Académique Documents

Professionnel Documents

Culture Documents

Double Layer Peltier Device

Transféré par

api-129748480Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Double Layer Peltier Device

Transféré par

api-129748480Droits d'auteur :

Formats disponibles

The Feature of Dual Module

By combining two Peltier modules in a dual layer, large temperature-difference can be obtained. We tried to enhance the thermal efficiency. To attain this goal, the base material in the middle of joint area has been attempted to make as thin as possible. As a result, thermal resistance can be reduced. Also, as our dual module consists of the materials whose expansion rate is much different, the strain arises. However, by absorbing this strain at the base material, we could enhance its durability. In addition, compared to conventional multiple module, the cost to produce our

Ceramic sheet -

heat

absorption

lead-free Sn/Sb solder is used in order to join semiconductors. Available maximum temperature is set up at 200 because the solder melts at 240 .

P P

Copper heat release

Semi conductor

Usage example

Parallel connection

Product DV2F4085 DV2F4060 DV2F6085

Parallel connection Let us explain how to connect in the figure above. First, apply +12V to the red lead at lower right side, and then connect the black lead at lower left side to ground. In a similar way, apply +6V to the red lead at upper right side, and then connect the black lead at upper left side to ground independently. Large temperature-difference can be obtained between heat absorption side and heat release side. Serial connection First, apply +14V to the red lead at lower right side, and then connect the black lead at lower left side to the red lead at upper right side. Finally, connect the black lead at upper left side to ground. In spite of power saving, our dual module can obtain as high temperature-difference as single module. As the amount of absorbed

external dimensionmm Imax Qcmax Vmax Tmax (A) (W) (V) W L T recital 2.6/8.5 41 8/17 90 40 40 6 heat absorption 040Type 2.5/6 38 7/17 86 40 40 6 heat absorption 040Type 2.8/8.5 43 6/17 78 40 40 6 heat absorption 060Type attention 1 attention 1Notation: heat absorption/ heat release, current and voltage in a dual module Th=50 external dimensionmm L T recital 40 6 heat absorption 085Type 40 6 heat absorption 060Type 40 6 heat absorption 085Type

Serial connection

Experimental performance (apply +14V) Vmax is 17 14V=I power comsumption Qcmax Tmax Product (A) (W) () W DV2F4085 2.5 35 26.5 60 40 DV2F4060 2.2 30.8 24 60 40 DV2F6085 3.6 50.4 30 60 40

Our dual module consists of two peltier modules whose features are different each other, and is combined in a dual layer. As a result, the performance changes due to the way of applied voltage. Also, the combination of modules enables to choose the Tmax or Qcmax value. Therefore, we can offer Peltier modules you need. Please contact Da Vinci (right information) for details.

Da Vinci , Co Ltd.

506-6, Tsukiyama, Yamatotakada-shi, Nara TEL0745-23-1441 FAX0745-23-1442

Basic knowledge of thermal module

1. About thermal module

Known as Peltier devices, or heat-to-electricty converting devices. A component having heat transferred from obverse side to reverse side. With switching the current polarity, it is capable of getting heat or cool. Electronic component working as small heat pump.

Figure 1

2. Feature

Small and light. Ability to adjust temperature partly and exactly (heating or cooling). No pollution with refrigerant gas like CFC. No vibration or noise.

3. Principle

Thermal module is a cooling device consisting of N type and P type semiconductor pair. With direct current, one absorbs heat (cooling), and the other releases heat (heating). With switching the current polarity, it is capable of getting heat or cool Peltier effect. Our module is the most suitable for high-accuracy temperature control or local cooling that heater or heat sink cannot be accepted. In addition, temperature difference enables to generate electricity Zeebeck effect.

Working principle Peltier effects mean, when two different metals or semiconductors connect together and conduct electricity, one gives off cold, while the other gives off heat. Today, practical Peltier devices consist of semiconductors. Let us explain how to work in figure 2 in the following Figure 2 section.

In terms of the action of electrons in Peltier effect, electrons travel from minus electrode to P type semiconductor. However, their speed is slow because of the transfer on its hole. When electrons reach a metal electrode drawn in blue, they travel faster in an electron cloud. Our module produces large effect of heat absorption and heat release against semiconductors whose potential energy is so different. This is because verocity difference among them is added. On the other hand, the action of electrons in Zeebeck effect is generated with electromotive force. This force is produced from temperature difference between heat absorption side and heat release side in the figure, which has nothing to do with external voltage. In Peltier effect, electrons travel to cool down heat release side (drawn in blue arrows). With this action, the larger temperature difference T between heat absorption side and heat release side is obtained, the less effect is due to back electromotive force in Zeebeck effect. Hence, in the environment where large can be

heat absorption side

metal electrode electron action in zeebeck effect

type

type

electron action in peltier effect

+ electrode

heat release side

- electrode

Our dual module consists of Peltier devices. They are combined in a dual layer with thin film sandwiched between metal electrodes drawn in blue in the figure 2. Now, patent is pending. Please contact representative given below for detailed technical inquiry or asking for sample.

