Académique Documents

Professionnel Documents

Culture Documents

Cnode Mini Inm A5 Size

Transféré par

craigleivDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cnode Mini Inm A5 Size

Transféré par

craigleivDroits d'auteur :

Formats disponibles

Instruction Manual

cNODE Mini Transponder

About this document

Rev D Date 30.03.2011 Written by IJG Checked by HAA Approved by SER

Updated manual with information about new Mini model 31-80V-D-St.

Copyright 2011 Kongsberg Maritime AS. All rights reserved. The information contained in this document remains the sole property of Kongsberg Maritime. No part of this document may be copied or reproduced in any form or by any means, and the information contained within it is not to be communicated to a third party, without the prior written consent of Kongsberg Maritime. Disclaimer Kongsberg Maritime endeavours to ensure that all information in this document is correct and fairly stated, but does not accept liability for any errors or omission. Warning The equipment to which this manual applies must only be used for the purpose for which it was designed. Improper use or maintenance may cause damage to the equipment and/or injury to personnel. The user must be familiar with the contents of the appropriate manuals before attempting to operate or work on the equipment. Kongsberg Maritime disclaims any responsibility for damage or injury caused by improper installation, use or maintenance of the equipment. Support

All Kongsberg Maritime products: Phone 24 hour: +47 815 35 355 E mail: km.support@kongsberg.com HiPAP, HPR, Transponder and ACS: Phone 24 hour: +47 992 03 808 E mail: km.support.hpr@kongsberg.com

Kongsberg Maritime AS

Strandpromenaden 50 P.O.Box 111 N-3191 Horten, Norway Telephone: +47 33 02 38 00 Telefax: +47 33 04 44 24 www.kongsberg.com E-mail: subsea@kongsberg.com

cNODE Mini transponder

Instruction Manual

Instruction Manual

Table of contents

1 ABOUT THIS MANUAL ........................................................................................ 1 Manual content .................................................................................................................. 1 Abbreviations .................................................................................................................... 1 2 BASIC TRANSPONDER INFORMATION ......................................................... 2 cNODE Mini transponders ............................................................................................. 2 Short description of the cNODE Mini ............................................................................ 2 Transponder options .......................................................................................................... 3 Transducers ............................................................................................................... 3 Top section modules.................................................................................................. 4 Tube........................................................................................................................... 4 Bottom end cap modules ........................................................................................... 4 Battery ....................................................................................................................... 5 Transponder accessories .................................................................................................... 5 Battery charger .......................................................................................................... 5 cNODE Power AC/DC unit ................................................................................... 6 TTC 30 ...................................................................................................................... 6 Available transponders ...................................................................................................... 6 How to handle a transponder ............................................................................................. 7 Important information ............................................................................................... 7 Transponder model identification principles ..................................................................... 8 Model name ............................................................................................................... 8 Model number ........................................................................................................... 8 Transducer beam width ............................................................................................. 8 Options ...................................................................................................................... 8 3 TECHNICAL SPECIFICATIONS......................................................................... 9 Transponder models ........................................................................................................ 10 cNODE Mini 34-40V .............................................................................................. 10 cNODE Mini 34-180 ............................................................................................... 10 cNODE Mini 31-80V-D-St ..................................................................................... 10 cNODE Mini 16-180-St .......................................................................................... 11 Common specifications for all models ............................................................................ 11

331869/D

cNODE Mini transponder

Responder ................................................................................................................ 11 Power supply ........................................................................................................... 12 Internal tilt sensor .................................................................................................... 12 Transducers...................................................................................................................... 12 Top section module ......................................................................................................... 15 Depth sensor (D) ..................................................................................................... 15 Tubes ............................................................................................................................... 15 Bottom end cap modules ................................................................................................. 16 Battery ............................................................................................................................. 18 Battery lifetime ........................................................................................................ 19 Transponder accessories .................................................................................................. 19 Battery charger ........................................................................................................ 19 cNODE Power AC/DC unit ................................................................................. 20 Pin out specification ................................................................................................ 21 4 CONFIGURATION AND SETUP ....................................................................... 22 Transponder set-up .......................................................................................................... 22 How to configure the transponder ................................................................................... 23 How to turn the transponder ON ..................................................................................... 23 How to turn the transponder OFF .................................................................................... 24 Changing the transponder channel .................................................................................. 24 Responder ........................................................................................................................ 25 Internal tilt sensor ............................................................................................................ 25 External power................................................................................................................. 25 cNODE Power AC/DC Module ................................................................................... 26 Cable layout for transponder with power module ................................................... 26 5 DEPLOYMENT AND OPERATION .................................................................. 27 Pre-deployment checks .................................................................................................... 27 Mounting ......................................................................................................................... 28 Deployment ..................................................................................................................... 28 Ready for operation ......................................................................................................... 28 Operation ......................................................................................................................... 28 Recovery checks .............................................................................................................. 28 Vent screw ....................................................................................................................... 29 Pressure relief valve......................................................................................................... 29 How to charge the battery................................................................................................ 30

II

331869/D

Instruction Manual

Charge procedure .................................................................................................... 31 How to replace the battery pack ...................................................................................... 33 Battery storage ................................................................................................................. 34 6 MAINTENANCE ................................................................................................... 35 O-rings ............................................................................................................................. 36 Preventive maintenance ................................................................................................... 36 How to open the transponder ........................................................................................... 36 Replacement of the transducer ........................................................................................ 38 How to assemble the transponder .................................................................................... 39 Lubrication of the subsea connectors .............................................................................. 40 7 SPARE PARTS ....................................................................................................... 41 cNODE Mini 34 Series ................................................................................................. 41 cNODE Mini 31 Series .................................................................................................... 41 cNODE Mini 16 Series ................................................................................................. 42 Transponder accessories .................................................................................................. 42 8 DRAWING FILE ................................................................................................... 43 Drawings .......................................................................................................................... 43 cNODE Mini 34-40V transponder P/N 328364 - outline dimensions ................ 44 cNODE Mini 34-40V transponder - internal layout ............................................ 45 cNODE Mini 34-180 transponder P/N 334307 - outline dimensions ................. 46 cNODE Mini 31-80V-D-St transponder P/N 354848 .......................................... 47 cNODE Mini 16-180-St transponder P/N 347310 - outline dimensions ............ 48 cNODE Power Module outline dimensions ...................................................... 49 Charger for cNODE Mini - outline dimensions ................................................... 50 9 INDEX ..................................................................................................................... 51

331869/D

III

About this manual

1 ABOUT THIS MANUAL

This is the Instruction manual for the cNODE Mini transponder.

Manual content

The manual contains the descriptions and illustrations required to set up and maintain the transponder unit. The system is described down to circuit board level, named as the Line Replaceable Units (LRUs). Block diagrams and drawings are used to simplify the descriptions.

