Académique Documents

Professionnel Documents

Culture Documents

ASP TSC May09final

Transféré par

Rashid Ahmed SiddiquiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ASP TSC May09final

Transféré par

Rashid Ahmed SiddiquiDroits d'auteur :

Formats disponibles

Innovative heat recovery solutions

Heat Recovery Chiller Systems

Engineered for flexibility and performance

McQuay Heat Recovery Chiller Systems

Heat Recovery Strategies and Green Solutions

Heat recovery provides such effective opportunities for energy savings that ASHRAE Standard 90.1 requires heat recovery be used for service hot water heating and reheat in many buildings. The Leadership in Energy and Environmental Design (LEED) guidelines also require compliance with Std 90.1. In addition, using heat recovery where not required may contribute toward additional LEED points. McQuay Templifier Water Heaters provide significant environmental impact advantages over a fossil-fired boiler or an electric resistance heater, as shown in the comparison below. Compared to a Templifier unit, a resistance heater burns seven times the fuel quantity and an on-site boiler consumes three times the fuel quantity to produce the same one million Btus of 120-degree water.

McQuay TSC Templifier units are available in capacities from 3,000 to 19,200 MBh (880 to 5,630 kW).

What is a Templifier?

A McQuay Templifier Water Heater uses a unique technology to recover large amounts of low grade heat that would typically be rejected from a process or the building to a cooling tower. It can raise the temperature of the water up to 140 F (60 C), making the heated water usable for processes, building heat, or domestic hot water. The name says it: Temperature AmplifierTemplifier. Templifiers can show dramatic improvements in the usefulness and economies of geothermal and solar systems. Since 1976 McQuay Templifier units have provided energy savings around the world in a variety of building types: manufacturing plants, hotels, hospitals, schools and fitness centers, to name a few.

Comparison of fuel required to produce 1,000,000 Btus of hot water at 120 F

McQuay Templifier unit = Electric Resistance Heater = Fossil-Fired Boiler =

Responsible Refrigerant

Another green advantage of McQuay TSC Templifier Water Heaters is that they use HFC-134a refrigerant which has no ozone depletion potential and no phase-out schedule under the Montreal Protocol.

How the Templifier Can Save You Money

Saves energy by heating water more economically than fuel-fired boilers or electric resistance heat Off-loads overloaded boilers or cooling towers, delaying or eliminating capital expenditures to increase their capacity Secondary benefits include: Saves tower make-up water Reduces chemical treatment costs and sewer charges

Innovation that Pays for Itself

Rapid Return on Your Investment

McQuay HSC heat recovery chillers are available with cooling capacities from 150 to 900 tons and heating capacities from 2,205 to 13,500 MBh (648 to 3,960 kW). End view of a McQuay heat recovery chiller showing the double condenser water connections.

To quantify the savings available with heat recovery systems, consider the example of a Chicago hospital with the following parameters.

480,000 sq ft, three-story building size 1600-ton chiller plant 22,000 MBh boiler plant Constant volume system with reheat 409,330 cfm supply air 192,000 cfm ventilation air

By using an energy economic analysis program such as the McQuay Energy Analyzer, results demonstrate the savings available with either a TSC Templifier unit heating water to 140 F or a HSC heat recovery centrifugal chiller heating to 105 F.

What is a Heat Recovery Chiller?

A McQuay heat recovery centrifugal chiller provides conventional chilled water while recovering heat in a second condenser bundle that would normally be rejected from a building to cooling tower. The recovered heat can reach 120 F and be used for space heating or domestic hot water.

Heat Recovery Chiller Applications

HSC heat recovery chillers can be used in process or comfort cooling applications. Hospitals and health care facilities Make-up air for schools and factories Reheat applications for humidity control including museums and art galleries. Heat source for the central loop of a water source heat pump system, including geothermal systems.

Economic Analysis Summary

Both the heat recovery chiller and the Templifier unit saved more than 6 million kBtu a year.

