Académique Documents

Professionnel Documents

Culture Documents

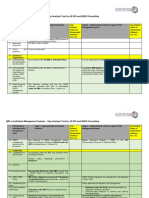

Conformance Matrix To ISO 9001-2008 ISO-14001-2004 OHSAS-18001-2007-Requirements

Transféré par

N.PalaniappanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Conformance Matrix To ISO 9001-2008 ISO-14001-2004 OHSAS-18001-2007-Requirements

Transféré par

N.PalaniappanDroits d'auteur :

Formats disponibles

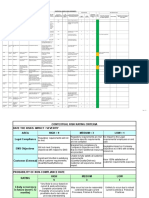

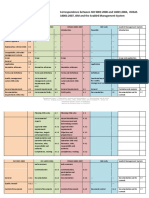

Conformance Matrix to ISO 9001: 2008, ISO 14001: 2004, OHSAS 18001: 2007, ISO 22000: 2005 Requirements

as Integrated Quality System

ISO 9001 : 2008

0.1 0.2 0.3 0.4 Introduction General Process approach Relationship with ISO 9004 Compatibility with other management systems Scope General Application Normative reference terms and definitions Quality management system General requirements Documentation requirements ( title only) General Quality manual Control of documents

ISO 14001 : 2004

Introduction

OHSAS 18001:2007

Introduction

ISO 22000 : 2005

Introduction

Procedures

Name Code -

1 1.1 1.2 2 3 4

Scope

Scope

Scope

2 3 4

Normative references Definitions Environmental management system requirements General requirements

2 3 4

Normative references Definitions OH&S management system requirements General requirements

2 3 4

Normative reference terms and definitions Food Safety management system General requirements Documentation requirements ( title only) General

4.1 4.2

4.1

4.1

4.1 4.2

4.2.1 4.2.2 4.2.3

4.4.4 4.4.5

Documentation Control of documents

4.4.4 4.4.5

Documentation Control of documents

4.2.1 4.2.3 7.7

Quality manual Control of documents. Updating of preliminary information and documents specifying the PRPs and the HACCP plan.

IQM-01 GP-423-01

4.2.4 5

Control of records Management responsibility ( title only ) Management commitment Customer focus

4.5.4 4.4.1

Control of records Structure and responsibility Structure and responsibility Environmental aspects

4.5.4 4.4.1

Control of records Structure and responsibility Structure and responsibility Hazard Identification, Risk Assessment & Determining controls. Legal and requirements Management Review OH&S policy Planning Objectives, targets and programme(s) Objectives, targets and programme(s)

4.2.4 5

Control of records Management responsibility ( title only ) Management commitment Emergency preparedness and response Food Safety policy Food safety management system planning. Updating the food safety management system. Communication

GP-424-01

5.1 5.2

4.4.1 4.3.1

4.4.1 4.3.1

5.1 5.7

5.3 5.4 5.4.1 5.4.2

Quality policy Planning Quality objectives Quality management system planning

4.3.2 4.6 4.2 4.3 4.3.3 4.3.3

Legal and requirements Management Review Environmental policy Planning Objectives, targets and programme(s) Objectives, targets and programme(s)

4.3.2 4.6 4.2 4.3 4.3.3 4.3.3

5.2 5.3

8.5.2

5.5

Responsibility authority and communication ( title only ) Responsibility and authority management representative

5.6

5.5.1

4.4.1

5.5.2

4.4.1

Resources, roles, responsibility and authority Resources, roles, responsibility and authority Communication

4.4.1

4.4.1

Resources, roles, responsibility and authority Resources, roles, responsibility and authority Communication, Participation and Consultation Management review

5.4

Responsibility and authority Food safety team leader

5.5

5.5.3

Internal communication

4.4.3

4.4.3

7.3.2 5.6.2

Food safety team Internal communication

5.6 5.6.1 5.6.2 5.6.3

Management review General Review input Review output

4.6

Management review

4.6

5.8 5.8.1 5.8.2 5.8.3

Management review General Review input Review output

6 6.1

Resource management Provision of resources 4.4.1 Resources, roles, responsibility and authority Competence, training and awareness Competence, training and awareness Resources, roles, responsibility and authority 4.4.1 Resources, roles, responsibility and authority Competence, training and awareness Competence, training and awareness Resources, roles, responsibility and authority