Da Vinci, Co Ltd.

Nara

506-6, Tsukiyama, Yamatotakada-shi, Representative : Kenji Higashi TEL : 0745-23-1441

Vous aimerez peut-être aussi

- Astm B19Document6 pagesAstm B19Davor IbarraPas encore d'évaluation

- Introduction PeltierDocument8 pagesIntroduction PeltierShubham TiwariPas encore d'évaluation

- Info para PreguntarDocument10 pagesInfo para PreguntarAgustin AvilaPas encore d'évaluation

- Project Work On Thermoelectric RefrigeratonDocument19 pagesProject Work On Thermoelectric RefrigeratonSatyajit RastogiPas encore d'évaluation

- Bicycle Based RefrigeratorDocument27 pagesBicycle Based RefrigeratorAanya SethPas encore d'évaluation

- A Review On Generation of Electricity Using PeltieDocument5 pagesA Review On Generation of Electricity Using PeltieUsama SherwaniPas encore d'évaluation

- What Is A Peltier Cooler?: The Heatsink GuideDocument4 pagesWhat Is A Peltier Cooler?: The Heatsink GuideygraoPas encore d'évaluation

- History and Introduction PeltierDocument15 pagesHistory and Introduction PeltierZilhaq Putra Edy SanjayaPas encore d'évaluation

- Thermionic Energy Conversion: Schlichter (1915) Hatsopoulos and Gyftopoulos, 1973 1979Document34 pagesThermionic Energy Conversion: Schlichter (1915) Hatsopoulos and Gyftopoulos, 1973 1979YyPas encore d'évaluation

- Peltier Thermoelectric Cooling ModuleDocument2 pagesPeltier Thermoelectric Cooling ModuleMark Genesis AlanoPas encore d'évaluation

- Thermoelectric Power Generator Design and Selection From TE Cooling Module SpecificationsDocument4 pagesThermoelectric Power Generator Design and Selection From TE Cooling Module SpecificationschesskingPas encore d'évaluation

- Thermoelectric Power GenerationDocument6 pagesThermoelectric Power GenerationDevi ArumugamPas encore d'évaluation

- Thermoelectric GeneratorsDocument17 pagesThermoelectric Generatorsrajat4kokanePas encore d'évaluation

- Thermoelectric GeneratorDocument7 pagesThermoelectric GeneratorJinesh100% (1)

- Unit ViDocument69 pagesUnit ViRavichandran SekarPas encore d'évaluation

- Mohammad AjazDocument17 pagesMohammad AjazMohammad Ajaz DeshmukhPas encore d'évaluation

- Bim Project ReportDocument4 pagesBim Project Reportelisha.owais1000Pas encore d'évaluation

- Generate Renewable Energy Efficiently Using Nanofabricated Silicon (GREEN Silicon)Document1 pageGenerate Renewable Energy Efficiently Using Nanofabricated Silicon (GREEN Silicon)ettypasewangPas encore d'évaluation

- Thermo-Electric GeneratorDocument19 pagesThermo-Electric GeneratorMomo PlayerPas encore d'évaluation

- AppendixDocument20 pagesAppendixDexServPas encore d'évaluation

- Development of TEC System For Commercial Cooling ApplicationsDocument6 pagesDevelopment of TEC System For Commercial Cooling ApplicationsEhtisham Khan JadoonPas encore d'évaluation

- Erode Sengunthar Engineering College Design and Fabrication of Peltier Based Mini CoolerDocument20 pagesErode Sengunthar Engineering College Design and Fabrication of Peltier Based Mini Coolerameer kannanPas encore d'évaluation

- ThermocoupleDocument3 pagesThermocoupleOctarina Adiati JuinasihPas encore d'évaluation

- Cooling, Heating, Generating Power, and Recovering Waste Heat With Thermoelectric SystemsDocument5 pagesCooling, Heating, Generating Power, and Recovering Waste Heat With Thermoelectric Systemsbrandon37Pas encore d'évaluation

- Te 2Document13 pagesTe 2Gurpreet singhPas encore d'évaluation

- Seebeck and Peltier EffectsDocument8 pagesSeebeck and Peltier EffectskiranpatruduPas encore d'évaluation

- TEG TubesDocument3 pagesTEG TubesPereira JenPas encore d'évaluation

- Engine Exhust Power Generasion System: Fig. 1 Seebeck EffectDocument5 pagesEngine Exhust Power Generasion System: Fig. 1 Seebeck EffectSajid ShaikhPas encore d'évaluation

