Académique Documents

Professionnel Documents

Culture Documents

Thermo-Mechanical Treatment of The C-MN Steel With NB, Ti, V and B Microadditions

Transféré par

Gaurav TripathiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Thermo-Mechanical Treatment of The C-MN Steel With NB, Ti, V and B Microadditions

Transféré par

Gaurav TripathiDroits d'auteur :

Formats disponibles

Archives of Materials Science and Engineering

Volume 28 Issue 6 June 2007 Pages 377-380

International Scientific Journal published monthly as the organ of the Committee of Materials Science of the Polish Academy of Sciences

Thermo-mechanical treatment of the C-Mn steel with Nb, Ti, V and B microadditions

M. Opiela*

Division of Constructional and Special Materials, Institute of Engineering Materials and Biomaterials, Silesian University of Technology, ul. Konarskiego 18a, 44-100 Gliwice, Poland * Corresponding author: E-mail address: marek.opiela@polsl.pl

Received 27.03.2007; accepted in revised form 15.05.2007

ABSTRACT Purpose: The paper presents the investigation results of the thermo-mechanical treatment parameters influence on the structure and mechanical properties of the low-carbon steel with Nb, Ti, V and B microadditions, destined for the weldable heavy plates production with the yield point above 960 MPa. Design/methodology/approach: Metallography, hot torsion test, tensile test, Charpy test have been used. Findings: It was found out that failing to attain the total static austenite recrystallization between the consecutive deformation stages results in a development of the segregation bands, causing the significant deterioration of the crack resistance of steel at the lowered temperature. Research limitations/implications: TEM investigations on structure of the steel after thermo-mechanical treatment were predicted. Practical implications: The investigation results obtained make it possible to work out the industrial scale technology for the weldable heavy plates with high strength and crack resistance at the lowered temperature, using the energy-saving thermo-mechanical method integrated with a ladle metallurgy of the molten steel and continuous slab casting. Originality/value: Adjusting the interval times between the deformation cycles in the multi-pass rolling process to the total recrystallization time of the plastically deformed austenite, by employing the retention shield, and the isothermal holding of the product at the temperature of the end of hot working for time t0.5 before quenching, offers the possibility of obtaining the homogenous austenite structure, and therefore, manufacturing the rolled products displaying high mechanical properties. Keywords: Thermo-mechanical treatment; Heat treatment; Mechanical properties; Crack resistance MATERIALS MANUFACTURING AND PROCESSING

1. Introduction 1. Introduction

The thermo-mechanical treatment, integrating the hot working of steel with the direct quenching of the products at the end of rolling temperature or after their preceding holding at this temperature for a certain time, is an energy-saving steel-making technology. In comparison with the classic heat treatment, boiling down to quenching and tempering, the steel products made from the toughening steels using the thermo-mechanical methods, require tempering only [1-4].

Rolling with the controlled recrystallization features the typical thermo-mechanical treatment of plates and long profile sections, consisting in the multi-pass rolling of the charge within the correct temperature range, whereas, in intervals between the consecutive passes, total recrystallization of austenite should take place, and after completing the rolling, before quenching, one should provide conditions to forming the 50% fraction of the recrystallized austenite. This technology is especially useful for production of the heavy plates with high strength and brittle resistance at the lowered temperatures from the low-carbon weldable steels, containing Mn, Cr, Ni, and Mo improving their hardenability, and the

