Académique Documents

Professionnel Documents

Culture Documents

Performance of A Double-Pipe Heat Exchanger: Unit Operations Laboratory

Transféré par

Mae Florizel FalculanDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Performance of A Double-Pipe Heat Exchanger: Unit Operations Laboratory

Transféré par

Mae Florizel FalculanDroits d'auteur :

Formats disponibles

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 1

PERFORMANCE OF A DOUBLE-PIPE HEAT EXCHANGER

INTRODUCTION

Modern manufacturing industries employ processes that require heating and cooling.

From the preparation of the raw materials, to their processing, to the conditioning of the

final products into sellable items and even down to the treatment of process effluents,

heat transfer mechanisms are always applied. Most of the time, heating and cooling

are done using heat exchangers and a double-pipe heat exchanger is one of the

commonly used type. Being such a vital industrial tool, it is of great importance that

chemical engineering students learn the basic concepts and theories especially the

operation of a double-pipe heat exchanger. The fundamental concepts applied will

enable the students to analyze and design other types of heat exchanger.

OBJECTIVES

1. To familiarize the students with the characteristics, parameters and problems

involved in the operation of a double-pipe heat exchanger when operated using

countercurrent or co-current flow.

2. To determine and compare measured and calculated mean temperature

difference between hot and cold water in both countercurrent and co-current

flow.

3. To compare experimental overall heat transfer coefficient obtained using data

from direct measurements with the theoretical overall heat transfer coefficients

calculated using available empirical equations.

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 2

THEORY

Although there are several ways of transferring heat between fluids, the most common is

the use of a heat-exchanger wherein the hot fluid and cold fluid are separated by a

solid boundary. Different types of heat exchangers have been developed. The simplest

type is a double-pipe heat exchanger. This consists essentially of two concentric pipes

with one fluid flowing through the inside of the inner pipe while the other fluid moves co-

currently in the annular space. This type of heat exchanger, however, is not

recommended for processes that require very large heating surfaces.

The heat transfer analysis of a double-pipe heat exchanger deals with the application

of several equations that relate the different parameters involved. Consider the heat

exchanger,

Where: mh = Mass flow rate of hot fluid, lbm/hr

mc = mass flow rate of cold fluid, lbm/hr

Tc = temperature of cold fluid, F

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 3

Th = temperature of hot fluid, F

**subscript 1 refers to entrance conditions, 2 refers to exit conditions

To determine the rate of heat loss by the hot fluid or the heat gained by the cold fluid,

we apply a steady overall energy balance between the two ends of the heat

exchanger. On the basis of 1 lbm/sec of fluid flowing, we have,

W + JQ = Z(

) +

+ J (1)

Where: W = shaft work

Z(

) = mechanical potential energy

= mechanical kinetic energy

= kinetic energy velocity correction factor

( = 1.0 for turbulent flow; 0.5 for laminar flow)

Since no shaft work W, is involved, Z(

) and

, are small compared with the

thermal energy transfer. Then for one fluid, the equation reduces to,

Q = H = (H2 H1) (2)

If no change in phase involved,

H = CpT (3)

Therefore, the rates of heat transfer for the cold and hot fluids are respectively,

qc = mcCpc(Tc2 Tc1) (4)

qh = mhCph(Th1 Th2) (5)

If heat losses to the surroundings are neglected,

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 4

qc = qh or (6)

mcCpc(Tc2 Tc1)= mhCph(Th1 Th2) (7)

To relate the heat transfer rate with the size of the heat exchanger, we apply the

transfer around the differential element of length, dL. Thus,

dq = U1(Th Tc)dA = Uo(Th Tc)dAo (8)

Where: U = Overall heat transfer coefficient, Btu/hr-ft

2

F

A = heat transfer area, ft

2

T = temperature driving force, F = (Th Tc)

**subscript 1 refers to the inside of the heating surface and

subscript o refers to the outside of the heating surface

For double-pipe heat exchangers, the overall heat transfer coefficient is almost

constant along the length of the heat exchanger and the driving potential may be

considered almost linear with q so that Equation (7) can be integrated to give,

q = UiAiTln = UoAoTln (9)

where: Tln = Logarithmic mean temperature difference

logarithmic mean temperature difference is defined by the

equation,

Tln =

(10)

Where: T1 = Temperature approach in one end

T2 = Temperature approach in the other end

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 5

The Tln is fairly accurate if the T is linear with q or L. however, in most situations, this

relationship is not always true. Let us compare therefore the log mean temperature

difference as defined by equation (9) and the arithmetic mean temperature difference,

To defined by,

To =

(11)

With the true mean temperature difference, Tm which is obtained directly from

equation (7) by expressing T in terms of L,

q = 2UD

= 2UDL(T)tm (12)

therefore,

(T)tm =

(13)

Equation (11) is evaluated using graphical or numerical integration by plotting values of

T against exchanger length and getting the area under the curve. These are then

divided by the total length of the exchanger.

It is given that the experimental overall heat transfer coefficient may be calculated

based on equation (8) by determining the rate of heat transfer by direct measurements.

