Académique Documents

Professionnel Documents

Culture Documents

The Design and Construction of Maize Threshing Machine

Transféré par

Abiodun GbengaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

The Design and Construction of Maize Threshing Machine

Transféré par

Abiodun GbengaDroits d'auteur :

Formats disponibles

AU J.T. 12(3): 199 -206 (Jan.

2009)

The Design and Construction of Maize Threshing Machine

Abdulkadir Baba Hassan, Matthew Sunday Abolarin, Olufemi Ayodeji Olugboji and Ikechukwu Celestine Ugwuoke

Department of Mechanical Engineering, Federal University of Technology Minna, Niger State, Nigeria Email: <abdulkadir_hassan2003@yahoo.com; abolarinmatthew@yahoo.com; olufem000@yahoo.com; ugwuokeikechukwu@yahoo.com >

Abstract

Many farmers grow maize but could not afford the cost of acquiring some of the imported threshing machines because of their cost. Such people resort to manual means of threshing which results into low efficiency, high level of wastage and exerting of much labor. This machine was constructed to shell maize and separate the cob from the grains. It was constructed from locally available materials and its cost is very low and affordable. Its threshing efficiency is 99.2% and breakage is very insignificant, as well as losses. Keywords: Hopper, shutter, threshing chamber, breakage, collector, wastage.

Introduction

Grains, according to Okaka (1997) are fruits of cultivated grasses belonging to the monocotyledonous family, Gramineae. The principal cereal grains of the world include wheat, barely, rye, sorghum, rice and maize. The last has become a popular staple in West Africa. Maize is another worlds most versatile seed crop. Its cultivation originated from Europe but was soon brought to Africa by explorers early in the sixteenth century. Within hundreds of years, it was well established as a staple food in areas around the north and south shores of Mediterranean Sea. In later years, maize cultivation spread widely into Africa down to Nigeria as well as many parts of Asia all at the same span of time. Its production in the southern states of the United States of America also expanded greatly just as it was in Africa and Asia (Adaokoma 2001). The use of sticks for threshing was predominant in the prehistoric era. In Egypt, livestock was earlier employed for threshing out grains after which it was winnowed. In Palestine, threshing sledge was used 3,000 years earlier. In Nigeria, maize was threshed originally by bare hands. Other popular method was the use of pestle and mortar. This method is still used in the rural areas today. The above methods became

Technical Report

unsatisfactory because of their low output, tediousness and their requirement of extra strength. According to Kaul and Egbo (1985), the performance of a thresher depends upon its size, cylinder speed, cylinder concave clearance, fan speed and the sieve shaker speed. Oni and Ali (1986) reported that the factors influencing threshability of maize in Nigeria are field drying, maize varieties, ear size cylinder speed and feed rate. The properties of the crop that affect the thresher performance are crop variety, shape and size, hardness of the seed, the moisture content of the seed and the density.

Design Analysis

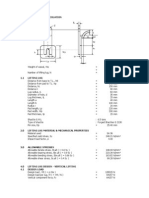

The Hopper The hopper (Fig. 1) is designed to be fed in a vertical position only. The material used for the construction is mild steel sheet metal, which is readily available in the market and relatively affordable. The hopper has the shape of a frustum of a pyramid truncated at the top, with top and bottom having rectangular forms. Calculation of the Overall Height Lengths AC and EG are calculated by 199

AU J.T. 12(3): 199 -206 (Jan. 2009)

using the Pythagorean theorem, AC 2 = AB 2 + BC 2. Also, AC = (AB 2 + BC 2)1/2, and OC = (AB 2 + BC 2)1/2/2, EG 2 = EH 2 + HG 2, EG = (EH 2 + HG 2)1/2, and MG = [(EH 2 + HG 2)/2]1/2.

P

The Threshing Bars Weight, W, of threshing bar is given by: W = mg, where: m = mass of threshing bar; g = acceleration due to gravity. Mass, m, of threshing bar: m = x V, where: = density of mild steel; V = volume of threshing bar. Volume, V, of threshing bar: V = l x b x h, where: 1 = length; b = breadth; h = height. Shaft Design A shaft is a rotating or stationary member, usually of circular cross-section having such elements as gears, pulleys, flywheels, cranks, sprockets and other power transmission elements mounted on it Shigley (1986). The shaft of this machine has a threshing tool attached to it (by welding) at two opposing sides and a pulley mounted on it. It is supported on bearings. Shaft design consists primarily of the determination of the correct shaft diameter to ensure satisfactory strength and rigidity when the shaft is transmitting power under various operating and loading conditions. Shafts are either solid or hollow. The following presentation is based on shafts of ductile materials and circular cross-section. The length of the shaft has been pre-determined at 770mm. Power Delivered By Shaft Power, P = work done per second: P = (work done)/time = (force x distance)/time = force x velocity. Calculation of Reactions RB and RD From Fig. 2: XT = total length of shaft; X = distance along the shaft; Wp = weight of the pulley; 200

F E H D G

Fig. 1. Schematic diagram of the hopper.