Copyright by International OCSCO World Press. All rights reserved. 2007

377

M. Opiela

microadditions like Nb, Ti, and V making it possible to control the development of the austenite microstructure during the hot working and after its completing, before quenching. Microadditions made to the steel, with a strong affinity to N and C develop, during the hot working, the dispersive precipitations of nitrides, carbonitrides, and carbides with the NaCl lattices, slowing recovery and static recrystallization of the austenite in intervals between the successive rolling passes, however, limiting grain growth of this phase. This makes developing of the fine-grained austenite structure possible, and therefore, development of the fine-grained transformation products of this phase, having a significant input into its strengthening and into the increase of its crack resistance [5-14]. The desired effect is attained only when the correct hot working temperature range is chosen for precipitation kinetics in the austenite of the interstitial phases of micro-additions introduced into the steel, described by the following equation: log [M][X] = B - A/T (1) where: [M] and [X] are the relevant mass fractions of the metallic microaddition and metalloid dissolved in solid solution at temperature T. Values of constants A and B for various interstitial phases are published in [3,6,15]. The goal of the work is investigation of the effect of hot working of steel on the structure heterogeneity and mechanical properties of austenite and determining conditions of the thermomechanical treatment (rolling with the controlled recrystallization) of the Cr-Mo steel, destined for manufacturing of the heat treated heavy plates, with the yield point exceeding 960 MPa and with the guaranteed cracking resistance at the lowered temperature.

The thermo-mechanical treatment of plates was carried out according to two variants. In the first one, the strip was air cooled between the passes to the temperature of the successive pass and held for the t0.5 time in stable conditions after completing the rolling, before quenching in water. In the second variant, however, the retention shield was used, making it possible to adjust intervals between successive passes to time close to tR and to hold the plate isothermally at the temperature of end of rolling for time t0.5 before its quenching. The test specimens of plates were tempered within the temperature range of 550 to 650C. To evaluate the effect of the conditions of plastic deformation on structure and mechanical properties of steel, the conventional heat treatment of the steel was carried out, i.e., quenching of specimens at the austenitizing temperature of 900C, proper for this steel, and tempering in the conditions identical with those applied to the rolled and quenched test plates.

3. Results of investigations Results investigations

Continuous torsion tests of the specimens carried out made it possible to determine the effect of temperature within the range of 1100 to 900 C on the V- curves shapes and on deformations m corresponding to the maximum yield stress value (Fig.1), and therefore, evaluation of the deformation necessary to originate the dynamical austenite recrystallization cd | 0.8 m. The torsion tests of the specimens made to obtain the required deformation revealed, that depending on temperature and time of holding the specimens between two deformation stages, partial or total decay of strain hardening occurs. It is a result of recovery and static recrystallization processes of the plastically deformed austenite.

2. Experimentalprocedure Experimental procedure

The investigations were made using the imported heat treatable steel, delivered as 40 mm thick plate. The steel containing 0.17% C, 1.37% Mn, 0.26% Si, 0.012% P, 0.001% S, 0.24% Cr, 0.48% Mo, 0.05% Ni, 0.019% V, 0.004% Ti, 0.025% Nb, 0.06% Al, 0.002% B, and 0.004% N, is destined for manufacturing the weldable heavy plates with the yield point exceeding 960 MPa and the fracture appearance transition temperature T45J equal to 40C. Effect of deformation temperature was investigated within the temperature range of 1100 to 900C by twisting the specimens in the SETERAM-7N torsional plastometer with the rate of 3 s-1. The plastically deformed austenite recrystallization kinetics was also determined in the same temperature range with = 0.2 at the deformation rate 3 s-1, i.e., in conditions close to rolling of heavy plates. Investigation results of the austenite strain strengthening kinetics decay were employed for determining the total austenite recrystallization time tR and the time t0.5 necessary for developing the 50% fraction of the recrystallized phase as a function of temperature. These investigations made it also possible to work out conditions of the thermo-mechanical treatment rolling with the controlled recrystallization of the flat bar with the 200 x 40 mm transverse section to the 15 mm thick plate in five passes within the temperature range of 1000 to 900C with decrements of 50C. Pass reductions of 20% were applied in the first three passes, and 15% in the last two ones.

