Académique Documents

Professionnel Documents

Culture Documents

Maintenance and Inspection of BTH Lifters

Transféré par

rpatel12Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Maintenance and Inspection of BTH Lifters

Transféré par

rpatel12Droits d'auteur :

Formats disponibles

Maintenance and Inspection of Below-the-Hook Lifting Equipment

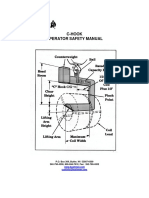

By the Bushman AvonTec Engineering Department Many of the C-hooks, coil grabs, tongs, and load beams used in the steel industry are among the least expensive components of the steel processing line. However, when the shipping dock stops loading coils because a coil grab ceased operation, or the furnace shuts down due to a cracked bushing in the linkage of the ingot tong, the equipment's cost takes on a new perspective. The purpose of this paper is to map out better maintenance and inspection techniques to help prevent inadvertent downtime of the line due to breakdowns of "Below-the-Hook" material handling equipment. C-hooks During Frequent Inspections, our inspectors first do a preliminary visual inspection of the entire C-hook to look for obvious problem areas: bail wear, bent bails, bent lower arm. They also ensure that the manufacturers nameplate and safety labels are attached. The next step would be to concentrate on visually looking for cracks at the crotch of the c-hook and verifying that the coil's inside edges are not gouging out metal from the crotch. One way to discover cracks visually is to look for cracking paint at the crotch that is not evident at other parts of the C-hook; many times the base metal will yield more than the hardened layer of paint on the surface. If there is any indication of contact between the coil and the crotch of the C-hook, a change in coil handling procedures is warranted. Continued contact of metal on metal at the crotch can create a site for crack initiation. The basic design of a C-hook creates a cyclic loading of the lifter, with the maximum load being concentrated at the crotch of the C-hook. These conditions set up the crotch of the Chook as a potential site for crack propagation and subsequent material failure. The next inspection would be to verify that the lower arm has not been bent so that it is out of parallel with the C-hook, or bent down because of excessive load on the lower arm. To determine if the lower arm is parallel with the rest of the assembly, we use a long straight edge and allow one to two percent of variance due to original manufacturing of the plate steel. To detect excessive loading on the C-hook, the inspector can measure the inside dimension between the upper part of the C-hook and the lower arm. More than a 1/2-inch variance would be considered unacceptable. The inspector should look for bail wear, gouging, and other discrepancies as previously discussed. A careful visual inspection of the welds that hold the bail to the base metal would be performed. The welds that hold the counterweights onto the C-hook will then be inspected; these are not usually structural welds, but failure of these welds could be hazardous to operators and equipment in the vicinity. Inspection of the saddle that the steel coil rests on is important to the economic handling of the coil, but is usually not a structural concern. Pads that may be applied on the nose of the C-hook or on the back vertical riser, revolving belts or other assemblies that protect the coil should be inspected. Each company should determine a quantifiable set point for allowable degradation of the protective surfaces that their maintenance department can use to determine when replacement is required.

Page1 www.BushmanAvonTec.com Sales@BushmanAvonTec.com

During Periodic Inspections, the same inspections as described above are performed and recorded for trending data. In addition, the following items are performed:

Dye-penetrant checks are performed at the lower and upper crotch of the C-hook. After removing paint, oil, and other debris, this non-destructive test should indicate no cracks in the base metal. Dye-penetrant checks are performed at all welds on the bail assembly (and bail pin if applicable.) After removing paint, oil, and other debris, this non-destructive test should indicate no cracks in the welds (or in the base metal of the pin.)

Maintenance on a C-hook is very limited by nature. Replacement of wear pads or other steel coil protective options is expected. Cleaning up the bail with very light grinding if "mushrooming" of the seating surface is evident would be advisable. (If this condition continues to occur, you may want to contact the manufacturer to determine a more appropriate seating surface configuration.) Welding on the C-hook should only be done after consulting with the manufacturer; many C-hooks are made from special alloys and require special welding procedures. No welding should be done on any portion of the lifter that had not been originally welded by the manufacturer. ANSI/AWS D14.1-97 "Specifications for Welding of Industrial and Mill Cranes and Other Material Handling Equipment" provides a section on Field Welding Repair and Modifications.

