Académique Documents

Professionnel Documents

Culture Documents

Aluminium Alloy 6061

Transféré par

choobyDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Aluminium Alloy 6061

Transféré par

choobyDroits d'auteur :

Formats disponibles

Aluminium Alloy 6061 - Composition, Properties, Temper and Applications of 6061 Aluminium

Topics Covered

Background Composition Key Properties Physical Properties Mechanical Properties Thermal Properties Electrical Properties Typical Heat Treatment/Temper States Typically Available Forms Applications

Background

Aluminium alloy 6061 is one of the most extensively used of the 6000 series aluminium alloys. It is a versatile heat treatable extruded alloy with medium to high strength capabilities.

Composition

Table 1. Typical composition of aluminium alloy 6061 Component Aluminium Magnesium Silicon Iron Copper Zinc Titanium Manganese Chromium Others Amount (wt.%) Balance 0.8-1.2 0.4 0.8 Max. 0.7 0.15-0.40 Max. 0.25 Max. 0.15 Max. 0.15 0.04-0.35 0.05

Key Properties

Typical properties of aluminium alloy 6061 include: Medium to high strength Good toughness Good surface finish Excellent corrosion resistance to atmospheric conditions Good corrosion resistance to sea water Can be anodized

Good weldability and brazability Good workability Widely available

Note: Property data is provided below, but should be used a guide only. As data may vary between manufacturers, you should consult your supplier for more exact figures.

Physical Properties

Density: 2.7 g/cm3 Melting Point: Approx 580C Modulus of Elasticity: 70-80 GPa Poissons Ratio: 0.33

Mechanical Properties

Temper Ultimate Tensile Strength (MPa) 110-152 180 179 min 260-310 0.2% Proof Stress (MPa) 65-110 95-96 110 min 240-276 Brinell Hardness (500kg load, 10mm ball) 30-33 Elongation 50mm dia (%) 14-16 16 9-13

0 T1 T4 T6

95-97

Thermal Properties

Co-Efficient of Thermal Expansion (20-100C): 23.5x10-6 m/m.C Thermal Conductivity: 173 W/m.K

Electrical Properties

Electrical Resistivity: 3.7 4.0 x10-6 .cm

Typical Heat Treatment/Temper States

Treatment F 0 T1 T4, T4511 T51 T6, T6511 Note: 1. This designation applies to products which are not cold worked after cooling from an elevated temperature shaping process, or in which the effect of cold work in Definition As fabricated Annealed to obtain lower strength temper Cooled from an elevated shaping process and naturally aged 1 Solution heat treated and naturally aged2,3 Cooled from an elevated shaping process and artificially aged Solution heat treated and artificially aged2,3

flattening or straightening has no effect on mechanical properties

2. This designation applies to products which are not cold worked after solution heat-treated, or in which the effect of cold work in flattening or straightening has no

effect on mechanical properties

3. This designation applies to products which are not cold worked after solution heat-treatment, or in which the effect of cold work in flattening or straightening does

not effect mechanical properties.

Typically Available Forms

Being and extruded grade of aluminium, alloy 6061 is typically available as: Tube Bar Pipe Rod

Although many manufacturers offer a range of other standard extruded profiles.

Applications

Typical applications for aluminium alloy 6061 include: Aircraft and aerospace components Marine fittings Transport Bicycle frames Camera lenses Driveshafts Electrical fittings and connectors Brake components Valves Couplings

Source: AZoM.com

Vous aimerez peut-être aussi

- Physics: FiitjeeDocument1 319 pagesPhysics: FiitjeeBISWAJEET100% (2)

- ASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelDocument2 pagesASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelBernice JohnsonPas encore d'évaluation

- Australian Steel StrengthDocument5 pagesAustralian Steel StrengthDonald HamiltonPas encore d'évaluation

- Aisi 1008Document2 pagesAisi 1008GANESH GPas encore d'évaluation

- Australian Standard: Metal Finishing-Thermoset Powder CoatingsDocument44 pagesAustralian Standard: Metal Finishing-Thermoset Powder Coatingsעומר כהןPas encore d'évaluation

- AISI 1050 Steel, As RolledDocument2 pagesAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoPas encore d'évaluation

- Schedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Document2 pagesSchedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Caolboy ButchPas encore d'évaluation

- High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingDocument3 pagesHigh-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingBernathTurnipPas encore d'évaluation

- Erection Manual Hydro-1Document63 pagesErection Manual Hydro-1rajfab100% (1)

- ASTM A108-07 Aço Carbono e Ligas, Acabados A FrioDocument7 pagesASTM A108-07 Aço Carbono e Ligas, Acabados A FrioVinicius BacellarPas encore d'évaluation

- Jis g3131 HotDocument3 pagesJis g3131 Hoteko_koesworoPas encore d'évaluation

- Data Analysis PDFDocument70 pagesData Analysis PDFMark De Guzman100% (1)

- Astm A690Document2 pagesAstm A690Genesis Lissette Loyola Ortiz100% (1)

- Wind-Induced Deflections of Fleestanding - GlanviUe Kwok PDFDocument13 pagesWind-Induced Deflections of Fleestanding - GlanviUe Kwok PDFMiguel CanasPas encore d'évaluation

- Fastener Connection To Structure - ExampleDocument12 pagesFastener Connection To Structure - ExamplekingdbmPas encore d'évaluation

- Astm A1008 CRC Crs PDFDocument9 pagesAstm A1008 CRC Crs PDFArul Edwin VijayPas encore d'évaluation

- Scania SOPS ParametersDocument32 pagesScania SOPS Parametersjose breno vieira silva89% (19)

- Roark's FormulasDocument14 pagesRoark's FormulasDavide FerraresePas encore d'évaluation

- Early Thermal CrackingDocument2 pagesEarly Thermal Crackingsudhir12345Pas encore d'évaluation

- Dimension, Shape, Weight and Tolerances For Hot Rolled Plates and SheetsDocument11 pagesDimension, Shape, Weight and Tolerances For Hot Rolled Plates and Sheetsjorge carlos jimenez mendozaPas encore d'évaluation

- Csa G40.21 PDFDocument4 pagesCsa G40.21 PDFmecano1Pas encore d'évaluation

- Grade 8 Math W2 LASDocument19 pagesGrade 8 Math W2 LASJaeda BaltazarPas encore d'évaluation

- A276 PDFDocument8 pagesA276 PDFsingaravelan narayanasamyPas encore d'évaluation

- Equivalent Materials 2Document5 pagesEquivalent Materials 2lalitlbw91Pas encore d'évaluation

- Timco TDS Drywall ScrewDocument2 pagesTimco TDS Drywall ScrewNajeeb AhmedPas encore d'évaluation

- A307 PDFDocument5 pagesA307 PDFxaviereduardoPas encore d'évaluation

- API5LDocument3 pagesAPI5LputrudePas encore d'évaluation

- ASTM A656 Grade 50: General Product DescriptionDocument1 pageASTM A656 Grade 50: General Product DescriptionHarsh ChopraPas encore d'évaluation

- CVEN3302 Structural Design CVEN3302 Structural DesignDocument404 pagesCVEN3302 Structural Design CVEN3302 Structural Designroy jackPas encore d'évaluation

- Electricity Board DocsDocument41 pagesElectricity Board DocsM_D_MendisPas encore d'évaluation

- Baker 2015 Microalloyed SteelsDocument45 pagesBaker 2015 Microalloyed SteelsHumbertzone O. Garcia CedilloPas encore d'évaluation

- SGT - Le.05 Eye BoltsDocument1 pageSGT - Le.05 Eye BoltsryangillespiePas encore d'évaluation

- ASTM A633 GR E Data Sheet 2012 04 01Document2 pagesASTM A633 GR E Data Sheet 2012 04 01FrancescoGuglielmo100% (1)

- Analizador XRF PDFDocument212 pagesAnalizador XRF PDFMaritza EstefesPas encore d'évaluation

- Tata Steel - YMPRESS S500MC - Data SheetDocument2 pagesTata Steel - YMPRESS S500MC - Data SheetpnagarajjPas encore d'évaluation

- Astm A325m PDFDocument8 pagesAstm A325m PDFDastaggir KarimiPas encore d'évaluation

