Académique Documents

Professionnel Documents

Culture Documents

MC Donald Supply Chain by Purvi

Transféré par

Purvi ChaudharyTitre original

Copyright

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

MC Donald Supply Chain by Purvi

Transféré par

Purvi ChaudharyDroits d'auteur :

PROJECT ON JIT SYSTEM AND SUPPLY CHAIN OF MCDONALDS

23RDMARCH 2012

SUBMITTED BY: PURVI R CHAUDHARY PGP27373 SECTION F

INDEX

Serial No.

TOPIC

Page no.

3 1. Introduction

2.

Supply Chain Management of McDonald

5 3. Leading and Innovative Practices 14 4. Conclusion 14 5. References

LIST OF FIGURES

Serial No.

TOPIC

Page no.

1.

Fig 1 : Chart of Vision of McDonalds Supply Chain Integration

2.

Fig 2: Distribution centres of McDonald in India

3.

Fig 3: Suppliers of McDonald in India

4.

Fig 4: Demand Forecasting method of McDonald

LIST OF TABLES

Serial No.

TOPIC

Page no.

1.

Table 1: Improvements supply chain of McDonald added by its new practices

12

Introduction

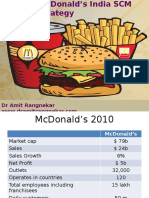

This project is on the supply chain management system of McDonald in India. McDonald's Corporation is the world's largest chain of hamburger fast food restaurants. Its a World Market leader in QSR ( Quick Service Restaurant ). It has a customer base of around 68 million customers daily in 119 countries. The McDonald headquarter called McDonald's Plaza, is in Oak Brook, Illinois, United States. The company opened in the year 1940 as a barbecue restaurant. It was operated by Richard and Maurice McDonald; in the year 1948 the business was reorganized as hamburger stand. Businessman Ray Kroc oversaw the companys growth. He joined the company as a franchise agent in 1955, purchased the chain from the McDonald brothers. Revenue: A McDonald's restaurant is operated by the following- a franchisee, an affiliate, or the corporation itself. The corporation's earnings come from the rent, royalties and fees paid by the franchisees and sales at its restaurants. McDonald's revenues shows 27% growth over the three years ending in 2007 to $22.8 billion, and operating income shows growth of 9% to generate $3.9 billion. Presence: McDonald's restaurants are found in 119 countries, employees: 1.5 million and serve 47 million customers per day, operates over 31,000 restaurants worldwide and operates other restaurant brands, such as Piles Caf. Its Corporate Strategy is : Quality, Service, Cleanliness and Value. Products : McDonald's primarily sells hamburgers, cheeseburgers, chicken, french fries, breakfast items, soft drinks, shakes and desserts. Expanded menu includes salads, wraps, smoothies and fruit. With increasing trend for coffee culture, McDonald's introduced McCaf, a caf-style accompaniment to McDonald's restaurants similar to Starbucks. McCaf is a concept that was starting with Melbourne in 1993. McDonald's throughout its beginning had an extensive advertising campaign. In addition to the media channels that include-television, radio, and newspaper, it also use billboards and signage, sponsoring sports events ( Little League to the Olympic Games ), and makes coolers of orange drink with its logo available for all sorts of local events.

4

Supply Chain Management of McDonald

McDonalds tries to ensure that each step of supply chain adds to the safety, quality, and availability of their final products. The three main parts of McDonalds supply chain are : Corporation, Suppliers and franchise owners or operators . The supply chain of McDonalds is multi-layered. Food ingredients are supplied by two categories of suppliers : Tier-I and Tier-2. Tier-2 suppliers includes raw material providers and processors that includes lettuce and potato farmers, poultry farms and manufacturing companies that coat the vegetable and chicken patties. These ingredients are then supplied to Tier-I suppliers. They process those items into - vegetable and chicken patties . This processing is done by Vista Processed Foods Pvt. Ltd. - or potato products ( say French fries, potato wedges and hashbrowns ) done by McCain Foods India Pvt. Ltd. The food is then transported to companys Distribution Centers via refrigerated trucks. From there the products are transferred to the 217 McDonalds restaurants in the country, via Multi-temperature and single temperature trucks.