To determine theoretical overall heat transfer coefficient, express Ui or Uo in terms of the

individual transfer coefficients by considering resistances involved when heat travels

from the hot to the cold fluid. Such a relationship, assuming relatively clean surface, is

given by:

(14)

Where: xm =Thickness of the tube wall

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 6

km = Thermal conductivity of the metal

A = Average heat transfer area

If Uo is desired, equation (12) simplifies to

(15)

If Ui is desired, we get

(16)

Since the values of the xm, Do, and km can easily be obtained from available data, the

problem now boils down to the evaluation of the individual heat transfer coefficients.

This involves the choice of a particular empirical equation based on several factors such

as mechanism of heat transfer, character of flow, geometry of the system type of fluid

involved, etc.

Since most of the conditions in this experiment can be set, the equations for h may be

limited to only several choices. Based on mechanism, we can limit it to forced

convection by using flow rates that yield turbulent flow. This will eliminate the effects of

natural convection. Based on geometry, we are limited to horizontal tubes with fluids

flowing inside the conduits, circular and annular. Based on the type of fluid, we are

limited to usng hot and cold water.

In general, for forced convection in turbulent flow, (NRE > 10,000), k may be calculated

considering the effect of tube length by

(

) (

=

(

(17)

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 7

Where the properties Cp, , k are evaluated based on the arithmetic mean bulk

temperature of the fluid defined by,

Tave =

(18)

The viscosity, based on the wall temperature, w will have to be determined by

estimating Tw by iterative calculation using individual resistances evaluated by first

neglecting the effect of w.

If the effect of the tube length can be ignored, (L/D > 60) and the (w/)

0.14

is

approximately equal to 1, the simpler Dittus-Boelter Equation (Foust 13-77), given by

NNu = 0.023(NRe)

0.8

(NPr)

n

(19)

May be applied, where n= 0.4 where the fluid is heated and 0.3 when it is being cooled.

Here, the dimensionless numbers are defined as

NNu =

Nusseltss Number

NRe =

Reynolds Number

NPr =

Prandtl Number

Another equation which is limited to water based temperature range of 40F to 220F,

turbulent flow, may be used. This is given by

h = 150 (1 + .011 T)

()

(20)

where: T = Arithmetic temperature of fluid, F

D = Tube diameter, inches

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 8

Equations (15), (16) and (17) are used to determine both hi and ho. to get hi, the

corresponding inside diameter of the tube is used for D. to get ho, the D is replaced by

the equivalent diameter, De, which is four times the hydraulic radius RH, defined to be

the ratio of the cross-sectional area of the annular space to the wetted perimeter. For

an annular space,

RH =

(

)

()

=

( ) (21)

Where: Dij = inside diameter of jacket (outer tube)

Dot = outside diameter of inner tube

It is possible that flow with Reynolds number less than 10,000 will be encountered. In this

case, Equations (15),(16) and (17) are no longer valid. For NRe = 2100 and for fluids of

moderate velocity.

Gr

1/3

= 1.75 (

(22)

For NRe between 2100 and 10,000, Figure 9-22 (MC) will have to be used. Also, if the flow

is laminar, the effect of natural convection should not be discounted. This effect can be

accounted for by multiplying hia (computed from equation (19) or figure 9-22) by the

factor

n =

(

(23)

NGr =

(24)

Where: De = equivalent diameter

= coefficient of thermal expansion, F

-1

f = subscript indicating that fluid properties should be based on

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 9

Tf =

EQUIPMENT

Figure 1. Side view of Double-pipe Heat Exchanger

Equipment Description

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 10

The double-pipe heat exchanger set-up as shown in the previous figure consists

essentially of concentric pipes welded in series. The inner is made of brass with an inside

diameter of 0.625 inch and an outside diameter of 0.815 inch. The outer tube made of

standard 1 steel pipe. The unit is composed of 12 sections in series. Each section is

approximately 50 inches long. Hot water, which comes from the nearby tubular heat

exchanger, is passed through the inner pipe and the cold water, coming from the

supply main is passed through the annular space between the tubes.

Valves are provided for reversing the direction of the cold stream to obtain either

countercurrent or co-current flow. Valves on both lines are also provided to control the

flow rates of the streams. Each section is provided with thermometer wells, which

contain small amount of oil, to measure the temperature of the streams at appropriate

points along the heat exchanger. At the exit ends of the pipes, weighing tanks with

calibrated levels are provided for measurement of flow rates.

PROCEDURE

It is important that this experiment should be performed with proper coordination with

Experiment B2, Performance of a Tubular Heat Exchanger, since the hot water used in

this experiment is the hot water discharged from the tubular exchanger. Any valve

movement in Experiment B2 will affect the temperature and flow rate of the hot water.

Therefore, each run for both experiments should start and end simultaneously.

1. Familiarizing yourself with the parts and operation of the equipment, especially

the use of the valves provided in the lines. Place the thermometers at the

appropriate wells provided.

