Académique Documents

Professionnel Documents

Culture Documents

CNC Programming

Transféré par

Yazad DoctorrDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CNC Programming

Transféré par

Yazad DoctorrDroits d'auteur :

Formats disponibles

COMPUTERISED NUMERICAL CONTROL MACHINES

CNC

New machine tools in CNC have enabled industry to consistently produce parts to accuracies undreamed of only a few years ago. The same part can be reproduced to the same degree of accuracy any number of times if the CNC program has been properly prepared and the computer properly programmed. The operating commands which control the machine tool are executed automatically with amazing speed, accuracy, efficiency, and repeatability. The ever-increasing use of CNC in industry has created a need for personnel who are knowledgeable about and capable of preparing the programs which guide the machine tools to produce parts to the required shape and accuracy. Almost everything that can be produced on a conventional machine tool can be produced on a computer numerical control machine tool, with its many advantages.

coordinate system

The coordinate system used for the tool path must be identical to the coordinate system used by the CNC machine. CNC machines milling machines can perform simultaneous linear motion along the three axis and are called three-axes machines.

More complex CNC machines have the capability of executing additional rotary motions (4thand 5thaxes).

Almost everything that can be produced on a conventional machine tool can be produced on a computer numerical control machine tool, with its many advantages. The machine tool movements used in producing a product are of two basic types: pointto-point (straight-line movements) and continuous path (contouring movements).

Machines Using CNC Lathe

Milling Machine

Programming Systems Two types of programming modes, the incremental system and the absolute system, are used for CNC. Both systems have applications in CNC programming, and no system is either right or wrong all the time. Most controls on machine tools today are capable of handling either incremental or absolute programming.

Incremental program locations are always given as the distance and direction from the immediately preceding point

Absolute program

locations are always given from a single fixed zero or origin point The zero or origin point may be a position on the machine table, such as the corner of the worktable or at any specific point on the workpiece. In absolute dimensioning and

programming, each point or location on the workpiece is given as a certain distance from the zero or reference point.

Interpolation The method by which contouring machine tools move from one programmed point to the next is called interpolation.

There are five methods of interpolation: linear, circular, helical, parabolic, and cubic. Linear Interpolation Curves can be produced with linear interpolation by breaking them into short, straight-line segments. This method has limitations, because a very large number of points would have to be programmed to describe the curve in order to produce a contour shape.

Circular Interpolation The development of MCUs capable of circular interpolation has greatly simplified the process of programming arcs and circles. To program an arc (Fig. 12), the MCU requires only the coordinate positions (the XY axes) of the circle center, the radius of the circle, the start point and end point of the arc being cut, and the direction in which the arc is to be cut (clockwise or counterclockwise)

Codes

The most common codes used when programming CNC machines tools are G-codes (preparatory functions), and M codes (miscellaneous functions). Other codes such as F, S, D, and T are used for machine functions such as feed, speed, cutter diameter offset, tool number, etc. G-codes are sometimes called cycle codes because they refer to some action occurring on the X, Y, and/or Z axis of a machine tool,

Code Function G00 Rapid positioning G01 Linear interpolation G02 Circular interpolation clockwise (CW) G03 Circular interpolation counterclockwise (CCW) G20* Inch input (in.) G21* Metric input (mm) G24 Radius programming (**) G28 Return to reference point G29 Return from reference point G32 Thread cutting (**) G40 Cutter compensation cancel G41 Cutter compensation left

G42 Cutter compensation right G43 Tool length compensation positive (+) direction G44 Tool length compensation minus (-) direction G49 Tool length compensation cancel G84 Canned turning cycle (**) G90 Absolute programming G91 Incremental programming Code Function M00 Program stop M02 End of program M03 Spindle start (forward CW) M04 Spindle start (reverse CCW) M05 Spindle stop M06 Tool change M08 Coolant on M09 Coolant off M10 Chuck - clamping M11 Chuck - unclamping M12 Tailstock spindle out M13 Tailstock spindle in M17 Toolpost rotation normal M18 Toolpost rotation reverse M30 End of tape and rewind M98 Transfer to subprogram M99 End of subprogram

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Design of Hydraulic Systems For Lift TrucksDocument264 pagesDesign of Hydraulic Systems For Lift TrucksThuan LePas encore d'évaluation

- XQ2000 Auto Paralleling - Quick Start v1.3 PDFDocument15 pagesXQ2000 Auto Paralleling - Quick Start v1.3 PDFVictor Nunez100% (1)

- P44x Enco E33Document14 pagesP44x Enco E33Dongro MalPas encore d'évaluation

- BK10 - HVAC - MTO For Installation of Fire Damper & Instruments REV.0 (20!07!2011)Document4 pagesBK10 - HVAC - MTO For Installation of Fire Damper & Instruments REV.0 (20!07!2011)vamcodongPas encore d'évaluation

