Académique Documents

Professionnel Documents

Culture Documents

Management Accounting Mega Drive

Transféré par

Gkæ E. GaleakelweCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Management Accounting Mega Drive

Transféré par

Gkæ E. GaleakelweDroits d'auteur :

Formats disponibles

Types of Cost Standards BASIC STANDARDS long term standards which remain unchanged over a period of years.

. Used to show trends over time for items such as material prices, labour rates and labour efficiency. They are also used to show the effect of using different methods over time. Least used and least useful type of standard. IDEAL STANDARDS based upon perfect operating conditions no wastage; no scrap; no breakdowns; no stoppages; no idle time. Will likely have an adverse motivational impact becoz they are unlikely to be achieved. ATTAINABLE STANDARDS based upon efficient(but not perfect) operating conditions. These standards include allowances for the following- normal or expected material losses; fatigue; machine breakdowns. Must be based on a high performance level so that with a certain amount of hardwork they are achievable. CURRENT STANDARDS based on current levels of efficiency in terms of allowance for breakdowns, wastage, losses etc. Disadvantage is they do not provide any incentive to improve on the current level of performance. Sales Variances

Sales Volume Variance calculates the effect on profit of the actual sales volume being different from that budgeted. The effect on profit will differ depending upon whether a marginal or absorption costing systems. = (Actual Quantity Sold * Standard Margin) (Budget Quantity Sold * Standard Margin NB: Standard margin = Contribution per unit (marginal costing) or the Profit per unit (Absorption costing) Sales Price Variance shows the effect on profit of selling at a different price from that expected. = (Actual Quantity Sold * Actual selling price) (Actual Quantity Sold * Budgeted selling price) Possible causes of sales variances 1. Unplanned price increases/reductions 2. Unexpected fall in demand due to recession 3. Additional demand attracted by reduced price 4. Failure to satisfy demand due to production difficulties. Materials Cost Variances Materials Total variance the difference between (a) the standard material cost of the actual production (flexed budget) and (b) the actual cost of

direct material. It can be analysed into two subvariances: materials price variance and a materials usage variance (ie. Add the two) Materials Price Variance analyses whether the company paid more or less than expected for material = (Actual Quantity Bought * Actual Price) (Actual Quantity Bought * Standard price per unit of material) Materials Usage Variance quantifies the effect on profit of using a different quantity of raw material from that expected for the actual production achieved. = (Actual Quantity Used * Standard price per unit) (Standard Quantity Used for actual production * Standard price per unit) Possible causes of material price variations 1. Suppliers from different sources 2. Unexpected general price increases 3. Changes in quantity discounts 4. Substitution of one grade of material for another 5. Materials price standards are usually set at a midyear price so one would expect a favourable price variance early in a period and an adverse variance later on in a budget period. Possible causes of material usage variance 1. A higher or lower incidence of scrap

2. An alteration to product design 3. Substitution of one grade of material for another Later Cost Variances Wage Rate Variance = (Standard wage rate per hour Actual wage rate) * Actual labour hours Labour Efficiency Variance = (Standard quantity of labour hours for actual production Actual labour hours) * Standard wage rate Possible causes of labour price variances 1. An unexpected national wage award 2. Overtime or bonus payments which are different from budgeted 3. Substitution of one grade of labour for another higher or lower grade. Possible causes of labour efficiency variances 1. Changes in working conditions, eg Better supervision 2. Consequences of the learning effect 3. Introduction of incentive schemes or staff training 4. Substitution of one grade of labour for another higher or lower grade

CONCEPT OF RELEVANT COSTING - Relevant costs and revenues are those costs and revenues that change as a result of decision taken. They are incremental costs and revenues, cash flows and future costs and revenues RELEVANT COST terms - Differential costs- the differences in total costs or revenues between two alternatives - Opportunity costs- represent the best alternative forgone - Avoidable costs- would be avoided if the activity didnt exist BREAK-EVEN & CVP ANALYSIS CVP analysis the study of the effects on future profits of changes in fixed costs, variable costs, selling price, quantity. Makes use of the contribution concept in order to assess the following measures for a single product: c/s ratio = contribution per unit/selling price p.u break-even point=fixed costs/cntrbution per unit margin of safety= budgeted sales - b/e point sales Target profit =(f.c + required profit) / contribution per unit

THROUGHPUT ACCOUNTING PRINCIPLES - a measure of profitability - aims to make the best use of a scarce recource in a JIT environment - aims to max profitability by utilising scarce resource and also reducing inventory costs - only variable cost in short term is raw materials - direct labour costs are not variable in the short term as usually guaranteed weekly minimum wage HOW TO IMPROVE TPAR - Increase sales price - Reduce materials cost change materials, switch suppliers - Reduce total operating expenses to reduce factory costs per hour Throughput = sales material costs