2. Open the supply valve for cold water, check whether water is flowing out the

measuring tanks, if not, checks exit valves. Pressure gauge provided should

indicate a constant reading. Adjust this valve to have a feel of the range of flow

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 11

rates to be used. Approximately determine the setting so as to get six different

flow rates later for each run. The exit valves in the measuring tanks should be

open to drain the liquid to avoid overflowing when flow is not being measured.

3. Adjust the four valves in the cold water line to get either co-current or

countercurrent flow. This is done by fully opening or closing two opposite valves.

Trace the direction of flow from inlet to exit to determine this.

4. If hot water is already available, allow this to flow through the lines by fully

opening the exit valves.

Note: you should not move any valve along the hot water line without the

consent of the people operating the tubular exchanger nor they should move

anything without you knowing it. The flow rate of the hot water is usually at their

control, so regular consultation is advised.

5. If flow rates have been established, prepare to continue the run by regularly

checking the temperature indicated by the thermometers at regular intervals of

time to determine whether steady conditions have already been established and

by measuring the flow rates of the two streams. The flow rate is measured by

closing the first exit valve for the water level to pass between pre-selected points

in the level gauge. The more time you spend in the measurement, the better. The

volumetric flow rate is obtained by dividing the volume of water collected by the

time interval.

6. If reasonable steady state conditions have been established, record all

temperature readings and flow rates i.e., no significant changes are observed,

and the run is completed.

7. Proceed with another run by adjusting the flow rate of the cold fluid and/or the

flow rate of the hot fluid. Each run should last approximately 20 minutes.

8. Perform a total of six runs; three countercurrent and three co-current flows.

9. Tabulate all data collected, measure the length of each section accurately,

check diameter of tubes, etc.

DATA SHEET

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 12

A. CO-Current Flow Operation

Trial 1

Well Number 1

st

Reading 2

nd

Reading 3

rd

Reading

TH (C) TC (C) TH (C) TC (C) TH (C) TC (C)

1 37 37 37 37 37 37

2 39.8 37 40 37 40 37

3 40.5 36 40.9 36.5 41 36.75

4 41.5 35.5 42 36 42 36

5 43 34 44 34.25 44 34.25

6 45.5 32 46 32.5 46 32.75

7 49 30 49.5 50 50 30

Flow Rate (kg/s) 0.266667 0.33333 0.3 0.366667 0.3 0.366667

Trial 2

Well Number 1

st

Reading 2

nd

Reading 3

rd

Reading

TH (C) TC (C) TH (C) TC (C) TH (C) TC (C)

1 33 33 32.5 32.5 33 33

2 43 33 45.5 32.5 45 33.5

3 46.5 32 46 32 46 32

4 49 35 48.5 34.5 50.25 34.5

5 53 37 53 37 54 32.5

6 53.5 36.5 53.5 36 54.5 32

7 54 36 54 35.5 55.5 31

Flow Rate (kg/s) 0.25 0.366667 0.258333 0.375 0.25 0.366667

B. Countercurrent Flow Operation

Trial 1

Well Number 1

st

Reading 2

nd

Reading 3

rd

Reading

TH (C) TC (C) TH (C) TC (C) TH (C) TC (C)

1 38.5 39.5 38.5 38.5 38.5 39

2 38 29 38 29 38.5 29

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 13

3 41 31 40 30.5 40.5 31

4 43 33 42 32.5 42.5 32.5

5 46 34 45 34 45.5 34

6 48 36 47 36.5 47.5 36

7 50.5 38 49.5 37.5 50.5 38

Flow Rate (kg/s) 0.272222 0.355556 0.283333 0.366667 0.283333 0.366667

Trial 2

Well Number 1

st

Reading 2

nd

Reading 3

rd

Reading

TH (C) TC (C) TH (C) TC (C) TH (C) TC (C)

1 42 42 42 42.5 42 42

2 45 42.5 45 42.5 46 42.5

3 46 40.5 46 40.5 46.5 40.5

4 48 39.5 48 39.5 47 39

5 50 38 49 38 49 38

6 50.5 37.5 49.5 37 49.5 37.5

50.5 51 37 50 36.5 51 37

Flow Rate (kg/s) 0.25 0.366667 0.258333 0.375 0.25 0.366667

ANALYSES AND CALCULATIONS

1. Plot for each run the temperature of the hot and cold fluid versus the length of

the heat exchanger indicating whether it is countercurrent flow or co-current

flow. Also, in the same graph, plot T versus length. Present these figures (1) to (6).

Did you get linear behavior? Explain.

2. Using the terminal temperatures for each run, calculate the logarithmic mean

and arithmetic mean temperature differences. Based on the plot of T versus L as

given in Figures (1) to (6), calculate the true mean temperature difference by

graphical integration. Calculate also the percentage deviation of Ta from Ttm.

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 14

Tabulate the results and present as Table 1. Explain the results you got as to the

validity of the various temperature differences you obtained.

3. Calculate the heat gained by the cold fluid, qc, and the heat lost, qh. Compare

the two by solving for the difference. Tabulate the results and present this as

Table 2.

4. Using qh as the basis, calculate for the experimental Ui, by calculating first A, and

using Tln in Equation (2). Tabulate the results and present this as Table 3.