What McQuay Heat Recovery Model is Right for You?

TSC Templifier Water Heater 3,000 to 19,200 MBh (880 to 5,630 kW) (not applicable) 140 F (60 C) R-134a BACnet, Modbus, LONWORKS HSC Heat Recovery Chiller 2,205 to 13,500 MBh (648 to 3,960 kW) 150 to 900 tons 120 F (49 C) R-134a BACnet, Modbus, LONWORKS

Heating capacity Cooling capacity Maximum hot water temperature Refrigerant Communication options

If your heat recovery system requires higher water temperatures or a smaller unit capacity, the McQuay TGZ Templifier water heater provides 160 F degree water and 600 to 3,100 MBh capacity.

A global leader in system solutions for air conditioning, heating, ventilating and refrigeration.

To learn what savings you could expect from a McQuay Templifier water heater or heat recovery chiller, contact your McQuay representative. To learn the name of your local McQuay rep, visit www.mcquay.com.

The following are tradenames or registered trademarks of their respective companies: BACnet from ASHRAE, LONWORKS from Echelon, Modbus from Schneider Electric, Templifier and Energy Analyzer from McQuay International.

(800) 432-1342 www.mcquay.com

2009 McQuay International A/SP TSC (05/09)

Vous aimerez peut-être aussi

- Domestic Water ControlDocument2 pagesDomestic Water ControlanescuveronicaPas encore d'évaluation

- WSHP PRC018H en - 07312017Document212 pagesWSHP PRC018H en - 07312017Josh HabingPas encore d'évaluation

- Appendix I.: Install Equation Editor and Double-Click Here To View EquationDocument26 pagesAppendix I.: Install Equation Editor and Double-Click Here To View EquationPhasin ChitutsahaPas encore d'évaluation

- Heat Meter Accuracy Testing ReportDocument155 pagesHeat Meter Accuracy Testing ReportDenisTarasPas encore d'évaluation

- EnergyPrimer LRDocument185 pagesEnergyPrimer LRbbliancePas encore d'évaluation

- Geo Con 2 McgrawDocument15 pagesGeo Con 2 McgrawDee RajaPas encore d'évaluation

- Effect of Heat Rejection Load and Wet Bulb On Cooling Tower PerformanceDocument7 pagesEffect of Heat Rejection Load and Wet Bulb On Cooling Tower PerformancetarzantrapPas encore d'évaluation

- Kypipe Reference ManualDocument76 pagesKypipe Reference ManualApril TrevinoPas encore d'évaluation

- Fall 1998 Outside The Loop Newsletter For Geothermal Heat Pump Designers and InstallersDocument8 pagesFall 1998 Outside The Loop Newsletter For Geothermal Heat Pump Designers and InstallersOutside the Loop Newsletter - GEO-HEAT CENTERPas encore d'évaluation

- Excess Heat 010559Document48 pagesExcess Heat 010559pasquetPas encore d'évaluation

- 12th International Symposium On District Heating and CoolingDocument326 pages12th International Symposium On District Heating and CoolingsighvaturPas encore d'évaluation

- Econet Heat Recovery SlidesDocument82 pagesEconet Heat Recovery Slidesbusterwong9958Pas encore d'évaluation

- Premium-Content CBSHeatingGuide en INT Article-LearningDocument54 pagesPremium-Content CBSHeatingGuide en INT Article-Learning185412Pas encore d'évaluation

- Cooling & Dehumidification Coil PDFDocument30 pagesCooling & Dehumidification Coil PDFonkarratheePas encore d'évaluation

- Ashrae Ashraejournal JHGVDFDocument69 pagesAshrae Ashraejournal JHGVDFArcgireiPas encore d'évaluation

- Thermal Energy Storage For Space CoolingDocument32 pagesThermal Energy Storage For Space CoolingAzim AdamPas encore d'évaluation

- Design GuideDocument36 pagesDesign GuideDaniel A. NorbergPas encore d'évaluation