Abbreviations

Abbreviations used in this manual:

FSK HiPAP HPR KM LBL LF MF N/A PSK ROV SSBL TBI TTC UTB UTB_HV Frequency Shift Keying High Precision Acoustic Positioning Hydroacoustic Position Reference Kongsberg Maritime Long Base Line Low Frequency Medium Frequency Not Applicable Phase Shift Keying Remotely Operated Vehicle Super-Short Base Line To Be Implemented Transponder Test and Configuration unit Universal Transponder Board Universal Transponder Board High Voltage (DC/DC)

331869/D

cNODE Mini transponder

BASIC TRANSPONDER INFORMATION

The purpose of this chapter is to provide an overall description of the transponder, and give information on how to handle a transponder.

Topics cNODE Mini transponders on page 2 Short description of the transponder on page 2 Transponder options on page 3 Transponder accessories on page 5 Available transponders on page 6 How to handle a transponder on page 7 Transponder model identification principles on page 7

cNODE Mini transponders

Mini 34-40V

Mini 34-180

Mini 31-80V-D-St

Mini 16-180-St

Short description of the cNODE Mini

The cNODE Mini transponders are compatible with both HiPAP Cymbal acoustic protocol for positioning and data link, and HPR 400 channels and telemetry.

331869/D

Basic transponder information

SSBL positioning, with a total of : 52 HiPAP Cymbal channels 56 HPR 400 channels. LBL positioning. Acoustic telemetry link for command and data transfer. It has both transponder and responder functions. A transponder is normally a self-contained unit, receiving power from an internal rechargeable NiMH battery pack. The transponder can also be powered from an external power supply. The transponder unit is designed with a modular construction such that the transducer, transponder electronics, battery pack and options (where applicable) can be replaced individually. The transponder may be secured to a subsea structure using mounting brackets. Designed for ROV manipulator handling.

Transponder options

Transducers

TD40V

TD40V has a 40 cone transducer beam width vertical. P/N: 332186

TD180

TD180 has a 180 transducer beam width. P/N: 333059 Stainless steel P/N: 334803

331869/D

cNODE Mini transponder

TD80V

TD80V has an 80 vertical transducer beam width. Stainless steel P/N: 352910

TD180LF

TD180LF has a 180 transducer beam width and is a low frequency transducer. P/N: Stainless steel P/N:

Top section modules

Pressure module P/N: 353515

Tube

P/N: 599-220673 Stainless steel P/N: 344472

Bottom end cap modules

End cap The end cap base holds the following: Vent screw ON / OFF switch including Pressure relief

4 331869/D

Basic transponder information

valves Two external connectors P/N: 332020 Stainless steel P/N: 349131

Battery

Rechargeable (NiMH)

P/N: 290-220675

See Technical specification for the battery on page 18.

Transponder accessories

Battery charger

P/N: 290-220687

331869/D

cNODE Mini transponder

cNODE Power AC/DC unit

Input: 110/230 Vac Output: 15 Vdc/300 W P/N: 346471

TTC 30

The TTC 30 unit is for on deck acoustic testing and configuration of the cNODE transponders. The TTC 30 can test all KM transponder channels, Cymbal and HPR 400. It can also test telemetry transponders with internal and external sensors. P/N: 345775

Available transponders

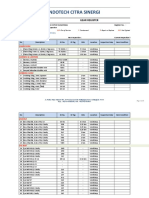

Transponder Series 34 Series 34-180 34-40V 31 Series 31-80V-D-St Depth Stainless steel 354848 Basic model 40 Vertical Aluminium Aluminium 344307 328364 Model Housing Material P/N

331869/D

Basic transponder information

31-80V-St 16 Series 16-180-St

80 Vertical

Stainless steel Stainless steel

353056

Low frequency

347310

How to handle a transponder

Important information

Note

The cNODE Mini must always be switched OFF when not used.

Do not point the transducer / end cap towards you self or others when you turn the cNODE Mini on. Charging of battery is connected with some risk.

Warning

Warning

Transponder with a NiMH battery:

Follow the procedure on page 30

331869/D

cNODE Mini transponder

Transponder model identification principles

The transponder name consists of the model name, the model number and any options included.

Model name

Mini

Model number

The three digits number describes (1, 2-3): Digit 1: frequency band Digit 2: depth rating The following are available:

1st number Frequency band 3 = 30 kHz 1 = 15 kHz 2nd number D epth rating 4 = 4000 m 6 = 6000 m 1 = 1000 m

Transducer beam width

40V = 40 vertical 80V = 80 vertical 180 = 180 180LF = 180 Low frequency

Options

D: St: Depth Stainless steel

Example:

This means that cNODE Mini 34-40V indicates that this transponder unit is operating in the 30 kHz band, rated to 4000 meters depth, with a 40 beam width vertical. The transponder housing material is Aluminium.

331869/D

Technical specifications

TECHNICAL SPECIFICATIONS

This chapter gives the technical specifications of the standard cNODE Mini transponder.

Topics Transponder models on page 10 Common specifications for all models on page 11 Transducers on page 12 Top section module on page 15 Tubes on page 15 Bottom end cap modules on page 16 Battery on page 18 Transponder accessories on page 19

331869/D

cNODE Mini transponder

Transponder models

cNODE Mini 34-40V

Frequency band Maximum depth rating Housing material Housing coating Overall length Diameter housing with coating Diameter transducer Weight in air / water Operation temperature Transducer beam MF 4000 m Anodised Aluminium Polyurethane 600 mm 85 mm 100 mm 6.7 kg / 3.4 kg -5 to +55 C 40 vertical

cNODE Mini 34-180

Frequency band Maximum depth rating Housing material Housing coating Overall length Diameter housing with coating Diameter transducer Weight in air / water Operation temperature Transducer beam MF 4000 m Anodised Aluminium Polyurethane 598 mm 85 mm 88 mm 6.7 kg /3.4 kg -5 to +55 C 180 vertical

cNODE Mini 31-80V-D-St

Frequency band Maximum depth rating Housing material Housing coating Overall length Diameter housing with coating MF 1000 m Stainless steel Polyurethane 718 mm 85 mm

10

331869/D

Technical specifications

Diameter transducer Weight in air / water Operation temperature Transducer beam Depth sensor

85 mm 15.4 kg /11.4 kg -5 to +55 C 80 vertical 1000 m, 0,1% FS

cNODE Mini 16-180-St

Frequency band Maximum depth rating Housing material Housing coating Overall length Diameter housing with coating Diameter transducer Weight in air / water Operation temperature Transducer beam LF 6000 m Stainless Steel Polyurethane 661 mm 85 mm 101 mm 15.5 kg / 11.5 kg -5 to +55 C 180 vertical

Common specifications for all models

Responder

Responder trigger connection - via the external signal connector.

