Académique Documents

Professionnel Documents

Culture Documents

Power Injector 1-Port Power-Over-Ethernet Installation Guide

Transféré par

Advantec SrlCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Power Injector 1-Port Power-Over-Ethernet Installation Guide

Transféré par

Advantec SrlDroits d'auteur :

Formats disponibles

Introduction

When users purchase a WLAN solution, they often need to place access points in obscure locations. In the past, a dedicated 24-hour, 90-264 VAC power source was required for each access point in addition to the Ethernet infrastructure. This often required an electrical contractor to install power drops at each access point location. With the Motorola Power Injector solution (pt # AP-PSBIAS-1P2-AFR), centralized power can be provided for devices without a local power supply for each.

The Power Injector is a small lightweight unit with a RJ-45 Ethernet cord input connector from the hub on the front right-hand side of the unit and a RJ-45 data and power output connector to the AP on the front left-hand side of the unit. On the back of the unit is a 110-220 VAC power input. A separate Power Injector is required for each device comprising the network. The Power Injector supports the following devices; AP100, AP200, AP300 and AP-5131. Caution - Using the Power Injector with an unsupported Motorola device could render the device inoperable and void your warranty. The Power Injector has the following features: Independent power controller (SPEAR), CPU controller and input (Data) and output (Data + Power) shielded RJ-45 connectors Supports standard 10/100BaseT Ethernet networks over a standard TIA/EIA-568 Category 5 (or higher) cabling Meets the IEEE 802.3af standard

Technical Specifications

Physical Specifications Width Height Depth Weight

Installation

Preparing for Site Installation

58.5mm 31mm 145mm 450gr

The Power Injector can be installed free standing, on an even horizontal surface or wall mounted using the power injectors wall mounting key holes. The following guidelines should be adhered to before cabling the Power Injector to the Ethernet source and Motorola device: Verify the device receiving converged power and Ethernet from the Power Injector is a product approved by Motorola (AP100, AP200, AP300 and AP-5131). Do not block or cover airflow to the Power Injector. Keep the Power Injector away from excessive heat, humidity, vibration and dust. 90VAC to 264VAC (47Hz - 63Hz) .15.4 W 48VDC The Power Injector is not a repeater, and does not amplify the Ethernet data signal. For optimal performance, ensure the Power Injector is placed as close as possible to the network data port. Do not configure the cable length between the Ethernet network source, the Power Injector and the Motorola AP beyond 100 meters (333ft).

Product Description

The Motorola Power Injector (pt # AP-PSBIAS-1P2-AFR) is a single-port, 802.3af compliant Power over Ethernet hub combining low-voltage DC with Ethernet data in a single cable connecting to an AP. The Power Injectors single DC and Ethernet data cable creates a modified Ethernet cabling environment eliminating the need for separate Ethernet and power cables.

Environmental Specifications Operating Temperature 0C to 40C (32F to 104F) Storage Temperature -20C to 70C (-4F to 158F) Operating Humidity 10% to 93% Non-condensing Storage Humidity 10% to 93% Non-condensing Electrical Specifications Input Voltage Maximum Output Power Nominal Output Voltage Ethernet Interface Input (Data In)

Data

Power

Power Injector to AP-5131 LAN Port

Universal AC Input: 110/220 V, 60/50 Hz. Minimum port output continuous allowable power of 15.4W at 48V (minimum 12.95W at the PDTE)

Ethernet 10/100Base-T (RJ-45 female socket) Ethernet 10/100Base-T, plus 48VDC RJ-45 female socket, with DC voltage on pairs 7-8 and 4-5

Cabling the Power Injector

To install the Power Injector to an Ethernet data source and Motorola device: Caution - Ensure AC power is supplied to the Power Injector using an AC cable with an appropriate ground connection approved for the country of operation. 1. Connect the Power Injector to an AC outlet (110VAC to 220VAC). 2. Connect RJ-45 Ethernet cable between the network data supply (host) and the Power Injector Data In connector. 3. Connect a RJ-45 Ethernet cable between the Power Injector Data & Power Out connector and the Motorola device receiving converged power and Ethernet.

Output (Data & Power Out)

AP-5131

Underload, overload, short-circuit & under/over voltage port protection. Port Status and Main power LED indicators Standalone or wall mount installation support Interconnection option with other Power Injector units.

Wireless LAN

(3)

(4)

(5)

Before using the unit, it must be configured to operate in the facilitys network and run your applications. If you have a problem running your unit or using your equipment, contact your facilitys Technical or Systems Support. If there is a problem with the equipment, they will contact Motrola.

