Académique Documents

Professionnel Documents

Culture Documents

9 A

Transféré par

Shajakhan HameedDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

9 A

Transféré par

Shajakhan HameedDroits d'auteur :

Formats disponibles

SECTION

9a

Bronze Y Type Strainers

Tel: +44 (0)1695 712800 Fax: +44 (0)1695 712820

Email: sales@hattersley.com export@hattersley.com www.hattersley.com

04.06

Contents and Numerical Index Bronze Y Strainers

Contents Figure Number Index Introduction Bronze Y Strainers Data Sheets

Page 2 3 4-8

Numerical Index Fig No 817 807 / 907 808 / 908 1807 1807C Page 4 5 6 7 8

In this catalogue we have endeavoured to make the information as accurate as possible, but we cannot accept any responsibility should it be found that in any respect the information is inaccurate or incomplete or becomes so as a result of further developments.

04.06

Fig. 807 / 817 / 808 Strainers

Removal of debris from fluid transfer systems is vitally important in protecting the performance of pipeline equipment. Corrosion deposits, scale, jointing compounds and welding slag as well as more unusual articles must be trapped and prevented from causing system contamination and subsequent problems. The Y type design offers a reliable, cost effective means of equipment protection, minimising downtime and maintenance costs. Design of the Hattersley strainer is backed by years of experience in fluid handling particularly in the field of strainer manufacture and under an approved Quality System to BS EN ISO 9001, a quality product is guaranteed. Screening Straining is by the process of direct interception where the fluid passes through the perforation holes in the element the size of which are small enough to prevent passage of the particles. The Hattersley screening element is constructed from perforated stainless steel sheet in accordance with DEO Spec.036 requirements and is inherently stronger than weak mesh type elements which are susceptible to breaching when partial blockage causes increased pressure drop or collapsing under transient vacuum conditions.

Fig 817 Fig 807

Fig 808

Figure 807 and 817 Features Bronze construction Threaded end 1/2 to 2in. Streamlined flow contours minimise pressure drop. Compact design with short face to face. Perforated stainless steel screen Captive asbestos-free non-stick gasket. Comprehensive flow characteristics available.

Figure 808 Features Bronze construction Flanged to BS EN 1092-3 PN25. Streamlined flow contours minimise pressure drop. Suitable for HTHW and saturated steam. Captive asbestos-free non-stick gasket. Perforated stainless steel screen Available up to 150mm Bolted cover 65mm and above. Comprehensive flow characteristics available.

04.06

Fig. 817 Bronze Y Type Strainer PN16

Pressure/Temperature Rating PN16 16 bar -10 to 100C 7 bar at 170C Test Pressure 24 bar hydraulic Specification Bronze body 304 stainless steel 40 mesh screen End connections threaded to BS EN 10266 (BS21 Taper ISO R7)

Pressure bar 18 16 14 12 10 8

tea m

6

tur ate

4 2 0 0

40 80 120 160 200 Temperature C

Material Specification Component Cap Screen Body Dimensions Nominal Size A B C D Weight Material Brass Stainless Steel Bronze Specification BS EN 12420 CW617N 1449 304S15 1982 CC491K ASTM B124 C37700 AISI 304 B62 C83600

in mm mm mm mm kg

1/2

3/4

62 40 15 53 0.2

68 48 18 66 0.3

1 79 53 23 75 0.5

11/4 113 64 27 90 0.9

11/2 119 74 31 107 1.2

Sa

dS

2 136 94 36 130 1.8

B D

A D=withdrawal distance for the screen

04.06

Fig. 807 / 907 Bronze Y Strainer PN32 Series B

36 32 28 Pressure bar 24 20 16

am

Pressure/Temperature Rating PN32 Series B 14 bar at 198C 32 bar from -10 to 100C Note: Fig 907 restricted to 135C Test Pressures (Hydraulic) Shell: 48 bar Specification Standard screen has 0.75mm diameter holes. Screwed cap. Ends threaded to BS EN 10266 (BS21 ISO R7) Figure 907 supplied complete with two Fig 631 test points and plugs. Specification BS EN 1982 CC491K 10088-1 X10CrNi18-10 1982 CC491K

