Académique Documents

Professionnel Documents

Culture Documents

WPS AMC-0195 Rev 01

Transféré par

umer.shariff87Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WPS AMC-0195 Rev 01

Transféré par

umer.shariff87Droits d'auteur :

Formats disponibles

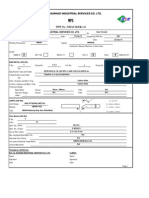

REQUEST FOR WELDING PROCEDURE APPROVAL

It is requested that the following Welding Procedure Specification(WPS) be reviewed and approved.The listed WPS has been qualification tested in accordance with SAES-W-011.It has been edited for clerical completeness and technical content.

Company Project JO/BI/Contract No WPS No. PQR No.

Al Muhaidib Contracting Co. Replace Fire Station - Shedgum Gas Plant.

BI-10-00659

AMC-0195 Rev.01 AMTC-0195RI

CODE/SPEC

ASME SEC VIII ANSI B 31.1 ASME SEC IX ANSI B 31.3

X X

API 1104 ANSI B 31.4

AWS D 1.1 ANSI B 31.8

DESIGN CONDITIONS:

OPERATING TEMPERATURE SERVICE FLUID APPLICABLE FOR SOUR SERVICE CHARPY IMPACT TEST(PQR) HARDNESS TEST(PQR) APPLICATION MATERIAL GRADES WELDING PROCESS DIAMETER RANGE WALL THICKNESS RANGE Minimum Temperature Oil,Gas and Water. YES YES YES See Attached SAES W-011 Table 3A/3B

NO NO

NO

Welding of Plant Piping(Pipes,Fittings and Flanges) P1 GROUP 1,2 SMAW GROOVE GROOVE NPS 2-1/2" & OVER 3/16" TO 3/4" FILLET FILLETALL ALL

SAUDI ARAMCO PROJECT MANAGEMENT TEAM

Name Telephone Fax Signature

Date Department Address

SAUDI ARAMCO PROJECT INSPECTION UNIT

Name Signature

Unit/Div./Dept Date

WELDING PROCEDURE SPECIFICATION(WPS)

Company Name WPS No. PQR No. Welding Process ASME SEC IX X Al Muhaidib Contracting Co AMC-0195 AMTC-0195RI SMAW API 1104 AWS D1.1 Prepared By Revision No Date Type(s) ANSI B31.3 X S.Umer Shariff 001 23-Jan-95 MANUAL ANSI 31.4 ANSI B 31.8 Date 6-Jun-12

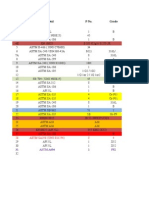

BASE METALS(QW-403) P No. OR Spec & Grade OR Chem.Analysis/Mech.Prop Thickness Groove Range Diameter Groove Range JOINT(QW-402) Joint Design Backing 3/16" to 3/4" NPS 2-1/2" & OVER N/A to Chem.Analysis/Mech.Prop N/A Fillet Fillet ALL ALL ASTM A 106 Gr.B or Equivalent Spec & Grade ASTM A 106 Gr.B or Equivalent 1 Group No. 1 to P No. 1 Group No. 1

Single VEE BUTT joint. NIL.

FILLER METALS(QW-404) WELDING PROCESS Weld Metal Analysis A No. Filler Metal F No. SFA Specification AWS Classification Size of Filler Metal.Dia Electrode Flux Class Electrode Trade Name Consumable Insert Other TECHNICAL APPROVAL(Al Muhaidib) SMAW 1 3&4 SFA 5.1 E6010 & E7018 3/32" & 1/8" N/A Lincoln Electrodes or Equivalent N/A N/A TECHNICAL APPROVAL(Client)

WELDING PROCEDURE SPECIFICATION(WPS)

POSITION(QW-405) Position of Groove Welding Progression(Up/Down) Position of Fillet Other All Uphill All N/A POST WELD HEAT TREATMENT(QW-407) Temp.Range Soak Period Heating Range Cooling Rate Other N/A N/A N/A N/A N/A

PREHEAT(QW-406) Preheat Temp Min Interpass Temp Max Preheat Maintenance See Attached SAES-W-011 Table 3A/3B N/A N/A

001

GAS(QW-408) Percent Composition Gas(es) Sheilding Trailing Backing N/A N/A N/A Mixture N/A N/A N/A Flow Rate N/A N/A N/A