- DistrictHeatingSubstationDesign PDFDocument45 pagesDistrictHeatingSubstationDesign PDFJovan MitrevskiPas encore d'évaluation

- Efficiency Vermont Stehmeyer Napolitan Ashrae Guideline 36 PDFDocument170 pagesEfficiency Vermont Stehmeyer Napolitan Ashrae Guideline 36 PDFZoidberg12100% (1)

- 52-57 Engineer's Notebook NallDocument5 pages52-57 Engineer's Notebook NallAnonymous 9pKSMxb8Pas encore d'évaluation

- Thermal StorageDocument78 pagesThermal StorageMohamed Mostafa AamerPas encore d'évaluation

- 2500 Valve BrochureDocument12 pages2500 Valve BrochureJurie_sk3608Pas encore d'évaluation

- AHRI-365 - Unitary Air Conditioning UnitsDocument18 pagesAHRI-365 - Unitary Air Conditioning UnitsfasihkhPas encore d'évaluation

- Mcquay": Absorption ChillerDocument88 pagesMcquay": Absorption ChillerMuzafar Ali ShahPas encore d'évaluation

- 25-01-10 Networking Event EMS FinalDocument41 pages25-01-10 Networking Event EMS FinalajeeshsivanPas encore d'évaluation

- Mechanical and Electrical Technical Specification: For TheDocument117 pagesMechanical and Electrical Technical Specification: For TheKo Pauk100% (1)

- Technical Support Document 50 Energy SavDocument145 pagesTechnical Support Document 50 Energy SavmarkPas encore d'évaluation

- Design and Simulation of Solar Powered Vapour Compression Refrigeration SystemDocument7 pagesDesign and Simulation of Solar Powered Vapour Compression Refrigeration SystemRohan BhairavkarPas encore d'évaluation

- Leed For Homes Program Pilot Rating SystemDocument0 pageLeed For Homes Program Pilot Rating Systemalkr3001Pas encore d'évaluation

- Geothermal Central SystemDocument7 pagesGeothermal Central SystemPaul KwongPas encore d'évaluation

- AHRI Guideline T 2002Document16 pagesAHRI Guideline T 2002trangweicoPas encore d'évaluation

- Guideline AccreditationDocument16 pagesGuideline AccreditationakanuruddhaPas encore d'évaluation

- Hydronic RecoveryDocument4 pagesHydronic RecoveryKhizerPas encore d'évaluation

- Control Valve Selection For Hydraulic SystemsDocument7 pagesControl Valve Selection For Hydraulic SystemszodedPas encore d'évaluation

- AHRI Standard 440 I-P 2019Document26 pagesAHRI Standard 440 I-P 2019Mahmoud GwailyPas encore d'évaluation

- ASHRAE Journal - September 2007Document7 pagesASHRAE Journal - September 2007caliche_362447Pas encore d'évaluation

- Combined Heat and Power Evaluating The Benefits of Greater Global InvestmentDocument39 pagesCombined Heat and Power Evaluating The Benefits of Greater Global InvestmenthoangpalestinePas encore d'évaluation

- GSHPA Thermal Pile StandardDocument85 pagesGSHPA Thermal Pile StandardMohamed MamdohPas encore d'évaluation

- Cold Air Distribution SystemDocument11 pagesCold Air Distribution Systemsushant_jhawerPas encore d'évaluation

- LEED 2.2 Rating SystemDocument78 pagesLEED 2.2 Rating SystemEDelsingPas encore d'évaluation

- Specifying The Thermal Performance of Cool Storage EquipmentDocument19 pagesSpecifying The Thermal Performance of Cool Storage EquipmentNay MyoPas encore d'évaluation

- ZumDocument8 pagesZumEngr SwapanPas encore d'évaluation

- Modulo 3 Procedures For Comm Buildings Energy AuditsDocument54 pagesModulo 3 Procedures For Comm Buildings Energy AuditspixelnutPas encore d'évaluation