6 6.1

Resource management Provision of resources

6.2 6.2.1 6.2.2 6.3

Human resources General Competence, training and awareness Infrastructure 4.4.2 4.4.2 4.4.1 4.4.2 4.4.2 4.4.1

6.2 6.2.1 6.2.2 6.3 7.2 6.4 7.2

Human resources General Competence, training and awareness Infrastructure Prerequisite programmes (PRPs) Work environment Prerequisite programmes (PRPs) Planning and realization of safe products General

6.4

Work environment

7 7.1 7.2 7.2.1

Product realization Planning of product realization Customer related processes Determination of requirements related to the product

4.4 4.4.6

Implementation and operation Operational control

4.4 4.4.6

Implementation and operation Operational control

7 7.1

4.3.1

Environmental aspects

4.3.1

4.3.2

Legal and other requirements Operational control Environmental aspects

4.3.2

Hazard Identification, Risk Assessment & Determining controls. Legal and other requirements Operational control Hazard Identification, Risk Assessment & Determining controls. Operational control Communication, Participation and Consultation

7.3.4

Intended use

7.3.5

4.4.6 7.2.2 Review of requirements related to the product 4.3.1

4.4.6 4.3.1

5.6.1

Flow diagrams, process steps and control measures External communication

4.4.6 7.2.3 Customer communication 4.4.3

Operational control Communications

4.4.6 4.4.3

5.6.1

External communication

7.3 7.3.1 7.3.2 7.3.3

Design and development Design and development planning Design and development inputs Design and development out puts

4.4.6

Operational control

4.4.6

Operational control

7.3 7.4 7.5

Preliminary steps to enable hazard analysis Hazard analysis Establishing the operational prerequisite programmes (PRPs) Establishing the HACCP plan

7.6

7.3.4 7.3.5 7.3.6 7.3.7

Design and development review Design and development verification Design and development validation Control of design and development changes

8.4.2 8.5.2

7.8 8.2 5.6.2

Evaluation of individual verification results. Updating the food safety management system. Verification planning Validation of control measure combinations. Internal communication. Product characteristics

7.4 7.4.1 7.4.2 7.4.3 7.5 7.5.1 7.5.2

7.5.3 7.5.4 7.5.5 7.6

Purchasing Purchasing process Purchasing information Verification of purchased product Production and service provision Control of production and service provision Validation of processes for production and service provision Identification and traceability Customer property Preservation of product Control of monitoring and measuring devices

4.4.6

Operational control

4.4.6

Operational control

7.3.3

4.4.6

Operational control

4.4.6

Operational control

7.2 7.6.1 8.2 7.9 7.2

Prerequisite programmes (PRPs). HACCP plan. Validation of control measure combinations. Traceability system. Prerequisite programmes (PRPs). Control of monitoring and measuring.

4.5.1

Monitoring and measurement

4.5.1

Monitoring and measurement

8.3

Measurement , analysis and improvement

4.5

Checking

4.5

Checking

8.1 8.2 8.2.1 8.2.2 8.2.3

General Monitoring and measurement Customer satisfaction Internal audit Monitoring and measurement of processes

4.5.1

Monitoring and measurement

4.5.1

Monitoring and measurement

8.1 8.4

4.5.5 4.5.1 Internal audit Monitoring and measurement Evaluation of compliance Monitoring and measurement Evaluation of compliance 4.5.5 4.5.1 Internal audit Monitoring and measurement Evaluation of compliance Monitoring and measurement Evaluation of compliance Incident Investigation, Nonconformity, Corrective Action and Preventive Action Incident Investigation Emergency preparedness and response Nonconformity, corrective and preventive action Monitoring and measurement 8.4.1 7.6.4

Validation, verification and improvement of the food safety management system. General Food safety management system verification. Internal audit. System for the monitoring of critical control points. Evaluation of individual verification results. -

4.5.2 8.2.4 Monitoring and measurement of product 4.5.1 4.5.2 -

4.5.2 4.5.1 4.5.2 4.5.3

8.4.2 -

8.3

Control of nonconforming product

4.5.2

Emergency preparedness and response Nonconformity, corrective and preventive action Monitoring and measurement