From the principle of similar triangles, for triangles PMG and POC: PM/MG = PO/OC, or PM = PO x MG/OC. Then the volume of the hopper is given by: Vhopper = [(area of base) x height]/3 = [(AB x BC) x h (EH x HG) x x]/3, where: h = overall height; x = height of the truncated top. The Main Frame The main frame supports the entire weight of the machine. The total weights carried by the main frame are: - weight of the hopper and housing; - weight of the threshing chamber; - the collector and pot; and - the bearings and pulleys. The two design factors considered in determining the material required for the frame are weight and strength. In this work, angle steel bar of 11/2 by 11/2 and 2mm thickness is used to give the required rigidity.

Technical Report

AU J.T. 12(3): 199 -206 (Jan. 2009)

T1 & T2 = tensions of belt.

w = angular velocity; r = radius of the arm of the threshing bar. To determine the mass, m, of the threshing bars: mass (m) = density () x volume (V), and volume (V) = length (L) x breadth (B) x thickness (t). Determination of Angular Velocity, The angular velocity, , is given by: = 2N/60, where: N = speed of the shaft in r.p.m. The Radius, r, of the Threshing Arm

Fig. 2. Distributed weights acting on the shaft at different sections of the shaft.

Taking moment about RB: sum of clockwise moments equal = sum of anticlockwise moments, i.e., (WP + T1 + T2)XT + Hx6 + Gx5 + Ex4 + Dx3 + Cx2 = RDx7, RD = [(WP + T1 + T2)XT + Hx6 + Gx5 + Ex4 + Dx3 + Cx2]/x7. But sum of upward forces = sum of downward forces: RD + RB = WP + T1 + T2 + C + D + E + G + H, RB = (WP + T1 + T2 + C + D + E + G + H ) RD. Calculation of the Shearing Force and Bending Moment of the Shaft at Different Sections of the Shaft Here: S.F. = upward forces downward forces; B.M = forces x perpendicular distances. Force Required to Thresh Maize along the Length of the Threshing Bars The threshing bars, which are attached to the shaft contained in the threshing chamber, rotate with the shaft, giving rise to centripetal force: F = m 2 r, where: F = centripetal force; m = mass of threshing bars;

Technical Report

The radius, r, of the threshing arm increases along the length of the shaft and also decreases towards the other end of the shaft, where: r = radius of threshing arm and it is given as rmax = 0.082m (assumed), rmin = 0.058m (assumed), so that centripetal force at rmax (F) = m2rmax, centripetal force at rmin (F) = m2rmin. Determination of Threshing Torque The torque, T, is given by: T = F x r, where: F = Force available along the threshing bar; r = threshing radius. Determination of Power Delivered by Shaft along the Length of Threshing Bars The power is given by power = energy/time = (work done)/time = (force x distance)/time = force x velocity, velocity = r, where: = angular velocity; r = radius. Therefore, power = Fr. Determination of Torsional Moment, MT The torsional moment, MT, is given by MT = 9,550 x KW/N, where: KW = power delivered; N = revolutions per minute. 201

AU J.T. 12(3): 199 -206 (Jan. 2009)

Determination Moment

of

Maximum

Bending

The maximum bending moment, Mbmax, is given by Mbmax = (MV 2 + MH 2)1/2. The Prime Mover The purpose of an electric motor is to develop the necessary power required for a task. The most common types of motors used for industrial purpose are: the squirrel cage induction motors where a continuous supply of power is required: and the split-ring induction motors being used for intermitted supply of power. The squirrel type motor has its current induced in the motor bars by induction thereby dispensing with commutators. For the purpose of this work, a squirrel induction motor is selected. The rating however will be determined by calculation results. Pulley i. Driver Pulley: Williams (1953), gives the horse power rating at a maximum pitch diameter of pulleys and the corresponding speeds. The horsepower rating of the electric motor will therefore determine the diameter of the driver pulley. ii. Driven Pulley: The spindle speed and the speed of the prime mover are related by the expression: N1D1 = N2D2, or N1/N2 = D2/D1, i.e., (speed of driver)/(speed of driven) = (diameter of driven)/(diameter of driver). The following factors determined the centre distance of pulleys:

Table 1. V-belt horse power*. Cross section A B C D E Load of drive (Kw) 0.75 5 2-15 7.5-75 22-50 30-190 Recommended min. pulley pitch diam., d (mm) 75 125 200 355 500

- the class of V-belt used; - the configuration of the machine; - the space available. However, the two pulleys must be near to each other. iii. Weight of Pulley: The weight of pulley on a shaft can be determined as follows: weight of pulley, WP = mg, with m = V, V = A x Lp = (d 2/4) x Lp, m = x (d2/4) x Lp, WP = x (d2/4) x Lpg, where: Lp = length of pulley. Belt Design A belt provides a convenient means of transferring power from one shaft to another. Belts are frequently necessary to reduce the higher rotational speeds of electric motors to lower values required by mechanical equipments (Spotts 1985). The belt driver relies on frictional effects for its efficient operation. When the belt connecting two pulleys is stationary, the tensions in the two portions of the belt are equal but when torque is applied to the driving pulley, one portion of the belt is stretched and the other portion becomes slack. The procedure for selecting a V-belt drive is dependent on the motor horse power and the speed (rpm) rating. V-belts are rated from class A to E (Table 1). The effective pull on belt: T = T1 T2, where: T1 = tension on tight side; T2 = tension on slack side; Torque, Ts, on shaft = F x r, and F = Ts/r.