Pigtail connector type Responder trigger signal Logic pulse Amplitude Duration Positive 5 V to 25 V 2 ms to 6 ms Subcon MCIL8M

331869/D

11

cNODE Mini transponder

Power supply

The following power supply options are available:

Internal External

NiMH battery 15 10% Vdc, 300 W

If the external power supply cannot deliver 300 W, the internal battery will be used for the high power transmitting pulse.

Internal tilt sensor

Max. detectable angles - Accuracy 90 2

Transducers

(Cd30102a)

Figure 1 TD40V beam pattern

12

331869/D

Technical specifications

(Cd30209)

Figure 2 TD180 beam pattern

Transducer Beam Pattern

-30 -10 0

30

-20 -60 60

-30

-40

-90

90

-120

120

-150

150

180

Figure 3 TD80V beam pattern

331869/D

13

cNODE Mini transponder

(Cd30208)

Figure 4 TD180LF Beam pattern

14

331869/D

Technical specifications

Source level and receiver sensitivity Model Receiver sensitivity Source level - max (4 steps of 3 dB) Max: 203 dB High: 197 dB Low: 191 dB Min: 183 dB Max: 190dB High: 184 dB Low: 178 dB Min: 173 dB Max: 188 dB High: 182 dB Low: 176 dB Min: 171 dB Max: 188 dB High: 182 dB Low: 176 dB Min: 168 dB

cNODE

Mini 34-40V 90 dB

cNODE

Mini 34-180 100 dB

cNODE

Mini 31-80V 85 dB

cNODE Mini 16180

100 dB

Top section module

Depth sensor (D)

Depth range - Accuracy 1000 m 0.1% FS

Tubes

Aluminium Tube material Tube coating Stainless steel Tube material Tube coating Stainless steel Polyurethane Anodized Aluminium Polyurethane

331869/D

15

cNODE Mini transponder

Bottom end cap modules

Figure 5 Mini bottom end cap module

External connectors

External signal connector: An eight (8) pin female Subcon MCBH8F connector for serial line, External power supply and Responder signal. External charge connector An eight (8) pin male Subcon MCBH8M connector for battery charging. The transponder external connectors are recessed within the transponder end cap.

Signal connector

5 6 7 8 1 2 4 3

Battery charger connector

5 4 3 2 1 8 6 7

(Cd300103)

16

331869/D

Technical specifications

Pin Layout

Pin no. 1 2 3 4 5 6 7 8

Signal TP TX GND TP RX Res+ ResGND Ext Power Ext Power

331869/D

17

cNODE Mini transponder

Battery

The battery pack is connected directly to the main board.

Wiring diagram - see drawing on page 46

Battery chemistry: NiMH Design: PTC - protected against short circuit Melt fuse - operating at 72 C NTC - temperature measurement The battery pack includes a circuit board with: * Diodes * Battery under voltage control - disconnects the battery from the electronics when the battery voltage is too low. This reduces the possibilities of reverse polarity. * ID chip - an EEPROM containing information about the battery pack (Remaining capacity, etc.) To get (read) correct remaining capacity, the battery must be fully charged before turning the transponder ON.

18

331869/D

Technical specifications

Battery lifetime

Lithium battery Model Quiescent [days] cNODE Mini 34-30V Series and cNODE Mini 16-180 Series 60 1 ping per sec [Millions No. of replies] Cymbal Max: Low: Min: 0.04 0.4 0.7 High: 0.15

HPR 400: Max: 0.1 High: 0.35 Low: Min: cNODE Mini 34-180 Series and cNODE Mini 31-80V Series 60 Max: Low: Min: 0.6 0.75 0.07 0.5 0.7

Cymbal: High: 0.2

HPR 400: Max: 0.15 High: 0.45 Low: Min: 0.65 0.75

Transponder accessories

Battery charger

Outline dimensions (Width x Hight x Depth) Weight IP

(256 x 83 x 355) mm 2.9 kg 30

331869/D

19

cNODE Mini transponder

Charge method: Constant current. Permit fast charge between 5 C and 40 C. Methods for detection of fully charged battery: Temperature rise (dT/dt), maximum temperature, maximum time (165 min). Trickle charge by pulse current. Charge the three battery strings (A, B, C) individually. It takes 2 hours and 45 minutes to recharge the battery from empty to fully recharged.

Refer to the status LEDs on the figure below

cNODE Power AC/DC unit

Maximum depth rating Housing material Housing coating Overall length Diameter housing with coating Weight in air / water Operation temperature 4000 m Anodised aluminium Polyurethane 309.2 mm 85 mm 3.2 kg/1.5 kg -5 to +55 C

Pin layout, refer to Pin out specification on page 21

20

331869/D

Technical specifications

Pin out specification

Figure 6 cNODE Power AC/DC module pin out specification

(Cd32012)

331869/D

21

cNODE Mini transponder

CONFIGURATION AND SETUP

This chapter describes the basic principles of operation. The transponder is designed for operation in water only. However, it may be operated in air for test purposes over a short period of time.

Topics Transponder set-up on page 22 How to configure the transponder on page 23 How to turn the transponder ON on page 23 How to turn the transponder OFF on page 24 Changing the transponder channel on page 24 Responder on page 25 Internal tilt sensor on page 25 External power on page 25 cNODE Power AC/DC module on page 26

Transponder set-up

The transponder configuration is preset by Kongsberg Maritime with: One unique serial number Two default channels. One channel for Cymbal One channel for HPR 400 Acoustic mode: Cymbal or HPR 400

To change acoustic mode or channels - see How to configure the transponder on page 23.

22

331869/D

Configuration and setup

How to configure the transponder

The transponder is configured by Kongsberg Maritime. The configuration may be altered if required. The procedure to perform alterations will depend on the HiPAP / HPR system in use. A transponder can operate with the following topside systems: HiPAP and the HPR 400 series. Altering the configuration is done by: Acoustic telemetry. HiPAP / HPR 400 system and TTC 30 Via serial line (transponder external connector) TTC 30 Download new transponder software is done by: Via serial line (transponder external connector) TTC 30

See TTC 30 Instruction Manual/TTC 30 Quick Reference Guide for more information.

How to turn the transponder ON

The ON/OFF switch has 4 positions. The transponder is only switched ON when the two marker dots are aligned. All other positions are OFF.

Refer to information on page Figure 5 on page 16.

Switch the unit ON. - Use a suitable screwdriver. Ensure the two marker dots are aligned.

331869/D

23

cNODE Mini transponder

The unit will transmit bursts to indicate that it is activated.

Each time the transponder is switched ON it will be reset to the two default channels.

How to turn the transponder OFF

Note

The cNODE Mini must always be switched OFF when not in use. 1 Switch the unit OFF.

Changing the transponder channel

If required, the channel setting may be changed. This is done as follows: By acoustic telemetry from a HiPAP or HPR 400 system - in the transponder configuration program, or Via serial line/acoustic telemetry from TTC (change of default channel) For information about set-up of a transponder:

Refer to the APOS Instruction manual / APOS on-line help.