4.5.3.1 4.5.2

7.6.5

Actions when monitoring results exceed critical limits. Control of nonconformity. Validation of control measure combinations. Analysis of results of verification activities. Improvement ( title only ) Continual improvement

4.5.3 8.4 Analysis of data 4.5.1

4.5.3.2 4.5.1

7.10 8.2 8.4.3

8.5 8.5.1

Improvement ( title only ) Continual improvement 4.2 4.3.3 4.6 4.5.3 Environmental policy Objectives, targets and programme(s) Management review Nonconformity, corrective and preventive action 4.2 4.3.3 4.6 4.5.3.2 OH&S policy Objectives, targets and programme(s) Management review Nonconformity, corrective and preventive action

8.5 8.5.1

8.5.2

Corrective action

7.10.2

Corrective action

8.5.3

Preventive action

4.5.3

Nonconformity, corrective action and preventive action

4.5.3.2

Nonconformity, corrective and preventive action

5.7

7.2

Emergency preparedness and response. Prerequisite programmes (PRPs).

LIST OF RELATED PROCEDURES

S.N.

1 2 3 4 5 6 7 8 9 10 11 12

Reference No.

PO-IMPR-01 PO-IMPR-02 PO-IMPR-03 PO-IMPR-04 PO-IMPR-05 PO-IMPR-06 PO-IMPR-07 PO-IMPR-08 PO-IMPR-09 PO-IMPR-10 PO-IMPR-11 PO-IMPR-12

Title

Response to Customer Requirements Design and Development of products Planning and Follow-up of Production Paints production control Ratengats production control Inspection and Test of products Control of nonconforming products Control of Inspection, Measuring and Test Equipment Maintenance Customer Support Documents & Data Control Records Control

S.N.

14 15 16 17 18 19 20 21 22 23 24 25

Reference No.

PO-IMPR-14 PO-IMPR-15 PO-IMPR-16 PO-IMPR-17 PO-IMPR-18 PO-IMPR-19 PO-IMPR-20 PO-IMPR-21 PO-IMPR-22 PO-IMPR-23 PO-IMPR-24 PO-IMPR-25

Title

Management Reviews Improvement Opportunities Environmental Performance Emergency , preparedness and response Communications Training , awareness and competence Recruitment Waste management Storage Local Purchasing Foreign Purchasing Local Selection and Evaluation of Suppliers

13

PO-IMPR-13

Internal Audits

26

PO-IMPR-26

Foreign Selection and Evaluation of Suppliers

Vous aimerez peut-être aussi

- Correlation between ISO management system standardsDocument7 pagesCorrelation between ISO management system standardsMajd Draidi100% (1)

- Corrective And Preventative Action A Complete Guide - 2020 EditionD'EverandCorrective And Preventative Action A Complete Guide - 2020 EditionPas encore d'évaluation

- ISO 9000,14000,22000 OHSAS18000 ComparisonDocument1 pageISO 9000,14000,22000 OHSAS18000 ComparisonKhalidPas encore d'évaluation

- Audit Scheme Reference Chart 2018 UpdateDocument6 pagesAudit Scheme Reference Chart 2018 UpdateAquino Sianipar0% (1)

- IMS IQA Audit Check ListDocument123 pagesIMS IQA Audit Check ListMahesh Jadhav75% (4)

- Iso ManualDocument69 pagesIso ManualAwasthiPas encore d'évaluation

- Orient Paper Mills, Amlai (Prop. Orient Paper & Industries Limited)Document1 pageOrient Paper Mills, Amlai (Prop. Orient Paper & Industries Limited)Ravi Shankar ChakravortyPas encore d'évaluation

- EMS AuditDocument62 pagesEMS AuditMansoor AliPas encore d'évaluation

- Aspect Impact Evaluation Procedure.Document3 pagesAspect Impact Evaluation Procedure.harshar2100% (1)

- IMS Project Implementation Plan - Rev 2 (111019)Document1 pageIMS Project Implementation Plan - Rev 2 (111019)Biell BalePas encore d'évaluation

- RTPS Internal Audit Check ListDocument3 pagesRTPS Internal Audit Check Listpradeep kodlekerePas encore d'évaluation

- IMS Matrix Comparision Annex 041019Document3 pagesIMS Matrix Comparision Annex 041019Gunasegaraj RPas encore d'évaluation