Nominal top width, w (mm) 13 17 22 32 38

Nominal thickness, T (mm) 8 11 14 19 22

Weight per meter (kg f) 0.106 0.189 0.343 0.596

* Design data (PSG Tech 1989)

Technical Report

202

AU J.T. 12(3): 199 -206 (Jan. 2009)

But T = F and T = Ts/r. Also, Ts = TM, and T = TM/r. But PM = TM, and TM = PM/. Therefore, T = PM/(r), and MT = (T1 - T2)r1, where: T = effective pull on bell; F = Force on driver pulley; TS = torque on shaft; TM = Torque on the motor; r1 = radius of driver pulley; T1 - Tension on the tight side of belt; T2 = Tension on the slack side of belt; MT = Torsional moment. Power Transmitted by Belt According to Hannah and Stephens (1970), the power transmitted by belt is given by P = (T1 T2)V. But V = (DN)/60. Also, T1/T2 = exp( cosec ), where: = groove semi-angle; = angle of lap; = angle of contact at the smaller pulley; = coefficient of friction. The coefficient of friction for rubber belt on cast iron or steel operating on dry surface is = 0.3 (Ogunwede 2003). The angle of lap for open V-belt drive is given as: = (180 2) x /180 rad. Also, sin = (r2 r1)/x, where: x = distance between pulleys; r1 = radius of smaller pulley; r2 = radius of bigger pulley. Centre Distance of Belt The maximum centre distance of belt in use depends on the size of the two pulleys and is given as: Xmax = 2(D + d). Length of Belt Belt length can be calculated if the diameters of both the bigger pulley and the smaller pulley and the belt centre distance are known: L = 2x + (/2)(D + d) + (D d)2/(4x).

Technical Report

Groove Dimension The groove for pulleys has been standardized depending on the type of class of belt intended for use (Williams 1953). Classes of belts, pitch diameters of pulleys, and the groove angles have been listed out by Williams (1953). Determination of Minimum Diameter of Shaft Design of shafts of ductile material based on strength is controlled by maximum shear theory. Shafting is usually subjected to torsion, bending and axial loads. For a solid shaft having little or no axial loading, the ASME code equation is given as (ASME 1995): d 3 = [16/(Ss)] x [(KbMb)2 + (KtMt)2]1/2, where: d = diameter of the shaft; Mt = torsional moment; Mb = bending moment; Kb = combined shock and fatigue factor applied to bending moment; Kt = combined shock and fatigue factor applied to torsional moment; Ss = Allowable Stress. For rotating shafts, when load is suddenly applied (minor shock): Kb = 1.5 to 2.0; Kt = 1.0 to 1.5. For shaft without key-way: Ss (allowable) = 55MN/m2. For shaft with key-way: Ss (allowable) = 40MN/m2. A shaft with key-way was used for this work. Bending Stress According to Hall et al. (1988), for bending load, bending stress (tension or compression) is: Sb = Mbr/I. Hence, Sb = (32Mb)/(d 3), where: Sb = bending stress; Mb = bending moment; d = shaft diameter; I = moment of inertia. 203

AU J.T. 12(3): 199 -206 (Jan. 2009)

Also, I = d4/64, for a cylindrical shaft (PSG Tech 1989). Torsional Stress According to Black and Adams (1968), torsional stress is determined using xy = MT r/J. But J = d4/32, hence, xy = (16MT)/(d3), where: xy = Torsional stress N/m2; MT = torsional moment; r = radius of shaft; J = Polar moment of area; d = diameter of shaft. Torsional Rigidity Torsional rigidity of a shaft is based on permissible angle of twist. The amount of twist permissible depends upon the particular application and varies from 0.3 degree/m for a machine tools shaft to about 3 degree/m for line shafting as given by: = (584 MTL)/(Gd4), where: = angle of twist (degree); L = length of shaft (m); MT = torsional moment (Nm); G = Torsional modulus of rigidity (N/m2); d = diameter of shaft (m). Lateral Rigidity The lateral rigidity of a shaft is based upon the permissible lateral deflection for proper bearing operation, accurate machine tool performance, shaft alignment etc. Amount of deflection can also be calculated by two successive integrals of the formula: d2y/dx2 = (Mb)/(EI), where: Mb = bending moment N/m2; E = Modulus 'of elasticity (N/m2) ; I = Moment of inertia (m4). Shear Stress The shear stress on the shaft is determined by the formula below (Black and Adams 1968): = (16T)/(d3), where: = Shear stress N/m2;