- Peltier Effect Based Solar Powered Air Conditioning SystemDocument6 pagesPeltier Effect Based Solar Powered Air Conditioning SystemManoj Kavedia100% (1)

- Project Report FinalDocument36 pagesProject Report FinalNiranjan ThimmappaPas encore d'évaluation

- Engineering Physics Minor ProjectDocument9 pagesEngineering Physics Minor ProjectSaketh ChintamaneniPas encore d'évaluation

- Thermoelectric CoolingDocument68 pagesThermoelectric CoolingdabrevipulPas encore d'évaluation

- Thermoelectric Refrigeraton1Document10 pagesThermoelectric Refrigeraton1Ejaz KPas encore d'évaluation

- Temperature Dependence of Different Resistors and Diodes With Cobra4Document6 pagesTemperature Dependence of Different Resistors and Diodes With Cobra4usama tariqPas encore d'évaluation

- Lecture 3 ThermocouplesDocument26 pagesLecture 3 ThermocouplesHassan El SayedPas encore d'évaluation

- Thermoelectric Generator For B Tech ProjectDocument24 pagesThermoelectric Generator For B Tech ProjectAditya MeenaPas encore d'évaluation

- Solar Refrigeration Using Peltier EffectDocument15 pagesSolar Refrigeration Using Peltier EffectSyko GamingPas encore d'évaluation

- Thermoelectric Module TEC1-12706Document4 pagesThermoelectric Module TEC1-12706reis emperorPas encore d'évaluation

- A Report On Design & Setup of Peltier Module Based Air CoolerDocument6 pagesA Report On Design & Setup of Peltier Module Based Air Coolervenkatesan appuPas encore d'évaluation

- 4.0 Advantages of Thermoelectric CoolingDocument5 pages4.0 Advantages of Thermoelectric CoolingKetan PaliwalPas encore d'évaluation

- Eco Friendly Generator Using Peltier DevicesDocument6 pagesEco Friendly Generator Using Peltier DevicesDhanrajPas encore d'évaluation

- Seminar-Paper-Roll-No-66 3Document3 pagesSeminar-Paper-Roll-No-66 3Lucifer MorningstarPas encore d'évaluation

- Thermo Electric SeminarDocument17 pagesThermo Electric SeminarDebashish MohantyPas encore d'évaluation

- Waste HeatDocument7 pagesWaste Heatosamarather2020mcePas encore d'évaluation

- Thermocouple: From Wikipedia, The Free EncyclopediaDocument9 pagesThermocouple: From Wikipedia, The Free EncyclopediaKiệt Huỳnh AnhPas encore d'évaluation

- Thermoelectric Converter PDFDocument4 pagesThermoelectric Converter PDFMizteri MizteriPas encore d'évaluation

- Abdallah Al Terek - MENG555L Final ReportDocument13 pagesAbdallah Al Terek - MENG555L Final Reportelia.laeilaPas encore d'évaluation

- Thermoelectric Refrigerator For Travelling: Lalit Bansal Nitesh Kumar Jha Rohan Kanodiya Sandeep JhambDocument3 pagesThermoelectric Refrigerator For Travelling: Lalit Bansal Nitesh Kumar Jha Rohan Kanodiya Sandeep JhambLalit BanaalPas encore d'évaluation

- A Thermoelectric GeneratorDocument6 pagesA Thermoelectric GeneratorFaqeeh AbrarPas encore d'évaluation

- What Is A Thermoelectric Generator PDFDocument4 pagesWhat Is A Thermoelectric Generator PDFJamerines C AllasgoPas encore d'évaluation

- Thermo Electric DevicesDocument5 pagesThermo Electric DevicesKedar A. MalusarePas encore d'évaluation

- Frequently Asked Questions About Our Cooling and Heating TechnologyDocument20 pagesFrequently Asked Questions About Our Cooling and Heating TechnologydoggybowPas encore d'évaluation

- Active Transducers - ThermocoupleDocument29 pagesActive Transducers - ThermocoupleKritika GuptaPas encore d'évaluation

- Thermo-Electric Coolers: TFAWS Short CourseDocument116 pagesThermo-Electric Coolers: TFAWS Short CourseChristop22Pas encore d'évaluation

- Peltier ModuleDocument4 pagesPeltier ModulekarthikdmPas encore d'évaluation

- Applications of Themocouples: Steel IndustryDocument4 pagesApplications of Themocouples: Steel IndustrySamarth GandhiPas encore d'évaluation

- Heattransfermanualsolution MatlabDocument23 pagesHeattransfermanualsolution Matlabdodydody25689Pas encore d'évaluation