- Thermal Storage PDFDocument54 pagesThermal Storage PDFPedro GordinhoPas encore d'évaluation

- ASHRAE Standard 41.3-2014 Standard Method For Pressure MeasurementDocument18 pagesASHRAE Standard 41.3-2014 Standard Method For Pressure MeasurementLPas encore d'évaluation

- Phuong Phap Tinh Tai Theo Phan Mem MistralDocument8 pagesPhuong Phap Tinh Tai Theo Phan Mem Mistralntt_121987Pas encore d'évaluation

- District CoolingDocument17 pagesDistrict CoolingNexus Zubin KondoorPas encore d'évaluation

- Best Practices For Energy Efficient Cleanrooms: Control of Chilled Water SystemDocument6 pagesBest Practices For Energy Efficient Cleanrooms: Control of Chilled Water SystemSing Yew LamPas encore d'évaluation

- ANSI - Ahri Standard 550-590 (I-P) With Addendum 3Document109 pagesANSI - Ahri Standard 550-590 (I-P) With Addendum 3Afzal KhanPas encore d'évaluation

- 1385-RP Final Report PDFDocument319 pages1385-RP Final Report PDFJeffPas encore d'évaluation

- Leed v4 For Interior Design and ConstrucDocument97 pagesLeed v4 For Interior Design and ConstrucNamarig AbdallaPas encore d'évaluation

- ASHRAE Journal - VAVR Vs ACB+DOAS PDFDocument12 pagesASHRAE Journal - VAVR Vs ACB+DOAS PDFmlamourPas encore d'évaluation

- Waste Heat Recovery Ppi00443en PDFDocument56 pagesWaste Heat Recovery Ppi00443en PDFdsahmedPas encore d'évaluation

- Geo Perform XDocument4 pagesGeo Perform Xthermosol5416Pas encore d'évaluation

- Optimizing Systems at District Scale PresentationDocument137 pagesOptimizing Systems at District Scale PresentationBioDistrict New OrleansPas encore d'évaluation

- Project Communication PlanDocument4 pagesProject Communication PlanImran AnjumPas encore d'évaluation

- Advantages of Centrifugal Chillers Over Screw Type ChillersDocument1 pageAdvantages of Centrifugal Chillers Over Screw Type ChillersAnonymous DJrec2100% (2)

- Water Cooled Chiller Plant With Economiser (VP) : Data CenterDocument10 pagesWater Cooled Chiller Plant With Economiser (VP) : Data CenterFirasPas encore d'évaluation

- TrapDocument4 pagesTrapdcsamaraweeraPas encore d'évaluation

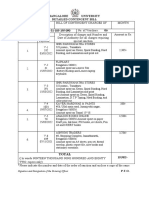

- List of Minimum Tools and Tackles To Be Deployed For The ConstructionDocument2 pagesList of Minimum Tools and Tackles To Be Deployed For The ConstructionRashid Ahmed SiddiquiPas encore d'évaluation

- Ventilation Calculation For Generators RoomDocument3 pagesVentilation Calculation For Generators RoomRashid Ahmed Siddiqui100% (1)

- Terrace Loop DesignDocument5 pagesTerrace Loop DesignRashid Ahmed SiddiquiPas encore d'évaluation

- Pipe On SupportsDocument8 pagesPipe On SupportsMahesh KoiladaPas encore d'évaluation

- Conan The Shadow of The SorcererDocument220 pagesConan The Shadow of The SorcererPierre Dupont100% (10)

- Hitachi ZX75USDocument9 pagesHitachi ZX75US3man 9394Pas encore d'évaluation

- Nursing Care of Client With HypospadiaDocument21 pagesNursing Care of Client With HypospadiaancoursPas encore d'évaluation

- Architecture Building Services: Assignment-1Document36 pagesArchitecture Building Services: Assignment-1santhu majiPas encore d'évaluation