Technical Report

T = Torque (Nm); d = Shaft diameter (m). Bearing Selection Bearing must be selected based on its load carrying capacity, life expectancy and reliability (PSG Tech 1989). The relationship between the basic rating life, the basic dynamic rating and the bearing load is: C = [L/L10]1/KP, or C/P = [L/L10]1/K, i.e., [C/P]K = L/L10, or L10 = [C/P]K/L. But L = 60n/106 million revolutions, therefore, L10 = (106/60n) x [C/P]K, where: L10 = life of bearing for 90% survival at one million revolutions; L = required life of bearing in million revolutions (mr); n = rotational speed (rev/min); C = basic dynamic load rating (N); P = equivalent dynamic bearing load (N); K = exponent for life equation with: K = 3 for ball bearing; K = 10/3 for roller bearing. Also, P = radial load + axial load, P = (XFr + YFa), where: X = radial load factor for the bearing; Y = axial load factor for the bearing; Fr = actual radial bearing load (N); Fa = actual axial bearing load (N). Table 2 shows the recommended life value in operation. It is assumed that this machine is designed to operate for 8 hours per day intermittently and whose breakdown will have serious consequences. The bearing life in operating hours is chosen to be 8,000.

Table 2. Recommended life value of bearings. Type of operation Infrequently operated Brief operation only Intermittent operation One shift operation Continuous operation Continuous operation with high production capacity

* Design data (PSG Tech 1989)

Life in operation 500 4,000-8,000 8,000-15,000 15,000-30,000 30,000-60,000 100,000

204

AU J.T. 12(3): 199 -206 (Jan. 2009) Table 3. Deep groove bearing selection factor. Bearing 6,406 6,407 6,408 6,409 Basic dynamic load, C (N) 3,350 4,300 5,000 5,850 Inner race max. diam., d (mm) 30 35 40 45 Outside diameter, D 90 100 110 120 Width, B 23 25 27 29 Max. speed, rpm 6,300 5,600 5,000 4,500

* Design data (PSG Tech 1989)

A deep grooved bearing will be used for this work due to its ability to withstand heavy radial loads at high speed (Table 3). Screen Purpose of the screen is to act as a separator between the threshed maize and the cobs. Screens are either woven-wire or plate with perforated round holes. The plate with perforations was selected for this work. This will allow threshed maize grains to escape into collector pot. Key The function of a key is to prevent relative rotation of a shaft and the member to which it is connected, e.g., hub of a gear, pulley or crank. Different types of keys are available, the choice of which is dependant on power requirements, tightness of fit, stability of connection and cost. For a light transmission, a set screw may be employed. But for this work, a flat key was adopted, as this is used where added stability is desired, e.g. machine tools. Proportion of a Key For a good result, the width of a key is made one-quarter the diameter of the shaft. The thickness of a key for equal strength of the key in failure by shearing of the key, and compression on the key may be determined by the corresponding allowable stresses in shear and compressions. The length of the key can be calculated as L = d/2 = 1.57d. The forces on the top and bottom of the key resist tipping of the key, and the force, F, between the side of the key and the key way in the hub is due to the resisting torque, T ': T ' = Fd/2 = FL/,

Technical Report

where: T ' = resisting torque; F = resisting force; d = diameter of shaft; L = length of key.

Design Calculation and Results

The average cylinder speed for high and efficient threshing output was estimated as 830 rpm. This cylinder speed was used as the basis for the calculation. Then: volume of hopper, V= 0.004797m3; overall height, H = 0.511m; mass required to thresh maize along the length of the threshing bars = 0.837 kg; angular velocity, = 86.92 rad/sec; maximum force available along the threshing arm, Fmax = 518.88N; threshing torque = 42.55Nm; power delivered by shaft along the length of threshing bars = 3.698KW; prime mover (electric motor) = 5Hp. According to Spotts (1985), for a 5 horse power motor and a speed of 870 rpm, the recommended minimum sheave pitch diameter is 3.8", which is equivalent to 96.52mm or 100mm diameter of pulley. For this range of speed, V-belt is the best. Referring to Table 2, a class B V-belt was selected for this work. According to Williams (1953), a groove angle of 38 was chosen for a pulley of 100mm diameter using class B V-belt. Then: weight of pulley, Wp = 10.01N; speed of driver pulley, N1 = 870 r.p.m; speed of driven pulley, N2 = 830 r.p.m; diameter of driver pulley, D1 = 100mm; diameter of driven pulley, D2 = 105mm; effective pull on belt, T = 518.9N; tension on tight side, T1 = 550.2N; tension on slack side, T2 = 31.33N; 205

AU J.T. 12(3): 199 -206 (Jan. 2009)

maximum centre distance of belt, Xmax = 102.5mm; length of belt, L = 537mm; reaction, RD = 647.9N; reaction, RB = -79.44, negative sign means one should reverse the direction of RB; maximum bending moment Mbmax = -50.25Nm; torsional moment, Mt = 42.55 Nm; maximum shear force = -87.43N, negative sign implies the direction of the force; shock and fatigue factor (bending moment), Kb = 1.5. Performance Test The completed work was subjected to test and it was found to thresh maize very effectively. Losses and breakages were found to be very negligible. The efficiency of the machine was found from the equation below to be equal to 99.2%: Efficiency = [(W1 W2)/W1] x 100, where: W1 = weight of unthreshed cobs; W2 = weight of cobs not well threshed.