Fig 1 : Chart of Vision of McDonalds Supply Chain Integration

Leading and Innovative Practices

1) No Frills Logistics :

Although the company growth rate is 30-40 percent in India

annually, McDonalds have no plans to increase its supply-chain staff for around two or three years. Even if it continue this growth trend is continued, by 2014 it may include only two more people in its supply-chain and that too because some of its categories like buying, may be hard to tackle by a person when business becomes large. Before the launch of its first outlet in 1996, Mc Donald did a lot of work to check the situation of Indias logistics industry, transport infrastructure, Such inspections were carried out from team from United States. The supply chain was made ready after doing a lot of ground work to ensure its efficiency. 2) Return Logistics : The supply-chain of McDonalds include the process of return logistics. Buns are packed in plastic crates to ensure their quality. These crates are sent back to McDonalds logistics facilities ( i.e. return logistics comes ). From there they are sent to the bakeries. 3) Hub-and-spoke model : The supply-chain of the fast food chain can be called a hub-andspoke model because the Distribution centers ( DCs ) act as hubs .The fast food chain has four Distribution Centers across India that serve 217 restaurants. Its like one McDonalds outlet is being opened every ten days in the country! The company owns DCs in Noida and Mumbai. These are the primary Distribution Centers. The other two are housed in leased properties.

Noida

Kolkata (2007)

DCs of McDonal d in India

Mumbai (1996)

Bengaluru

(2004)

Fig 2: Distribution centres of McDonald in India

4) Outsourcing : Unlike other companies which outsource only components of its supply

chain, the company has 100 percent outsourced supply chain. It outsource everything to a companies. McDonalds expect Quality assurance from Suppliers and not employees as Employees are not well-Qualified to identify Quality standards. McDonalds Tier-I suppliers : 14 core suppliers who supply directly to the fast food chain McDonald Tier-2 Supplier : Forward ingredients to the Tier-I suppliers first. The fast food chain has about 40 suppliers from whom it sources its ingredients ( Mostly local Suppliers ). The transportation of McDonalds also is completely outsourced. Eighty percent of transportation is refrigerated truck movement, the company has a dedicated fleet for goods transportation.

Fig 3: Suppliers of McDonald in India

5) Pull-supply chain strategy :

McDonalds efficiency and effectiveness are also due to the fact that it has a pull-supply chain. The restaurant issues orders to the Distribution Center which, in turn, sends the order to the supplier and only on order arrival the supplier produce it.

6) Cold Chain Supply :

Cold Chain was one of the unique concepts of McDonalds supply chain in India, whihc took more than six years to get in place. It involves activities like - procurement, warehousing, transportation and retailing of perishable food products, all of which are done under controlled temperatures. McDonald's Quality InspectionProgramme (QIP) is there for quality checks at over 20 different points in the Cold Chain system.

7) Home Delivery :

McDonalds added Mc delivery, an innovative option which delivers meals to the customers doorstep. This service has grown at stratospheric levels by more than 400 percent. Mc delivery was first launched in the city of Mumbai and Delhi in 2004. The service is now offered in seven cities in India.

8) Forecasting Demand : Managers here can predict the time required for goods transfer between different locations. If a truck takes four or five days to travel between a suppliers premises from location X to location Y, dedicated McDonalds trucks will accomplish it in two days due to non-stop running of the fleet.

The restaurants give a three-day to one-week forecast to the Distribution Center. The DC, in turn, has a three-month rolling forecast with the suppliers which enables them to plan their production schedules meticulously.

For extensive long-term planning, McDonalds has devised the 31Q system3 stands for the three years that the fast food chain will keep checking its plans, 1 represents the detailed forecast of the next year and Q symbolizes the quarterly monitoring of these forecasts. Suppliers are included in the budgeting process, briefed on the new products and restaurants to be launched.

Using this information, the suppliers roll out their production schedules. The schedule for the next year is carefully fixed and then stringently monitored. McDonalds supply-chain network is everything its cracked up to beeach cog in the wheel is set precisely in place to ensure spot on distribution. Every restaurant manager knows the exact time of arrival of each product which enables the supply chain team to work backwards to ensure timely distribution.