Bushman Equipment Coil Lifter with a Motorized Rotating Bottom Block

Motorized Coil Lifters During Frequent Inspections, our inspectors first do a preliminary visual inspection of the entire coil lifter to look for obvious problem areas: bail wear, smooth operation of the sliders, smooth rotation of the grab (if applicable,) all guards and stops are attached, and that the manufacturer's nameplate and safety labels are attached. Our next step is to check each of the safety features associated with the lifter. (A safety feature is defined as an interlock that prevents loss of control of the load.) Many coil lifters have a device that detects when a coil is engaged and simultaneously disables the ability of the grab to open

Page2 www.BushmanAvonTec.com Sales@BushmanAvonTec.com

the sliders. These safety features should be challenged without a load and verified that they work properly. One method is to compress the pad switches and attempt to open the grab; it should not open. If there are any indications that this safety feature does not work or has been tampered with, the lifter should be immediately tagged out of service until repairs can be made. Other interlocks that protect the coil should be checked including flappers or proximity sensors that prevent damaging the coils when the sliders are closed. Failure of these interlocks needs to be addressed individually, based on their relative importance to the protection of the coil. The structural components of the lifter can then be inspected. A visual inspection of the slider would include verifying the wear surfaces are properly greased and have no excessive gouges. The welds at the "knee" of the slider (the 90 turn when the slider becomes the vertical leg) should be checked for obvious cracks. The horizontal pad that the coil rests upon during handling should be checked for cracks at the crotch of the leg. Visual inspection of the welds that make up the attachment point between the lifter and the crane is necessary. Ensure the keeper bar for the bail pin is attached and the retaining devices are in working order. The bail pin or bail should be visually inspected as discussed in the previous section. Any weld cracks that are considered hazardous to the structural integrity of the lifter should warrant the lifter being tagged out of service until repairs can be made. Before the electrical inspection begins, all power should be disconnected at the source per ANSI Z244.1 "Personnel Protection Lockout/Tagout of Energy Sources" and the lifter verified as de-energized with a multi-meter. The first thing we check in our electrical inspection is the plug and cabling between the crane and the lifter. The plug and receptacle housings should have no cracks, and there should be no signs of wires sticking out of the plug or receptacle. Cord grips should be installed at the plug/receptacle and at the junction box on the grab to take off strain from the ends of the cable. Conversely, the pendent (if applicable) should be inspected and verified to ensure that the cable is not frayed, has proper cord grips, and the enclosure is not cracked or broken. A visual inspection inside the electrical controls enclosure should reveal no indications of burned or cracked wire insulation, foreign material lying at the bottom of the panel or obvious loose connections. Outside of the enclosure, the wiring to the sensors and motors should be inspected. Discrepancies to look for include frayed wires, sliced insulation, stretched or taut wires, discolored insulation or broken connectors. Any electrical discrepancy that is considered hazardous or violates the NFPA-70 National Electric Code should warrant the lifter being tagged out of service until repairs can be made. Once the lifter is reenergized, the pendent should be tested through all of its operations to verify that all controls function properly. The mechanical drive and rotation (if applicable) components should be inspected for wear and alignment. Verify the integrity of the bearings, chains, belts, couplings, clutches and other drive line components. Is there an obvious alignment problem or wear indications that would translate into failure? Are there any foreign materials or metal shavings near the drive components? Are the chains and belts properly adjusted? Check to see that greasing and lubrication of these moving components have been properly performed. Operate the drive system with the

Page3 www.BushmanAvonTec.com Sales@BushmanAvonTec.com

covers off and listen and watch for noises or irregularities that could indicate potential problems. During Periodic Inspections, the same inspections as above are performed and recorded for trending data. In addition, the following items are performed:

Dye-penetrant checks are performed at the crotch of the horizontal pad that the coil rests on. After removing paint, oil, and other debris, this non-destructive test should indicate no cracks in the base metal. Dye-penetrant checks are performed at all structural welds in the bail assembly and the knee of the sliders. After removing paint, oil, and other debris, this nondestructive test should indicate no cracks in the welds (or in the base metal of the pin.) Record the alignment of the bull gears in the drive components. Significant changes over time in angles between the bull gear and other drive components such as the gear rack may indicate unacceptable wear or potential bearing failure. Record the clear height (the distance from the horizontal pad that the coil rests on to the bottom of the lifter frame) as the sliders extend. Measure the clear height with the sliders closed and then when open. Most models experience a difference in the clear height in these two positions when the slider droops at their furthest extension. However, if this clear height sharply increases over time or the sliders hang up when fully extended, there is indication that the wear surfaces have excessive wear or other more serious structural problems may be occurring. Do the legs operate simultaneously? If your coil grab has a drive and idler side configuration, measure the difference between when the drive side starts movement and when the idler actuates. We use a pair of dial indicators to measure the difference in movement. If this difference sharply increases over time, bearing, chain, or belt failure may be indicated.

Some recommend maintenance practices include:

Coat teeth of rack and pinion with a product such as jet lube gear guard open gear lubricant. Lubricate sliders and slide ways using a product such as Benz oil moly alumaplex EP #2. Lubricate bearings and/or bushings as needed. For rotating coil lifters, inspect and lubricate the ring bearing per manufacturer instructions. Lubricate roller chains, bull gears, sprockets, etc. as needed. Many reducers have vent plugs that need to be cleaned per manufacturer instructions. (Verify that when the lifter was received at the plant, a solid-pipe-plug was not left in after the lifter was put into service at the plant.) Using a test load, adjust the clutch per manufacturer's instructions. Check the reducer or gear motor for proper oil levels. If the level is low, add proper lubrication through the filler plug until it comes out of the oil level plug; refer to the manufacturer's manual for the location of each plug. Are the reducer seals leaking? These seals are wear items and need replacing

Page4 www.BushmanAvonTec.com Sales@BushmanAvonTec.com

periodically. Replace wear pads or other steel coil protective options as needed. Adjust the chain or belt slack. We allow for approximately 2% slack.

Please consult with the coil lifter manufacturer for specific maintenance instructions and lubricants.

Bushman Equipment Tong Grab

Tong Grabs During Frequent Inspections, our inspectors first do a preliminary visual inspection of the entire tong grab to look for obvious problem areas; bail wear, smooth operation of the linkages and safety latch, all guards and stops are attached, and that the manufacturers nameplate and safety labels are attached. Then the following components are reviewed:

Inspect the bail and determine the loss of material that has occurred where the tong interfaces with the hook. (See previous section on Bail Wear.) Inspect the pins that connect the linkage of the tong. Are there wear indications? If there is more than 2 - 5% (obvious indentations in the pins), consult the manufacturer about replacement. Inspect the automatic latch. Ensure that there is no peening or wear at the interface between the piston and the catch. Are the pins that connect the linkage straight and round? We tend to see deformation of the pins before the links show signs of overloading. Are the retaining devices that hold the pins in place (collars, roll pins, cotter pins, etc.) intact and working properly? Are the bushings in good condition, or are they cracked and worn? Any indications of cracks should result in the lifter being tagged out of service until repairs can be performed. How much play or "slop" is in the linkage? This may indicate the retaining devices are worn or the bushings/bearings are worn. Are the legs of the tong straight, and do they meet in the center when the tong is closed? Bent linkages could indicate that the tong has experienced excessive loadings that have caused permanent yielding of the base metal (metal

Page5 www.BushmanAvonTec.com Sales@BushmanAvonTec.com

deformation.) These linkages should be replaced. Have any unauthorized modifications been performed on the tong? Are there any visual cracks of the linkages? Check fasteners, covers and stops to ensure they are properly attached. Operate the grab and verify that it works smoothly. Does the automatic (manual) latch work properly? Do the pads operate properly (swivel, rotate, if applicable)? Are the pads or points worn to the extent that they need replacement? It is important that these interface points are maintained since the gripping ratio or coefficient of friction that they create may be a basis of the original design. Contact the lifter manufacturer for allowable wear of these components.

Periodic Inspections would include documenting the same inspections described for the Frequent Inspections plus:

Dye-penetrant testing of the bail assembly. No crack indication is the criteria. Dye-penetrant testing of the pins that hold the linkages together. "No crack observed" is the minimum criteria that we find acceptable.