Conclusion

Self-reliance is the major drive of development and vibrant economy. This machine has been fabricated with the use of locally available materials. The machine is simple, less bulky and effective with its selfcleaning ability. Grains loss and mechanical visible damage have been very minimal. Performance test has revealed that the efficiency of the machine is 99.2%. The machine threshes 200kg of maize within an hour. The machine can either be powered by an electric motor or engine (diesel or petrol). The electric motor seat provides adjustment so that the V-belt can be fixed easily. There is no doubt that the machine will ease the long term scourge of youth unemployment in our land.

References

Adaokoma, A. 2001. The design and fabrication of a multi-purpose grain

dehauler. M. Eng. Thesis, Department of Mechanical Engineering, Federal University of Technology (FUT), Minna, Nigeria. ASME. 1995. Design of Transmission Shafting. American Society of Mechanical Engineering, New York, NY, USA. Black, P.H.; and Adams, O.E., Jr. 1968. Machine design. 3rd ed. McGraw-Hill, New York, NY, USA. Hall, A.S.; Holowenko, A.R.; and Laughlin, H.G. 1988. Theory and problems of machine design. Shaums Outline Series, S.I. (metric) ed. McGraw-Hill, New York, NY, USA. pp. 113-4. Hannah, J.; and Stephens, R.C. 1970. Mechanics of machines: elementary theory and examples. Edward Arnold, London, England. Kaul, R.N.; and Egbo, C.O. 1985. Introduction to agricultural mechanization. Macmillan, London, England, UK. pp. 128-41. Ogunwede, O.I. 2003. Design and construction of plastic crushing machine. PGD Thesis, Department of Mechanical Engineering, Federal University of Technology (FUT), Minna, Nigeria. Okaka, J.C. 1997. Cereals and legumes: storage and processing technology. Nigeria Data and Microsystem Publishers, Enugu, Nigeria. pp. 47-53. Oni, K.C.; and Ali, M.A. 1986. Factors influencing the threshability of maize in Nigeria. Agricultural Mechanization in Asia, Africa and Latin America (AMA) 17(4): 39-44. PSG Tech. 1989. Design data. Faculty of Mechanical Engineering, Poolamedu Sathankulam Govindsamy Naidu College of Technology (PSG Tech), DPV Printers, Coimbatore, India. Shigley, J.E. 1986. Mechanical engineering design. S.I. (metric) ed. McGraw-Hill, New York, NY, USA. Spotts, M.F. 1985. Design of machine elements. 6th ed. Prentice Hall, Englewood Cliffs, NJ, USA. Williams, W.A. 1953. Mechanical power transmission manual. Conover-Mast Publ., New York, NY, USA.

Technical Report

206

Vous aimerez peut-être aussi

- Design and Fabrication of Groundnut Shelling MachineDocument17 pagesDesign and Fabrication of Groundnut Shelling Machinesasi100% (1)

- 12 (3) 8MaizeThreshing PDFDocument8 pages12 (3) 8MaizeThreshing PDFGuiiPas encore d'évaluation

- Career Episode 3Document7 pagesCareer Episode 3Nishar Alam Khan 19MCD0042Pas encore d'évaluation

- Design Consideration of Corn Sheller MachineDocument6 pagesDesign Consideration of Corn Sheller MachineIJIRST100% (2)

- Heat Exchanger FoundationDocument11 pagesHeat Exchanger FoundationLandon Mitchell100% (2)

- Design, Construction and Evaluation of Motorized Okra SlicerDocument8 pagesDesign, Construction and Evaluation of Motorized Okra SlicerBaba shehu Abba kyariPas encore d'évaluation

- Calculation Salim 1Document9 pagesCalculation Salim 1Abdullahi AwwalPas encore d'évaluation

- Phase 2.1Document13 pagesPhase 2.1Neil Allison Najorda CabilbilPas encore d'évaluation

- FLYWHEEELSDocument22 pagesFLYWHEEELSRex OabelPas encore d'évaluation

- Name: Aarsh Trivedi Roll No: 16BME176D Sub: MD 2 Case Study Topic: Worm GearDocument40 pagesName: Aarsh Trivedi Roll No: 16BME176D Sub: MD 2 Case Study Topic: Worm GearVirajPas encore d'évaluation

- Design Methodology of Garlic Peeling MachineDocument11 pagesDesign Methodology of Garlic Peeling MachineIJSTEPas encore d'évaluation

- Design of Gantry GirderDocument46 pagesDesign of Gantry GirderGOVINDARAJU SPas encore d'évaluation

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruPas encore d'évaluation

- Turning Moment Diagram & FlywheelDocument88 pagesTurning Moment Diagram & FlywheelAvinash Jayashankar100% (5)

- Development of Cassava Grating Machine - A Dual-Operational Mode From Leonardo JDocument6 pagesDevelopment of Cassava Grating Machine - A Dual-Operational Mode From Leonardo Jryxor-mrbl100% (1)

- EMDDocument23 pagesEMDPrakash ArumugamPas encore d'évaluation

- Design and Manuf of TribotesterDocument23 pagesDesign and Manuf of Tribotesterozoemena29Pas encore d'évaluation

- Manufacturing EnggDocument37 pagesManufacturing EnggChandrajit DeorePas encore d'évaluation