TECHNIQUE(QW-410) String or Weave Bead Oscillation Multi-Pass or single pass /Side Single or Multiple Electrode Initial and Interpass Cleaning Orifice or Gas Cup Size Method of Backgouging Contact Tube to Work Distance Peening other ELECTRICAL CHARACTERISTICS(QW-409) Weld Layer(S) Process Filler Metal Class ROOT HOT PASS FILL/CAP SMAW SMAW SMAW E6010 E7018 E7018 Diameter 1/8" 1/8" 1/8" Polarity DCRP DCRP DCRP Current Amp.Range 80-100 90-120 110-140 Volt Range 18-26 18-26 18-26 4-8 IPM 4-8 IPM 4-8 IPM Travel Speed String or Weave N/A Multiple Pass Single Electrode Wire Brushing and Grinding when Required N/A N/A N/A N/A N/A

Vous aimerez peut-être aussi

- Base Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4Document3 pagesBase Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4MAT-LIONPas encore d'évaluation

- Process Op GAS PROCESSINGDocument3 pagesProcess Op GAS PROCESSINGjohn MPas encore d'évaluation

- QATAR Pin Braze pdfr1Document14 pagesQATAR Pin Braze pdfr1Karunanithi NagarajanPas encore d'évaluation

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoPas encore d'évaluation

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocument1 pageWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiPas encore d'évaluation

- Chapter 5 - Conclusion & RecommendationDocument4 pagesChapter 5 - Conclusion & RecommendationMohamad Shukri0% (1)

- S-23804-Eng - 22 12 HTDocument2 pagesS-23804-Eng - 22 12 HTbiliboi5Pas encore d'évaluation

- Material Approval: Sub Contractor Submission Date Name of Material Sample Supplier Specification DetailsDocument1 pageMaterial Approval: Sub Contractor Submission Date Name of Material Sample Supplier Specification DetailsM Helmi Yunan PanggabeanPas encore d'évaluation

- Hts 2134981 RHM Bolting Proposal Yanbu 11.05.13Document4 pagesHts 2134981 RHM Bolting Proposal Yanbu 11.05.13George ManuelPas encore d'évaluation

- Dibia Ifeanyichukwu Peter Updated CV (Resume)Document7 pagesDibia Ifeanyichukwu Peter Updated CV (Resume)wizzy basseyPas encore d'évaluation

- Welding Log DW-CWDocument12 pagesWelding Log DW-CWhasan shahriarPas encore d'évaluation

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Daterohitbhat2345Pas encore d'évaluation

- QG - Rover Operator Campaign SummaryDocument3 pagesQG - Rover Operator Campaign SummaryBadredine EDDAIDJPas encore d'évaluation

- Structural Steel and Pipe Work ProcedureDocument5 pagesStructural Steel and Pipe Work ProcedureMohamed100% (2)

- Precommissioning Activities Reinstatement ChecklistDocument1 pagePrecommissioning Activities Reinstatement ChecklistYusufPas encore d'évaluation

- CV - Project ManagerDocument2 pagesCV - Project ManagerDARA SINGHPas encore d'évaluation

- Test Pack Flow / Control Log: Punch List / Inspection Prior For Hydro TestDocument2 pagesTest Pack Flow / Control Log: Punch List / Inspection Prior For Hydro Testsyedahmad39Pas encore d'évaluation

- Link To Notes On Casing Design Overview Google DriveDocument33 pagesLink To Notes On Casing Design Overview Google DriveGhebache OtakuPas encore d'évaluation

- Tank Fabrication & ErectionDocument72 pagesTank Fabrication & ErectionPramod GrPas encore d'évaluation

- Nde-1711-T393-F0005 Annular To Bottom Plate JointDocument1 pageNde-1711-T393-F0005 Annular To Bottom Plate Jointdada khalandar100% (1)

- Weld ElectrodesDocument42 pagesWeld ElectrodesNarendraPas encore d'évaluation

- ITR-C (Instrument) 16cDocument1 pageITR-C (Instrument) 16cMomo ItachiPas encore d'évaluation

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavPas encore d'évaluation

- Heavy Equipment OperatorDocument2 pagesHeavy Equipment OperatorAnonymous nqf1acDZWPas encore d'évaluation

- STOD-GEN-AED-0000-PR-DAT-0011 - Chemical Injection Packages Data SheetDocument13 pagesSTOD-GEN-AED-0000-PR-DAT-0011 - Chemical Injection Packages Data SheetAHMED AMIRAPas encore d'évaluation

- JKKP (DOSH) - QC Manual - Process Flow - Simple SampleDocument1 pageJKKP (DOSH) - QC Manual - Process Flow - Simple Samplemohd_zaieriPas encore d'évaluation

- Jawaid Shut Down ResumeDocument4 pagesJawaid Shut Down ResumeRaj AryanPas encore d'évaluation

- Itp For Field Erected Tank Rev A PDF FreeDocument9 pagesItp For Field Erected Tank Rev A PDF FreeMahmoud GaberPas encore d'évaluation