24

331869/D

Configuration and setup

Responder

cNODE will automatically change to responder mode if responder trigger signal is present. cNODE will change back to transponder mode if no new trigger signal is received within the next 30 seconds. Information about set-up of a responder:

Refer to the APOS Instruction manual / APOS on-line help.

Internal tilt sensor

+Y FWD FWD +X

Figure 7 Top view of the transponder to the left in this figure showing the FWD direction. FWD is marked with the two holes in the bottom end cap module.

External power

The transponder can be powered from an external power supply. Use always two (2) pins for Ext power, and two (2) pins for GND in the Signal connector

See page 15, cause of high power transmitting pulses.

331869/D

25

cNODE Mini transponder

cNODE Power AC/DC Module

Cable layout for transponder with power module

SUBCONN MCBH6MAS SUBCONN MCBH6FAS

R OV

der pon rans To t

From

Signal connector Battery charger connector

Figure 8 Power AC/DC Module

(Cd32013)

26

331869/D

Deployment and operation

DEPLOYMENT AND OPERATION

Pre-deployment checks on page 27 Mounting on page 28 Deployment on page 28 Ready for operation on page 28 Operation on page 28 Positioning of a transponder on page 28 Recovery checks on page 28 Vent screw on page 29 Pressure relief valve on page 29 How to charge the battery on page 30 How to replace the battery pack on page 33 Battery storage on page 34

Pre-deployment checks

Before you deploy the transponder, you must: 1 2 Check that the battery contains sufficient power for the proposed operation. Before deployment, perform a visual inspection of the transponder. - The Vent screw and the Pressure relief valve must be closed. - The Charger connector must be fitted with a dummy plug. - The Signal connector must be fitted with an external cable or a dummy plug. Perform a functional check to ensure it will operate correctly once it has been positioned on the seabed. - Ensure the transponder replies to the correct interrogation frequency. Transponder on deck use TTC for cNODE transponders.

The functional check can be performed as follows:

331869/D

27

cNODE Mini transponder

Transponder in water - use HiPAP or HPR 400 system. When checking, lower the transponder on a rope over the vessels side.

Refer to the APOS Instruction manual/APOS on-line help.

Mounting

The transponder may be secured to a subsea structure using mounting brackets.

Deployment

Caution During deployment prevent the transponder slamming against other solid objects. from

When you deploy the transponder: The unit must be positioned with the transducer upright. Ensure a clear line of sight between the transponders head and the ships transducer. The transponder requires brackets to hold the transponder securely in position.

Ready for operation

Once deployed, the transponder is ready for operation.

Operation

Refer to the APOS Instruction manual / APOS on-line help.

Recovery checks

1 2 3 After recovery switch the unit OFF. Wash the unit thoroughly in warm fresh water to dissolve any salt deposits and clean off any sand or silt. As an extra precaution, it is recommended that the unit is left to soak in fresh water to allow salt to dissolve and diffuse from hard-to-reach areas, such as crevices around O-rings, and between mating parts. - Leave the unit to soak for 24 hours, or as long as practical conditions allow.

28

331869/D

Deployment and operation

If a rechargeable unit is to be re-deployed imminently, put the unit on charge.

Vent screw

The vent screw is used when charging the battery, to prevent build-up of gases inside the cNODE Mini. The vent screw can be opened by hand, or use a suitable screwdriver.

Pressure relief valve

The ON/OFF switch also acts as a pressure relief valve. The ON/OFF switch has two dual O-rings and work as follows: One O-ring will seal only when the switch is pressed fully into its seat. The other O-ring will seal, even with the switch pushed approximately 2 mm outwards. If the switch rest in a not fully home position, or they feel springy when pushed in place, it means there is some over-pressure inside the cNODE Mini. If the pressure becomes too big, the valve will vent. When the pressure has been relieved, the switch can be pushed back into position.

331869/D

29

cNODE Mini transponder

How to charge the battery

The battery is charged inside the cNODE Mini. This is connected with some risk, so please read the information below, and follow the charge procedure carefully.

Warning When you are charging the battery ensure the following: - Good ventilation and stable temperature. - The transponder is not covered. - No open fire, sparks or smoking in the area. Before you start charging

NiMH batteries can generate some hydrogen and oxygen gas, the amount depending on certain conditions. Most often this generation occurs during charging. To prevent build-up of gasses inside the cNODE Mini, there are 2 countermeasures. 1

Caution

Vent screw.

The vent screw must be open during charging.

a Unscrew the vent screw until you feel some resistance (a nylon washer is forced against a metal surface). The O-ring is now visible. b Hold the cNODE Mini in an upright position while you do this, so that any water droplets caught around the vent screw comes out, rather than going inside the cNODE Mini. c When the charging is complete - tighten the vent screw by hand only, until you feel a rather sudden resistance. (an internal axial O-ring hits a metal surface, compresses 0.3 mm, before 2 metal surfaces meet). The main flat circular surface of the end cap should now align with the edge of a semicircular groove that runs all around the vent screw. This is to visually confirm that the vent screw has been properly tightened.

30

331869/D

Deployment and operation

Safety valve - The ON/OFF switch also acts as a safety valve. a In case of a pressure build-up inside the cNODE Mini, the safety valve will pop open when the pressure reaches 0.1-0.2 bar. Under normal conditions this valve will never operate, as any gas build-up is released through the manually opened vent screw. Initialization (charger measures battery status) Fast charge (charge mode) Complete charge (Trickle charge battery fully charged) Error

Charge modes

Status LEDs

There are three status LEDs on the charger: A, B and C - for charging of the three battery strings (A, B, C) individually.

Charge procedure

1 2 Switch OFF the transponder. Climatize the transponder. - The battery must have a temperature between 5 C and 40 C. Recommended charging temperature is 25 C.

Note

Charging cold batteries (below 10 C) will give less capacity and shorter service life. 3 4 5 6 7 Manually vent the transponder - use the vent screw. Connect the charger plug to the cNODE Mini. Connect Power supply to mains (110 Vac or 220 Vac). Switch on the charger. - All status LEDs - constant orange light. The charging will start: Stage 1 - Charger measures the battery status (Initialization mode): All status LEDs - constant yellow light.

331869/D

31

cNODE Mini transponder

If the battery temperature is out of range, (ref point 2 in this procedure), the charger will show error mode. * Status LED - flashing orange / green light.

-

Refer to the Action for Error mode below.

Stage 2 - Fast charge mode All status LEDs - constant orange light.

Caution Ensure that all (A, B, C) status LEDs show fast charge mode after a few seconds.