- Design and Construction of A Motorized TricycleDocument3 pagesDesign and Construction of A Motorized TricycleAlok Nath SharmaPas encore d'évaluation

- DomeDocument5 pagesDomemohamed AliPas encore d'évaluation

- Numerical Study On Performance of Curved Wind Turbine Blade For Loads ReductionDocument9 pagesNumerical Study On Performance of Curved Wind Turbine Blade For Loads ReductionCid CastroPas encore d'évaluation

- Design of ThrehsherDocument27 pagesDesign of ThrehsherMussage Virgilio SaidePas encore d'évaluation

- Development and Evaluation of A Motorized Peanut Shelling MachineDocument6 pagesDevelopment and Evaluation of A Motorized Peanut Shelling Machineumi fazaPas encore d'évaluation

- Design of Gantry GirderDocument28 pagesDesign of Gantry Girders_bharathkumar75% (12)

- Design and Fabrication of Model Feed PelletizerDocument5 pagesDesign and Fabrication of Model Feed PelletizerSh.nasirpurPas encore d'évaluation

- Crane Gantry Girder (BS5950 - Part1 - 2000)Document6 pagesCrane Gantry Girder (BS5950 - Part1 - 2000)sayed100% (1)

- Gantry CraneDocument18 pagesGantry Craneamirthraj7494% (16)

- Turning Moment Diagram & FlywheelDocument88 pagesTurning Moment Diagram & FlywheelAshishAgarwal100% (1)

- Sea Fastening Desig MannualDocument36 pagesSea Fastening Desig Mannualjamesmec20013588100% (2)

- Lifting LugDocument8 pagesLifting LugAzwan ShahPas encore d'évaluation

- Mechanics Ii Time Allowed: 2 HoursDocument8 pagesMechanics Ii Time Allowed: 2 HourssubipuruPas encore d'évaluation

- Bow Thruster CalculationDocument12 pagesBow Thruster CalculationHyoga Rio PratamaPas encore d'évaluation

- .Design and Development of Lat Pull Down Machine For Power Generation PDFDocument3 pages.Design and Development of Lat Pull Down Machine For Power Generation PDFMANISH SINGH IET Lucknow StudentPas encore d'évaluation

- Bme Exp 8Document3 pagesBme Exp 8Sanjay KajalPas encore d'évaluation

- Garg, Aamod. 'Gantry Girders in India' - IJCMES PDFDocument5 pagesGarg, Aamod. 'Gantry Girders in India' - IJCMES PDFAamod GargPas encore d'évaluation

- Van Benthuysen Adrian ReportDocument8 pagesVan Benthuysen Adrian Reportapi-299532402Pas encore d'évaluation

- Gantry GirderDocument25 pagesGantry GirderYash DhabaliaPas encore d'évaluation

- Velocity in the pipe = 2m/s Using the formula Diameter of penstock (Dm) = ( (4 ×Q m3/s) / (π ×Vm/s) ) = ( (4 ×0.15) / (π ×2) ) = 0.31mDocument4 pagesVelocity in the pipe = 2m/s Using the formula Diameter of penstock (Dm) = ( (4 ×Q m3/s) / (π ×Vm/s) ) = ( (4 ×0.15) / (π ×2) ) = 0.31mSujan JoshiPas encore d'évaluation

- Design and Fabrication of A Palm Kernel Oil Expeller MachineDocument8 pagesDesign and Fabrication of A Palm Kernel Oil Expeller MachineRicham HamzePas encore d'évaluation

- Slab Bridge DesignDocument73 pagesSlab Bridge DesignAmy MengistuPas encore d'évaluation

- Dynamic of Machine PDFDocument42 pagesDynamic of Machine PDFl8o8r8d8s8i8v8100% (1)

- Design of Electrical Machines NotesDocument24 pagesDesign of Electrical Machines Notesmadhes14Pas encore d'évaluation

- Presentation 2Document36 pagesPresentation 2parnitejuPas encore d'évaluation

- The International Journal of Engineering and Science (The IJES)Document6 pagesThe International Journal of Engineering and Science (The IJES)theijes100% (1)

- Sitti Al 2001Document8 pagesSitti Al 2001scribdcheeallePas encore d'évaluation

- Pressure Vessel and Stacks Field Repair ManualD'EverandPressure Vessel and Stacks Field Repair ManualÉvaluation : 4 sur 5 étoiles4/5 (4)

- Machine Design Elements and AssembliesD'EverandMachine Design Elements and AssembliesÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Mechanical Science for Technicians: Volume 1D'EverandMechanical Science for Technicians: Volume 1Évaluation : 5 sur 5 étoiles5/5 (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresD'EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresÉvaluation : 4 sur 5 étoiles4/5 (1)

- O level Physics Questions And Answer Practice Papers 2D'EverandO level Physics Questions And Answer Practice Papers 2Évaluation : 5 sur 5 étoiles5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume ID'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IPas encore d'évaluation

- Modeling of Complex Systems: Application to Aeronautical DynamicsD'EverandModeling of Complex Systems: Application to Aeronautical DynamicsPas encore d'évaluation

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesD'Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesPas encore d'évaluation