(6)

Service Information

http://www.motorola.com

MOTOROLA INC. 1303 E. ALGONQUIN ROAD SCHAUMBURG, IL 60196

72-99410-01 Revision A May 2007

South Africa Italy/Italia France United Kingdom United States Europe/Mid-East Distributor Operations Latin America Sales Support Sweden/Sverige Netherlands/Nederland Denmark/Danmark Australia 11-8095311 7020-1718 0800 328 2424 01-40-96-52-21 1-800-653-5350 1-631-738-2400 Contact local distributor or call +44 118 945 7360 1-800-347-0178 Inside US +1-954-255-2610 Outside US 1-800-672-906 84452900 2-484441 315-271700 Finland/Suomi Asia/Pacific Germany/Deutschland Canada Austria/sterreich Mexico/Mxico Spain/Espaa Norway/Norge +34 91 324 40 00 Outside Spain 905-629-7226 1-505-5794-0 5-520-1835 +47 2232 4375 +65-6796-9600 9 5407 580 6074-49020 91 324 40 00 Inside Spain

1-Port Power-over-Ethernet

Power Injector

Installation Guide

Inspect the package contents and report any missing or damaged items to your sales representative. The packages should contain the following:

Verifying Package Contents

This guide is intended for the technician responsible for installing the Power Injector. It assumes the technician is familiar with basic Ethernet LAN-based networking and device installation concepts. This guide provides specifications, procedures and guidelines to use during the installation process. This guide does not provide site-specific installation procedures. For detailed site-specific installation procedures, refer to the site-specific documentation derived from site survey and site network analysis.

To the Installer

This Power Injector Installation Guide (72-99410-01)

Power Injector (pt # AP-PSBIAS-1P2-AFR)

(1)

Warnings

Before operating any equipment, review this document for any hazards associated with installation and use of the device. Also, review standard practices for preventing accidents.

Safety Information

Read the installation instructions before connecting the Power Injector to a power source. Follow basic electricity safety measures whenever connecting the Power Injector to its power source. This product relies on on the building installation for short-circuit (over current) protection. Ensure a fuse or circuit breaker no larger than 120 VAC, 3A U.S. (240VAC, 1.5A international) is used on the phase conductor. A volatge mismatch can cause equipment damage and could pose a fire hazard. If the voltage indicated on the label is different from the power outlet voltage, do not connect the Power Injector to that particular outlet. The Power Injector Data In and Data & Power Out ports are shielded RJ-45 sockets. Only RJ-45 data connectors should be connected to these sockets.

Only trained and qualified personnel should install and remove the Power Injector. A power cord is not supplied with the device. Use only a correctly rated power cord thats certified, as appropriate, for the country of operation. The power cord must be a three-conductor type (two current carrying conductors and one ground conductor) terminated on one end by an IEC 60320 appliance coupler (for Power Injector connection) and on the other end by a plug containing a ground (earth) contact. The power cord must be rated for a minimum of 250VAC RMS operation, with a minimum rated current capcity of 5A [or a minimum wire gauge of 18AWG (0.75mm)]. The AC wall-socket outlet must be near the Power Injector and easily accessible. The Power Injector Data and Data & Power interfaces are qualified as SELV (Safety Extra-Low Voltage) circuits according to to IEC 60950. These interfaces can only be connected to SELV interfaces on other equipment.

(2)

Ensure the cable length from the Ethernet source (host) to the Power Injector and Motorola device receiving converged power and Ethernet does not exceed 100 meters (333 ft).

A Power Injector port indicator is not illuminated and the Motorola AP does not operate

1. 2. 3. 4. 5. 6. The Power Injector did not detect the AP and thus the port is not enabled. Ensure you are using a standard 5/5e/6, straight-wired cable with four pairs. Verify the input Ethernet cable is connected to the Power Injector Data In port. Verify the Motorola AP is connected to the Power Injector Data & Power port. Reconnect the Motorola AP to a different Power Injector. If the AP receives power, there is probably a faulty port or RJ-45 connection on the Power Injector. Verify there is not a short over any of the twisted pair cables or over the RJ-45 connectors.

International Contacts

Outside North America, Motorola. Symbol Place Winnersh Triangle, Berkshire, RG41 5TP United Kingdom Telephone: 0800-328-2424 (Inside UK), +44 118 945 7529 (Outside UK)

Marking and European Economic Area (EEA) Statement of Compliance

Motorola hereby declares that this device is in compliance with all the applicable Directives, 89/336/EEC, 73/23/EEC. A Declaration of Conformity may be obtained from http:// www2.symbol.com/doc/

Copyright

Copyright 2007 by Motorola - All rights reserved. Motorola and the Symbol logo are registered trademarks of Symbol Technologies, Inc. Other product names mentioned in this guide may be trademarks or registered trademarks of their respective companies and are hereby acknowledged.