Fig. 1. Effect of temperature on the Vwith the deformation rate of 3 s-1

curves in the twist test

The strain hardening decay kinetics curves obtained for the austenite (Fig.2) demonstrate that the time of the total austenite recrystallization tR at temperature of 1100 C is about 50 sec and increases to about 300 sec at a temperature of 900 C. However, the t0.5 time required for developing of 50% fraction of the

378 378

Archives of Materials Science and Engineering

Thermo-mechanical treatment of the C-Mn steel with Nb, Ti, V and B microadditions

Fig. 2. Effect of the test temperature on the strain hardening (recrystallization) kinetics decay curves of the plastically deformed austenite in the torsion test at the rate of 3 s-1 ( = 0.2)

Fig. 3. Austenite structure with distinct segregation bands

recrystallized austenite at a temperature of 1100 C is 9 sec, and increases to 60 sec at a temperature of 900 C. The metallographic examinations of the specimens deformed in cycles revealed that if the interval between the consecutive deformations is smaller than the time of the total austenite recrystallization tR, then because of the superposition of the consecutive deformation cycles shearing bands develop in the austenite. The similar segregation bands were revealed in the primary austenite (Fig.3) and in martensite (Fig.4) of the test sections of plates made using the first variant of the thermomechanical treatment. Segregation bands do not develop if the interval between the successive deformation cycles makes total recrystallization of the plastically deformed austenite possible. Adjusting the interval times between the consecutive deformation cycles to time tR, by employing the retention shield, and the isothermal holding of the rolled strip for time t0.5 at the temperature of the end of hot working before quenching, has added to improvement of the chemical composition homogeneity. Steel structure developed in these conditions contains about 20% of the fine-grained, statically recrystallized austenite, and the remaining portion of the phase in the significantly larger grains of the statically recovered austenite, with no traces of segregation bands (Fig.5). The differentiated steel structure, both in the quenched state for both thermo-mechanical working variants and in the tempered state has small effect on the mechanical properties, however, a significant one on the Charpy V-notched specimens breaking energy at a temperature of 40 C and anisotropy of the plastic properties of the plate test segments, expressed by the ratio of the transverse to longitudinal KV-40oC specimens. Tensile test results indicate that the test plate segments made in both thermo-mechanical working variants, tempered in the temperature range 550 to 650 Cs demonstrate the comparable mechanical properties, that is: yield stress Rp0.2 from 1000 to 1089 MPa, Ultimate Tensile Strength Rm from 1030 to 1120 MPa, elongation A from 17 to 19%, and reduction of area at fracture Z from 60 to 69%.

Fig. 4. Low-carbon lathe martensite with distinct segregation bands

Fig.5. Fine grains of the statically recrystallized austenite distributed at the grain boundaries of the statically recovered austenite; deformation temperature 900 C, t0.5 = 60 sec

Volume 28

Issue 6

June 2007

379

Top Rp0.2 and Rm values refer to the test plate segment made using the first thermo-mechanical working variant, whereas, the bottom ones refer to the second variant. Moreover, the transverse specimens have, in general, slightly better strength properties, and lower plastic ones. However, the conventionally quenched steel, after austenitizing the specimens at the temperature of 900 C demonstrates the properties comparable with those given above for the thermo-mechanically worked specimens, only after tempering at a temperature of 550 C. Increasing the tempering temperature to 650 C results in decreasing the yield stress Rp0.2 to 990 MPa with UTS (Rm) of about 1040 MPa, A about 19% and Z from 67 to 70%. The significant differences refer to crack resistance of the test segments of the plate made using both variants of the thermomechanical working, and after the conventional quenching and tempering of the steel. It turns out, from V-notched Charpy test results at the temperature of -40 C that KV energy, for both transverse specimens and for the longitudinal ones, increase along with the increase of the tempering temperature. However, the energy values of breaking the specimens taken from the segment of the plate manufactured in the conditions of total recrystallization of the plastically deformed austenite at intervals between the successive rolling passes and isothermal holding for time t0.5 at the temperature of finish-rolling prior to quenching, is nearly two times larger than the energy of breaking the specimens taken from the test segments of the plate made in the first thermo-mechanical working variant.

quenching, offers the possibility of obtaining the homogenous austenite structure, and therefore, manufacturing the rolled products displaying high mechanical properties.