- On The Effectiveness of Watermelon Seeds As Coagulant For Removal of Turbidity and Colour in Beverage Industry WastewaterDocument2 pagesOn The Effectiveness of Watermelon Seeds As Coagulant For Removal of Turbidity and Colour in Beverage Industry WastewaterAbiodun GbengaPas encore d'évaluation

- Beverage Wastewater XteristicsDocument7 pagesBeverage Wastewater XteristicsAbiodun GbengaPas encore d'évaluation

- Coagulation-Flocculation Mechanisms in Wastewater Treatment Plants Through Zeta Potential MeasurementsDocument11 pagesCoagulation-Flocculation Mechanisms in Wastewater Treatment Plants Through Zeta Potential MeasurementsAbiodun GbengaPas encore d'évaluation

- Safe Bearing Capacity Values of Different Soils & Rocks - CivilblogDocument4 pagesSafe Bearing Capacity Values of Different Soils & Rocks - CivilblogAbiodun GbengaPas encore d'évaluation

- Treatment of Softdrink Industry Wastewater Using An Integrated Anaerobicaerobic Membrane BioreactorDocument154 pagesTreatment of Softdrink Industry Wastewater Using An Integrated Anaerobicaerobic Membrane BioreactorAbiodun Gbenga100% (1)

- A Review of Wastewater Management and Best Practices For Dischargers in The Food Processing SectorDocument279 pagesA Review of Wastewater Management and Best Practices For Dischargers in The Food Processing SectorAbiodun GbengaPas encore d'évaluation

- Federal Environmental Protection Agency ActDocument153 pagesFederal Environmental Protection Agency ActAbiodun GbengaPas encore d'évaluation

- Compliance Monitoring in Nigeria's IndustriesDocument5 pagesCompliance Monitoring in Nigeria's IndustriesAbiodun GbengaPas encore d'évaluation

- Effectiveness of Moringa Oleifera Coagulant Protein As Natural Coagulant Aid in Removal of Turbidity and Bacteria From Turbid WatersDocument3 pagesEffectiveness of Moringa Oleifera Coagulant Protein As Natural Coagulant Aid in Removal of Turbidity and Bacteria From Turbid WatersAbiodun GbengaPas encore d'évaluation

- Determination of TurbidityDocument12 pagesDetermination of TurbidityAkash SahuPas encore d'évaluation

- 5843 Trends in Water Use and Potable Water Limits in Beverage and Brewing IndustriesDocument24 pages5843 Trends in Water Use and Potable Water Limits in Beverage and Brewing IndustriesAbiodun GbengaPas encore d'évaluation

- A Comparative Study On Wastewater Treatment MethodsDocument5 pagesA Comparative Study On Wastewater Treatment MethodsAbiodun GbengaPas encore d'évaluation

- Effect of Industrial Effluent On The Surrrounding EnvironmentDocument8 pagesEffect of Industrial Effluent On The Surrrounding EnvironmentAbiodun GbengaPas encore d'évaluation

- 7 BiologicalDocument9 pages7 BiologicalDiya GhosalPas encore d'évaluation

- African BeverageDocument8 pagesAfrican BeverageAbiodun GbengaPas encore d'évaluation

- dk2041 FMDocument17 pagesdk2041 FMAnonymous VfH06fQXbAPas encore d'évaluation

- A Study On Industrial Waste Effluents and Their Management at Selected Food and Beverage Industries of BangladeshDocument5 pagesA Study On Industrial Waste Effluents and Their Management at Selected Food and Beverage Industries of BangladeshAbiodun GbengaPas encore d'évaluation

- Drinking Water QualityDocument7 pagesDrinking Water QualityAbiodun GbengaPas encore d'évaluation

- Alaro - Heavy Metals in Snail and Water Samples From Alaro River in IbadanDocument8 pagesAlaro - Heavy Metals in Snail and Water Samples From Alaro River in IbadanAbiodun GbengaPas encore d'évaluation

- 2,4 DTechDocument13 pages2,4 DTechAbiodun GbengaPas encore d'évaluation

- Alaro - Heavy Metals in Snail and Water Samples From Alaro River in IbadanDocument8 pagesAlaro - Heavy Metals in Snail and Water Samples From Alaro River in IbadanAbiodun GbengaPas encore d'évaluation

- Design ObjectivesDocument4 pagesDesign ObjectivesAbiodun GbengaPas encore d'évaluation

- Fundamental Aspects of Gaseous Breakdown-IDocument55 pagesFundamental Aspects of Gaseous Breakdown-IsnehithPas encore d'évaluation

- Space Charge in Solid DielectricsDocument55 pagesSpace Charge in Solid Dielectricssnehith100% (1)

- DK2041 10 PDFDocument39 pagesDK2041 10 PDFHassenLPas encore d'évaluation

- DK2041 09 PDFDocument36 pagesDK2041 09 PDFHassenLPas encore d'évaluation

- DK2041 05Document84 pagesDK2041 05Abiodun GbengaPas encore d'évaluation

- Absorption and Desorption CurrentsDocument47 pagesAbsorption and Desorption CurrentssnehithPas encore d'évaluation