Fig 4: Demand Forecasting method of McDonald

9) Efficiency in delivery and Supply with SKUs :

30-35 independent SKUs are sold at its outlets. But by making various combinations (a meal can be small, medium or large, while a Coke can also be sold as regular, medium or large), there are 100-150 SKUs which are sold to customers. Having limited SKUs, unlike regional food restaurants which have hundreds of items on their menus, has helped McDonalds supplychain achieve streamlined system of operations.

10) Maintaining Efficiency through Vendor Selection : Even though there are 40-50 vendors across the country, 80 percent of the buy comes from just 14 core vendors. This is how efficiency in my supply-chain is maintained. When a new product is launched, the existing vendor is given priority and opportunity to produce it first; if it fails to fulfill required demand than only new supplier is given opportunity. McDonald's India benefits other Indian businesses through local sourcing. Example : Trikaya Agriculture - McDonald's Supplier of Fresh Iceberg Lettuce, Radhakrishna Foodland McDonald's Distribution Partner, Dynamix Dairy - McDonald's Supplier of Cheese.

10

11) Use of SAP and ERP :

Supply-chain network of McDonalds, which appears to work effortlessly use SAP ( Service Management application ) Its Distribution Centers uses RAMCO Marshall ERP ( ERP Enterprise Resource Planning ) with Cobra software. McDonald's Distribution PartnerRadhakrishna Foodland (P) Ltd. [ called "Foodland" ] is a part of the Radhakrishna Group, which is in business of food and related service businesses. Foodland is the first Indian company engaged in such business models to make use of customized software for smoother operations.

12) Quality in Raw material supply :

In 1991, McDonald's needed a particular variety of potato for manufacturing its famous French fries. The right quality potato in India was unavailable. As per Quality requirements, McDonald's needed the process-grade variety of potato for its products. So, McCain Foods Pvt. Ltd. partnered with McDonald's to work with Gujarat farmers to interact with agronomists and field assistants to demonstrate the best practices i.e. better agronomy techniques (example irrigation system, sowing seed treatments, planting methods and better storage methods for the required raw material )

Innovation in Supply Chain: A marked feature of McDonalds supply-chain is that the entire network ( even suppliers are a part of it) consists of movement of goods through a cold chain. A marked feature of McDonalds supply-chain is that the entire network consists of movement of goods through a cold chain. 13) Multi- temperature Vehicles : An innovative feature that has been added to cold chain is that the same truck can carry products at different temperatures, that ranges from frozen products at low temperatures of -18C(Celsius) to -25C, chilled products from 1C-4C

11

and dry products at required temperatures. McDonalds is the only company whose supplychain network is has this features as a result of successful experimentation. Need for Multi - temperature Vehicles : Store numbers and distances increased, so there was a need of multi-temperature vehicles which could carry all three temperature products. Truck containers were introduced with two side doors along with one rear door. The side doors are there to unload products without moving the products kept in other temperature zones.

PRACTICES No Frills Logistics, Return Logistics, Hub-and-spoke model Outsourcing

IMPROVEMENTS

Helps reduce costs and Hub-and-spoke model helps in Efficient Supply of Materials

The selected companies are Experts in their subject matter. Their performance is monitored by Mc Donald so that Key Performance Indicators (KPIs) are not affected

Pull-supply chain strategy

Only in case of contingency, like the overhaul or servicing of machinery, supplier produce surplus stocks, fill rate to store is 99.8 percent. So, inventory holding cost is reduced

Cold Chain Supply

Able to both cut down on its operational wastage, as well as maintain the freshness and nutritional value of raw and processed food products

Forecasting Demand

Plan schedules and performances monitored every quarter performance ensured. Lead times for trucks and deliveries is predictable. Maximum inventory of ten days in system, so able to maintain an efficient inventory turn ratio of 36

Vendor Selection

With partnerships based on trust and progress, stage set for a large number of companies for supplies and services. Speed of service with a one-minute guarantee of service becomes easier as the number of items on the menu are limited and sourcing ingredients becomes infinitely easier as fewer products

12

Efficiency in delivery and Supply with SKUs

and suppliers to deal with

Home Delivery

It does not burden the existing supply chain as the more the sale, the more economies of scale and it helps to keep supply-chain more efficient

Use of SAP and ERP

These systems has helped to directly upload store orders. Inhouse developed technologies (At the restaurant level in the fast food chain ) helps to track day-to-day sales, enable restaurants to schedule staff and send forecast orders to DCs

Quality in Raw material supply

Process-grade variety of potato are available and it also benefits farmers through incremental monetary gains as they dont need commission agents and can sell directly to McCain Foods Pvt. Ltd.