- Precision MeasurementDocument39 pagesPrecision MeasurementNishanth Shannmugam100% (1)

- Go Silently at High Pressure & High Speed: CONTINUUM® SeriesDocument54 pagesGo Silently at High Pressure & High Speed: CONTINUUM® SeriesYazad DoctorrPas encore d'évaluation

- JX-2 Operation and Maintenance ManualDocument14 pagesJX-2 Operation and Maintenance ManualKunpeng Zhou100% (1)

- 4.01.1 Fish Bone Diagram InvoicesDocument19 pages4.01.1 Fish Bone Diagram InvoicesmfernandPas encore d'évaluation

- 04-03-PODFA-Function-Roller Mill QUADROPOL-Hydraulic SystemDocument16 pages04-03-PODFA-Function-Roller Mill QUADROPOL-Hydraulic SystemДен СтаднікPas encore d'évaluation

- Step by Step Maintenance Guide For Mast Hose: Used in Over-the-Sheave ApplicationsDocument6 pagesStep by Step Maintenance Guide For Mast Hose: Used in Over-the-Sheave ApplicationsYazad DoctorrPas encore d'évaluation

- Parflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeDocument2 pagesParflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeYazad DoctorrPas encore d'évaluation

- Parflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeDocument2 pagesParflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeYazad DoctorrPas encore d'évaluation

- New High-Performance PU-Cover Rubber Hoses: The Fusion of Two Worlds in OneDocument10 pagesNew High-Performance PU-Cover Rubber Hoses: The Fusion of Two Worlds in OneYazad DoctorrPas encore d'évaluation

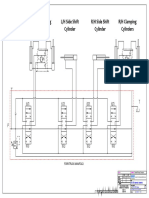

- 5TD STD Hydraulic SchematicDocument1 page5TD STD Hydraulic SchematicYazad DoctorrPas encore d'évaluation

- Pressure Reducing Valve Spool Type, Pilot-Operated SAE-8 Cartridge - 350 BarDocument2 pagesPressure Reducing Valve Spool Type, Pilot-Operated SAE-8 Cartridge - 350 BarYazad DoctorrPas encore d'évaluation

- Bucher Ctype Flow - Control - Valve - Test ReportDocument1 pageBucher Ctype Flow - Control - Valve - Test ReportYazad DoctorrPas encore d'évaluation

- Filter Selection Procedure: We Produce Fluid Power SolutionsDocument9 pagesFilter Selection Procedure: We Produce Fluid Power SolutionsYazad DoctorrPas encore d'évaluation

- DSN 09 F1 - 00 - Testing and Validation Request FormDocument1 pageDSN 09 F1 - 00 - Testing and Validation Request FormYazad DoctorrPas encore d'évaluation

- Parflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeDocument2 pagesParflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeYazad DoctorrPas encore d'évaluation

- CKTDocument1 pageCKTYazad DoctorrPas encore d'évaluation

- Hydac Pressure Compensator Validation On Inlet & D Port Validation SheetDocument2 pagesHydac Pressure Compensator Validation On Inlet & D Port Validation SheetYazad DoctorrPas encore d'évaluation

- Java Mock InterviewDocument78 pagesJava Mock InterviewYazad DoctorrPas encore d'évaluation

- hdm18 - 200 P 991210 enDocument19 pageshdm18 - 200 P 991210 enAlejandro NavaPas encore d'évaluation

- Load Sensing Pressure Booster: 1 DescriptionDocument2 pagesLoad Sensing Pressure Booster: 1 DescriptionYazad DoctorrPas encore d'évaluation

- Leak-Free Load-Control Valve, Size 6Document9 pagesLeak-Free Load-Control Valve, Size 6Yazad DoctorrPas encore d'évaluation

- RFT 043 RFT 072: Return Filters - LightlineDocument5 pagesRFT 043 RFT 072: Return Filters - LightlineYazad DoctorrPas encore d'évaluation

- Pressure Compensated Partially Adjustable Flow Regulators, With Male-Female SleeveDocument2 pagesPressure Compensated Partially Adjustable Flow Regulators, With Male-Female SleeveYazad DoctorrPas encore d'évaluation

- Dimensions For Banjo Eye (BSP) : Size Dimension D' Dimension D' Dimension H'Document1 pageDimensions For Banjo Eye (BSP) : Size Dimension D' Dimension D' Dimension H'Yazad DoctorrPas encore d'évaluation

- Danfoss Guide To CleanlinessDocument24 pagesDanfoss Guide To CleanlinessYazad DoctorrPas encore d'évaluation

- Essential Components of Business AcumenDocument2 pagesEssential Components of Business AcumenYazad DoctorrPas encore d'évaluation

- Ofsj2433Document11 pagesOfsj2433Yazad DoctorrPas encore d'évaluation

- E7106 16 11 16 - RFM 2 Loch - KatalogversionDocument6 pagesE7106 16 11 16 - RFM 2 Loch - KatalogversionYazad DoctorrPas encore d'évaluation