- ISO 14001 EMS Templates for Environmental ManagementDocument8 pagesISO 14001 EMS Templates for Environmental ManagementgwakbarPas encore d'évaluation

- ISO Standards Comparison: 9001, 14001 & 450001Document6 pagesISO Standards Comparison: 9001, 14001 & 450001muhammad AndiPas encore d'évaluation

- Internal Audit Report: SR - No. Name Department/Activity In-Charge Designation 1 2 3 4 5 6 7Document7 pagesInternal Audit Report: SR - No. Name Department/Activity In-Charge Designation 1 2 3 4 5 6 7Prabhakar Sv100% (1)

- Mandatory Documents and Records ISO 14001Document1 pageMandatory Documents and Records ISO 14001anon_984094294Pas encore d'évaluation

- Checklist ISO14001Document43 pagesChecklist ISO14001Sara CarvalhoPas encore d'évaluation

- Continual Improvement ProcedureDocument6 pagesContinual Improvement ProcedureRonald SarillanaPas encore d'évaluation

- Integrated Management System: IL&FS Property Management & Services Limited HyderabadDocument27 pagesIntegrated Management System: IL&FS Property Management & Services Limited HyderabadSubroto Ghosh100% (4)

- 01 Context & Interested PartiesDocument6 pages01 Context & Interested PartiesOgheneruemu EtasPas encore d'évaluation

- IMS Gap Anaysisis Check 290919 1Document11 pagesIMS Gap Anaysisis Check 290919 1Gunasegaraj RPas encore d'évaluation

- ISO 14001 DocumentationDocument7 pagesISO 14001 Documentationzahidned100% (1)

- ISO 45001 ChecklistDocument5 pagesISO 45001 Checklistrajivfr144100% (1)

- ISO 14001 Int-Audit ChecklistDocument6 pagesISO 14001 Int-Audit ChecklistSANTOSH KUMARPas encore d'évaluation

- HSEQ INTEGRATED MANAGEMENT SYSTEM INTERNAL AUDITDocument14 pagesHSEQ INTEGRATED MANAGEMENT SYSTEM INTERNAL AUDITnice guy100% (1)

- 46 - Internal Audit Report FormatDocument9 pages46 - Internal Audit Report FormatGurvinder Mann Singh PradhanPas encore d'évaluation

- IVRCL IMS Audit ChecklistDocument9 pagesIVRCL IMS Audit ChecklistAkd DeshmukhPas encore d'évaluation

- Contextual Issues and Risk Assessment - AfconsDocument3 pagesContextual Issues and Risk Assessment - AfconsAnonymous i3lI9MPas encore d'évaluation

- Procedure For Identification of Aspect Impact & HIRADocument1 pageProcedure For Identification of Aspect Impact & HIRAArjun Rathore100% (2)

- Checklist - ISO 14001 - 2015Document9 pagesChecklist - ISO 14001 - 2015Rubini Devi SelvarajooPas encore d'évaluation

- Qehsms Audit ChecklistDocument1 pageQehsms Audit Checklistgaurav100% (1)

- ISO 45001 checklist documentsDocument9 pagesISO 45001 checklist documentsSiddhartha Sankar RoyPas encore d'évaluation

- RoSPA Safety ChecklistDocument2 pagesRoSPA Safety ChecklistOnaFajardo100% (2)

- IMS ChecklistDocument11 pagesIMS ChecklistSaq Jamee96% (24)

- QMS Internal Audit Schedule Template ISO 45001Document1 pageQMS Internal Audit Schedule Template ISO 45001Gaurav DeshwalPas encore d'évaluation

- Environmental Aspect ID and AnalysisDocument3 pagesEnvironmental Aspect ID and AnalysisAnonymous r3SWKnHbw100% (1)

- ISO 14001 v. 2004Document61 pagesISO 14001 v. 2004HSSE SGMWPas encore d'évaluation

- Irca 106 Audit Log SheetDocument18 pagesIrca 106 Audit Log Sheetpkkohli123100% (1)

- Corrective Action and Preventive ActionDocument1 pageCorrective Action and Preventive ActionBisma MasoodPas encore d'évaluation

- EOHSP 07 Communication Consultation Participation PDFDocument5 pagesEOHSP 07 Communication Consultation Participation PDFSyafiq KhalilPas encore d'évaluation