12

ur ate d

8 4 0 0

t Sa

40 80 120 160 200 240 Temperature C

Material Specification Component Body Screen Gasket Cap Dimensions Nominal Size A B C k Factor Weight Screen Data Nominal Size Holes Dia Holes/cm2 Free Flow Area/cm2 Element Area Free Flow Area % Nominal Bore Material Bronze Stainless Steel Asbestos Free (non-stick) Bronze ASTM B62 AISI 304 B62

in mm mm mm kg

Ste

1/2

3/4

68 49 65 3.3 0.4

80 64 90 4.2 0.5

1 95 89 115 3.6 0.9

11/4 115 97 135 3.2 1.5

11/2 130 116 165 3.3 1.8

2 153 159 235 3.5 3.3

in mm % cm2 cm2

1/2 0.75 50 22.6 24.6 5.5 434

3/4 0.75 50 22.6 36 8.1 284

1 0.75 50 22.6 68.5 15.5 305

11/4 0.75 50 22.6 107.1 24.2 305

11/2 0.75 50 22.6 143.1 32.3 283

2 0.75 50 22.6 255 57.6 284

B C

C=withdrawal distance for strainer element

04.06

Fig. 808 / 908 Bronze Y Strainer PN25

Pressure/Temperature Rating PN25 10.5 bar at 186C 25 bar from -10 to 100C Note: Fig 908 restricted to 135C

Pressure bar 28 24 20 16 12 8 4 0 0 40 80 120 160 200 240 Temperature C

Test Pressures (Hydraulic) Shell: 37.5 bar Specification Standard screen has 0.75mm diameter holes up to and including 50mm size. Larger sizes have 1.6mm holes Screwed cap up to and including 50mm. Larger sizes have bolted cover Flanged to BS EN 1092-3 Figure 908 supplied complete with two Fig 631 test points and plugs.

Material Specification Component Body Screen Gasket Cap Dimensions Nominal Size A C D E k Factor Weight Screen Data Nominal Size Holes Dia Material Bronze Stainless Steel Asbestos Free (non-stick) Bronze Specification BS EN 1982 CC491K 10088-1 X10CrNi18-10 1982 CC491K ASTM B62 AISI B62

mm mm mm mm mm kg

15 100 49 95 65 3.3 1.4

20 110 64 105 90 4.2 1.8

25 120 89 115 115 3.6 3.0

32 157 97 140 135 3.2 4.1

40 165 116 150 165 3.3 5.8

50 200 159 165 235 3.5 7.7

65 267 200 185 290 6.0 16

80 318 222 200 325 5.6 22

100 356 265 235 390 7.3 32

Sa

tur ate dS

125 445 337 270 450 5.1 67

tea

150 489 381 300 560 5.7 83

mm mm

15 0.75 50 22.6 24.6 5.5 434

20 25 0.75 0.75 50 22.6 36 8.1 284

32 0.75

40 50 0.75 0.75 50 22.6 255 57.6 284

65 1.6 17 34 425 144 430

80 1.6 17 34 579 196 385

100 1.6

125 1.6

150 1.6

Holes/cm2 Free Flow Area/cm2 % Element Area cm2 Free Flow Area cm2 % Nominal Bore

50 50 50 22.6 22.6 22.6 68.5 107.1 143.1 15.5 24.2 32.3 305 305 283

17 17 17 34 34 34 849 1277 1680 288 434 570 360 350 320

E C

E=withdrawal distance for strainer element

04.06

Fig 1807 Dezincification Resistant Strainer Ball Valve PN25

28 24

1 /2

20 Pressure bar 16 12 8 4 0 0

Pressure/Temperature Rating PN25 - 1/2 to 11/2 Sizes 25 bar -0C to 20C 7 bar at 120C