The simplicity of the tong grab leads to minimal maintenance requirements. One important item on the preventive maintenance program for a tong grab would be lubrication of the tong where there are sliding interface locations or where grease fittings are provided. Consult the manufacturer before lubricating your automatic latches; greasing some automatic latches might inhibit the piston movement and cause the latch to malfunction. Other items on the preventive maintenance program might be replacement of pads or points.

Bushman Equipment Spreader Beam

Lifting Beams Lifting beams come in many different configurations, but the inspection of them is very similar. The Frequent Inspection starts with a global review of the beam, looking for obvious material deformation, bent hooks, missing retaining pins, keeper bars, safety signs and manufacturer's labels. We would then inspect the hooks or attachment points of the load to the beam:

Are the hooks bent? If so, they need to be replaced.

Page6 www.BushmanAvonTec.com Sales@BushmanAvonTec.com

Are the pins that connect the "J" hooks or other lifting points to the beam in good condition? If there is more than 2 - 5% (obvious indentations), consult the manufacturer about replacement. For beams with adjustable lifting points or bails, we carefully inspect the mechanism that holds the assembly in position. Is there sufficient wear or degradation that would allow the assembly to slip out of position inadvertently during a pick? Are the pins or clips that hold the position in good condition? Are the shackles/links/hooks/slings in proper condition? Do they have the pins or other retaining devices to prevent the load from being released? Are they sized properly if they have been substituted from the original design?

Visually inspecting the lifting beam for obvious weld cracks or other signs of deformation would be the next step. Cracks in structural members would warrant the beam being tagged out of service until repairs can be made. Cracks in spacers or other non-load bearing members need to be evaluated to determine if they would be detrimental to the operation of the beam. The bail or bail pin between the crane and the beam should be inspected for obvious wear and excessive indentations as discussed in the Bail Wear section. If the lifting beam is made of channel, I-beams or other structural members, checking the straightness of the beam may indicate if the beam has been subjected to excessive forces or loads. A simple piece of string pulled taught along the edge of the structural member will quickly determine the difference in the camber and sweep of the lifter. Anything in excess of 3 out of alignment should be investigated. During Periodic Inspections, the same inspections as above are performed and recorded for trending data. In addition, the following items are performed:

Dye-penetrant checks are performed at the critical loading areas on all hooks or other members that connect the load to the beam. After removing paint, oil, and other debris, this non-destructive test should indicate no cracks in the base metal. Dye-penetrant checks are performed at all structural welds in the bail assembly and the beam. After removing paint, oil, and other debris, this non-destructive test should indicate no cracks in the welds (or in the base metal of the pin.)

Maintenance of a lifting beam is usually limited to replacement of protective pads, liners or hardware that attaches the load to the beam. On beams with adjustable bails or hooks, properly greasing the contact points would be advisable. Note that many lifting beams are motorized for rotation or other axis motions. If you have a motorized unit, many of the items covered in the motorized coil lifter section will pertain in this case including electrical safety, bearings, gears, clutches, reducers, etc. Conclusion The mill duty equipment found in the industry is usually designed for a severe duty cycle and minimal maintenance. The inspection criteria and maintenance procedures in this paper are what we at Bushman Equipment have found to be useful in maximizing the

Page7 www.BushmanAvonTec.com Sales@BushmanAvonTec.com

longevity of the lifting equipment. This is not intended to usurp the original manufacturer's recommendations or other regulatory authority. Although required by ASME standards, inspection of all lifting equipment is also a prudent maintenance procedure because it will improve the overall productivity of the manufacturing line. Maintaining a regular inspection and maintenance program on the lifters will help ensure a long useful life of the lifter and a better return on your investment. Reference 1 ASME B30.20 "Below-the-Hook Lifting Devices."