Multi- temperature Vehicles

This finesse and attention to detail has helped McDonalds achieve its own USP of quality, standards of service, cleanliness and value. It will also help fulfill its own professed target of launching 40 outlets across the country every year

Table 1: Improvements supply chain of McDonald added by its new practices

1) Demand Forecasting is part of MRP ( Material Resource planning ) technique. 2) Pull-supply chain strategy and Cold Chain Supply, Multi-temperature vehicles are Inventory control measures. The former cuts Inventory holding costs and others prevent damage to inventory thereby cutting overhead costs. 3) Pull-chain, SKUs, Home delivery help in JIT (Just-In-Time) implementation. 4) No Frills Logistics, Return Logistics helps in Lean Operations.

13

Conclusion : McDonald has established a ERP and JIT system that is completely adequate for all its needs and covers all essential aspects of the supply chain to the degree necessary. The Supply chain system is reliable and effective and all the details of the system have been well established. The system are optimized to McDonalds needs and methods of functioning. Every restaurant manager knows the exact time of arrival of each product which enables the supply chain team to work backwards to ensure timely distribution. The ERP system established by McDonald is completely satisfactory in all key areas. The system established has kept control of all the factors within McDonalds reach.

References :

1) http://logisticsweek.com/feature/2011/07/the-big-idea-mcdonalds-unravels-its-supply-chain/ 2) http://www.scribd.com/doc/28339073/mc-donalds-supply-chain-management 3) http://www.mcdonaldsindia.com/aboutus/cold-chain.html 4) http://www.articlesbase.com/marketing-articles/mcdonalds-india-supply-chain-729402.html 5) http://en.wikipedia.org/wiki/McDonald%27s

14

Vous aimerez peut-être aussi

- McDonalds supply chain managementDocument5 pagesMcDonalds supply chain managementShalini Suman100% (1)

- Operations and Information Management CHECK, FORMAT AND NUMBERDocument13 pagesOperations and Information Management CHECK, FORMAT AND NUMBERShahnewaj SharanPas encore d'évaluation

- McDonalds Operations Management ReportDocument11 pagesMcDonalds Operations Management ReportknavstragetyPas encore d'évaluation

- McDonalds India Supply ChainDocument12 pagesMcDonalds India Supply ChainManu GuptaPas encore d'évaluation

- Mcdonald's SCMDocument28 pagesMcdonald's SCMMaria KerawalaPas encore d'évaluation

- Mcdonalds in IndiaDocument20 pagesMcdonalds in IndiaAnupam KhandrePas encore d'évaluation

- Mcdonald's Supply Chain in IndiaDocument23 pagesMcdonald's Supply Chain in IndiaCadet ShaniPas encore d'évaluation

- MC DonaldDocument12 pagesMC DonaldAbhishek NehaPas encore d'évaluation

- Mcdonald Case StudyDocument30 pagesMcdonald Case StudySaurabh KothawadePas encore d'évaluation

- Domino's India Logistics ManagementDocument6 pagesDomino's India Logistics ManagementJhon DavidPas encore d'évaluation

- Mcdonald'S in India: M. Noman BariDocument20 pagesMcdonald'S in India: M. Noman BariMuhammad NbPas encore d'évaluation

- McDonald Supply Chain in PakistanDocument28 pagesMcDonald Supply Chain in PakistanAwais Chaudhary33% (3)

- Business Strategy: TechnicalDocument3 pagesBusiness Strategy: TechnicalDinuPas encore d'évaluation

- Supply Chain of KFC India: TUSHAR SHARMA-150301007 PRANJAL JOSHI-150301005Document18 pagesSupply Chain of KFC India: TUSHAR SHARMA-150301007 PRANJAL JOSHI-150301005Nishant goyalPas encore d'évaluation

- Morrisons ReportDocument100 pagesMorrisons ReportMihai BudaPas encore d'évaluation