Fast charge - the charger will measure temperature, voltage and time during this mode. Stage 3 - Detection of fully charged battery:

-

All status LEDs - green light with yellow flash for 1 minute. Methods for detection of fully charged battery: - Temperature rise (dT/dt) - maximum time. When one of these criteria occur, the charger will stop the fast charge mode. - If the battery temperature reaches the maximum temperature (60 C), the charger will show error mode. * Status LED - flashing orange / green light.

Refer to the Action for Error mode below. Action for error mode:

a. b. c

Stop charging. Climatize the battery. Start charging again.

Ref to point 2 in the charge procedure on page 31

Stage 4 - Completely charged battery and trickle charge (Complete charge mode) All status LEDs - constant green light.

32

331869/D

Deployment and operation

Caution

Ensure that all (A, B, C) status LEDs show complete mode.

When the battery is fully charged, the charger will start trickle charge the battery.

Note

It is not recommended that the battery is trickle charged for a long time. It is better to start fast charge again to top the battery just before operation.

The transponder is now ready for operation!

8 9 10 Switch off the charger. Disconnect charger plug from the cNODE Mini transponder (external connector). Ensure that the ON / OFF switch and the vent screw are in closed position.

The recommended temperature range for long-term storage of the rechargeable battery cells is -20 degrees C to +35 degrees C*. Stored capacity decreases over time due to the selfdischarge of the rechargeable battery cells.

How to replace the battery pack

The battery is build into the chassis. To replace it, follow the procedure below: 1 2 3 Open the transponder.

Refer to page 19 for details.

Disconnect the battery connector. The connector is placed at the top of the battery. Pull the battery out. - The battery is fastened to the electronic chassis with double-faced tape. Assembly is the reverse of dismantling.

331869/D

33

cNODE Mini transponder

Battery storage

Store the battery in a suitable environment if the unit is not to be re-deployed in the near future. The recommended temperature range for long-term storage of the rechargeable battery cells is -20 C to +30 C*. Stored capacity decreases over time due to the self-discharge of the rechargeable battery cells. Self-discharge is dependent on temperature and the higher the temperature the greater the self-discharge over time. Long-term storage has no permanent effect on capacity. Loss in capacity due to self-discharge is reversible.

*The relative humidity should be < 50%.

34

331869/D

Maintenance

MAINTENANCE

The following maintenance is normally required: Washing the unit. Lubrication of the external connector

Caution

Electronic devices can be destroyed by static electricity. It is therefore essential that full protection against static is practised by service engineers. Although the unit is resistant to mechanical vibration and shock, every effort must be made to avoid careless handling when the unit is in use or being transported.

Topics O-rings on page 36 Preventive maintenance on page 36 How to open the transponder on page 36 Replacement of the transducer on page 38 How to assemble the transponder on page 39 Lubrication of the subsea connectors on page 40 Related topics How to charge the battery on page 30 Testing the transponder on page 26 Drawings on page 43

331869/D

35

cNODE Mini transponder

O-rings

Whenever the transponder is opened and the O-rings are exposed, precautions must be taken. This includes keeping the O-rings and mating surfaces free of dust and debris. If any of the mentioned surfaces is to be cleaned, it is important to use lintfree objects. Q-tips must never be used to clean areas anywhere near an O-ring. When inserting an O-ring, make sure the surface is clean, and that it is covered with a thin film of silicone grease.

Preventive maintenance

Preventive maintenance is limited to keeping the unit clean.

Caution Do not use high pressure water as this will damage the transducer face.

Remove all traces of salt and debris. Before any connectors are disconnected, ensure the surrounding areas are dry. Inspect the unit for damage at regular intervals. Pay particular attention to the transducer surface. This is manufactured of a synthetic rubber material, and can easily be damaged.

How to open the transponder

Before you open the unit:

1 2 3 4

Wash the unit thoroughly in fresh water, and dry off any moisture on the outside. Place the transponder horizontally on a flat, clean workbench, and support it so it cannot roll off. Disconnect any external cable. Turn OFF the transponder.

36

331869/D

Maintenance

Opening the unit:

The unit is held together by a lock cord inserted (see photo above) in a groove between the tube and the end cap / transducer. Access to the cord is via two clearly visible slots at either end of the transponder tube. The cord is inserted by hand, and it is removed by picking up the free end visible in one slot, and pushing the other end (visible in the other slot).

Caution Take care not to use sharp objects that can damage the anodized surface of the aluminium. Observe the 5 mm orientation peg at either end of the tube. When pulling apart, make sure to keep this orientation until parts are completely free from each other. Forceful twisting of the parts relative to each other while the internal parts are still mated, will damage the unit.

Caution

5 6

Remove the retaining cord between the end cap and the tube, as described above. Carefully pull the end cap from the unit. - There is a padding between the end cap and the battery, to secure the battery.

331869/D

37

cNODE Mini transponder

Take care when replacing / removing the padding, to avoid damaging the cables.

The end cap is fitted with two guiding pins that fit into two holes in the electronic chassis.

See drawing on page 45

8 9

Remove the lock cord between the transducer and the tube, as described above. Pull the tube from the transducer. Support the transducer as it is withdrawn. - All internal parts are now clearly visible and accessible. Once the O-ring is clear of the housing, the transducer and electronics chassis may be removed.

10

Replacement of the transducer

The transducer is a sealed unit and cannot be opened. If the unit is not working, the whole unit must be replaced. 1 Open the transponder.

Refer to page 36 for details.

38

331869/D

Maintenance

(Cd30111)

2 3

Note

Remove the transducer from the electronics chassis (2 fixing screws). Assembly is basically the reverse of dismantling.

The transducer part contains a matching transformer.

How to assemble the transponder

Before you start:

Inspect the O-rings and backup rings for damage. If in doubt, or if they have been used for more than one year, they should be replaced. Place the new bag of silica-gel desiccant into the housing to absorb any humidity that may have entered the unit while it was open. Ensure all surfaces, O-rings and backup rings are completely clean and then wipe a thin film of silica-gel over the rings and mating surfaces.

Caution

Ignoring these recommendations may result in flooding of the transponder unit. Assembling:

Assembly is the reverse of disassembly. Handling the O-rings:

331869/D

39

cNODE Mini transponder

1 2 3 4

Check the condition of the rings and carry out any necessary replacements. Ensure the O-ring surfaces are clean and free from any dust, debris or old grease. Lightly grease the rings prior to assembly using Molykote 33 grease or similar. Re-fit the O-rings (see figure below).

Retaining cord

Transducer

End cap

(Cd6418)

2 O-rings

2 O-rings

Lubrication of the subsea connectors

The two 8-pin connectors should be kept free from grit and dirt. The manufacturer recommends lubricating the pins with: Molykote 44M silicone based grease. You must not use silicone based sprays like 5-55, WD-40 or similar. These will degrade the rubber fused around the metal pins.

Note

Use it sparingly; half a match-head dose per contact is adequate.