- ISO90011400145001 IMS Manual PDFDocument49 pagesISO90011400145001 IMS Manual PDFMartahanManurung100% (4)

- Iso 45001:2018Document3 pagesIso 45001:2018fansamaster50% (6)

- Integrated Management System ManualQMS, EMS, OHSASDocument46 pagesIntegrated Management System ManualQMS, EMS, OHSASTrivesh S100% (7)

- SWOT ANALYSIS For ISO Context of The OrganizationDocument1 pageSWOT ANALYSIS For ISO Context of The OrganizationZach JavelonaPas encore d'évaluation

- IMS ChecklistDocument19 pagesIMS Checklistcmancuso124_61798429Pas encore d'évaluation

- ISO 45001 2018 OHSMS Audit ChecklistDocument7 pagesISO 45001 2018 OHSMS Audit ChecklistRonald Abadi TariganPas encore d'évaluation

- ISO 45001 HSE Manual and Forms ListDocument5 pagesISO 45001 HSE Manual and Forms ListWAN NORASHIKIN WAN MUSAPas encore d'évaluation

- Sample of IMS PDFDocument24 pagesSample of IMS PDFhatakesumaPas encore d'évaluation

- List of External DocsDocument2 pagesList of External DocsSyed Mujtaba Ali Bukhari100% (1)

- ISO 14001 - 2015 Audit Checklist - SafetyCultureDocument15 pagesISO 14001 - 2015 Audit Checklist - SafetyCultureSanjeev VermaPas encore d'évaluation

- ISO 9001 QMS Requirements MatrixDocument24 pagesISO 9001 QMS Requirements MatrixVictor SuPas encore d'évaluation

- Correspondence Between OHSAS 18001:2007, ISO 14001:2004 and ISO 9001:2000Document3 pagesCorrespondence Between OHSAS 18001:2007, ISO 14001:2004 and ISO 9001:2000Deni NoizPas encore d'évaluation

- Correspondence ISO 9001 14001Document10 pagesCorrespondence ISO 9001 14001irfanyudiaPas encore d'évaluation

- PART 1 "General Part": IMS Comparison ISO 9001:2015 - ISO 14001:2015 - ISO 45001:2018 - ISO 50001:2018 - ISO 22301:2019Document9 pagesPART 1 "General Part": IMS Comparison ISO 9001:2015 - ISO 14001:2015 - ISO 45001:2018 - ISO 50001:2018 - ISO 22301:2019Jogesh KumarPas encore d'évaluation

- ISO 9001-14001-OHSAS comparison tableDocument1 pageISO 9001-14001-OHSAS comparison tableDianaPas encore d'évaluation

- ISO 29001 - Correlation Matrices ISO 29001Document12 pagesISO 29001 - Correlation Matrices ISO 29001ValentinPas encore d'évaluation

- TeamsDocuments - 11 - Equal Assurance - Integrated Audit Criteria Q15-E15-V11 (Issue 4)Document1 pageTeamsDocuments - 11 - Equal Assurance - Integrated Audit Criteria Q15-E15-V11 (Issue 4)Fadhel Audia YusranPas encore d'évaluation

- Meeting Consumers ' Connectivity Needs: A Report From Frontier EconomicsDocument74 pagesMeeting Consumers ' Connectivity Needs: A Report From Frontier EconomicsjkbuckwalterPas encore d'évaluation

- Sunrise Conveyors Maintenance OfferDocument3 pagesSunrise Conveyors Maintenance OfferRampwalker ConveyorPas encore d'évaluation

- 2016-2017 Course CatalogDocument128 pages2016-2017 Course CatalogFernando Igor AlvarezPas encore d'évaluation

- Lecture 1 - Introduction - A2LDocument40 pagesLecture 1 - Introduction - A2LkhawalmannPas encore d'évaluation

- Political Behavior: The Handbook ofDocument22 pagesPolitical Behavior: The Handbook ofnonyelum EzeonuPas encore d'évaluation

- Marketing, Advertising and Product SafetyDocument15 pagesMarketing, Advertising and Product SafetySmriti MehtaPas encore d'évaluation

- Lughaat Al Quran G A ParwezDocument736 pagesLughaat Al Quran G A Parwezscholar786Pas encore d'évaluation