Vous aimerez peut-être aussi

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- An Investigation Into The Impact of The Adoption of Third Generation (3G) Wireless Technology On The Economy, Growth and Competitiveness of A Country. by Galeakelwe Kolaatamo.Document58 pagesAn Investigation Into The Impact of The Adoption of Third Generation (3G) Wireless Technology On The Economy, Growth and Competitiveness of A Country. by Galeakelwe Kolaatamo.Gkæ E. GaleakelwePas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Formulae For The Computation of The VariancesDocument5 pagesFormulae For The Computation of The VariancesGkæ E. GaleakelwePas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Admission Offers 2010-11Document8 pagesAdmission Offers 2010-11Gkæ E. GaleakelwePas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The History of Management Accounting: OriginsDocument24 pagesThe History of Management Accounting: OriginsGkæ E. GaleakelwePas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Statement 115377 Oct-2022Document8 pagesStatement 115377 Oct-2022Mary MacLellanPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Findings and SuggestionDocument5 pagesFindings and SuggestionShobhit Mishra0% (1)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Instructional Material Product Management Topic 1Document10 pagesInstructional Material Product Management Topic 1Rita DanielaPas encore d'évaluation

- Plantillas MarketingDocument26 pagesPlantillas MarketingAntelmoPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Flow of Accounting Entries in Oracle AppDocument19 pagesFlow of Accounting Entries in Oracle AppSrinivas AzurePas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Nasdaq Composite White PaperDocument8 pagesNasdaq Composite White PaperavaresearchPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Research Update - July 30 - 09Document8 pagesResearch Update - July 30 - 09mrahman2k4Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Exchanges Special Report Features Holli Holden HeflinDocument16 pagesExchanges Special Report Features Holli Holden HeflinHhheflinPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Edit 2022-23 - Textes 1 - Assignments - Enjeux Mondialisation EUDocument30 pagesEdit 2022-23 - Textes 1 - Assignments - Enjeux Mondialisation EUirolines kolaplPas encore d'évaluation

- 3032 Main ProjectDocument71 pages3032 Main Projectamanmukri1Pas encore d'évaluation

- Transfer Pricing EssayDocument8 pagesTransfer Pricing EssayFernando Montoro SánchezPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- 01 Demand and Supply AnalysisDocument61 pages01 Demand and Supply Analysisyajur_nagiPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

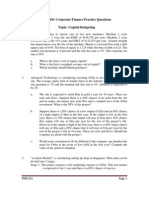

- FIN3101 Corporate Finance Practice Questions Topic: Capital BudgetingDocument3 pagesFIN3101 Corporate Finance Practice Questions Topic: Capital BudgetingKelly KohPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Electronic Payment Systems Development in A DeveloDocument17 pagesElectronic Payment Systems Development in A DeveloMinh ThưPas encore d'évaluation

- The Role of Ethiopia's Developmental State in Building A Strong State-Society Relationship To Eradicate PovertyDocument10 pagesThe Role of Ethiopia's Developmental State in Building A Strong State-Society Relationship To Eradicate PovertyInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Micmath 7Document5 pagesMicmath 7Nana YuniarPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- SAPM Module 1 HandoutDocument10 pagesSAPM Module 1 HandoutmmuneebsdaPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- Chapter 9 Standard Costing - SynopsisDocument8 pagesChapter 9 Standard Costing - SynopsissajedulPas encore d'évaluation

- Brand Mantras Rationale Criteria and ExamplesDocument11 pagesBrand Mantras Rationale Criteria and ExamplesBrownbrothaMPas encore d'évaluation

- Unit 9 - Perfect CompetetionDocument101 pagesUnit 9 - Perfect CompetetionRavi GargPas encore d'évaluation

- Gold Mastercard Titanium Mastercard Platinum MastercardDocument3 pagesGold Mastercard Titanium Mastercard Platinum MastercardRoseyy GalitPas encore d'évaluation

- Goni MahwashDocument27 pagesGoni MahwashChandan ChoudharyPas encore d'évaluation

- Perfettivan Melle IndiaDocument4 pagesPerfettivan Melle IndiaMeenakshi KolayPas encore d'évaluation

- Design Brief For (Insert Company Name) : Business OverviewDocument5 pagesDesign Brief For (Insert Company Name) : Business OverviewImi FeketePas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Business Plan TemplateDocument4 pagesBusiness Plan TemplateFahadKhanPas encore d'évaluation

- Salesmanship CHAPTER 2Document45 pagesSalesmanship CHAPTER 2Israel Ad FernandoPas encore d'évaluation

- Amity Bba Solved AssignmentsDocument2 pagesAmity Bba Solved AssignmentsBUSHRA FATIMA APas encore d'évaluation

- Source of Regular Input VATDocument1 pageSource of Regular Input VATMarie Tes LocsinPas encore d'évaluation

- I. Mckinsey'S 7S Model Approach To Coca-Cola OrganizationDocument17 pagesI. Mckinsey'S 7S Model Approach To Coca-Cola OrganizationHoàng NhiPas encore d'évaluation

- RareWine Invest Investment Guide 0921-WebDocument11 pagesRareWine Invest Investment Guide 0921-Webines marino garciaPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)