- CJP & PJPDocument3 pagesCJP & PJPRobertBostanPas encore d'évaluation

- OPSS 906 - Nov12Document20 pagesOPSS 906 - Nov12umerfr2Pas encore d'évaluation

- Stainless Steel Bolts ManufacturerDocument3 pagesStainless Steel Bolts ManufacturerRajtilak MetalPas encore d'évaluation

- Astm 434Document3 pagesAstm 434Fabián MartínezPas encore d'évaluation

- Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelDocument2 pagesPressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelSofiaJabadanEspulgarPas encore d'évaluation

- GALVALUMEDocument3 pagesGALVALUMETravis WoodPas encore d'évaluation

- A 434 04Document1 pageA 434 04asepoPas encore d'évaluation

- Steel Design IntroDocument22 pagesSteel Design IntroAira Choy Poliquit CargoPas encore d'évaluation

- General Brochure eDocument6 pagesGeneral Brochure eShafeek GhreebPas encore d'évaluation

- CSA FastenersDocument7 pagesCSA FastenersBarnabás KissPas encore d'évaluation

- Astm A659-18Document3 pagesAstm A659-18Ryan ZhangPas encore d'évaluation

- SANS-1431 Withdrawal (2010)Document1 pageSANS-1431 Withdrawal (2010)Darryl007Pas encore d'évaluation

- Astm 143Document3 pagesAstm 143JH_ProjectPas encore d'évaluation

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDocument12 pagesThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelPas encore d'évaluation

- Astm A588-A588m-05Document3 pagesAstm A588-A588m-05Hoang Kien100% (1)

- ASTM A615 Grade 70 PDFDocument2 pagesASTM A615 Grade 70 PDFAnonymous vRtCW4hszPas encore d'évaluation

- GB T1591 Q345B Carbon and Low Alloy High Strength Steel PlateDocument1 pageGB T1591 Q345B Carbon and Low Alloy High Strength Steel Platejcvalencia100% (1)

- Aalco Metals LTD Stainless Steel 1.4003 Nirosta 4003 3CR12 96Document2 pagesAalco Metals LTD Stainless Steel 1.4003 Nirosta 4003 3CR12 96Xingfeng HanPas encore d'évaluation

- Al Busbar 6060 DatasheetDocument1 pageAl Busbar 6060 DatasheetpiirsaluPas encore d'évaluation

- Essar Steel Galvanised BrochureDocument9 pagesEssar Steel Galvanised BrochureSukanya Sen DuttaPas encore d'évaluation

- Domex 100 XF Data SheetDocument2 pagesDomex 100 XF Data Sheetzubblwump5063Pas encore d'évaluation

- Is 1852 PDFDocument10 pagesIs 1852 PDFSIVAPas encore d'évaluation

- 304 Stainless Steel Technical Data SheetDocument4 pages304 Stainless Steel Technical Data SheetMani KannaPas encore d'évaluation

- Astm B411B411M-14Document3 pagesAstm B411B411M-14Gabriel Perez CruzPas encore d'évaluation

- ASTM D 2000: Specification NumberDocument3 pagesASTM D 2000: Specification NumberjanarthananPas encore d'évaluation

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartKiara Ticangan Argel100% (1)

- LM6 Alloy DetailDocument4 pagesLM6 Alloy DetaildsoPas encore d'évaluation

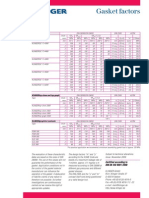

- Klinger - Gasket FactorsDocument4 pagesKlinger - Gasket FactorsFelip PrietoPas encore d'évaluation

- Aluminium Alloy 6061 - Composition, Properties, Temper and ApplicationsDocument4 pagesAluminium Alloy 6061 - Composition, Properties, Temper and ApplicationsMadhu SudanPas encore d'évaluation

- Aluminium Alloy 6061 Composition Properties Temper and Applications of 6061 AluminiumDocument5 pagesAluminium Alloy 6061 Composition Properties Temper and Applications of 6061 AluminiumCésar TapiaPas encore d'évaluation