1 /2

2"

20 40 60 80 100 120140 Temperature C

Material Specification Component Handle Stem Stem Seal Gland Seals Ball Seat Rings Body Screen Cap Gasket Cap Dimensions Nominal Size A B C D E Drain Plug Weight Material Aluminium DZR Copper Alloy EPDM Virgin PTFE DZR Copper Alloy Hard chrome plated Virgin PTFE DZR Copper Alloy Stainless Steel Asbestos Free DZR Copper Alloy Specification BS EN 12164 CW602N ASTM

PED Categorisation Valve Size Group 2 Liquids Cat

"t o1

Si ze

PN20 - 2 Size 20 bar -0C to 20C 6 bar at 120C Test Pressure 25 bar pneumatic Specification DZR body Blow-out proof stem Hard chrome plated ball Virgin PTFE seats T - handle operated 0.8mm diameter perforated 304 stainless steel screen Drain plug BS EN 10266 Taper threaded (ISO R7) WRAS Approved Product Optional Features Lever Extension stem Fig 103 hose outlet blowdown valve

in mm mm mm mm mm BSP kg

"S

s ize

12164 CW602N

12165 CW602N AISI 304 12165 CW602N

1/2 110 31

3/4 129 35

1 151 42 59 50 56 1/4 1.23

D

48 38 47 1/4 0.54

60 46 56 1/4 0.80

1/2 SEP

3/4 SEP

1 SEP

B A

04.06

Fig 1807C Dezincification Resistant Strainer Ball Valve PN16

Pressure/Temperature Rating PN16 5 bar at 120C 6 bar at 110C 10 bar at 65C 16 bar at 30C Test Pressure 25 bar pneumatic Specification DZR body Blow-out proof stem Hard chrome plated ball Virgin PTFE seats T - handle operated 0.8mm diameter perforated 304 stainless steel screen Drain plug Compression ends to BS EN 1254-2 Use with R250 (half hard) copper tube WRAS Approved Product Optional Features Lever Extension stem Fig 103 hose outlet blowdown valve

18 16 14 Pressure bar 12 10 8 6 4 2 0 0 20 40 60 80 100 120 140 Temperature C

Material Specification Component Handle Stem Stem Seal Gland Seals Ball Seat Rings Body Screen Cap Gasket Cap Compression Ring Compression Nut Dimensions Nominal Size A B C D E Drain Plug Weight Material Aluminium DZR Copper Alloy EPDM Virgin PTFE DZR Copper Alloy Hard chrome plated Virgin PTFE DZR Copper Alloy Stainless Steel Asbestos Free DZR Copper Alloy Brass Brass Specification BS EN 12164 CW602N ASTM

12164 CW602N

12165 CW602N AISI 304 12165 CW602N 12165 CW617N B124 C37700

in mm mm mm mm mm BSP kg

15 137 45 48 38 47 1/4 0.6

22 159 50 60 46 56 1/4 0.9

28 175 53 59 50 56 1/4 1.3

C B A

PED Categorisation Valve Size Group 2 Liquids Cat

15 SEP

22 SEP

28 SEP

04.06

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Vadivel Schedule For Civil Clearance 3-7-2012Document15 pagesVadivel Schedule For Civil Clearance 3-7-2012Shajakhan HameedPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Duct Static Pressure CalculationDocument6 pagesDuct Static Pressure CalculationShajakhan Hameed100% (8)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Static Calculation ExampleDocument3 pagesStatic Calculation ExampleShajakhan HameedPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Yns (Fire Suppression)Document32 pagesYns (Fire Suppression)Shajakhan HameedPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Reviewer 2Document5 pagesReviewer 2Nini JimbuuPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Piping Coordination Systems - IsometricDocument18 pagesPiping Coordination Systems - IsometricGodwinPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Rimska ArhitekturaDocument11 pagesRimska ArhitekturadebbronnerfilesPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