5. Calculate the theoretical Ui by first solving hi and ho using appropriate empirical

formulas. Summarize the results by preparing a table indicating the run number,

average bulk temperature, Reynolds number, Prandtl number, h and theoretical

U. also compare h obtained using Equations (14) and (15). Present this as Table 4.

6. Calculate the percentage difference between the experimental and the

theoretical Ui. Present this as Table 5.

7. Using only the date from one run each for co-current and countercurrent flow,

calculate h using equations (13), (14), and (15). Compare by tabulating the

results. Present this as Table 6.

GUIDE QUESTIONS

1. Based on your findings, discuss the applicability of the arithmetic mean and

logarithmic temperature difference in double pipe heat exchanger calculations.

What affects accuracy?

In computation for the temperature difference, a little variation has been

observed. The logarithmic mean temperature difference records a value of

several decimal places, which can be considered as more accurate than of the

arithmetic mean temperature difference. In a double pipe heat exchanger,

logarithmic mean difference should be used instead of arithmetic mean

difference, although a small deviations exist considering an accuracy of the

value, the former hold true. Accuracy of the measurement might due to parallax

error relative to the reader of the of the thermometer in each well on the double

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 15

pipe heat exchanger. The condition of the atmosphere or the surroundings might

intervene as well.

The behavior of a heat exchanger in variable regime can be described by a two

parameter model with a time lag and a time constant. In many studies, the

analytical calculation based on the energy balance permitted to express the

time constant in various configurations of the device operating. However, the

time lag is only experimentally determined. An empirical method for the

prediction of this parameter when a double pipe heat exchanger is submitted to

a flow rate step at the entrance.

2. Give your comments as to the validity of the theoretical and experimental overall

heat transfer coefficients you obtained.

Certain possibilities can be considered as to how the heat gained by the cold

fluid differs from the heat lost by the hot fluid, the wall resistance of the tube, the

length the fluid travels in the heat exchanger and the type of the materials used

for the pipe system.

The overall heat transfer coefficient can also be calculated by the view of

thermal resistance. The wall is split in areas of thermal resistance where

- the heat transfer between the fluid and the wall is one resistance

- the wall itself is one resistance

- the transfer between the wall and the second fluid is a thermal resistance

3. What are the problems you encountered in the operation of the double-pipe

heat exchanger? How did you overcome these problems and what

recommendations can you give to streamline or improve the use of such

experiment?

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 16

The distance between the sheets in the spiral channels are maintained by using

spacer studs that were welded prior to rolling. Once the main spiral pack has

been rolled, alternate top and bottom edges are welded and each end closed

by a gasketed flat or conical cover bolted to the body. This ensures no mixing of

the two fluids will occur. If a leakage happens, it will be from the periphery cover

to the atmosphere, or to a passage containing the same fluid.

4. Give the physical significance of NRe, NNu and NPr in relation to heat transfer

characteristics.

Reynolds Number, Nusselt, and Prandtl Numbers are significant in the calculations

and widely applicable in the heat exchange principle. NRe determines the type

of flow regime in the heat exchanger equipment as well as in the pipeline. The

flow of the fluid or the velocity affects the temperature in somewhat

considerable amount. The laminar or turbulence behavior of the fluid also

accounts to the film resistance of the fluid and thus needed to be determined.

NNu or the Nusselt number is a dimensionless quantity, which is define as the ratio

of the tube diameter to the equivalent thickness of the laminar layer. Further,

Nusselt number is the resulting correlation on the ratio of the total heat transfer by

molecular and turbulent transport to heat transfer by molecular transport alone.

The physical significance of the Prandtl number appears that it is the ratio of the

velocity to the thermal diffusivity, it is therefore a measure of the magnitude of

the momentum, diffusivity relative to that of the thermal diffusivity. Its numerical

value depends on the temperature and pressure of the fluid, and therefore it is a

true property.

Low-Reynolds Number turbulent flow, and laminar non-Newtonian flow. Heat

exchaner configurations and materials were examined, as were compact and

noncompact versions and heat transfer and fouling.

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 17

The Prandtl number effects on heat transfer are categorized into two

perspectives: fin perspective and array perspective. The fin perspective Prandtl

number effects explain the dependence of the periodic fully developed Nusselt

number on Prandtl number. The array perspective is analogous to the thermal

entry length perspective in duct flow. Array perspective Prandtl number effects

yield higher Nusselt numbers in the entrance region of the offset fin array.

Nusselt numbers are measured in three counterflow tube-in-shell heat exchangers

with flow rates and temperatures representative of thermosyphon operation in

solar water heating systems. Mixed convection heat transfer correlations for these

tube-in-shell heat exchangers were previously developed in Dahl and Davidson

(1998) from data obtained in carefully controlled experiments with uniform heat

flux at the tube walls. The data presented in this paper confirm that the uniform

heat flux correlations apply under more realistic conditions. Water flows in the

shell and 50 percent ethylene glycol circulates in the tubes. Actual Nusselt

numbers are within 15 percent of the values predicted for a constant heat flux

boundary condition. The data reconfirm the importance of mixed convection in

determining heat transfer rates. Under most operating conditions, natural

convection heat transfer accounts for more than half of the total heat transfer

rate.