Customer Support Web Sites

Comprehensive on-line support is available at the Support Central site at http://www.symbol.com/support/. Support Central provides our customers with a wealth of information and online assistance including developer tools, software downloads, product manuals and online repair requests. Downloads http://www.symbol.com/downloads Manuals http://www.symbol.com/manuals

Access Point receives power but no Ethernet

1. 2. 3. 4.

5.

Verify the Ethernet cable is connected to an active hub or switch port on the network. Verify the port indicator on the front panel is continuously illuminated. Verify you are using a standard UTP/FTP Category 5 straight (non-crossover) cabling with all four pairs. Ensure the Ethernet cable length is less than 100 meters from the Ethernet data source to the Power Injector. Reconnect the Motorola AP to a different Power Injector. If the AP receives power, there is probably a faulty port or RJ-45 connection on the Power Injector.

Patents

This product is covered by one or more of the patents listed on: www.symbol.com/patents

Additional Information

Obtain additional information by contacting Motorola at: 1-800-722-6234, inside North America +1-631-738-5200, in/outside North America http://www.motorola.com/

Customer Support

The Power Injector has no On/Off power switch. The Power Injector receives power and is ready for Motorola device connection and operation as soon as AC power is applied. Motorola provides its customers with prompt and accurate customer support. Use Support Central as the primary contact for any technical problem, question or support issue involving Motorola products. If the Support Central specialists cannot solve a problem, access to all technical disciplines within Motorola becomes available for further assistance and support. Motorola Support Central responds to calls by email, telephone or fax within the time limits set forth in individual contractual agreements. When contacting Support Central, please provide the following information: Serial number of unit Model number or product name Software type and version number

Multiple Power Injector Installations

Each Power Injector has a coupling rail designed to connect Power Injectors together to support multiple device installations. Align the power injectors and slide the units together using the coupling rail to connect the units. Cable each device as described in the Cabling the Power Injector section of this document. Only one Motorola device (AP 100, AP 200, AP 300 or AP-5131) can be powered from a single Power Injector.

(7)

(9)

(11)

(13)

Power Injector LED Indicators

The Power Injector demonstrates the following LED behavior under normal and/or problematic operating conditions:

North American Contacts

Inside North America, contact Motorola at: For sales and product information: One Symbol Plaza Holtsville, New York 11742-1300 Telephone: 1-631-738-2400/1-800-SCAN 234 Fax: 1-631-738-5990 For product support and service: Support Central Telephone: 1-800-653-5350, +1-631-738-6213 (Outside North America) Fax: 631-563-5410 Email: http://www.symbol.com/support

Regulatory Information

This device is approved under the Symbol Technologies brand; Symbol Technologies, Inc., is the Enterprise Mobility business of Motorola, Inc (Motorola). All devices are designed to comply with rules and regulations in locations they are sold and will be labeled as required. Any changes or modifications not expressly approved by Motorola, could void the users authority to operate the equipment. Local language translations are available at the following website: http://www.symbol.com/manuals. EMI Compliance: Category 5 foiled twisted-pair cables must be used to ensure compliance with Class B emission limits.

Radio Frequency Interference Requirements

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the Tested to Comply FCC rules. These limits are designed to provide reasonable With FCC Standards protection against harmful interference in a residential For Home or Office Use installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

Symbol Technologies Inc.

LED Green (Steady)

AC (Main) Power Injector is receiving power from AC outlet

Port Indicates a device is connected to the Power Injectors outgoing Data & Power cable The Power Injector is overloaded or has a short circuit

Green (Blinking)

Output voltage source is out of range

Troubleshooting

The following potential Power Injector problem scenarios should be addressed as follows:

Reorient or relocate the receiving antenna Increase the separation between the equipment and receiver Connect the equipment to an outlet on a circuit different from that to which the receiver is connected Consult the dealer or an experienced radio/TV technician for assistance

Power Injector does not power up properly

1. 2. 3. Verify the power cord power cord is operational for the intended country of operation Verify the voltage at the power inlet is between 100 and 240 VAC. Remove and reapply power to the Power Injector and verify the LED behavior during the powering sequence.

Radio Frequency Interference Requirements Canada

This Class B digital apparatus complies with Canadian ICES-003. Cet appareil numrique de la classe B est conforme la norme NMB-003 du Canada.