- Supply Chain of MilkDocument6 pagesSupply Chain of MilkFahad TatlaPas encore d'évaluation

- Declaration: Mcdonald'S With Special Reference To Is A Bonafide Record Done by Me DuringDocument39 pagesDeclaration: Mcdonald'S With Special Reference To Is A Bonafide Record Done by Me Duringabhinav071985Pas encore d'évaluation

- Supply Chain Management of McDonalds IndiaDocument5 pagesSupply Chain Management of McDonalds Indiamohiuddin alamgirPas encore d'évaluation

- MIS ProjectDocument27 pagesMIS ProjectPallav MowkePas encore d'évaluation

- Mcdonalds Final Supply ChainDocument34 pagesMcdonalds Final Supply ChainAmmar Imtiaz100% (1)

- Survey On Mcdonalds: "The World's Best Quick Service Restaurant Experience."Document34 pagesSurvey On Mcdonalds: "The World's Best Quick Service Restaurant Experience."Zeenat AnsariPas encore d'évaluation

- Advanced Operations Management: Operation Analysis OrganizationDocument5 pagesAdvanced Operations Management: Operation Analysis OrganizationAdarsh PandeyPas encore d'évaluation

- Amul Supply Chain ManagementDocument6 pagesAmul Supply Chain Managementutkarsh130896Pas encore d'évaluation

- McDonald's Global Supply Chain StrategyDocument7 pagesMcDonald's Global Supply Chain StrategyAnnas Syaifullah100% (2)

- Supply Chain of Coca Cola CompanyDocument27 pagesSupply Chain of Coca Cola CompanyMANISH JAIN0% (1)

- McDonald S Cost Leadership StrategyDocument17 pagesMcDonald S Cost Leadership StrategyMEPas encore d'évaluation

- 3 Supply Chain ManagementDocument9 pages3 Supply Chain ManagementkarimakkiPas encore d'évaluation

- Supply Chain ManagementDocument23 pagesSupply Chain ManagementRoHit Sharma100% (1)

- Domino's Pizza Supply Chain ManagementDocument12 pagesDomino's Pizza Supply Chain ManagementAnant MauryaPas encore d'évaluation

- McDonald's Integrated Supply ChainDocument19 pagesMcDonald's Integrated Supply ChainPutri AmandhariPas encore d'évaluation

- Amul 1Document30 pagesAmul 1kishi0% (1)

- Case StudyDocument2 pagesCase StudyAnthony RajPas encore d'évaluation

- Sravan KFCDocument47 pagesSravan KFCSravan Kumar RatakondaPas encore d'évaluation

- McDonald's Supply Chain ManagementDocument27 pagesMcDonald's Supply Chain ManagementShashi KumarPas encore d'évaluation

- Coca ColaDocument7 pagesCoca ColaAnonymous pZ4X8tK8QPas encore d'évaluation

- Mcdonald'S Corporation: April 25, 2005Document75 pagesMcdonald'S Corporation: April 25, 2005Alan YungPas encore d'évaluation

- Compare operations of McDonald's vs Burger KingDocument4 pagesCompare operations of McDonald's vs Burger KingJessica Miller0% (1)

- POM in Coco ColaDocument32 pagesPOM in Coco ColaMabroor AhmedPas encore d'évaluation

- Dominos PizzaDocument8 pagesDominos PizzaNoor AzizahPas encore d'évaluation

- McDonald's Agribusiness Supply Chain in IndiaDocument23 pagesMcDonald's Agribusiness Supply Chain in IndiaAbhilasha Sharma100% (1)

- A On Supply Chain of Anjan's: Submitted To: Instructor: Course Title: Course CodeDocument26 pagesA On Supply Chain of Anjan's: Submitted To: Instructor: Course Title: Course CodeDipock MondalPas encore d'évaluation

- Mcdonaldse ProcurementDocument41 pagesMcdonaldse ProcurementNikhil Kadam0% (1)

- Coca-Cola Company: World's Largest Beverage CompanyDocument3 pagesCoca-Cola Company: World's Largest Beverage CompanySwapnil Nemade0% (2)

- FINAL CASE MATERIAL - MCDONALDS - AsdDocument9 pagesFINAL CASE MATERIAL - MCDONALDS - AsdJon Manuel0% (1)