Page8 www.BushmanAvonTec.com Sales@BushmanAvonTec.com

Vous aimerez peut-être aussi

- Mutants & Masterminds 3e - Power Profile - Death PowersDocument6 pagesMutants & Masterminds 3e - Power Profile - Death PowersMichael MorganPas encore d'évaluation

- U 336380Document332 pagesU 336380Nguyễn Văn ĐiệpPas encore d'évaluation

- AZZ Galv Fab BookDocument27 pagesAZZ Galv Fab BookDaren NeradPas encore d'évaluation

- Aise - No 11 Standards - Pr-tr011-007Document11 pagesAise - No 11 Standards - Pr-tr011-007Tango Beltza100% (3)

- Discussion - Design Concepts For Jib CranesDocument2 pagesDiscussion - Design Concepts For Jib Cranesheitor29Pas encore d'évaluation

- Structural Inspection of Overhead Cranes (ILH Magazine Version)Document4 pagesStructural Inspection of Overhead Cranes (ILH Magazine Version)Gary J. Davis, P. E.Pas encore d'évaluation

- Tips For Heavy Lifting and Rigging EngineeringDocument23 pagesTips For Heavy Lifting and Rigging EngineeringmortezaheidarianPas encore d'évaluation

- Student Management System - Full DocumentDocument46 pagesStudent Management System - Full DocumentI NoPas encore d'évaluation

- Cranes Today March 2004 What To Look ForDocument3 pagesCranes Today March 2004 What To Look FordomsonengPas encore d'évaluation

- NSTS-08307 (Criteria For Preloaded Bolts)Document38 pagesNSTS-08307 (Criteria For Preloaded Bolts)ffontanaPas encore d'évaluation

- Enerpac CLRG Series CatalogDocument4 pagesEnerpac CLRG Series CatalogTitanplyPas encore d'évaluation

- Csa-G40 350WLRDocument2 pagesCsa-G40 350WLRMario VenturaPas encore d'évaluation

- C HookDocument11 pagesC HookPradip SitaparaPas encore d'évaluation

- Tong HookDocument8 pagesTong HookEricPas encore d'évaluation

- G DavitarmsDocument30 pagesG Davitarmsosvald97Pas encore d'évaluation

- Vishwanat Kanal, Vinod Nirale, Ravindra Kondaguli: Impact Factor: 1.479Document4 pagesVishwanat Kanal, Vinod Nirale, Ravindra Kondaguli: Impact Factor: 1.479divjak70Pas encore d'évaluation

- Crane Girder Camber - Industrial Lift & Hoist Jan 2014Document4 pagesCrane Girder Camber - Industrial Lift & Hoist Jan 2014Gary J. Davis, P. E.Pas encore d'évaluation

- Stainless Steel Laser Fused Universal Beams and ColumnsDocument8 pagesStainless Steel Laser Fused Universal Beams and ColumnsDushyantha JayawardenaPas encore d'évaluation

- Sherman - Extended Shear TabsDocument148 pagesSherman - Extended Shear TabsRohan KarandePas encore d'évaluation

- 2 Concept of Limit State DesignDocument3 pages2 Concept of Limit State DesignVinoth KumarPas encore d'évaluation

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDocument12 pagesThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelPas encore d'évaluation

- HSS CatalogueDocument56 pagesHSS CataloguenenmilPas encore d'évaluation

- Tolerances Monorail BeamDocument9 pagesTolerances Monorail BeamLuis MogrovejoPas encore d'évaluation

- Size RangeDocument15 pagesSize RangelucidbasePas encore d'évaluation

- TurnbucklesDocument2 pagesTurnbuckleschondroc11Pas encore d'évaluation

- Eot Crane During SeismicDocument12 pagesEot Crane During SeismicboyzesPas encore d'évaluation

- Hinge DesignDocument2 pagesHinge Designpare222Pas encore d'évaluation

- MonorailDocument14 pagesMonorailZain AndabloPas encore d'évaluation

- Connections I V2.1.0.a1Document49 pagesConnections I V2.1.0.a1gissel vicencioPas encore d'évaluation

- The Effect of Eccentricity On Brace-To-Gusset AnglesDocument6 pagesThe Effect of Eccentricity On Brace-To-Gusset AnglesAnonymous 7MdZQn10% (1)

- Sundriyal (2015) - Stress Analysis of Crane Hook With Different Cross Sections Using ANSYSDocument6 pagesSundriyal (2015) - Stress Analysis of Crane Hook With Different Cross Sections Using ANSYSGogyPas encore d'évaluation

- CJP & PJPDocument3 pagesCJP & PJPRobertBostanPas encore d'évaluation

- Overhead Crane Governing Bodies and Specs PDFDocument1 pageOverhead Crane Governing Bodies and Specs PDFscofiel1Pas encore d'évaluation