- Special Educational Needs, Inclusion and DiversityDocument665 pagesSpecial Educational Needs, Inclusion and DiversityAndrej Hodonj100% (1)

- TARIFFS AND POLITICS - EVIDENCE FROM TRUMPS Trade War - Thiemo Fetze and Carlo Schwarz PDFDocument25 pagesTARIFFS AND POLITICS - EVIDENCE FROM TRUMPS Trade War - Thiemo Fetze and Carlo Schwarz PDFWilliam WulffPas encore d'évaluation

- Charity Extends Help To Seniors: Donating Is Made EasierDocument16 pagesCharity Extends Help To Seniors: Donating Is Made EasierelauwitPas encore d'évaluation

- True or FalseDocument3 pagesTrue or FalseRB AbacaPas encore d'évaluation

- The Princess AhmadeeDocument6 pagesThe Princess AhmadeeAnnette EdwardsPas encore d'évaluation

- Asset To LiabDocument25 pagesAsset To LiabHavanaPas encore d'évaluation

- Penyebaran Fahaman Bertentangan Akidah Islam Di Media Sosial Dari Perspektif Undang-Undang Dan Syariah Di MalaysiaDocument12 pagesPenyebaran Fahaman Bertentangan Akidah Islam Di Media Sosial Dari Perspektif Undang-Undang Dan Syariah Di Malaysia2023225596Pas encore d'évaluation

- Revision FinalDocument6 pagesRevision Finalnermeen mosaPas encore d'évaluation

- Orientation and Training On Climate Change Adaptation Program (Bantay Kalikasan Expanded Clean and Green Program)Document2 pagesOrientation and Training On Climate Change Adaptation Program (Bantay Kalikasan Expanded Clean and Green Program)Cdrrmc DigosPas encore d'évaluation

- Pharma: Conclave 2018Document4 pagesPharma: Conclave 2018Abhinav SahaniPas encore d'évaluation

- SH-3 Sea King - History Wars Weapons PDFDocument2 pagesSH-3 Sea King - History Wars Weapons PDFchelcarPas encore d'évaluation

- MTWD HistoryDocument8 pagesMTWD HistoryVernie SaluconPas encore d'évaluation

- Family Law Final Exam ReviewDocument2 pagesFamily Law Final Exam ReviewAriellePas encore d'évaluation

- RIZAL Childhood ScriptDocument3 pagesRIZAL Childhood ScriptCarla Pauline Venturina Guinid100% (2)

- Addressing Menstrual Health and Gender EquityDocument52 pagesAddressing Menstrual Health and Gender EquityShelly BhattacharyaPas encore d'évaluation

- Ricoh MP 4001 Users Manual 121110Document6 pagesRicoh MP 4001 Users Manual 121110liliana vargas alvarezPas encore d'évaluation

- Usui MemorialDocument6 pagesUsui MemorialstephenspwPas encore d'évaluation

- ACC WagesDocument4 pagesACC WagesAshish NandaPas encore d'évaluation

- Sweetlines v. TevesDocument6 pagesSweetlines v. TevesSar FifthPas encore d'évaluation

- Olimpiada Engleza 2010 Etapa Locala IXDocument4 pagesOlimpiada Engleza 2010 Etapa Locala IXAdrian TufanPas encore d'évaluation

- IB English L&L Paper 1 + 2 Tips and NotesDocument9 pagesIB English L&L Paper 1 + 2 Tips and NotesAndrei BoroianuPas encore d'évaluation

- 2022 AUSL Purples Notes Criminal Law and Practical ExercisesDocument305 pages2022 AUSL Purples Notes Criminal Law and Practical ExercisesNathalie Joy Calleja100% (6)

- Guidelines For ValuationDocument6 pagesGuidelines For ValuationparikhkashishPas encore d'évaluation

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptD'EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptÉvaluation : 5 sur 5 étoiles5/5 (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksD'EverandArizona, Utah & New Mexico: A Guide to the State & National ParksÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Bahamas a Taste of the Islands ExcerptD'EverandThe Bahamas a Taste of the Islands ExcerptÉvaluation : 4 sur 5 étoiles4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoD'EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoÉvaluation : 5 sur 5 étoiles5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksD'EverandNew York & New Jersey: A Guide to the State & National ParksPas encore d'évaluation

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensD'EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensPas encore d'évaluation