- 1) Semester II /1 / IV Exam 2020 (Even) (Old / New Syllabus) BacklogDocument5 pages1) Semester II /1 / IV Exam 2020 (Even) (Old / New Syllabus) BacklogHarsh VardhanPas encore d'évaluation

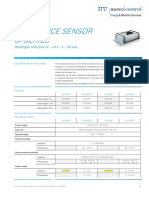

- DB Irradiance Sensor Si-Series en 20171016Document3 pagesDB Irradiance Sensor Si-Series en 20171016Solar ProjectsPas encore d'évaluation

- CH 13Document27 pagesCH 13Shaivy TyagiPas encore d'évaluation

- Opsis Technique Eng 2007Document4 pagesOpsis Technique Eng 2007sukumariicbPas encore d'évaluation

- Hubert de Sousleau - Witchcraft Ghosts and AlchemyDocument7 pagesHubert de Sousleau - Witchcraft Ghosts and AlchemyErrovioPas encore d'évaluation

- Final Field ProjectDocument7 pagesFinal Field ProjectKarl KaiPas encore d'évaluation

- Service Manual: Bassbreaker™ 15Document22 pagesService Manual: Bassbreaker™ 15John govanPas encore d'évaluation

- Activity Sheets Grade 8 Geometry CDocument15 pagesActivity Sheets Grade 8 Geometry CLeopold Laset33% (3)

- Is.11921.1993 Fuel Efficiency StandardDocument12 pagesIs.11921.1993 Fuel Efficiency StandardParminder SinghPas encore d'évaluation

- Polymer-Plastics Technology and EngineeringDocument6 pagesPolymer-Plastics Technology and Engineeringsamuelben87Pas encore d'évaluation

- Laboratory Assignments On Experiment 1: Measurement of Self-Inductance by Maxwell's BridgeDocument2 pagesLaboratory Assignments On Experiment 1: Measurement of Self-Inductance by Maxwell's BridgesparshPas encore d'évaluation

- RC OscillatorDocument8 pagesRC OscillatorRavi TejaPas encore d'évaluation

- Linear Interpolation Equation Formula Calculator PDFDocument3 pagesLinear Interpolation Equation Formula Calculator PDFMatthew HalePas encore d'évaluation

- LISTENING THE INVENTION THAT CHANGED THE WORLD (I) - Revisin Del IntentoDocument2 pagesLISTENING THE INVENTION THAT CHANGED THE WORLD (I) - Revisin Del IntentoÁngela67% (3)

- Pfaff Hobbymatic 917 Sewing Machine Instruction ManualDocument88 pagesPfaff Hobbymatic 917 Sewing Machine Instruction ManualiliiexpugnansPas encore d'évaluation

- Numerical Analisis 2015Document357 pagesNumerical Analisis 2015mariaPas encore d'évaluation

- Silver Nanoparticles DataDocument6 pagesSilver Nanoparticles DataSanwithz SittiPas encore d'évaluation

- Neil - Bernardo@eee - Upd.edu - PH Bernalyn - Decena@eee - Upd.edu - PH Ephraim - Lizardo@eee - Upd.edu - PHDocument3 pagesNeil - Bernardo@eee - Upd.edu - PH Bernalyn - Decena@eee - Upd.edu - PH Ephraim - Lizardo@eee - Upd.edu - PHbdec95Pas encore d'évaluation

- W 9540Document6 pagesW 9540imharvePas encore d'évaluation

- CCNA 4 - Chapter 2 QuzDocument1 pageCCNA 4 - Chapter 2 Quzchobiipiggy26Pas encore d'évaluation

- LG FlatRon RepairDocument55 pagesLG FlatRon Repairdany89roPas encore d'évaluation

- Altronics CPU-2000 BLLTN 10-2009 PDFDocument4 pagesAltronics CPU-2000 BLLTN 10-2009 PDFSMcPas encore d'évaluation

- Seismic Enhancement of Circular RC Bridge Piers With Fiber CompositesDocument9 pagesSeismic Enhancement of Circular RC Bridge Piers With Fiber CompositesGerardoSosaDavilaPas encore d'évaluation

- What Is An AtheistDocument62 pagesWhat Is An AtheistLBL_LowkeePas encore d'évaluation