- Macy's Omni-Channel Case StudyDocument1 pageMacy's Omni-Channel Case StudyTalha KhanPas encore d'évaluation

- Inventory Management of McDonald'sDocument2 pagesInventory Management of McDonald'sRafaelKwongPas encore d'évaluation

- Supply Chain Management of Print MediaDocument39 pagesSupply Chain Management of Print MediaHector MoodyPas encore d'évaluation

- Supply Chain McdonaldsDocument9 pagesSupply Chain McdonaldsAditya MayekarPas encore d'évaluation

- Supply Chain Management of McDonaldsDocument10 pagesSupply Chain Management of McDonaldsSahil AroraPas encore d'évaluation

- Monginise Inventory ManagementDocument36 pagesMonginise Inventory ManagementTejNaikPas encore d'évaluation

- Sourcing and Supply Management 4Document22 pagesSourcing and Supply Management 4Zainab FahimPas encore d'évaluation

- McDonalds SCMDocument57 pagesMcDonalds SCMDr Amit Rangnekar100% (1)

- How Special Promotions Can Increase Sales? (Case Study of A Selected McDonald's)Document68 pagesHow Special Promotions Can Increase Sales? (Case Study of A Selected McDonald's)ayazturiPas encore d'évaluation

- McDonald's Case AnalysisDocument5 pagesMcDonald's Case AnalysisSubhransu SahuPas encore d'évaluation

- McDonald PROJECTfinalDocument19 pagesMcDonald PROJECTfinalAlok SinghPas encore d'évaluation

- McDonald's Global Fast Food Chain Strategy OverviewDocument7 pagesMcDonald's Global Fast Food Chain Strategy OverviewK.Y OoiPas encore d'évaluation

- SCM at McdonaldsDocument16 pagesSCM at McdonaldsBeingAbhishek RupawatePas encore d'évaluation

- Mcdonald'S Food Chain in IndiaDocument34 pagesMcdonald'S Food Chain in IndiaGovind N VPas encore d'évaluation

- POM Assignment 1Document4 pagesPOM Assignment 1Nyi Nyi WinPas encore d'évaluation

- Supply Chain MCDDocument24 pagesSupply Chain MCD064 VISHAL ADKEPas encore d'évaluation

- Performance Appraisal Management at InfosysDocument18 pagesPerformance Appraisal Management at InfosysPurvi Chaudhary80% (5)

- 2010 Ibm AnnualDocument140 pages2010 Ibm AnnualaflecheaPas encore d'évaluation

- Queuing ModelsDocument19 pagesQueuing ModelsAnuj KumarPas encore d'évaluation

- Game Theory: By: Purvi R. ChaudharyDocument28 pagesGame Theory: By: Purvi R. ChaudharyPurvi Chaudhary100% (1)

- PrologDocument26 pagesPrologPurvi ChaudharyPas encore d'évaluation

- Asp ADODocument35 pagesAsp ADOPurvi ChaudharyPas encore d'évaluation

- Representation of A Database: 1. Tuple Facts 2. Attribute Facts 3. List of StructuresDocument21 pagesRepresentation of A Database: 1. Tuple Facts 2. Attribute Facts 3. List of StructuresPurvi ChaudharyPas encore d'évaluation

- Representation of A Database: 1. Tuple Facts 2. Attribute Facts 3. List of StructuresDocument21 pagesRepresentation of A Database: 1. Tuple Facts 2. Attribute Facts 3. List of StructuresPurvi ChaudharyPas encore d'évaluation

- Handout2 Fischer CarbeneDocument5 pagesHandout2 Fischer CarbeneMuhammad ShimaPas encore d'évaluation

- Guerra, Germae Joyce - Media JournalDocument2 pagesGuerra, Germae Joyce - Media JournalGERMAE JOYCE GUERRAPas encore d'évaluation

- Ethylene Glycol PDFDocument2 pagesEthylene Glycol PDFAngela0% (1)

- Fem 3202-1 IntroductionDocument29 pagesFem 3202-1 IntroductionRon ChongPas encore d'évaluation

- Geoheritage of Labuan Island: Bulletin of The Geological Society of Malaysia December 2016Document14 pagesGeoheritage of Labuan Island: Bulletin of The Geological Society of Malaysia December 2016songkkPas encore d'évaluation