5. Discuss briefly the relative merits of countercurrent and co-current flow of fluids

for the transfer of heat?

Countercurrent exchange along with Concurrent exchange comprise the

mechanisms used to transfer some property of a fluid from one flowing current of

fluid to another across a semipermeable membrane or thermally-conductive

material between them. The property transferred could

be heat, concentration of a chemical substance, or others. Countercurrent

exchange is a key concept in chemical engineeringthermodynamics and

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 18

manufacturing processes, for example in extracting sucrose from sugar

beet roots.

Concurrent Flow In this exchange system, the two fluids flow in the same

direction. As the diagram shows, a concurrent exchange system has a

variable gradient over the length of the exchanger. With equal flows in the

two tubes, this method of exchange is only capable of moving half of the

property from one flow to the other, no matter how long the exchanger is. If

each stream changes its property to be 50% closer to that of the opposite

stream's inlet condition, exchange will stop because at that point equilibrium

is reached, and the gradient has declined to zero. In the case of unequal

flows, the equilibrium condition will occur somewhat closer to the conditions

of the stream with the higher flow.

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 19

Countercurrent Flow - By contrast, when the two flows move in opposite

directions, the system can maintain a nearly constant gradient between the

two flows over their entire length. With a sufficiently long length and a

sufficiently low flow rate this can result in almost all of the property being

transferred. However, note that nearly complete transfer is only possible if the

two flows are, in some sense, "equal". If we are talking about mass transfer,

then this means equal flowrates of solvent or solution, depending on how the

concentrations are expressed. For heat transfer, then the product of the

average specific heat capacity (on a mass basis, averaged over the

temperature range involved) and the mass flow rate must be the same for

each stream. If the two flows are not equal (for example if heat is being

transferred from water to air or vice-versa), then conservation of mass or

energy requires that the streams leave with concentrations or temperatures

that differ from those indicated in the diagram.

6. Give a summary of your findings and conclusions and give recommendations, if

any.

The experiment presents the results of an experimental study of shell-side heat

transfer and flow resistance performance of multi-tube type of double-tube heat

exchanger units, which is a double-pipe heat exchanger with smooth or roughen

tubes and a segmental baffled one with smooth tubes, using water and crude oil

(a mixture of oil and water) as working fluids. The experimental results indicate

that the double-tube heat exchanger with a spiral groove tube bundle provides

superior shell-side heat transfer and pressure drop characteristics. Double-tube

heat exchanger is installed for heating crude oil in a solar energy system.

1. Plot of Temperature vs Length of Pipe

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 20

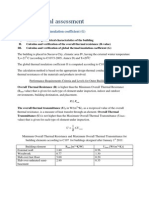

2. Computing for the Logarithmic Mean Temperature Difference

1 2

1

2

T -T

LMTD =

T

ln

T

Where: T1 = Tleaving temperature , hot fluid Tentering temperature, cold fluid

T2 = Tentering temperature, hot fluid Tleaving temperature, cold fluid

| |

|

\ .

(39-32.6)-(40.5-33.5)

LMTD=

39-32.6

ln

40.5-33.5

LMTD = 6.6955

0

C

3. Computing for the Arithmetic Mean Temperature Difference

1 2

2

T T A + A

AMTD =

( ) ( )

0

2

. . . 39 32 6 + 4 5 33 5

AMTD =

Length of the heat exchanger pipe

Temperature,

o

C

Plot of Temperature vs Length of pipe

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 21

AMTD = 6.70

0

C

4. Comparison of LMTD and AMTD for Counter-current Flow

LMTD AMTD

Flow 1 6.6955 6.70

Flow 2 6.4499 6.450

Flow 3 6.1434 6.150

Flow 4 5.8994 5.90

Flow 5 6.2467 6.25

Flow 6 6.2467 6.25

5. Plot of Temperature vs Length of Pipe

6. Computing for the Logarithmic Mean Temperature Difference

1 2

1

2

T -T

LMTD =

T

ln

T

Length of the heat exchanger pipe

Temperature, C

Plot of Temperature vs Length of pipe

Experiments in Chemical Engineering Double- Pipe Heat

Exchanger

Unit Operations Laboratory Page 22

Where: T1 = Tleaving temperature , hot fluid Tentering temperature, cold fluid

T2 = Tentering temperature, hot fluid Tleaving temperature, cold fluid

40 27 5

38 29 5

.

.

| |

|

\ .