(10) (12) (14)

(8)

Vous aimerez peut-être aussi

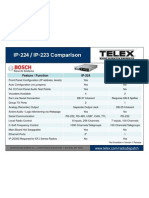

- IP 224 Vs IP 223 Comparison SheetDocument1 pageIP 224 Vs IP 223 Comparison SheetAdvantec SrlPas encore d'évaluation

- Motorola Solutions AP7161 Access Point Installation Guide (Part No. 72E-165267-01 Rev. B) 16526701bDocument64 pagesMotorola Solutions AP7161 Access Point Installation Guide (Part No. 72E-165267-01 Rev. B) 16526701bAdvantec SrlPas encore d'évaluation

- IP 224 Technical DatasheetDocument2 pagesIP 224 Technical DatasheetAdvantec SrlPas encore d'évaluation

- ES6510 Spec SheetDocument2 pagesES6510 Spec SheetAdvantec SrlPas encore d'évaluation

- IP - 224 - Brochure - 2012Document2 pagesIP - 224 - Brochure - 2012Advantec SrlPas encore d'évaluation

- Motorola Solutions WING 5.4.1 Wireless Controller CLI Reference Guide (Part No. 72E-170137-01 Rev. A) 72e-170137-01aDocument1 354 pagesMotorola Solutions WING 5.4.1 Wireless Controller CLI Reference Guide (Part No. 72E-170137-01 Rev. A) 72e-170137-01aAdvantec Srl100% (1)

- Education - Manipal UniversityDocument3 pagesEducation - Manipal UniversityAdvantec SrlPas encore d'évaluation

- Outdoor - ChattanoogaDocument4 pagesOutdoor - ChattanoogaAdvantec SrlPas encore d'évaluation

- Telex C Soft BrochureDocument4 pagesTelex C Soft BrochureAdvantec SrlPas encore d'évaluation

- Healthcare - KAGesDocument4 pagesHealthcare - KAGesAdvantec SrlPas encore d'évaluation

- Healthcare - Memorial Medical CenterDocument4 pagesHealthcare - Memorial Medical CenterAdvantec SrlPas encore d'évaluation

- Radiolinie SIAE ALS ALFO Series 2Document57 pagesRadiolinie SIAE ALS ALFO Series 2Advantec Srl50% (2)

- Outdoor - StratfordDocument4 pagesOutdoor - StratfordAdvantec SrlPas encore d'évaluation

- Education - Turkish University Goes WirelessDocument2 pagesEducation - Turkish University Goes WirelessAdvantec SrlPas encore d'évaluation

- Big Results On: A Small BudgetDocument4 pagesBig Results On: A Small BudgetAdvantec SrlPas encore d'évaluation

- Keller Case Study US-EnDocument4 pagesKeller Case Study US-EnAdvantec SrlPas encore d'évaluation

- Education - Lewis UniversityDocument4 pagesEducation - Lewis UniversityAdvantec SrlPas encore d'évaluation

- Retail - BordersDocument4 pagesRetail - BordersAdvantec SrlPas encore d'évaluation

- Education - Campbell CountyDocument4 pagesEducation - Campbell CountyAdvantec SrlPas encore d'évaluation

- Education - Charles Sturt UniversityDocument2 pagesEducation - Charles Sturt UniversityAdvantec SrlPas encore d'évaluation

- Cambium: PMP 400/430 Series Networks PTP 200/230 Series BridgesDocument79 pagesCambium: PMP 400/430 Series Networks PTP 200/230 Series BridgesalexxxPas encore d'évaluation

- IP 223+Product+SheetDocument1 pageIP 223+Product+SheetAdvantec SrlPas encore d'évaluation

- SMMB1Document1 pageSMMB1Advantec SrlPas encore d'évaluation

- Education - Goliad Texas Independent School DistrictDocument2 pagesEducation - Goliad Texas Independent School DistrictAdvantec SrlPas encore d'évaluation

- Telex Radio Dispatch LRDocument24 pagesTelex Radio Dispatch LRDaniel OlmedoPas encore d'évaluation

- 72E-164153-01 Rev A ADSP User GuideDocument208 pages72E-164153-01 Rev A ADSP User GuideAdvantec SrlPas encore d'évaluation

- Motorola Solutions AP6521 Access Point Installation Guide (Part No. 72E-155456-01 Rev. A) 15545601aDocument56 pagesMotorola Solutions AP6521 Access Point Installation Guide (Part No. 72E-155456-01 Rev. A) 15545601aAdvantec Srl100% (1)