- Ebs1-Ptfa30-Sacm-Prmm-1003 (Material Control Procedure) - 4Document7 pagesEbs1-Ptfa30-Sacm-Prmm-1003 (Material Control Procedure) - 4AhmedPas encore d'évaluation

- Vertical Sand SeparatorDocument2 pagesVertical Sand SeparatorKapwell LimitedPas encore d'évaluation

- Nawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFDocument29 pagesNawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFAhmed AbidPas encore d'évaluation

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedPas encore d'évaluation

- Painting ReportDocument29 pagesPainting ReportDimas Afiefan AmirPas encore d'évaluation

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 pagesMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GPas encore d'évaluation

- Witness Joint & Sampling MatrixDocument13 pagesWitness Joint & Sampling MatrixPazhamalai RajanPas encore d'évaluation

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifPas encore d'évaluation

- WPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)Document1 pageWPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)ufomskiPas encore d'évaluation

- DBB BNCPP B M v29 0015 Revb IfaDocument6 pagesDBB BNCPP B M v29 0015 Revb IfaIzzadAfif1990Pas encore d'évaluation

- SABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingDocument2 pagesSABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingAnas AbdoPas encore d'évaluation

- Weld Repairs:: 1) Production Repairs 2) In-Service RepairsDocument4 pagesWeld Repairs:: 1) Production Repairs 2) In-Service RepairsEhsan KhanPas encore d'évaluation

- MMP-CKL-0007 PID Check ListDocument5 pagesMMP-CKL-0007 PID Check ListQWAS111Pas encore d'évaluation

- Koc L 026 PDFDocument32 pagesKoc L 026 PDFJigarPas encore d'évaluation

- 14 Inspection and TestingDocument3 pages14 Inspection and TestingelmiraPas encore d'évaluation

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithPas encore d'évaluation

- Off Shore Piping Design, Layout and Stress Analysis (Project Standards and Specifications)Document5 pagesOff Shore Piping Design, Layout and Stress Analysis (Project Standards and Specifications)sachin nagavkarPas encore d'évaluation

- Inspectable MaterialsDocument2 pagesInspectable MaterialsMohamed RedaPas encore d'évaluation

- MRB IndexDocument1 pageMRB IndexVishnuGKPas encore d'évaluation

- SGGP Reference No: P0116-TAK-P01-0072-02Document14 pagesSGGP Reference No: P0116-TAK-P01-0072-02Jabel Oil Services Technical DPTPas encore d'évaluation

- Name: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiPas encore d'évaluation

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickPas encore d'évaluation

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiPas encore d'évaluation

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilPas encore d'évaluation

- Description Price Unit Mob-Demob Sub-Total TotalDocument2 pagesDescription Price Unit Mob-Demob Sub-Total TotalArif HakimPas encore d'évaluation

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalPas encore d'évaluation

- Jms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0001 - 1 Code 3Document11 pagesJms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0001 - 1 Code 3amir hakim100% (1)

- Title: WQ 482 Welding Procedure Specification (WPS) : SupersedesDocument1 pageTitle: WQ 482 Welding Procedure Specification (WPS) : SupersedesdethamrnPas encore d'évaluation

- Internal Audit Non-Conformity ReportDocument4 pagesInternal Audit Non-Conformity ReportSparrow Green StudiosPas encore d'évaluation

- Rubber Gasket TypesDocument92 pagesRubber Gasket Typessushant_moreyPas encore d'évaluation

- WPS TemplateDocument3 pagesWPS TemplateAldin MemidzanPas encore d'évaluation

- WPS 204 NewDocument6 pagesWPS 204 Newarockiyathass100% (1)

- Wavi Strong Installation GuideDocument44 pagesWavi Strong Installation Guideumer.shariff87Pas encore d'évaluation

- FP-006 - DOC Rev. ADocument6 pagesFP-006 - DOC Rev. Aumer.shariff87Pas encore d'évaluation

- Chemical Resistant RackModelDocument1 pageChemical Resistant RackModelumer.shariff87Pas encore d'évaluation

- Fosroc CatalogueDocument298 pagesFosroc CatalogueGeorge Tsiamtsouris75% (4)

- SSL-VPN Service: End User GuideDocument19 pagesSSL-VPN Service: End User Guideumer.shariff87Pas encore d'évaluation

- 12 Samss 007Document29 pages12 Samss 007umer.shariff87100% (1)

- Vc-90200.01.03-En Ecoline DJDocument6 pagesVc-90200.01.03-En Ecoline DJGary IrawanPas encore d'évaluation

- Accelerator Design For Proton Therapy: OutlineDocument8 pagesAccelerator Design For Proton Therapy: OutlineriomjPas encore d'évaluation