(40-27.5)-(38-29.5)

LMTD=

ln

LMTD = 10.3718

0

C

Computing for the Arithmetic Mean Temperature Difference

1 2

2

T T A + A

AMTD =

AMTD = 10.50

0

7. Comparison of LMTD and AMTD for Counter-current Flow

LMTD AMTD

Flow 1 10.3718 10.50

Flow 2 8.6084 7.5

Flow 3 5.4389 5.5

Flow 4 3.6995 3.75

Flow 5 2.4663 2.5

Flow 6 2.0

( ) ( )

40 27 5 38 29 5

2

. . +

AMTD =

Vous aimerez peut-être aussi

- Double Pipe Heat Exchanger ExperimentDocument7 pagesDouble Pipe Heat Exchanger ExperimentBenedicta Monis100% (1)

- Stationary Collectors: Flat Plate and Evacuated TubeDocument18 pagesStationary Collectors: Flat Plate and Evacuated TubeRony Bou cheblPas encore d'évaluation

- Concentric Tube Water-Water Heat Exchanger Study UnitDocument12 pagesConcentric Tube Water-Water Heat Exchanger Study Unitseraj ibramemPas encore d'évaluation

- Heat ExchangersDocument29 pagesHeat Exchangersprotoscope photographyPas encore d'évaluation

- Heat ExchangeDocument10 pagesHeat ExchangeAhmed GadPas encore d'évaluation

- Tuo Modules PDF VersionDocument25 pagesTuo Modules PDF VersionEcy YghiPas encore d'évaluation

- HjjooDocument28 pagesHjjooJohn Patrick DaglePas encore d'évaluation

- Energies: Analysis and Experiment of Hot-Spot Temperature Rise of 110 KV Three-Phase Three-Limb TransformerDocument12 pagesEnergies: Analysis and Experiment of Hot-Spot Temperature Rise of 110 KV Three-Phase Three-Limb Transformeraisya mutia syafiiPas encore d'évaluation

- Part 2Document4 pagesPart 2naimPas encore d'évaluation

- Heat Exchanger ExperimentDocument5 pagesHeat Exchanger ExperimentMithileshPas encore d'évaluation

- ChE 154Document16 pagesChE 154DennisShinPas encore d'évaluation

- Heat Transfer LecturesDocument200 pagesHeat Transfer LecturesdnkindrajithPas encore d'évaluation

- Heat Transfer Collection of Formulas and Tables - 2009Document78 pagesHeat Transfer Collection of Formulas and Tables - 2009Suta Vijaya100% (1)

- Design of Heat ExchangersDocument20 pagesDesign of Heat ExchangersSudhir JadhavPas encore d'évaluation

- Exercise 1-2 Answers 1-2Document8 pagesExercise 1-2 Answers 1-2Kr AyushPas encore d'évaluation

- Transport Phenomenon NotesDocument7 pagesTransport Phenomenon Notesvishakha goelPas encore d'évaluation

- Private and Confidential PropertyDocument12 pagesPrivate and Confidential PropertyBhavi PatelPas encore d'évaluation

- Thermal Considerations in Pipe FlowsDocument11 pagesThermal Considerations in Pipe FlowsWaqas AhmadPas encore d'évaluation

- The E-NTU Method, 250313Document18 pagesThe E-NTU Method, 250313sajni123100% (1)

- Heat Exchanger PracticalDocument21 pagesHeat Exchanger PracticalwellemanesiphoPas encore d'évaluation

- Natural and Forced Convection Heat Transfer ExperimentDocument12 pagesNatural and Forced Convection Heat Transfer ExperimentOmar Yamil Sanchez Torres25% (4)

- Experiment 16Document8 pagesExperiment 16SarahPas encore d'évaluation

- Energía y ExergíaDocument55 pagesEnergía y ExergíaJesús Paz GonzálezPas encore d'évaluation

- 1.1 Introduction To ConductionDocument22 pages1.1 Introduction To ConductionAjay YadavPas encore d'évaluation

- BMS College of Engineering Lab ManualDocument35 pagesBMS College of Engineering Lab ManualAditya Gayatri Sastry KaipaPas encore d'évaluation

- Concentric Tube Heat ExchangersDocument8 pagesConcentric Tube Heat ExchangersHazryPas encore d'évaluation

- Prediction of Temperature Distribution in Shell-And-Tube Heat ExchangersDocument4 pagesPrediction of Temperature Distribution in Shell-And-Tube Heat Exchangerscristhian choque leonPas encore d'évaluation

- Thermal Conduction Heat Transfer AnalysisDocument23 pagesThermal Conduction Heat Transfer AnalysisAkay BayatPas encore d'évaluation

- HTC SingleFin in Water 031506Document5 pagesHTC SingleFin in Water 031506Anya CooperPas encore d'évaluation

- Heat Transfer Coefficient - ...Document6 pagesHeat Transfer Coefficient - ...Vincent_Gold_R_4775Pas encore d'évaluation

- Heat Sink Shape and Topology Optimization With Pareto-Vector Length Optimization For Air CoolingDocument15 pagesHeat Sink Shape and Topology Optimization With Pareto-Vector Length Optimization For Air CoolingRameshPas encore d'évaluation

- Heat Exchanger Part 1 PDFDocument22 pagesHeat Exchanger Part 1 PDFRyu RyloPas encore d'évaluation

- Manual HEAT TRANSFER IN NATURAL CONVECTIONDocument5 pagesManual HEAT TRANSFER IN NATURAL CONVECTIONSasi TejaPas encore d'évaluation