- Communicating Across AgesDocument35 pagesCommunicating Across AgesConrad TarihoranPas encore d'évaluation

- FOCAL DYSTONIA-A NEUROLOGICAL CONDITION-TREATED WITH CAUSTICUM - Karl Robinson MDDocument2 pagesFOCAL DYSTONIA-A NEUROLOGICAL CONDITION-TREATED WITH CAUSTICUM - Karl Robinson MDFaker FockerPas encore d'évaluation

- EXERCISE 1.1.2: Daub, Elycka Dela Cruz, Jesson Igne, Cyril Joy Labbao, Trinity RZL110 - A56Document7 pagesEXERCISE 1.1.2: Daub, Elycka Dela Cruz, Jesson Igne, Cyril Joy Labbao, Trinity RZL110 - A56-Pas encore d'évaluation

- Kawasaki Ultra 250x Manual de Taller PDFDocument477 pagesKawasaki Ultra 250x Manual de Taller PDFAntonio Jose Planells100% (3)

- 08-05-2021 JR - Super60 ActP (In Coming) Jee-Main WTM-01 Question PaperDocument14 pages08-05-2021 JR - Super60 ActP (In Coming) Jee-Main WTM-01 Question Paperpurandar puneetPas encore d'évaluation

- Govt Schemes - 1 MWCD MOSJEDocument36 pagesGovt Schemes - 1 MWCD MOSJEshaheen razaPas encore d'évaluation

- The Benefit of Power Posing Before A High-Stakes Social EvaluationDocument20 pagesThe Benefit of Power Posing Before A High-Stakes Social EvaluationpaolaPas encore d'évaluation

- Air Regulations CPL Level QuestionsDocument56 pagesAir Regulations CPL Level QuestionsRahul100% (3)

- Original Instruction Manual: Hypro Series 9303Document24 pagesOriginal Instruction Manual: Hypro Series 9303vandoPas encore d'évaluation

- Save Our Forests Through Sustainable DevelopmentDocument33 pagesSave Our Forests Through Sustainable DevelopmentGeehthanJIPas encore d'évaluation

- Specifications of TES-593Document2 pagesSpecifications of TES-593symasiPas encore d'évaluation

- Self Level Pu FlooringDocument2 pagesSelf Level Pu FlooringRyan EncomiendaPas encore d'évaluation

- Pub - New Directions in Progressive Relaxation TrainingDocument176 pagesPub - New Directions in Progressive Relaxation TrainingRafael Bagus100% (1)

- Desensitization ProtocolsDocument28 pagesDesensitization ProtocolsAnonymous 9dVZCnTXSPas encore d'évaluation

- Sister Letty G. Kuan Retirement and Role DiscontinuitiesDocument26 pagesSister Letty G. Kuan Retirement and Role DiscontinuitiesAbigail Faith Pretesto100% (1)

- Quickscan™ Lite Qw2100: Multi-Purpose Uses For Different ApplicationsDocument2 pagesQuickscan™ Lite Qw2100: Multi-Purpose Uses For Different ApplicationsHaythem BchirPas encore d'évaluation

- Masagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningDocument6 pagesMasagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningjhonaPas encore d'évaluation

- NCPDocument18 pagesNCPChristian Karl B. LlanesPas encore d'évaluation

- SITHCCC018 Assessment 2Document9 pagesSITHCCC018 Assessment 2Taimoor Ahmed0% (1)

- Establishment of Retirement PlanDocument3 pagesEstablishment of Retirement PlanVioleta StancuPas encore d'évaluation

- Performance Task MidTerm Second Sem. AY 2022 2023Document2 pagesPerformance Task MidTerm Second Sem. AY 2022 2023KZpathryn Jemimench AleurevPas encore d'évaluation

- t-47 Residential Real Property Affidavit - 50108 ts95421Document1 paget-47 Residential Real Property Affidavit - 50108 ts95421api-209878362Pas encore d'évaluation

- Tools and EquipmentDocument30 pagesTools and EquipmentEhm Jhay78% (9)

- PGDHM SyllabusDocument34 pagesPGDHM SyllabusankushlmpPas encore d'évaluation