References References

[1] [2] M. Korchynsky (ed.), Proceedings of the International Conference Microalloying95, Pittsburgh, 1995. K.A. Taylor, S.W. Thompson, F.B. Fletcher (eds.), Proceedings of the Symposium Physical Metallurgy of Direct Quenched Steels, Chicago, Ilionis, 1992. J. Adamczyk, Engineering of Steel Products, The Silesian University of Technology Publishers, Gliwice 2001, (in Polish). J. Adamczyk, Engineering of Metallic Products, The Silesian University of Technology Publishers, Gliwice 2004, (in Polish). J. Adamczyk, E. Kalinowska-Ozgowicz, W. Ozgowicz, R. Wusatowski, Interaction of carbonitrides V(C,N) undissolved in austenite on the structure and mechanical properties of microalloyed V-N steels, Journal of Materials Processing Technology 53 (1995) 23-32. T. Gladman, The physical matallurgy of microalloyed steels, The Institute of Materials, University Press, Cambridge 1997. J. Adamczyk, A. Grajcar, Structure and mechanical properties of DP-type and TRIP-type sheets obtained after the thermomechanical processing, Journal of Materials Processing Technology 162-163 (2005) 267-274. J. Adamczyk, M. Opiela, Influence of the thermo-mechanical treatment parameters on the inhomogeneity of the austenite structure and mechanical properties of the Cr-Mo steel with Nb, Ti and B microaddition, Journal of Materials Processing Technology 157-158 (2004) 456-461. Y. Wang, B. Appolaire, S. Denis, P. Archambault, B. Dussoubs, Study and modelling of microstructural evolutions and thermomechanical behaviour during the tempering of steel, International Journal of Microstructure and Materials Properties 1 (2006) 197-207. J. Adamczyk, M. Opiela, Engineering of forged products of microalloyed constructional steels, Journal of Achievements Materials and Manufacturing Engineering 15 (2006) 153-158. J. Adamczyk, Development of the microalloyed constructional steels, Journal of Achievements in Materials and Manufacturing Engineering 14 (2006) 9-20. S. Rusz, L. Cizek, P. Filipec, Evaluation of fatigue of microalloyed 23MnB4 steel, Journal of Achievements in Materials and Manufacturing Engineering 18 (2006) 223-226. J. Adamczyk, Manufacturing of mass-scale products from structural microalloyed steels in integrated production lines, Journal of Achievements in Materials and Manufacturing Engineering, 20 (2007) 399-402. K. Hulka, Microalloyed Constructional and Engineering Steel, Niobium Product Company GmbH, 1990. H. Adrian, Thermodynamic calculations of carbonitride precipitation as a guide for alloy design of microalloyed steels, Proceedings of the International Conference Microalloying95, Pittsburgh 1995, 285-305.

[3] [4] [5]

[6] [7]

4. Conclusions Conclusions

The investigations carried out revealed that the process of plastic deformation of steel in the temperature range from 1100 to 900 C in conditions close to heavy plate rolling is controlled by the dynamic recovery flow, where the strain hardening decay of the austenite between the successive deformation cycles occurs through static recovery and static recrystallization. The nonuniform plastic metal flow is a reason for origination of the deformation bands (shearing) in the plastically deformed austenite, spreading in the direction of the load, disappearing during the static recrystallization of the austenite. The time of the total recrystallization tR of the plastically deformed austenite of = 0.2 with a rate of 3 s-1 at the temperature of 1100 C is 50 sec, and increases to about 300 sec at the temperature of 900 C. However, time t0.5 - necessary to develop 50% fraction of the recrystallized austenite after plastic deformation of steel at the temperature of 1100 C, determined basing on the strain hardening decay kinetics - is 9 sec and increases to 60 sec at the temperature of 900 C. If the intervals between the plastic deformation cycles are shorter than the time of the statical recrystallization of the austenite then overlapping of the nonuniform flow of plastic metal in the successive deformation cycles leads to development of the shearing bands in the austenite. The deformation (shear) bands do not develop if the time between the consecutive deformation cycles makes total recrystallization of the plastically deformed austenite possible. Adjusting the interval times between the deformation cycles in the multi-pass rolling process to the total recrystallization time of the plastically deformed austenite, by employing the retention shield, and the isothermal holding of the product at the temperature of the end of hot working for time t0.5 before [8]

[9]

[10]

[11]

[12]

[13]

[14] [15]