- Forced ConvectionDocument5 pagesForced ConvectionRahul NairPas encore d'évaluation

- Heat Exchanger PerformanceDocument17 pagesHeat Exchanger PerformancealamgirPas encore d'évaluation

- HEAT TRANSFER EXPERIMENTDocument19 pagesHEAT TRANSFER EXPERIMENTBen Widdowson100% (2)

- Reynolds Vs Heat Transfer CoeffDocument15 pagesReynolds Vs Heat Transfer CoeffquantumfeelingPas encore d'évaluation

- CFD Calculation of Convective Heat Transfer Coefficients and Validation - Part I: Laminar FlowDocument15 pagesCFD Calculation of Convective Heat Transfer Coefficients and Validation - Part I: Laminar FlowAlejandro GastonPas encore d'évaluation

- Dostal PDFDocument12 pagesDostal PDFATUL SONAWANEPas encore d'évaluation

- Chapter 5Document56 pagesChapter 5kwangjin1980Pas encore d'évaluation

- Translate Bab IIDocument17 pagesTranslate Bab IIFirdaus NuhaPas encore d'évaluation

- HE TheoryDocument6 pagesHE TheoryMutiaRezaPas encore d'évaluation

- Entropy generation in a condenserDocument22 pagesEntropy generation in a condenserChandu PPas encore d'évaluation

- Chapter 11 Heat TransferDocument21 pagesChapter 11 Heat TransferaimanrslnPas encore d'évaluation

- Design Validation of Shell and Tube Heat Exchanger by HTRI Xchanger SoftwareDocument5 pagesDesign Validation of Shell and Tube Heat Exchanger by HTRI Xchanger SoftwareAhmed HassanPas encore d'évaluation

- Thermal Considerations in Pipe FlowsDocument11 pagesThermal Considerations in Pipe FlowsjayPas encore d'évaluation

- Theoretical and Numerical Analysis of Heat Transfer in Pipeline SystemDocument9 pagesTheoretical and Numerical Analysis of Heat Transfer in Pipeline SystemSigit MaulanaPas encore d'évaluation

- Chapter 4: Heat Exchangers: Two Fluids That Are at Different Temperatures WhileDocument90 pagesChapter 4: Heat Exchangers: Two Fluids That Are at Different Temperatures Whilesohaib389892Pas encore d'évaluation

- CPE533 Shell and Tube Heat Exchanger Full Lab ReportDocument32 pagesCPE533 Shell and Tube Heat Exchanger Full Lab ReportFazsroul89% (44)

- Calculation Methods For Heating and Ventilation System of Electrical MachinesDocument34 pagesCalculation Methods For Heating and Ventilation System of Electrical MachinesAnaZanattaPas encore d'évaluation

- 6 Heat TransferDocument19 pages6 Heat TransferPrecious Mae Cuerquis BarbosaPas encore d'évaluation

- 05.02heat TransferDocument21 pages05.02heat TransferjationonaPas encore d'évaluation

- Heat ExchangersDocument7 pagesHeat Exchangersonezero111Pas encore d'évaluation

- A Modern Course in Statistical PhysicsD'EverandA Modern Course in Statistical PhysicsÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Energy Balance Energy Balance On Saw Dust DigesterDocument12 pagesEnergy Balance Energy Balance On Saw Dust DigesterMae Florizel FalculanPas encore d'évaluation

- OutlineDocument2 pagesOutlineMae Florizel FalculanPas encore d'évaluation

- CaDocument1 pageCaMae Florizel FalculanPas encore d'évaluation

- ExamDocument3 pagesExamMae Florizel FalculanPas encore d'évaluation

- SYLLABUSDocument2 pagesSYLLABUSMae Florizel FalculanPas encore d'évaluation

- BreakevenDocument3 pagesBreakevenMae Florizel FalculanPas encore d'évaluation

- Revisions For The NTH TimeDocument1 pageRevisions For The NTH TimeMae Florizel FalculanPas encore d'évaluation

- HPMC Experimental ProcedureDocument2 pagesHPMC Experimental ProcedureMae Florizel FalculanPas encore d'évaluation

- JobdescrptionDocument1 pageJobdescrptionMae Florizel FalculanPas encore d'évaluation

- Answer KeyDocument3 pagesAnswer KeyMae Florizel FalculanPas encore d'évaluation

- RadiationDocument2 pagesRadiationMae Florizel FalculanPas encore d'évaluation

- Summary (Group4)Document2 pagesSummary (Group4)Mae Florizel FalculanPas encore d'évaluation

- BreakevenDocument3 pagesBreakevenMae Florizel FalculanPas encore d'évaluation

- Answer KeyDocument3 pagesAnswer KeyMae Florizel FalculanPas encore d'évaluation

- Testing LabDocument5 pagesTesting LabAlbert LorenzPas encore d'évaluation

- How Acetylene is Produced from Calcium Carbide and Natural GasDocument3 pagesHow Acetylene is Produced from Calcium Carbide and Natural GasJoy MukherjePas encore d'évaluation