- Thermoelectric Power Plant Principle of OperationDocument53 pagesThermoelectric Power Plant Principle of OperationEnnavy YongkolPas encore d'évaluation

- Thermoelectric Cooling - WikipediaDocument38 pagesThermoelectric Cooling - WikipediaVenkat AlluPas encore d'évaluation

- PMP Assesment TestDocument17 pagesPMP Assesment Testwilliam collinsPas encore d'évaluation

- Literatura Tecnica 3Document10 pagesLiteratura Tecnica 3Christian PerezPas encore d'évaluation

- EPAS 11 - Q1 - W1 - Mod1Document45 pagesEPAS 11 - Q1 - W1 - Mod1Alberto A. FugenPas encore d'évaluation

- English Homework 10 Grammar Focus 2: Lecturer: Mr. Dr. H. Abdul Hamid, M.SiDocument4 pagesEnglish Homework 10 Grammar Focus 2: Lecturer: Mr. Dr. H. Abdul Hamid, M.SiMutiara siwa UtamiPas encore d'évaluation

- Clockwork Dragon's Expanded ArmoryDocument13 pagesClockwork Dragon's Expanded Armoryabel chabanPas encore d'évaluation

- B I o G R A P H yDocument17 pagesB I o G R A P H yRizqia FitriPas encore d'évaluation

- (1921) Manual of Work Garment Manufacture: How To Improve Quality and Reduce CostsDocument102 pages(1921) Manual of Work Garment Manufacture: How To Improve Quality and Reduce CostsHerbert Hillary Booker 2nd100% (1)

- Review On AlgebraDocument29 pagesReview On AlgebraGraziela GutierrezPas encore d'évaluation

- Activity On Noli Me TangereDocument5 pagesActivity On Noli Me TangereKKKPas encore d'évaluation

- Where We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Document1 pageWhere We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Safia-umm Suhaim- FareedPas encore d'évaluation

- Leadership Styles-Mckinsey EdDocument14 pagesLeadership Styles-Mckinsey EdcrimsengreenPas encore d'évaluation

- Skills Checklist - Gastrostomy Tube FeedingDocument2 pagesSkills Checklist - Gastrostomy Tube Feedingpunam todkar100% (1)

- Apexi Powerfc Instruction ManualDocument15 pagesApexi Powerfc Instruction ManualEminence Imports0% (2)

- Sample - SOFTWARE REQUIREMENT SPECIFICATIONDocument20 pagesSample - SOFTWARE REQUIREMENT SPECIFICATIONMandula AbeyrathnaPas encore d'évaluation

- Algoritm BackTracking EnglezaDocument6 pagesAlgoritm BackTracking Englezaionutz_67Pas encore d'évaluation

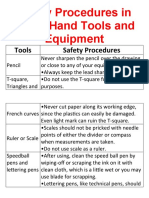

- Safety Procedures in Using Hand Tools and EquipmentDocument12 pagesSafety Procedures in Using Hand Tools and EquipmentJan IcejimenezPas encore d'évaluation

- SOL LogicDocument21 pagesSOL LogicJa RiveraPas encore d'évaluation

- Jackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairDocument65 pagesJackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairTeamMichael100% (2)

- CL57T V4.0Document14 pagesCL57T V4.0dimitriPas encore d'évaluation

- Government College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniqueDocument11 pagesGovernment College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniquepriyankaPas encore d'évaluation

- Subject Manual Tle 7-8Document11 pagesSubject Manual Tle 7-8Rhayan Dela Cruz DaquizPas encore d'évaluation

- PSA Poster Project WorkbookDocument38 pagesPSA Poster Project WorkbookwalliamaPas encore d'évaluation

- Phytotherapy On CancerDocument21 pagesPhytotherapy On CancerSiddhendu Bhattacharjee100% (1)

- SLA in PEGA How To Configue Service Level Agreement - HKRDocument7 pagesSLA in PEGA How To Configue Service Level Agreement - HKRsridhar varmaPas encore d'évaluation

- Contents EEMUA Publication 190 Edition1 May 2015Document4 pagesContents EEMUA Publication 190 Edition1 May 2015Aditya JainPas encore d'évaluation

- CV & Surat Lamaran KerjaDocument2 pagesCV & Surat Lamaran KerjaAci Hiko RickoPas encore d'évaluation

- What's New in CAESAR II: Piping and Equipment CodesDocument1 pageWhat's New in CAESAR II: Piping and Equipment CodeslnacerPas encore d'évaluation

- PFEIFER Angled Loops For Hollow Core Slabs: Item-No. 05.023Document1 pagePFEIFER Angled Loops For Hollow Core Slabs: Item-No. 05.023adyhugoPas encore d'évaluation

- Notes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0MDocument1 pageNotes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0Mسجى وليدPas encore d'évaluation