- 72E-168332-01 ADSP 9 0 2 Service Module InstallationDocument14 pages72E-168332-01 ADSP 9 0 2 Service Module InstallationAdvantec SrlPas encore d'évaluation

- WiNG v5.2 ADSP Integration Best Practices v3Document2 pagesWiNG v5.2 ADSP Integration Best Practices v3Advantec SrlPas encore d'évaluation

- 72E-148064-01 InfrastructureManagementSupported Devices (Rev C)Document6 pages72E-148064-01 InfrastructureManagementSupported Devices (Rev C)Advantec SrlPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CSO Computer ProgrammingDocument73 pagesCSO Computer ProgrammingAjPas encore d'évaluation

- Korfund Spring MountsDocument50 pagesKorfund Spring Mountsuamiranda3518Pas encore d'évaluation

- IRS Questions QbankDocument2 pagesIRS Questions Qbanktest1qaz100% (1)

- Manual Catia V5 R12Document262 pagesManual Catia V5 R12Leandro SebastiánPas encore d'évaluation

- Bosnia Water Information SystemDocument15 pagesBosnia Water Information SystemNamik HadziibrahimovicPas encore d'évaluation

- Decision Support SystemDocument32 pagesDecision Support Systemdirection20018800Pas encore d'évaluation

- Manual Da MB Asaki P3 141Document65 pagesManual Da MB Asaki P3 141Alex Alfa100% (2)

- Embedded System Project ReportDocument55 pagesEmbedded System Project ReportManoj Saini0% (1)

- On Solidworks Modeling Tank AssemblyDocument10 pagesOn Solidworks Modeling Tank AssemblyAbdul Khaliq KhanPas encore d'évaluation

- PDFDocument107 pagesPDFyahiatenePas encore d'évaluation

- Useful Logging Information For CM and DMDocument2 pagesUseful Logging Information For CM and DMSachid10Pas encore d'évaluation

- AOS - Alcatel-Lucent Operating SystemDocument4 pagesAOS - Alcatel-Lucent Operating SystemKito TomPas encore d'évaluation

- Components 2010Document164 pagesComponents 2010oscar6033Pas encore d'évaluation

- Lab 5Document10 pagesLab 5Jaber Al NahianPas encore d'évaluation

- F8101 BrochureDocument6 pagesF8101 Brochuregus289Pas encore d'évaluation

- Aixcmds5 PDFDocument838 pagesAixcmds5 PDFAvl SubbaraoPas encore d'évaluation

- 1.1 Computer TerminologyDocument7 pages1.1 Computer TerminologyEver MontoyaPas encore d'évaluation

- Facial Recognition Door Security System Using Raspberry PiDocument41 pagesFacial Recognition Door Security System Using Raspberry PiAnonymous UHfQqEHDIEPas encore d'évaluation

- NA-F60A6 F756A F806X Dll.Document34 pagesNA-F60A6 F756A F806X Dll.Rachmat KometPas encore d'évaluation

- HP Pavilion 14b065br 14b050 Quanta Da0u33mb6d0 Laptop SchematicsDocument37 pagesHP Pavilion 14b065br 14b050 Quanta Da0u33mb6d0 Laptop SchematicsSuport ItecXalapa67% (3)

- Arduino Handouts For StudentsDocument8 pagesArduino Handouts For StudentsEliane DadoPas encore d'évaluation

- DCS Versus FCS: Host Computer: HSE FieldbusDocument7 pagesDCS Versus FCS: Host Computer: HSE Fieldbusgalih santosoPas encore d'évaluation

- G41MX 2.0 Series Motherboard: Downloaded From Manuals Search EngineDocument75 pagesG41MX 2.0 Series Motherboard: Downloaded From Manuals Search EngineHuber EspinozaPas encore d'évaluation

- 8251A Programmable Communication InterfaceDocument25 pages8251A Programmable Communication InterfaceRohith YerrabachalaPas encore d'évaluation

- Chapter1Document19 pagesChapter1naveen muvvalaPas encore d'évaluation

- Conquest Lathe Manual PDFDocument47 pagesConquest Lathe Manual PDFHaitham Mohammad100% (1)

- Data Processing 1Document5 pagesData Processing 1Khushboo PatelPas encore d'évaluation

- MICROCONTROLLERDocument22 pagesMICROCONTROLLERdhirenPas encore d'évaluation

- RAID Level 0 - Striping: AdvantagesDocument19 pagesRAID Level 0 - Striping: AdvantagesoakkarPas encore d'évaluation

- Case Study c36-677449Document4 pagesCase Study c36-677449El Patron 1Pas encore d'évaluation