- Kuhnke IA Series Relay DatasheetDocument4 pagesKuhnke IA Series Relay DatasheetKishore KPas encore d'évaluation

- En 609-1 PDFDocument14 pagesEn 609-1 PDFSURESHKUMARPas encore d'évaluation

- Hydraulic Turbines: Turbines and That Con Vert Mechanical Energy IntoDocument22 pagesHydraulic Turbines: Turbines and That Con Vert Mechanical Energy IntosaitejaPas encore d'évaluation

- Power System Stability Vol II KimbarkDocument296 pagesPower System Stability Vol II KimbarkShashidhar Kasthala100% (11)

- KEW2117R: Instruction ManualDocument1 pageKEW2117R: Instruction ManualMuthohPas encore d'évaluation

- Ebook 4 PrintingDocument91 pagesEbook 4 PrintingManuel AsitimbayPas encore d'évaluation

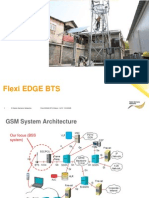

- Flexi Bts Nokia SeimensDocument16 pagesFlexi Bts Nokia SeimensSarah AndersonPas encore d'évaluation

- Maching Learning Methods Used in Data MiningDocument11 pagesMaching Learning Methods Used in Data MiningYunir Causil NoyaPas encore d'évaluation

- Nte1855 - LA 7835Document3 pagesNte1855 - LA 7835ArjunroyEdwardPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document20 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Angga supriyantoPas encore d'évaluation

- Rotary ActuatorsDocument34 pagesRotary Actuatorsmr3478Pas encore d'évaluation

- Automobile Industry: A Pre-And post-GST Analysis of The 4 Wheeler SegmentDocument20 pagesAutomobile Industry: A Pre-And post-GST Analysis of The 4 Wheeler SegmentAyushBishtPas encore d'évaluation

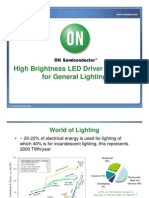

- Overview of Led LightingDocument63 pagesOverview of Led Lightingpcharwood100% (3)

- Catalog - For - Surface - Grinding - Machines - by - Kohinoor - Machine - ToolsDocument2 pagesCatalog - For - Surface - Grinding - Machines - by - Kohinoor - Machine - ToolsKohinoor Machine ToolsPas encore d'évaluation

- Technical Specification For 20 MVA Transformer PDFDocument21 pagesTechnical Specification For 20 MVA Transformer PDFamulya00428100% (10)

- Section 15250 - Mechanical InsulationDocument8 pagesSection 15250 - Mechanical Insulationrizviabbas2012Pas encore d'évaluation

- Sugar Industry PrimerDocument38 pagesSugar Industry PrimerDody IrawanPas encore d'évaluation

- Pio Joe Sleiman 11D Science Capstone ProjectDocument18 pagesPio Joe Sleiman 11D Science Capstone ProjectpiojoesleimanPas encore d'évaluation

- Sizing Phase-Change Energy Storage Units For Air-Based Solar Heating SystemsDocument5 pagesSizing Phase-Change Energy Storage Units For Air-Based Solar Heating Systemsfabio1199Pas encore d'évaluation

- A320LEAP1A-B12-0008.7 Oil R1 220517Document82 pagesA320LEAP1A-B12-0008.7 Oil R1 220517simsimsomPas encore d'évaluation

- ITS Energie Jar and Energizer Operation - Techincal Brochure PDFDocument18 pagesITS Energie Jar and Energizer Operation - Techincal Brochure PDFsaeed65Pas encore d'évaluation

- Calefaccion Mazda 3 2006 - 2010Document2 pagesCalefaccion Mazda 3 2006 - 2010Jhon ConnorPas encore d'évaluation

- Outotec: Managing Talent Globally With Successfactors® SolutionsDocument3 pagesOutotec: Managing Talent Globally With Successfactors® SolutionsxandaniPas encore d'évaluation

- Chemical3 8Document51 pagesChemical3 8Shambhu Singh RathorePas encore d'évaluation

- Omnik - Let Mankind Share and Enjoy Blue Sky and White Clouds Professional Inverter ManufacturerDocument18 pagesOmnik - Let Mankind Share and Enjoy Blue Sky and White Clouds Professional Inverter ManufactureromnikshanPas encore d'évaluation

- Year 7 Activity Pack Samples - UNIT 7IADocument11 pagesYear 7 Activity Pack Samples - UNIT 7IAAFuentesCaballeroPas encore d'évaluation

- Hysil Brochure MailDocument19 pagesHysil Brochure Mailsudershan_babbarPas encore d'évaluation

- G 08Document7 pagesG 08zbkt07Pas encore d'évaluation