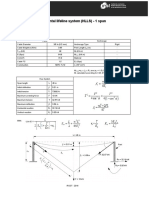

- Horizontal Life Line CalculationDocument1 pageHorizontal Life Line Calculationhasan_676489616100% (1)

- I3CON Handbook 2 FinalDocument260 pagesI3CON Handbook 2 FinalNeshvar DmitriPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- DR - Fixit Pidicrete - CF BRLDocument1 pageDR - Fixit Pidicrete - CF BRLnickdash09Pas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Systems of Wiring: Shresth Sarthak Vashisht Raviraj Saurabh Prakhar PrabalDocument22 pagesSystems of Wiring: Shresth Sarthak Vashisht Raviraj Saurabh Prakhar PrabalPrabal SethiPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Iso 12149Document22 pagesIso 12149klasPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Overview of The Building Delivery ProcessDocument2 pagesOverview of The Building Delivery ProcessMekonen YeteshaPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Excavation For Structures: Unit Cum Unit CumDocument4 pagesExcavation For Structures: Unit Cum Unit CumGunawan AchmadPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Beta PMDocument2 pagesBeta PMSeif el dean MamdouhPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- DOP Sikadur 31 96198030 EN 15044 2004Document4 pagesDOP Sikadur 31 96198030 EN 15044 2004pirke2412Pas encore d'évaluation

- Gland SelectionDocument8 pagesGland SelectionJignesh ParmarPas encore d'évaluation

- Chapter 10 Thermal Processing of Metal AlloysDocument44 pagesChapter 10 Thermal Processing of Metal Alloyssyed izzuddin alhadyPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Administrative Order No. 23 Compliance Report TemplateDocument7 pagesAdministrative Order No. 23 Compliance Report TemplateVILMA BASEPas encore d'évaluation

- Ensat Self Tapping Inserts 302 Series ImperialDocument1 pageEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesPas encore d'évaluation

- Landscape Geoffrey AlanDocument9 pagesLandscape Geoffrey AlanTarun Srivastava 2018Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Numerical Analysis of Rail Structure Interaction and Resonance in Railway BridgesDocument11 pagesNumerical Analysis of Rail Structure Interaction and Resonance in Railway BridgesJEETENDRA PRAKASHPas encore d'évaluation

- Checklist For Dismantling & Preservation of Existing MEP Works-FinalDocument2 pagesChecklist For Dismantling & Preservation of Existing MEP Works-FinalMohammed Javid100% (1)

- Mud ArchitectureDocument61 pagesMud ArchitectureAshok Nene100% (1)

- Fire Protection SystemsDocument9 pagesFire Protection SystemsDiscord GamingPas encore d'évaluation

- NiraliDocument13 pagesNiraliNIYATI PANDYAPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Neuesmuseum DcaDocument4 pagesNeuesmuseum Dcaandreeastefania30Pas encore d'évaluation

- Chapter 8 - Rock TestingDocument52 pagesChapter 8 - Rock TestingTeaMeePas encore d'évaluation

- BPA Englisch 2016Document63 pagesBPA Englisch 2016Carlos RojasPas encore d'évaluation

- 3 Drill StringDocument43 pages3 Drill StringShabaz HazharPas encore d'évaluation

- Glycodur Cat enDocument52 pagesGlycodur Cat enjhhvgPas encore d'évaluation

- The Use of Project Time Management Processes and The Schedule Performance of Construction Projects in MexicoDocument10 pagesThe Use of Project Time Management Processes and The Schedule Performance of Construction Projects in MexicokamranPas encore d'évaluation

- 28 DAY Spring Cleaning ChallengeDocument1 page28 DAY Spring Cleaning ChallengeApril StoneroadPas encore d'évaluation

- A2 Accu-Flo Clamped Metal Pump: Engineering Operation MaintenanceDocument28 pagesA2 Accu-Flo Clamped Metal Pump: Engineering Operation MaintenanceThanh Nghị BùiPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)