40

331869/D

Spare parts

SPARE PARTS

This chapter lists the parts and modules defined by Kongsberg Maritime as Line Replaceable Units (LRUs). The unit name and order number are given. Mounting components (such as nuts, bolts, washers etc.) have not been allocated order numbers as we regard these items as standard commercial parts available from retail outlets around the world.

See transponder availability and P/N in the Drawing file chapter on page 44

cNODE Mini 34 Series

Unit name Transponder main units Chassis w/circuit boards Housing coated (tube) Transducer Options Battery Battery pack NiMH Bottom units Bottom end cap Transponder maintenance kit cNODE Mini maintenance kit 351794 331957 290-220675 Transducer TD40V Transducer TD180 332186 333059 329992 599-220673 Unit P/N

cNODE Mini 31 Series

Unit name Transponder main units Chassis w/circuit boards Housing coated (tube) 329992 344472 Unit P/N

331869/D

41

cNODE Mini transponder

Transducer Transducer TD80V Top section modules Depth sensor Battery Battery pack NiMH Bottom end cap modules Bottom end cap Transponder maintenance kit cNODE Mini maintenance kit 351794 349131 290-220675 344472 332186

cNODE Mini 16 Series

Unit name Transponder main units Chassis w/circuit boards Housing coated (tube) Battery Battery pack NiMH Transducers Transducer TD180LF Bottom end cap modules Bottom end cap Transponder maintenance kit cNODE Mini maintenance kit 351784 349131 334803 290-220675 354758 344472 Unit P/N

Transponder accessories

Unit name Transponder main units cNODE Power AC/DC module Battery charger

42

Unit P/N 346097 290-220687

331869/D

Drawing file

DRAWING FILE

This chapter holds illustrations referred to in various sections in this manual. The illustrations are based on the original system drawings and wiring diagrams. Unless otherwise noted, all dimensions are in millimetres. The illustrations are not in scale. The original drawings are available in electronic format upon request.

Drawings

Drawing No. 329305 328364 351790 356189 351217 346097 830-220919 Rev. A A A A A A A Description cNODE Mini 34-40V transponder - outline dimensions cNODE Mini 34-40V transponder - internal layout cNODE Mini 34-180 transponder - outline dimensions cNODE Mini 31-80-D-St transponder - outline dimensions cNODE Mini 16-180-St transponder outline dimensions cNODE Power module outline dimensions Charger for cNODE Mini - outline dimensions Ref. on page 44 on page 45 on page 46 on page 47 on page 48 on page 49 on page 50

331869/D

43

cNODE Mini transponder

cNODE Mini 34-40V transponder P/N 328364 - outline dimensions

Note: All measurements are in mm. The drawing is not in scale.

44

331869/D

Drawing file

Tube coated

cNODE Mini 34-40V transponder internal layout

Guiding pin (2) O-rings El-chassis

Lock cord End cap

End support for battery TD40V Lock cord O-rings

Battery pack

UV-plug dummy MCDC8M 8p

Note: All measurements are in mm. The drawing is not in scale.

UTB HV

UTB1

UV-plug dummy MCDC8F 8p

331869/D

45

cNODE Mini transponder

cNODE Mini 34-180 transponder P/N 334307 - outline dimensions

Note: The drawing is not in scale.

Cd30211 Page 1 351790 Rev. A

46

331869/D

Drawing file

cNODE Mini 31-80V-D-St transponder P/N 354848

Note: All measurements are in mm. The drawing is not in scale.

331869/D

47

cNODE Mini transponder

cNODE Mini 16-180-St transponder P/N 347310 - outline dimensions

Note: The drawing is not in scale.

Cd30207 Page 1 351217 Rev. A

48

331869/D

Drawing file

cNODE Power Module outline dimensions

Note: The drawing is not in scale.

Cd30210 Page 1 346097 Rev. A

331869/D

49

cNODE Mini transponder

Charger for cNODE Mini - outline dimensions

Note: All measurements are in mm. The drawing is not in scale.

50

331869/D

Index

INDEX

The next pages present the index of this manual.

A

Abbreviations, 1 About this m anual, 1 Altering the configuration, 23 APOS, 24, 25, 28 APOS Instruction m anual, 24, 25, 28 Assem bling, 39 Before you start, 39 External connectors, 16 External pow er, 25

F

Frequency band, 8 Frequency Shift Keying, 1 FSK, 1

B

Basic transpond er inform ation, 2 Battery Before you start charging, 30 Battery charger, 19 Battery connector, 33 Battery pack, 18 Battery storage, 34 Before you open the unit, 36

H

High Precision Acoustic Positioning, 1 HiPAP, 1 H ow to assem ble the transpond er, 35, 39 H ow to open the transpond er, 36 HPR, 1 H PR 400 series, 23 Hydroacoustic Position Reference, 1

C

Change of battery pack, 33 Change transpond er channel, 24 Changing the battery, 35 Channel setting, 24 Charge m od es, 31 Charge proced ure, 31 Charger for cN ODE Mini - outline d im ensions, 50 Charging the battery, 30 cN ODE Mini 16-180-St transpond er, 48 cN ODE Mini 31-80V-D-St transpond er, 47 cN ODE Mini 34-180 transpond er - outline d im ensions, 46 cN ODE Mini 34-40V transpond er - internal layout, 45 cN ODE Mini 34-40V transpond er - outline d im ensions, 44 Cym bal, 3 Id entification principles, 8 Im portant inform ation, 7 ind ex, 51

K

KM, 1

L

LBL, 1 Line Replaceable Units, 1 Lithium battery, 19 Long Base Line, 1 Long-term storage, 34 LRUs, 1 Lu brication of the subsea connectors, 40

D

Dam age, 36 Deploym ent, 28 D epth rating, 8 Draw ings, 43

M

Maintenance, 35 Manual content, 1 MF, 1 Mod el nam e, 8 Mod el num ber, 8 Molykote 33 m ed ium , 40 Mounting, 28

331869/D

51

cNODE Mini transponder

N

N/A, 1 N iMH battery, 3, 7

ROV, 1

S O

Self-d ischarge, 34 Source level, 15 Spare parts, 41 SSBL, 1 Static electricity, 35 Status LEDs, 31 Super-Short Base Line, 1 Sw itch the unit on, 23, 24

On-line help , 24, 25, 28 Opening the unit, 37 Operation, 28 Options, 8 O-ring, 38, 39 O-rings, 36

P

Phase Shift Keying, 1 Pin out specification, 21 Pow er supply, 12 Pre-d eploym ent checks, 27 Pressure relief valve, 29 Preventive m aintenance, 36

T

Technical specifications, 9 Transd ucer, 28 Transd ucer beam w id th, 3, 4, 8 Transd ucer TD40V, 41 Transd ucers, 3 Transpond er d esign, 3 Transpond er m od el, 8 Transpond er set-up, 22