- DK2041 07 PDFDocument54 pagesDK2041 07 PDFDivyanshu BhatnagarPas encore d'évaluation

- Dielectric Loss and Relaxation - IIDocument35 pagesDielectric Loss and Relaxation - IIsnehith100% (1)

- Reinforced Concrete Designers Handbook 10th Edition Reynolds Steedman 2 Part PrintDocument7 pagesReinforced Concrete Designers Handbook 10th Edition Reynolds Steedman 2 Part Printikanyu79Pas encore d'évaluation

- 2 Wheel Drive Forklift For Industry WarehouseDocument2 pages2 Wheel Drive Forklift For Industry Warehousesyed zakirPas encore d'évaluation

- Gilson Test-Master® Testing Screens TM-5 & TM-6: Operating ManualDocument21 pagesGilson Test-Master® Testing Screens TM-5 & TM-6: Operating ManualEduardo AcostaPas encore d'évaluation

- Conveyor PulleyDocument4 pagesConveyor Pulleyprashant mishraPas encore d'évaluation

- Lesson Plan: DOC / LP / 01 / 28.02.02Document10 pagesLesson Plan: DOC / LP / 01 / 28.02.02Jessy RenjithPas encore d'évaluation

- Basic Tech Note For Year 8 WK 2 Summer TermDocument5 pagesBasic Tech Note For Year 8 WK 2 Summer Termobumneame azukaPas encore d'évaluation

- Drilling Engineering SlidesDocument175 pagesDrilling Engineering SlidespppppPas encore d'évaluation

- Parts Guide Manual Fs-517 - Ao7rDocument57 pagesParts Guide Manual Fs-517 - Ao7rHugo Luis EscalantePas encore d'évaluation

- 3000 LR NSK Double - Row - Ball - BearingDocument40 pages3000 LR NSK Double - Row - Ball - BearingÇağlar AYKUTALPPas encore d'évaluation

- Design and Fabrication of Pneumatic Rotary Lifting MachineDocument18 pagesDesign and Fabrication of Pneumatic Rotary Lifting MachineAravind AravindPas encore d'évaluation

- Emergency StopDocument28 pagesEmergency StopipliprensPas encore d'évaluation

- Requirements For Transferees MidtermDocument30 pagesRequirements For Transferees MidtermKaren GedalangaPas encore d'évaluation

- Unit - III FrictionDocument40 pagesUnit - III FrictionTapaTap BOLTEPas encore d'évaluation

- Timing BeltDocument3 pagesTiming BeltEts VOATRA SY DINIKAPas encore d'évaluation

- V Semster 2018Document32 pagesV Semster 2018Sanjay CPas encore d'évaluation

- Test Bank For Physics For Scientists and Engineers 4th by KnightDocument27 pagesTest Bank For Physics For Scientists and Engineers 4th by Knightguyzunigaiadzrbpfes100% (23)

- Belt TensionDocument4 pagesBelt TensionMaulik Trivedi100% (1)

- hyundaiDCT CVTFDocument1 pagehyundaiDCT CVTFrajPas encore d'évaluation

- Belt, Rope and Chain Drives Denition: M Arshad Zahangir ChowdhuryDocument12 pagesBelt, Rope and Chain Drives Denition: M Arshad Zahangir ChowdhuryMelindaPas encore d'évaluation

- Frame Saw Manual 1902Document111 pagesFrame Saw Manual 1902wolf143Pas encore d'évaluation

- Booklet 17: Installation Instructions For SpiritDocument112 pagesBooklet 17: Installation Instructions For SpiritJaime MarchantPas encore d'évaluation

- Introduction Timing BeltDocument3 pagesIntroduction Timing BeltAmir ChipPas encore d'évaluation

- Inspection Report - 52NH1777Document8 pagesInspection Report - 52NH1777Tanush KumarPas encore d'évaluation

- Qdoc - Tips - Volvo Penta Installation ManualDocument53 pagesQdoc - Tips - Volvo Penta Installation ManualJorge GomezPas encore d'évaluation

- PulleyDocument9 pagesPulleypedropicapiedrantomePas encore d'évaluation

- Fabrication of Two Wheel Drive Forklift For IndustryDocument32 pagesFabrication of Two Wheel Drive Forklift For IndustryDinesh Kumar100% (1)

- Engineering Mechanics Practical 02 It Deals With The Verification of Law of Triangle of ForcesDocument3 pagesEngineering Mechanics Practical 02 It Deals With The Verification of Law of Triangle of ForcesAbdur Rasheed NiazyPas encore d'évaluation

- PC v01Document128 pagesPC v01traminerPas encore d'évaluation

- Power Transfer: 2.2 Velocity Ratio, Belt Tension 2.1 Belt Drive SystemDocument25 pagesPower Transfer: 2.2 Velocity Ratio, Belt Tension 2.1 Belt Drive SystemHamizan AzliPas encore d'évaluation

- Nissan RE0F11A - JATCO JF015E Manuel Bloc HydrauliqueDocument42 pagesNissan RE0F11A - JATCO JF015E Manuel Bloc Hydrauliquehakim dhaouadiPas encore d'évaluation