- REF 2 SCIENCES EE Take HomeDocument7 pagesREF 2 SCIENCES EE Take HomeJevan SoberanoPas encore d'évaluation

- SCK Cai548756Document152 pagesSCK Cai548756Adis Sarac0% (1)

- Advanced Design and Analysis of BOG Treatment Process in LNG Fueled ShipDocument12 pagesAdvanced Design and Analysis of BOG Treatment Process in LNG Fueled Shipsameh tawfeekPas encore d'évaluation

- IESVE Compliance For ASHRAE 90.1Document13 pagesIESVE Compliance For ASHRAE 90.1Moriyasu NguyenPas encore d'évaluation

- Glass Melting Techniques: Regenerative, Recuperative, Oxy-Fuel & ElectricDocument7 pagesGlass Melting Techniques: Regenerative, Recuperative, Oxy-Fuel & ElectricRicardo VelozPas encore d'évaluation

- Class 7 Chapter HeatDocument10 pagesClass 7 Chapter HeatBranded HackerPas encore d'évaluation

- RAW Air Conditioner ComponentsDocument3 pagesRAW Air Conditioner ComponentsAnnisa Yasmin Noor ZainPas encore d'évaluation

- Thermodynamic Properties of R134a (1112-Tetrafluoroethane) PDFDocument11 pagesThermodynamic Properties of R134a (1112-Tetrafluoroethane) PDFJuan Daniel Perez LopezPas encore d'évaluation

- Statistical and Low Temperature PhysicsDocument76 pagesStatistical and Low Temperature PhysicsFran JaksicPas encore d'évaluation

- Applied Thermodynamics-II BTech 7th Mechanical UNIT 1Document6 pagesApplied Thermodynamics-II BTech 7th Mechanical UNIT 1Arjumand MehakPas encore d'évaluation

- Design and Fabrication of Solar Powered Stirling EngineDocument35 pagesDesign and Fabrication of Solar Powered Stirling EngineShubham shendePas encore d'évaluation

- Increase in Energy Efficiency of A Steel Billet Reheating Furnace by Heat Balance Study and Process ImprovementDocument8 pagesIncrease in Energy Efficiency of A Steel Billet Reheating Furnace by Heat Balance Study and Process ImprovementRaheel NadeemPas encore d'évaluation

- Lecture Thermodynamic Basics of Physical ChemistryDocument26 pagesLecture Thermodynamic Basics of Physical ChemistryAshish RajPas encore d'évaluation

- Thermodynamics 2Document4 pagesThermodynamics 2Martono Dwi SPas encore d'évaluation

- VTC 511 Series Thermostatic Radiator ValveDocument4 pagesVTC 511 Series Thermostatic Radiator ValveViorellPas encore d'évaluation

- Chapter Five: The Second Law of ThermodynamicsDocument48 pagesChapter Five: The Second Law of ThermodynamicsBiru EshetePas encore d'évaluation

- 14thermal Expansion of Materials - 227-249Document11 pages14thermal Expansion of Materials - 227-249KAMAL KANT KUSHWAHAPas encore d'évaluation

- Steam Saturation Tables MetricDocument2 pagesSteam Saturation Tables MetricEniabire AyodejiPas encore d'évaluation

- Solutions - Callen H.B. - Exercicios Resolvidos (Cap (01-06) )Document61 pagesSolutions - Callen H.B. - Exercicios Resolvidos (Cap (01-06) )Leonardo Xavier Neves79% (14)

- Unit 4 - Week 3: Assignment 3Document4 pagesUnit 4 - Week 3: Assignment 3Sankar SabarishPas encore d'évaluation

- Friction Losses and Pump HorsepowerDocument4 pagesFriction Losses and Pump HorsepowerChristian Lucio RanadaPas encore d'évaluation

- Hygrothermal AssessmentDocument9 pagesHygrothermal AssessmentGeorge LazarPas encore d'évaluation

- Thermodynamics 2018 (Repaired)Document15 pagesThermodynamics 2018 (Repaired)carolPas encore d'évaluation

- Belaria Dual AR 60 DatblDocument2 pagesBelaria Dual AR 60 Datblboumaraf.minergPas encore d'évaluation

- Mechanism of Heat TransferDocument31 pagesMechanism of Heat Transferedna padrePas encore d'évaluation

- Refrigeration & Air - Conditioning LabDocument60 pagesRefrigeration & Air - Conditioning LabDevendra kumarPas encore d'évaluation

- 4 Way Reversing Valve Series SHF L Data PDFDocument3 pages4 Way Reversing Valve Series SHF L Data PDFDharani PathyPas encore d'évaluation

- Chemical Process CalculationsDocument3 pagesChemical Process CalculationsRusheenRathore0% (1)

- QB Unit 1Document6 pagesQB Unit 1Gaurav GadhesariaPas encore d'évaluation

- Modelling Annealing Lehrs For Flat Glass: Robert GardonDocument8 pagesModelling Annealing Lehrs For Flat Glass: Robert GardonAmer AlkalaifhPas encore d'évaluation