- High Performance Vane Pump: VP SPDocument3 pagesHigh Performance Vane Pump: VP SPYazad DoctorrPas encore d'évaluation

- Dimensions For Banjo Eye (BSP) : Size Dimension D' Dimension D' Dimension H'Document1 pageDimensions For Banjo Eye (BSP) : Size Dimension D' Dimension D' Dimension H'Yazad DoctorrPas encore d'évaluation

- Hose SpecsDocument3 pagesHose SpecsYazad DoctorrPas encore d'évaluation

- Dimensions For Banjo Eye (BSP) : Size Dimension D' Dimension D' Dimension H'Document1 pageDimensions For Banjo Eye (BSP) : Size Dimension D' Dimension D' Dimension H'Yazad DoctorrPas encore d'évaluation

- Ep Catalog 2007-1Document16 pagesEp Catalog 2007-1gadacz111Pas encore d'évaluation

- Sample ReportDocument19 pagesSample Reporthacker123456Pas encore d'évaluation

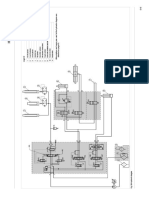

- PR754 (Working Hydraulic)Document10 pagesPR754 (Working Hydraulic)Tomi Ananda PradistyPas encore d'évaluation

- Palfinger PK 6001Document6 pagesPalfinger PK 6001luis gonzalezPas encore d'évaluation

- Method Statement Riyadh School Project Fire Fighting SystemDocument3 pagesMethod Statement Riyadh School Project Fire Fighting Systemkhantoseef84Pas encore d'évaluation

- Manual Biffi f01 2000 Electric Actuator en en Us 5898808Document118 pagesManual Biffi f01 2000 Electric Actuator en en Us 5898808ErwinCahyonoPas encore d'évaluation

- Schuler Electronics Instructor CH14 Electronics ComtrolDocument30 pagesSchuler Electronics Instructor CH14 Electronics ComtrolRíõ EscanillaPas encore d'évaluation

- TSG SRF: Triggered Spark Gap Surge Reduction FiltersDocument8 pagesTSG SRF: Triggered Spark Gap Surge Reduction FiltersAngela TienPas encore d'évaluation

- Telguard GDC1 - Installation ManualDocument2 pagesTelguard GDC1 - Installation ManualAlarm Grid Home Security and Alarm MonitoringPas encore d'évaluation

- Equipment Spares CompanyDocument8 pagesEquipment Spares CompanyBalraj BawaPas encore d'évaluation

- A88438-23 Critical Procedure 11-01 - Pipeline Cut Outs - A5X9W9Document7 pagesA88438-23 Critical Procedure 11-01 - Pipeline Cut Outs - A5X9W9mahmoudPas encore d'évaluation

- Version Von DFMC b10034 00 Simotics Motoren72dpiDocument26 pagesVersion Von DFMC b10034 00 Simotics Motoren72dpiRakshit SharmaPas encore d'évaluation

- Manual Compresor SHD245Document21 pagesManual Compresor SHD245eduardo toroPas encore d'évaluation

- DW 1030 For Web 2017 SmallerDocument12 pagesDW 1030 For Web 2017 SmallerMaxi452Pas encore d'évaluation

- Q7 & Q8 @trial 2021Document61 pagesQ7 & Q8 @trial 2021nuraliahPas encore d'évaluation

- Pipe Sizing Table AnalysisDocument7 pagesPipe Sizing Table AnalysisDarryl GelacioPas encore d'évaluation

- Discipline Build GuideDocument12 pagesDiscipline Build Guidekatherine bellmanPas encore d'évaluation

- MX-M264N Series Service ManualDocument256 pagesMX-M264N Series Service ManualJJ JJ100% (2)

- Bipotentiostat Installation and SetupDocument2 pagesBipotentiostat Installation and SetupwjawichPas encore d'évaluation

- 1pages From GR-500N-1 - C1-1E-2Document4 pages1pages From GR-500N-1 - C1-1E-2Ihsan AhmedPas encore d'évaluation

- Singer 291U1, U3Document46 pagesSinger 291U1, U3Datum VivelacriquePas encore d'évaluation

- Contactor 3RT 3TF6 - E86060 k1010 A191 A1 7600Document29 pagesContactor 3RT 3TF6 - E86060 k1010 A191 A1 7600Mai Hồng QuânPas encore d'évaluation

- CSS 1st QuarterDocument4 pagesCSS 1st QuarterBarbie BeltranPas encore d'évaluation

- Stage II Pa System Unit-1,2,3,4 & CHP - Unit-1Document1 pageStage II Pa System Unit-1,2,3,4 & CHP - Unit-1jp mishraPas encore d'évaluation