R

Receiver sensitivity, 15 Recovery checks, 28 Related m anuals APOS Instruction manual, 28 Relative hum id ity, 34 Remotely Operated Vehicle, 1 Replacem ent of the transd ucer, 38 Respond er, 11, 25 Respond er trigger signal, 11

U

Universal Transponder Board, 1 Universal Transponder Board High Voltage, 1 UTB, 1 UTB_HV, 1

V

Vent screw , 29

52

331869/D

2012 Kongsberg Maritime

Vous aimerez peut-être aussi

- Hipap Product Description PDFDocument87 pagesHipap Product Description PDFswapneel_kulkarniPas encore d'évaluation

- HiPAP Use of Third Party Wideband Transponders PDFDocument1 pageHiPAP Use of Third Party Wideband Transponders PDFPedro Paulo CordeiroPas encore d'évaluation

- Non-Lethal Technologies-An Overview PDFDocument15 pagesNon-Lethal Technologies-An Overview PDFprincedrdoPas encore d'évaluation

- Underwater Locator Beacon (ULB) Market Research Report 2020Document8 pagesUnderwater Locator Beacon (ULB) Market Research Report 2020mahi singhPas encore d'évaluation

- Node Transponders: Mini - Medium Frequency, 4000 MDocument4 pagesNode Transponders: Mini - Medium Frequency, 4000 MRafael LourençoPas encore d'évaluation

- Hipap Product Description: High Precision Acoustic Positioning 502/452/352/102 SystemsDocument70 pagesHipap Product Description: High Precision Acoustic Positioning 502/452/352/102 SystemsTEUKUPas encore d'évaluation

- Edward Cudahy and Stephen Parvin - The Effects of Underwater Blast On DiversDocument64 pagesEdward Cudahy and Stephen Parvin - The Effects of Underwater Blast On DiversMallamaxPas encore d'évaluation

- S2C Modem User Manual PDFDocument65 pagesS2C Modem User Manual PDFHenrique Ribeiro DelgadoPas encore d'évaluation

- Artificial Intelligence Vehicle: Fundamentals and ApplicationsD'EverandArtificial Intelligence Vehicle: Fundamentals and ApplicationsPas encore d'évaluation

- Automatic Target Recognition: Fundamentals and ApplicationsD'EverandAutomatic Target Recognition: Fundamentals and ApplicationsPas encore d'évaluation

- Naval 1Document12 pagesNaval 1Nick NumlkPas encore d'évaluation

- Hipap-502 452 352 102 PDFDocument71 pagesHipap-502 452 352 102 PDFAhmad Fawaiz SafiPas encore d'évaluation

- Radio Remote-Control and Telemetry and Their Application to MissilesD'EverandRadio Remote-Control and Telemetry and Their Application to MissilesÉvaluation : 4 sur 5 étoiles4/5 (1)

- Mobile Computing Deployment and Management: Real World Skills for CompTIA Mobility+ Certification and BeyondD'EverandMobile Computing Deployment and Management: Real World Skills for CompTIA Mobility+ Certification and BeyondPas encore d'évaluation

- Tps 4767Document3 pagesTps 4767kirkleeleomoPas encore d'évaluation

- European Working Group Non-Lethal WeaponsDocument2 pagesEuropean Working Group Non-Lethal WeaponsHRCPas encore d'évaluation

- 04 FaisanesDocument10 pages04 FaisanesMiguel ArroyoPas encore d'évaluation

- ProFlex500 RMDocument664 pagesProFlex500 RMjmills42Pas encore d'évaluation

- FusionDocument20 pagesFusionelshadPas encore d'évaluation

- G - ST - TSH - 017B - GapsDocument29 pagesG - ST - TSH - 017B - GapssrvshdrrPas encore d'évaluation

- A Brief Taxonomy of Autonomous Under Water Vehicle Design LiteratureDocument4 pagesA Brief Taxonomy of Autonomous Under Water Vehicle Design Literaturedavid_okahPas encore d'évaluation

- Product BrochureDocument6 pagesProduct BrochureAnh Tuan Cao100% (1)

- Service Manual: Survival Craft 2-Way RadioDocument34 pagesService Manual: Survival Craft 2-Way RadioAlexPas encore d'évaluation

- Swath Bathymetry & Side Scan Sonar: Features & BenefitsDocument2 pagesSwath Bathymetry & Side Scan Sonar: Features & BenefitsRich ManPas encore d'évaluation

- SR02 01DSDocument4 pagesSR02 01DSharis_fikriPas encore d'évaluation

- Mu MT9 FRDocument55 pagesMu MT9 FRtom_northmillavoncliffPas encore d'évaluation

- NJC Signal Processor UnitDocument1 pageNJC Signal Processor UnitAkhil ViswanathanPas encore d'évaluation

- GPS 2019 Week 1024 Rollover: TB-119515 / February 2019Document2 pagesGPS 2019 Week 1024 Rollover: TB-119515 / February 2019vu2jptPas encore d'évaluation

- Operator'S Manual: 6" Echo SounderDocument52 pagesOperator'S Manual: 6" Echo SounderDaniel IzquierdoPas encore d'évaluation

- Vehicle Manual Strv122Document9 pagesVehicle Manual Strv122Rasmus PeterssonPas encore d'évaluation

- Sonardyne Ranger 2 USBLDocument24 pagesSonardyne Ranger 2 USBLMarine CaptainPas encore d'évaluation

- TCI 903S Portable Com SystemDocument8 pagesTCI 903S Portable Com Systemmavv5455Pas encore d'évaluation

- Sonar Introduction 2012 Compressed PDFDocument11 pagesSonar Introduction 2012 Compressed PDFBrenno Moura MouraPas encore d'évaluation

- Icom Ic-M36 ManualDocument36 pagesIcom Ic-M36 ManualhollingermikePas encore d'évaluation

- Sonobuoys BakchodiDocument38 pagesSonobuoys Bakchodisatyarth sharmaPas encore d'évaluation

- Detector With DFDocument13 pagesDetector With DFNarayanan ManojPas encore d'évaluation

- 2007 On SceneDocument44 pages2007 On SceneawernercirPas encore d'évaluation

- SeaSonde v2 SpecificationDocument2 pagesSeaSonde v2 SpecificationQualitas RemosPas encore d'évaluation

- TRIGGERFISH Tech Overview March 2013Document27 pagesTRIGGERFISH Tech Overview March 2013Ndomadu100% (1)

- HFSparesStructureList CDDocument76 pagesHFSparesStructureList CDzrzahzahPas encore d'évaluation

- TruTrak Evolution Type II FINAL - Cleared 08aug12Document2 pagesTruTrak Evolution Type II FINAL - Cleared 08aug12smouhabPas encore d'évaluation

- Echo Surveyor VI Flyer PDFDocument2 pagesEcho Surveyor VI Flyer PDFThomas ThomasPas encore d'évaluation