380 380

READING DIRECT: www.archivesmse.org

Vous aimerez peut-être aussi

- Catalog BakerDocument152 pagesCatalog BakerArenita Wright100% (2)

- ASM Specialty Handbook Carbon and Alloy SteelsDocument2 pagesASM Specialty Handbook Carbon and Alloy SteelsGaurav Tripathi25% (4)

- AMS Style ManualDocument117 pagesAMS Style ManualDiego LunaPas encore d'évaluation

- Heat-Treatment of High Carbon Steel Wire - PatentingDocument4 pagesHeat-Treatment of High Carbon Steel Wire - Patentingعزت عبد المنعم100% (1)

- Effect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelDocument7 pagesEffect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelMahmood KhanPas encore d'évaluation

- The Influence of Hot-Working Conditions On A Structure of High-Manganese SteelDocument10 pagesThe Influence of Hot-Working Conditions On A Structure of High-Manganese SteelPiranha TourniquetPas encore d'évaluation

- Metals: Influence of Hot Forging Parameters On A Low Carbon Continuous Cooling Bainitic Steel MicrostructureDocument11 pagesMetals: Influence of Hot Forging Parameters On A Low Carbon Continuous Cooling Bainitic Steel Microstructureth34560Pas encore d'évaluation

- Intercritical Heat Treatment Effect PDFDocument6 pagesIntercritical Heat Treatment Effect PDFmuthu_g6942Pas encore d'évaluation

- Heat Treatment of Nodular Cast IronDocument4 pagesHeat Treatment of Nodular Cast IronRoman_RomeoPas encore d'évaluation

- The Effect of Microstructure On Tensile Behaviour of X80 Microalloyed SteelDocument7 pagesThe Effect of Microstructure On Tensile Behaviour of X80 Microalloyed SteelMarcelo Varejão CasarinPas encore d'évaluation

- Applying Computer Simulation in Improving Heat Treating Condition of Thin High-Carbon Steel PartsDocument5 pagesApplying Computer Simulation in Improving Heat Treating Condition of Thin High-Carbon Steel PartssathishelakkiyaPas encore d'évaluation

- Obiukwu Osita, Udeani Henry, Ubani ProgressDocument12 pagesObiukwu Osita, Udeani Henry, Ubani ProgressPrashant KumarPas encore d'évaluation

- Improving Tribological Properties of Tool Steels Through Combination of Deep Cryogenic Treatment and Plasma Nitriding 2012 WearDocument6 pagesImproving Tribological Properties of Tool Steels Through Combination of Deep Cryogenic Treatment and Plasma Nitriding 2012 WearclebertasparPas encore d'évaluation

- Hot RollingDocument10 pagesHot Rollingpoom2007Pas encore d'évaluation

- Dilatometric and Hardness Analysis of C45 Steel PDFDocument4 pagesDilatometric and Hardness Analysis of C45 Steel PDFInaamPas encore d'évaluation

- Dilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesDocument4 pagesDilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesInaamPas encore d'évaluation

- Dilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesDocument4 pagesDilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesInaamPas encore d'évaluation

- The Influence of Heat Treatment On The Microstructure and PDFDocument43 pagesThe Influence of Heat Treatment On The Microstructure and PDFtblosPas encore d'évaluation

- Wear Behavior of 100cr6-PolatDocument6 pagesWear Behavior of 100cr6-PolatAntonioPas encore d'évaluation

- Structural SteelsDocument5 pagesStructural SteelsijazPas encore d'évaluation

- X. Y. LI - Surface Engineering 17 (2001) 147-152 - Low Temperature Plasma Nitriding of 316 SS-Nature of S Phase and Its Thermal StablityDocument6 pagesX. Y. LI - Surface Engineering 17 (2001) 147-152 - Low Temperature Plasma Nitriding of 316 SS-Nature of S Phase and Its Thermal StablityTania DanielPas encore d'évaluation

- Javaheri 2018Document28 pagesJavaheri 2018SOUADPas encore d'évaluation

- Ojay 1ST Publication PDFDocument16 pagesOjay 1ST Publication PDFvenkatrangan2003Pas encore d'évaluation