- 40 Ton Crane Tender DocumentDocument12 pages40 Ton Crane Tender DocumentJaay VelPas encore d'évaluation

- American Crane PDFDocument12 pagesAmerican Crane PDFJuan Carlos RuizPas encore d'évaluation

- 15.lattice (Cage) Beam Design and Finite Element Analysis of Gantry CraneDocument3 pages15.lattice (Cage) Beam Design and Finite Element Analysis of Gantry CraneravirajPas encore d'évaluation

- Ultimate Strength of Fillet Welded Connections Loaded in PlaneDocument13 pagesUltimate Strength of Fillet Welded Connections Loaded in PlanePatrick PolujanPas encore d'évaluation

- ANSI Standard A14.3-2000Document3 pagesANSI Standard A14.3-2000Jairo WilchesPas encore d'évaluation

- Load Dev Silo DesignDocument0 pageLoad Dev Silo Designuser 54Pas encore d'évaluation

- ANSI MH27.1-2003 Specifications For Patented Track StandardsDocument35 pagesANSI MH27.1-2003 Specifications For Patented Track StandardsDD3NZPas encore d'évaluation

- Design of Self Balanced Lifting TackleDocument56 pagesDesign of Self Balanced Lifting TackleDhanuPas encore d'évaluation

- OPSS 906 - Nov12Document20 pagesOPSS 906 - Nov12umerfr2Pas encore d'évaluation

- Cisc Vs AiscDocument11 pagesCisc Vs Aiscanon_326950184100% (1)

- Dynamic Design For AnchorsDocument44 pagesDynamic Design For AnchorshoustonhimselfPas encore d'évaluation

- Din 471 Ext CirclipsDocument5 pagesDin 471 Ext Circlipschaitanya_kumar_13Pas encore d'évaluation

- Lessons From Crane RunwaysDocument5 pagesLessons From Crane Runwaysdicktracy11Pas encore d'évaluation

- Gancho Tipo CDocument1 pageGancho Tipo CEricPas encore d'évaluation

- Below The Hook Lifting HanesDocument26 pagesBelow The Hook Lifting HanesmaomontesPas encore d'évaluation

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDocument75 pagesWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbiePas encore d'évaluation

- AISC 360-2010 PinDocument3 pagesAISC 360-2010 PinihpeterPas encore d'évaluation

- Problem 1-015 PDFDocument3 pagesProblem 1-015 PDFOscar SanchezPas encore d'évaluation

- Childers Insulation Products Selection GuideDocument8 pagesChilders Insulation Products Selection GuideAnonymous ynJByUs0% (1)

- En1991.1-Forklift LoadsDocument2 pagesEn1991.1-Forklift LoadsColin TanPas encore d'évaluation

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600Pas encore d'évaluation

- AISC Local Wheel Bending StressDocument2 pagesAISC Local Wheel Bending StressD SRINIVASPas encore d'évaluation

- Design of Main Girder (Compatibility Mode)Document58 pagesDesign of Main Girder (Compatibility Mode)Mohamed Azazy100% (1)

- Tips For Heavy Lifting AND Rigging Engineering: Inspection: 1Document25 pagesTips For Heavy Lifting AND Rigging Engineering: Inspection: 1pablodugalPas encore d'évaluation

- Roughter Crane ManualDocument33 pagesRoughter Crane ManualAbdul Majid Zulkarnain56% (9)

- Overhead CranesDocument50 pagesOverhead CraneshamzanusratPas encore d'évaluation

- Mechanical Overhaul Procedures For Hydroelectric Units: Facilities Instructions, Standards, and Techniques Volume 2-7Document58 pagesMechanical Overhaul Procedures For Hydroelectric Units: Facilities Instructions, Standards, and Techniques Volume 2-7anshikas_4100% (1)

- The Visual Inspection Includes Removal of Inspection Cover Plates As Necessary To Do A Thorough JobDocument6 pagesThe Visual Inspection Includes Removal of Inspection Cover Plates As Necessary To Do A Thorough JobBenjamin HidalgoPas encore d'évaluation

- Tateni Home Care ServicesDocument2 pagesTateni Home Care ServicesAlejandro CardonaPas encore d'évaluation