- The 5-Phase New Pentagon Driver Chip Set: 1. Excitation Sequence GeneratorDocument11 pagesThe 5-Phase New Pentagon Driver Chip Set: 1. Excitation Sequence GeneratorFreddy MartinezPas encore d'évaluation

- Choral Music Hits PDFDocument9 pagesChoral Music Hits PDFstefano bettineschiPas encore d'évaluation

- Seed Health Testing in Field Crops Seeds........... AaaaaaaDocument37 pagesSeed Health Testing in Field Crops Seeds........... AaaaaaaJagadish GowdaPas encore d'évaluation

- IED Copy of Reading-Report-and-Learning-Diary-Revised-20190220 - 27th-Anniv-Revised-Form.Document3 pagesIED Copy of Reading-Report-and-Learning-Diary-Revised-20190220 - 27th-Anniv-Revised-Form.Noxian TelicPas encore d'évaluation

- Module 7 - Badminton - Fundamental SkillsDocument45 pagesModule 7 - Badminton - Fundamental SkillsJoshua AltamiranoPas encore d'évaluation

- LeasePlanIndia-GSTUpdate-June2017.pdf - Filename - UTF-8''LeasePlanIndia-GSTUpdate-June2017 PDFDocument2 pagesLeasePlanIndia-GSTUpdate-June2017.pdf - Filename - UTF-8''LeasePlanIndia-GSTUpdate-June2017 PDFyogiprathmeshPas encore d'évaluation

- 3 Decomposition PDFDocument40 pages3 Decomposition PDFPyae Phyo KyawPas encore d'évaluation

- Liphardt ResumeDocument4 pagesLiphardt Resumeapi-398834878Pas encore d'évaluation

- Computerized Embroidery MachineDocument165 pagesComputerized Embroidery Machinehajar100% (1)

- Why Facts Don't Change Our MindsDocument9 pagesWhy Facts Don't Change Our MindsYoshio MatsuoPas encore d'évaluation

- Truth Beyond Paradox (Final Download)Document217 pagesTruth Beyond Paradox (Final Download)andreas waneyPas encore d'évaluation

- 10 kVA - PI044E PDFDocument9 pages10 kVA - PI044E PDFYogi PurchasingPas encore d'évaluation

- Indra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043Document28 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043AnhTuấnPhanPas encore d'évaluation

- Gs Reported Speech - ExercisesDocument6 pagesGs Reported Speech - ExercisesRamona FloreaPas encore d'évaluation

- First ContingencyDocument2 pagesFirst Contingencymanju bhargavPas encore d'évaluation

- HA2 Week 9: Lesson 1 Homework: X y X yDocument9 pagesHA2 Week 9: Lesson 1 Homework: X y X ySebastien TaylorPas encore d'évaluation

- EnglishDocument44 pagesEnglishP DasPas encore d'évaluation

- Arquitectura de SoftwareDocument6 pagesArquitectura de SoftwareDiego Alejandro Muñoz ToroPas encore d'évaluation

- Sullair 1600H AF User Manual PDFDocument88 pagesSullair 1600H AF User Manual PDFhacknote100% (1)

- Test Report: LaboratoryDocument5 pagesTest Report: LaboratorybethPas encore d'évaluation

- How To Accelerate Your InternetDocument313 pagesHow To Accelerate Your Internet5songPas encore d'évaluation

- Slow LearnerDocument33 pagesSlow LearnerMuhammad Khairul Nizam100% (1)

- Tom Wolf Mit ThesisDocument5 pagesTom Wolf Mit Thesisjpcbobkef100% (1)

- Singapore Airlines PDFDocument10 pagesSingapore Airlines PDF....Pas encore d'évaluation

- Aluminex 5: Material Safety Data SheetDocument10 pagesAluminex 5: Material Safety Data SheetocalensPas encore d'évaluation

- Other Procedures and Acceptable Means of ComplianceDocument244 pagesOther Procedures and Acceptable Means of ComplianceBobi GuauPas encore d'évaluation