- Phase Transformation in AISI 410 Stainless Steel PDFDocument10 pagesPhase Transformation in AISI 410 Stainless Steel PDFirajfarjiPas encore d'évaluation

- Erdem 2005Document7 pagesErdem 2005vinayakPas encore d'évaluation

- Research Regarding The Heat-Treatment Influence On The Properties of Ca-15 Martensitic Stainless SteelDocument8 pagesResearch Regarding The Heat-Treatment Influence On The Properties of Ca-15 Martensitic Stainless SteelFernando RomeroPas encore d'évaluation

- AISI 1015 Carbon Steel NitridedDocument4 pagesAISI 1015 Carbon Steel NitridedRamil SerdanPas encore d'évaluation

- Physical and Numerical Modelling of Heat Treatment The Precipitation-Hardening Complex-Phase Steel (CP)Document4 pagesPhysical and Numerical Modelling of Heat Treatment The Precipitation-Hardening Complex-Phase Steel (CP)rodrigosiqueiraPas encore d'évaluation

- Influence of Heat Treatments On The Microstructure and Degree of Sensitization of Base Metal and Weld of AISI 430 Stainless SteelDocument8 pagesInfluence of Heat Treatments On The Microstructure and Degree of Sensitization of Base Metal and Weld of AISI 430 Stainless SteelAshish Kumar AgrawalPas encore d'évaluation

- Semi-Hot Stamping As An Improved Process of Hot StampingDocument8 pagesSemi-Hot Stamping As An Improved Process of Hot StampingAndress SsalomonnPas encore d'évaluation

- CA 6NM CastingsDocument11 pagesCA 6NM CastingsvasanthiPas encore d'évaluation

- Title: Effects of Thermo-Mechanical Processing On The Microstructure and Mechanical Properties of NB Micro-Alloyed SteelDocument15 pagesTitle: Effects of Thermo-Mechanical Processing On The Microstructure and Mechanical Properties of NB Micro-Alloyed SteelAshutosh GautamPas encore d'évaluation

- The Kinetics of Phase Transformations During Tempering of Cr-Mo-V Medium Carbon SteelDocument4 pagesThe Kinetics of Phase Transformations During Tempering of Cr-Mo-V Medium Carbon SteelfdcarazoPas encore d'évaluation

- Kim 2018Document26 pagesKim 2018Muhammad Rizki Gorbyandi NadiPas encore d'évaluation

- Karakteristik Material LanjutDocument24 pagesKarakteristik Material Lanjuthengkiirawan2008Pas encore d'évaluation

- l'LA!MA Hot Machining For New Engineering Materials : Wear, 139 (1990) 251-267 251Document17 pagesl'LA!MA Hot Machining For New Engineering Materials : Wear, 139 (1990) 251-267 251GAURAV KUMARPas encore d'évaluation

- 1 Effect of The Intercritical Annealing Temperature On The Mechanical Properties of 10 PCT MN Multi-Phase Steel PDFDocument8 pages1 Effect of The Intercritical Annealing Temperature On The Mechanical Properties of 10 PCT MN Multi-Phase Steel PDFJulio Hernandez MartinezPas encore d'évaluation

- Enhancement of Mechanical Properties of Low Carbon Dual Phase Steel Via Natural AgingDocument19 pagesEnhancement of Mechanical Properties of Low Carbon Dual Phase Steel Via Natural AgingMoin APas encore d'évaluation

- Comparison Between Traditional and Innovative SteelsDocument10 pagesComparison Between Traditional and Innovative SteelsIonut AdrianPas encore d'évaluation

- The Mechanical Properties and Microstructures of 9% Chromium Steel P92 WeldmentsDocument23 pagesThe Mechanical Properties and Microstructures of 9% Chromium Steel P92 WeldmentspkguptaqaqcPas encore d'évaluation

- Volchok 22Document4 pagesVolchok 22amitkkamblePas encore d'évaluation

- 3 Eng Stainless Steel Tube AnnealingDocument16 pages3 Eng Stainless Steel Tube AnnealingVictor HugoPas encore d'évaluation