- ZultaniteDocument4 pagesZultaniteAcharya BalwantPas encore d'évaluation

- Company Profile RadioDocument8 pagesCompany Profile RadioselviPas encore d'évaluation

- Not Just Another Winter Festival: Rabbi Reuven BrandDocument4 pagesNot Just Another Winter Festival: Rabbi Reuven Brandoutdash2Pas encore d'évaluation

- HSE Induction Training 1687407986Document59 pagesHSE Induction Training 1687407986vishnuvarthanPas encore d'évaluation

- Bon JourDocument15 pagesBon JourNikolinaJamicic0% (1)

- FACT SHEET KidZaniaDocument4 pagesFACT SHEET KidZaniaKiara MpPas encore d'évaluation

- Sugar Industries of PakistanDocument19 pagesSugar Industries of Pakistanhelperforeu50% (2)

- Earnings Statement: Hilton Management Lane TN 38117 Lane TN 38117 LLC 755 Crossover MemphisDocument2 pagesEarnings Statement: Hilton Management Lane TN 38117 Lane TN 38117 LLC 755 Crossover MemphisSelina González HerreraPas encore d'évaluation

- Boylestad Circan 3ce Ch02Document18 pagesBoylestad Circan 3ce Ch02sherry mughalPas encore d'évaluation

- ReportDocument8 pagesReportTrust Asia Cargo in OfficePas encore d'évaluation

- Surefire Hellfighter Power Cord QuestionDocument3 pagesSurefire Hellfighter Power Cord QuestionPedro VianaPas encore d'évaluation

- AFI 90-901 Operational Risk ManagementDocument7 pagesAFI 90-901 Operational Risk ManagementJohan Lai100% (1)

- PDF - Unpacking LRC and LIC Calculations For PC InsurersDocument14 pagesPDF - Unpacking LRC and LIC Calculations For PC Insurersnod32_1206Pas encore d'évaluation

- Skylab Our First Space StationDocument184 pagesSkylab Our First Space StationBob AndrepontPas encore d'évaluation

- Modul9 VPNDocument34 pagesModul9 VPNDadang AbdurochmanPas encore d'évaluation

- Manual StereoDocument29 pagesManual StereoPeter Mac RedPas encore d'évaluation

- Solved SSC CHSL 4 March 2018 Evening Shift Paper With Solutions PDFDocument40 pagesSolved SSC CHSL 4 March 2018 Evening Shift Paper With Solutions PDFSumit VermaPas encore d'évaluation

- Project CharterDocument10 pagesProject CharterAdnan AhmedPas encore d'évaluation

- Atlantean Dolphins PDFDocument40 pagesAtlantean Dolphins PDFBethany DayPas encore d'évaluation

- Bus Organization of 8085 MicroprocessorDocument6 pagesBus Organization of 8085 MicroprocessorsrikrishnathotaPas encore d'évaluation

- Sorsogon State College: Republic of The Philippines Bulan Campus Bulan, SorsogonDocument4 pagesSorsogon State College: Republic of The Philippines Bulan Campus Bulan, Sorsogonerickson hernanPas encore d'évaluation

- College PrepDocument2 pagesCollege Prepapi-322377992Pas encore d'évaluation

- Referensi PUR - Urethane Surface coating-BlockedISO (Baxenden) - 20160802 PDFDocument6 pagesReferensi PUR - Urethane Surface coating-BlockedISO (Baxenden) - 20160802 PDFFahmi Januar AnugrahPas encore d'évaluation

- The Bipolar Affective Disorder Dimension Scale (BADDS) - A Dimensional Scale For Rating Lifetime Psychopathology in Bipolar Spectrum DisordersDocument11 pagesThe Bipolar Affective Disorder Dimension Scale (BADDS) - A Dimensional Scale For Rating Lifetime Psychopathology in Bipolar Spectrum DisordersDM YazdaniPas encore d'évaluation

- Odisha Block Summary - NUAGAONDocument8 pagesOdisha Block Summary - NUAGAONRohith B.NPas encore d'évaluation

- Bio Lab Report GerminationDocument10 pagesBio Lab Report GerminationOli Damaskova100% (4)

- BROADCAST Visual CultureDocument3 pagesBROADCAST Visual CultureDilgrace KaurPas encore d'évaluation