauret123Pas encore d'évaluation

- Savitsky Brown 76Document20 pagesSavitsky Brown 76yauret123Pas encore d'évaluation

- IMO WorksDocument5 pagesIMO Worksnourtia_nilPas encore d'évaluation

- UNCLOS Defines Nations' Rights to OceansDocument3 pagesUNCLOS Defines Nations' Rights to Oceansnourtia_nilPas encore d'évaluation

- Calibration of TanksDocument3 pagesCalibration of Tanksnourtia_nilPas encore d'évaluation

- Is 1626 Part 3Document14 pagesIs 1626 Part 3Sheetal JindalPas encore d'évaluation

- Reinforced AAC Panel SpecificationsDocument12 pagesReinforced AAC Panel SpecificationswinsonecPas encore d'évaluation

- 2 Checklist For Structural Work (Pre-Pour)Document2 pages2 Checklist For Structural Work (Pre-Pour)alfie100% (1)

- ML-PRD01-EnG-CCAL-0113 - Rev 3 - Calculation Sheet For Pipe Support Wellpad ML-ADocument114 pagesML-PRD01-EnG-CCAL-0113 - Rev 3 - Calculation Sheet For Pipe Support Wellpad ML-AZukri EmailPas encore d'évaluation

- Recent Technology of Prestressed Concrete Bridges in Japan PDFDocument10 pagesRecent Technology of Prestressed Concrete Bridges in Japan PDFYuli Ana Fransisca SantanaPas encore d'évaluation

- Foundation Design Chapter 11Document85 pagesFoundation Design Chapter 11ES JoandreyPas encore d'évaluation

- Howe Truss ConceptDocument5 pagesHowe Truss ConceptMoly MuliyaniPas encore d'évaluation

- DESIGN OF STAIR FLIGHTS AND LANDINGS - XLSMDocument7 pagesDESIGN OF STAIR FLIGHTS AND LANDINGS - XLSMAbel MulugetaPas encore d'évaluation

- Steel Structure Final 1 PDFDocument50 pagesSteel Structure Final 1 PDFMesfinPas encore d'évaluation

- ABC-Draft - 03 Dated 18.07.13Document96 pagesABC-Draft - 03 Dated 18.07.13Ratul RanjanPas encore d'évaluation

- Technical Specification For Proposed OneDocument5 pagesTechnical Specification For Proposed OneAngel JinHiroPas encore d'évaluation

- Rilem TC 162-Tdf: Test and Design Methods For Steel Fibre Reinforced ConcreteDocument17 pagesRilem TC 162-Tdf: Test and Design Methods For Steel Fibre Reinforced ConcreteJaniele MoreiraPas encore d'évaluation

- Statically Indeterminate StructuresDocument9 pagesStatically Indeterminate StructuresAdam SalimiPas encore d'évaluation

- Structural inspection requirementsDocument720 pagesStructural inspection requirementsJohneal Matias80% (5)

- Seismic Performance of Steel-Encased Composite ColumnsDocument21 pagesSeismic Performance of Steel-Encased Composite ColumnsatyanPas encore d'évaluation

- Bar Bending Schedule of Box CulvertDocument1 pageBar Bending Schedule of Box CulvertrayPas encore d'évaluation

- Mto Pcj-3060-Ca (11-12-19) PDFDocument1 pageMto Pcj-3060-Ca (11-12-19) PDFOky Mahertwo Septian100% (1)

- Construction and Building Materials study compares concrete pipe typesDocument7 pagesConstruction and Building Materials study compares concrete pipe typesSafwat El RoubyPas encore d'évaluation

- Precast connection solutionDocument6 pagesPrecast connection solutionNaveen NunnaPas encore d'évaluation

- Design and Construction of Burj-Dubai 104Document11 pagesDesign and Construction of Burj-Dubai 104Selvam KaliamoorthyPas encore d'évaluation

- Irs CBC Loads & LcsDocument6 pagesIrs CBC Loads & Lcslakshmi1011Pas encore d'évaluation

- Daily Progress Report Diaphragm Wall Pilling BMRCL 01-01-2023Document1 pageDaily Progress Report Diaphragm Wall Pilling BMRCL 01-01-2023Rakshith MarichennaiahPas encore d'évaluation

- CP 114 1969 The Structural Use of RC in Bldgs (Metric)Document83 pagesCP 114 1969 The Structural Use of RC in Bldgs (Metric)lennylamPas encore d'évaluation

- Nanoshi Samajik SabhagrahDocument4 pagesNanoshi Samajik SabhagrahAkshay NaikPas encore d'évaluation

- Plastering ChecklistDocument2 pagesPlastering Checklistkeshav chaturvediPas encore d'évaluation

- A Report On Analysis and Design of Ongoing Project AT B. G. Shirke Construction Technology Pvt. LTDDocument4 pagesA Report On Analysis and Design of Ongoing Project AT B. G. Shirke Construction Technology Pvt. LTDdamle_neha247248Pas encore d'évaluation

- Design of Combined Footing For Two Columns: AAI PatnaDocument2 pagesDesign of Combined Footing For Two Columns: AAI PatnaShakil AkhterPas encore d'évaluation

- Behaviour and Stability of Double Coped Beam To Girder Connections Under Combined LoadingDocument12 pagesBehaviour and Stability of Double Coped Beam To Girder Connections Under Combined LoadingKLPas encore d'évaluation

- Detail A: STEEL BEAM (300x150x6.5x9)Document1 pageDetail A: STEEL BEAM (300x150x6.5x9)Aaris AdePas encore d'évaluation

- Composition and Testing of ConcreteDocument3 pagesComposition and Testing of ConcreteGerald CatiponPas encore d'évaluation