- Effect of Hardness and Wear Resistance On en 353 Steel by Heat TreatmentDocument4 pagesEffect of Hardness and Wear Resistance On en 353 Steel by Heat TreatmentIJMERPas encore d'évaluation

- 01 - A CCT Diagram For An Offshore Pipeline Steel of X70 TypeDocument6 pages01 - A CCT Diagram For An Offshore Pipeline Steel of X70 TypeŞarîngă George AlexandruPas encore d'évaluation

- Jurnal Logam MirnaDocument8 pagesJurnal Logam MirnaIrsan Rahman Buat ArasemenPas encore d'évaluation

- Effect of Tempering Pass On HSLA-80 Steel HAZ MicrostructuresDocument8 pagesEffect of Tempering Pass On HSLA-80 Steel HAZ MicrostructuresElias KapaPas encore d'évaluation

- Panduan BeasiswaDocument7 pagesPanduan BeasiswaAmalia Tri WPas encore d'évaluation

- Normalizing Heat Treatment PDFDocument6 pagesNormalizing Heat Treatment PDFsmani170100% (1)

- IWIT2017-Proceeding FullpaperDocument8 pagesIWIT2017-Proceeding FullpaperKittichai SojiphanPas encore d'évaluation

- Mechanical Properties Enhancement of Conventional Mild Steel For Fastener ApplicationDocument8 pagesMechanical Properties Enhancement of Conventional Mild Steel For Fastener ApplicationTeddy MokhoPas encore d'évaluation

- Roqtuf PDFDocument6 pagesRoqtuf PDFLeonidio CamposPas encore d'évaluation

- Journal of Materials Processing TechnologyDocument8 pagesJournal of Materials Processing TechnologyHARIMETLYPas encore d'évaluation

- The Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelDocument8 pagesThe Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelGopala Rao ThellaputtaPas encore d'évaluation

- Forging + Quenching Knowledge PDFDocument8 pagesForging + Quenching Knowledge PDFAnonymous MAJuDk100% (1)

- Nanoausferritic Matrix of Ductile IronDocument7 pagesNanoausferritic Matrix of Ductile IronMostafa OthmanPas encore d'évaluation

- Poletskov 2020 IOP Conf. Ser. Mater. Sci.Document8 pagesPoletskov 2020 IOP Conf. Ser. Mater. Sci.Александр ТиньгаевPas encore d'évaluation

- IJMMSE - Effect of Annealing On Low Carbon Steel Grade 1008Document6 pagesIJMMSE - Effect of Annealing On Low Carbon Steel Grade 1008TJPRC PublicationsPas encore d'évaluation

- Performance Optimization of High Resistant White Cast Iron For Severe Working ApplicationsDocument6 pagesPerformance Optimization of High Resistant White Cast Iron For Severe Working ApplicationsANA LAURA BRAGA NASCIMENTOPas encore d'évaluation

- Bake Hardening ST 14 SteelDocument8 pagesBake Hardening ST 14 SteelDavid JendraPas encore d'évaluation

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesD'EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášPas encore d'évaluation

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014D'EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014Pas encore d'évaluation

- Thermomechanical Processing of High-Strength Low-Alloy SteelsD'EverandThermomechanical Processing of High-Strength Low-Alloy SteelsPas encore d'évaluation

- Thermo-Mechanical Treatment of The C-MN Steel With NB, Ti, V and B MicroadditionsDocument4 pagesThermo-Mechanical Treatment of The C-MN Steel With NB, Ti, V and B MicroadditionsGaurav TripathiPas encore d'évaluation

- 3 MetallographyDocument5 pages3 MetallographyGaurav TripathiPas encore d'évaluation

- RT 04 2012 - Final WEB ADVT ET 2012Document7 pagesRT 04 2012 - Final WEB ADVT ET 2012shashee2020Pas encore d'évaluation

- BOE-Medical-QCOs Ad For Web-Final 23 Aug 11Document7 pagesBOE-Medical-QCOs Ad For Web-Final 23 Aug 11Freshers Plane IndiaPas encore d'évaluation