- Sailor 150 Fleetbroadband: User ManualDocument158 pagesSailor 150 Fleetbroadband: User ManualalexPas encore d'évaluation

- Security Underwater - DSIT's AquaShield DDSDocument1 pageSecurity Underwater - DSIT's AquaShield DDSIsrael ExporterPas encore d'évaluation

- An Introduction To Inertial NavigationDocument37 pagesAn Introduction To Inertial NavigationZee ZouPas encore d'évaluation

- SARDocument204 pagesSARArash MazandaraniPas encore d'évaluation

- EWBS Warning SystemDocument40 pagesEWBS Warning SystemAnonymous PHP579Rn78Pas encore d'évaluation

- Compas MagneticDocument4 pagesCompas Magneticcst89Pas encore d'évaluation

- Quick Start Guide Mu Phinsiii 001 BDocument33 pagesQuick Start Guide Mu Phinsiii 001 BMoorthy PakisamyPas encore d'évaluation

- Side Scan Drivers: Interfacing NotesDocument33 pagesSide Scan Drivers: Interfacing NotesOCEANO ManPas encore d'évaluation

- MacArtney Final VersionDocument21 pagesMacArtney Final Versionysukka25Pas encore d'évaluation

- Navigat X MK 1: Microprocessor Controlled Digital Gyrocompass SystemDocument4 pagesNavigat X MK 1: Microprocessor Controlled Digital Gyrocompass SystemNguyen Phuoc HoPas encore d'évaluation

- Need Asthales PDFDocument9 pagesNeed Asthales PDFSunil NinawPas encore d'évaluation

- 6248 User Manual Sailor VHF DDocument66 pages6248 User Manual Sailor VHF DChristiano Engelbert SilvaPas encore d'évaluation

- Scanbridge A2 Skanti: Communication Console For GMDSS Sea Area A2Document48 pagesScanbridge A2 Skanti: Communication Console For GMDSS Sea Area A2Parul MehtaPas encore d'évaluation

- CERDEC Fact Sheet - CREW Duke V3Document1 pageCERDEC Fact Sheet - CREW Duke V3RDECOM CERDECPas encore d'évaluation

- Hipap Instruction ManualDocument209 pagesHipap Instruction ManualCaroline MariaPas encore d'évaluation

- K-Pos DP OS Dynamic Positioning and Offshore Loading SystemDocument402 pagesK-Pos DP OS Dynamic Positioning and Offshore Loading Systemasd80% (5)

- Inb100036-1 Usermanual Series1 MMD Rev33Document114 pagesInb100036-1 Usermanual Series1 MMD Rev33dharanPas encore d'évaluation

- User Manual: Fibertec™ M6 1020/1021Document84 pagesUser Manual: Fibertec™ M6 1020/1021osklav100% (1)

- L5CoachMentorReflectiveLog TemplateDocument9 pagesL5CoachMentorReflectiveLog TemplateHadusssPas encore d'évaluation

- Gaara Hiden Series Light NovelDocument127 pagesGaara Hiden Series Light NovelartfardadPas encore d'évaluation

- Brochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Document2 pagesBrochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Fernanda RizaldoPas encore d'évaluation

- CHEM 111 Assignment 2024Document3 pagesCHEM 111 Assignment 2024Ben Noah EuroPas encore d'évaluation

- Project Report: MES Dental College and HospitalDocument28 pagesProject Report: MES Dental College and HospitalAnurtha AnuPas encore d'évaluation

- Literature 101 Assignment: Step 1: Graphic OrganizerDocument2 pagesLiterature 101 Assignment: Step 1: Graphic OrganizercatarinaPas encore d'évaluation

- Grade 8 For Demo Cigarette SmokingDocument3 pagesGrade 8 For Demo Cigarette SmokingSteven TaperoPas encore d'évaluation

- Kelley DavisDocument3 pagesKelley Davisapi-626701108Pas encore d'évaluation

- Symptoms and DiseasesDocument8 pagesSymptoms and Diseaseschristy maePas encore d'évaluation

- Problems 1Document2 pagesProblems 1Andoy Don M.Pas encore d'évaluation

- Adsa Ka SyllabusDocument3 pagesAdsa Ka SyllabusHacker RanjanPas encore d'évaluation

- Dossat PrinciplesOfRefrigerationDocument554 pagesDossat PrinciplesOfRefrigerationHernan CobaPas encore d'évaluation

- ESQLDocument2 pagesESQLajay110125_kumarPas encore d'évaluation

- July 2014 GEARSDocument76 pagesJuly 2014 GEARSRodger BlandPas encore d'évaluation

- 17 Safety InventoryDocument47 pages17 Safety Inventorymishrakanchan 2396Pas encore d'évaluation

- Dyn ST 70 Ser 2Document12 pagesDyn ST 70 Ser 2alexgirard11735100% (1)

- Data Structures and Algorithms AssignmentDocument25 pagesData Structures and Algorithms Assignmentعلی احمد100% (1)

- Galaxy A8 User ManualDocument193 pagesGalaxy A8 User ManualHüseyin ACARPas encore d'évaluation

- BP KWN RPM W KGW KGW KGW KG SFC GM KWHR Caloricfivalue MJ KGDocument3 pagesBP KWN RPM W KGW KGW KGW KG SFC GM KWHR Caloricfivalue MJ KGHoàng Khôi100% (1)

- Differential Association Theory - Criminology Wiki - FANDOM Powered by WikiaDocument1 pageDifferential Association Theory - Criminology Wiki - FANDOM Powered by WikiaMorningstarAsifPas encore d'évaluation

- Inspection List For Electrical PortableDocument25 pagesInspection List For Electrical PortableArif FuadiantoPas encore d'évaluation

- TrapsDocument11 pagesTrapsAmandeep AroraPas encore d'évaluation

- Vocabulary: Activity 1Document18 pagesVocabulary: Activity 1Aurora GonzalezPas encore d'évaluation

- Intro To Geometric Design and Vertical AlignmentDocument25 pagesIntro To Geometric Design and Vertical AlignmentAhsan ArfanPas encore d'évaluation

- A Research Paper On DormitoriesDocument5 pagesA Research Paper On DormitoriesNicholas Ivy EscaloPas encore d'évaluation

- 0192-En 13948-2008Document9 pages0192-En 13948-2008Borga ErdoganPas encore d'évaluation

- IUK Routemap - GovernanceDocument27 pagesIUK Routemap - GovernanceTom RedwayPas encore d'évaluation

- Final PaperDocument12 pagesFinal PaperReikooPas encore d'évaluation

- Comparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterDocument4 pagesComparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterSurendar KesavanPas encore d'évaluation

- FINAL Shivani Confined Space PermitDocument1 pageFINAL Shivani Confined Space PermitVimal SinghPas encore d'évaluation