- A/SA 333 Spec Sheet A333 Pipe Specifications: ScopeDocument8 pagesA/SA 333 Spec Sheet A333 Pipe Specifications: ScopeAdrian EspinosaPas encore d'évaluation

- BEP 348 - Purchasing (Part 1) : Sourcing SuppliersDocument12 pagesBEP 348 - Purchasing (Part 1) : Sourcing SuppliersTrần ThơmPas encore d'évaluation

- HSE KIK Monitoring Hot Work Ceilling Dan OfficeDocument13 pagesHSE KIK Monitoring Hot Work Ceilling Dan Officeandri setiawanPas encore d'évaluation

- Building Materials ReviewerDocument104 pagesBuilding Materials ReviewerAl RomanoPas encore d'évaluation

- Welding of Stainless Steels & Duplex: Roshan RampureDocument74 pagesWelding of Stainless Steels & Duplex: Roshan Rampureapurva karlePas encore d'évaluation

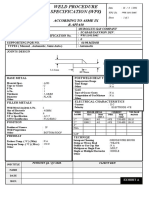

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyPas encore d'évaluation

- Manual DF 2009Document493 pagesManual DF 2009ioana968Pas encore d'évaluation

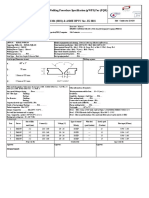

- Nisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)Document3 pagesNisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)pejman.imaniPas encore d'évaluation

- 02 Fitup ReportsDocument1 page02 Fitup ReportsSam RajaPas encore d'évaluation

- NACE IndexDocument9 pagesNACE IndexRoger SchvepperPas encore d'évaluation

- Aws-A5 32 PDFDocument26 pagesAws-A5 32 PDFCGRRPas encore d'évaluation

- Case Study On Corrosion Assessment of Infield Pipelines byDocument10 pagesCase Study On Corrosion Assessment of Infield Pipelines byHazim NaharPas encore d'évaluation

- B1e 004 PDFDocument40 pagesB1e 004 PDFNguyễn Xuân ĐiệpPas encore d'évaluation

- Complying With Nace Hardness RequirementsDocument5 pagesComplying With Nace Hardness Requirementsmanimaran100% (2)

- 133 Trepanier Pelton 2005Document7 pages133 Trepanier Pelton 2005AssyakurPas encore d'évaluation

- SWRCH18ADocument2 pagesSWRCH18AHari SuthanPas encore d'évaluation

- API 577 EXAM QUESTION For 653 ExamsDocument27 pagesAPI 577 EXAM QUESTION For 653 ExamsEjaz AsgharPas encore d'évaluation

- 6 Tube Plate Heat Exchanger Graphite Blocks Mersen 01Document20 pages6 Tube Plate Heat Exchanger Graphite Blocks Mersen 01mohsen123Pas encore d'évaluation

- Dissimilar WeldingDocument24 pagesDissimilar WeldingVishnupriya SunilPas encore d'évaluation

- Final Exam Steel 2020 Semester 1Document3 pagesFinal Exam Steel 2020 Semester 1Malak ShatiPas encore d'évaluation

- 173 13 12 Steel Degassing USDocument8 pages173 13 12 Steel Degassing USAl M JamilPas encore d'évaluation

- ElicaDocument58 pagesElicaDorin ȘuvariPas encore d'évaluation

- Engineering and Material Standard For Double Pipe Heat ExchangersDocument13 pagesEngineering and Material Standard For Double Pipe Heat ExchangersRezaPas encore d'évaluation

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanPas encore d'évaluation

- Grundfos Basic DatabookDocument52 pagesGrundfos Basic DatabookDwi NugrohoPas encore d'évaluation

- GMAW of Creep Resistant SteelsDocument5 pagesGMAW of Creep Resistant SteelsJustin Morse100% (1)

- Sa 179Document3 pagesSa 179Raju SkPas encore d'évaluation

- M 2 SAW D1.1 2015 Form PDFDocument1 pageM 2 SAW D1.1 2015 Form PDFyounessPas encore d'évaluation