Académique Documents

Professionnel Documents

Culture Documents

md-1 2008

Transféré par

Gurpreet SinghDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

md-1 2008

Transféré par

Gurpreet SinghDroits d'auteur :

Formats disponibles

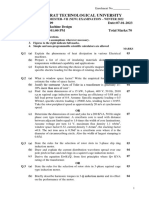

Roll No: Total No. of Questions: 091 [Total No.

of Pages:02

PaperID [A08141

(Pleasefill this Paper ID in ONtIt Sheet)

B. Tech. (Sem. - 5'h)

MACHTNE DESTGN- r (ME - 301) Time : 03 Hours Instmction to Candidates: l) Section A is Compulsory. 2) 3) Attempt any Four questions from Section- B. Attempt any Two questions from Section- C. Section- A Ql) a) b) c) d) Whatarethe general considerations MachineDesign? in What do you understand aboutComputer aidedDesign? lvhat is meantby endurance strengthof a material? (10x2:20) Maximum Marks : 60

Explain how the factor of safetyis determinedunder steadyload conditions. Differentiate between ChaulkingandFulleringwith a help of neatsketch. fuhut arethe assumptions madein the designof weldedjoint? Enumerates causes shaftfailures. the of What do you understand leverage? by What areflexible couplingsandwhat aretheir applications? With the neatsketches, enlisttwo typesof pipejoint commonlyusedin practice. engineering

e) 0 g) h) r) j)

E-606 [1208]

PTO.

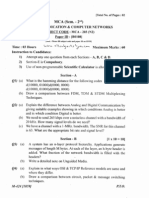

Section- B

o, each of e2) Twoplates 15mmthickness areto bejoined *.unrfl i ^tori,{/"

rivet pitch, strap riveteddoublestrapbuttjoint. Determinethe rivet diameter; in thickness efficiencyof thejoint. Taketheworking stresses tensionand and shearingas 80 N/mm2and 60 N/mm2respectively. Q3) A shaft of 60 mm diametertransmitspower at maximum shearstressof to Find the lengthof a 18mm wide key required rnounta pulleyon 5.2N/cm2. in 3.5 the shaftso that the stress the key doesnot exceed N/crn2. Q4) Determinethe diameterof a hollow shaft with a ratio of internaito external 250 is of diameter 0.75,capable transmitting kW at 350 rev.per minute.It betrveen bearings the caniesa centralioadof 1000N andis simplysupported with 3 metersapart.The load is suddenlyappliedwith minor shocksfor is stress 56 Mpa. torsionalmomentandbendingmomentandallowableshear f'or for the to of Q5) Discuss variousfactors be considered the selection materials elements? the designof machine procedure a leverfor a leversafctl vaive. the of Q6) Explain design Section- C (2 x l{}:2A) type flangecouplingto transmit25kW at 1000 Q7) Designa castiron protective nlotor to a compressor. The service faclor mai' be rpm from an electric. rnay as The followingpennissible stresses be used: assumed 1.50. : for for bolt and key mater"ial 40 Mpa, Crushingstr'.'ss Shearstress sha{1, stress castiron : 8 Mpa" firr bolt and k.y: 80 Mpa, Shear piate is to Q8) A plate 120mm wide and 12.5rninthictrrness ro be rr"'cicled another to by means parallel of are fiilet welds.The plates sr-rbjecteda Icailof 50 kN. Find the lengthof the weld so thai ihe rnaxirnum stl'ess doesnot exceeil 56 joint firstunderstatic anri Mpa.Consider the loading thenu:iijerfhtrgr-re iriarJilrg. pipejoint fcr pipes internal a flanged of diar;:eier rnil subiecteci 5{i Q9) Design square to an internaltluid pressure 7 l.trmirrr. of T'hemaxinrun:r tensiiest;"ess ti:e in pipematerial not to be exceed N{paandin tlie bolis2EMpa. is 21

@@@@ E-606 2

Vous aimerez peut-être aussi

- Machine Design II Exam with Questions on Belts, Bearings, Springs, Clutches, Gears and FlywheelsDocument2 pagesMachine Design II Exam with Questions on Belts, Bearings, Springs, Clutches, Gears and FlywheelsVikasPas encore d'évaluation

- MTP 5Document4 pagesMTP 5tinku singhPas encore d'évaluation

- Btech Ee 6 Sem Conventional and Cad of Electrical Machines Nee 023 2016 17Document2 pagesBtech Ee 6 Sem Conventional and Cad of Electrical Machines Nee 023 2016 17Tanisha ShahPas encore d'évaluation

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPalak AriwalaPas encore d'évaluation

- DME 30MKS Aug15Document3 pagesDME 30MKS Aug15palashPas encore d'évaluation

- Design of Machine Elements IDocument8 pagesDesign of Machine Elements Imesab100Pas encore d'évaluation

- (Engineering) - : B.Tech. Degree Examtnation, DecemberDocument2 pages(Engineering) - : B.Tech. Degree Examtnation, DecemberBrandon AllenPas encore d'évaluation

- Mech Btech PapersDocument7 pagesMech Btech PapersThanatos XPas encore d'évaluation

- ' "" 'I F 5:t"il) I:"h'xt'ilffi' : Pappr ID: (. (08191Document2 pages' "" 'I F 5:t"il) I:"h'xt'ilffi' : Pappr ID: (. (08191RaJan GargPas encore d'évaluation

- Machine Design-I Exam Guide for University of Pune StudentsDocument56 pagesMachine Design-I Exam Guide for University of Pune Studentsavinash119870% (1)

- 9EH EoC Test 2013 No SolsDocument11 pages9EH EoC Test 2013 No SolsDanny EtievePas encore d'évaluation

- Winsem2015 16 Cp3870 Qz01qst Dme Tee QP ModelDocument3 pagesWinsem2015 16 Cp3870 Qz01qst Dme Tee QP ModelyashvantPas encore d'évaluation

- BE ElectricalDocument45 pagesBE ElectricalOmkar ShetePas encore d'évaluation

- Assignment Booklet: BTME ProgrammeDocument20 pagesAssignment Booklet: BTME ProgrammeSarvanKumarPas encore d'évaluation

- Dmm1 Mar2007Document8 pagesDmm1 Mar2007prk74Pas encore d'évaluation

- (WWW - Entrance-Exam - Net) - PTU B. Tech Civil Engineering-5th Semester - Design of Steel Structures Sample Paper 1Document2 pages(WWW - Entrance-Exam - Net) - PTU B. Tech Civil Engineering-5th Semester - Design of Steel Structures Sample Paper 1Abi Nesh100% (1)

- Design of Machine Members - IDocument8 pagesDesign of Machine Members - IPradeepkumarKatgiPas encore d'évaluation

- Machine Design I - ME501 - Sup 011Document2 pagesMachine Design I - ME501 - Sup 011Saurav JainPas encore d'évaluation

- Assignment 7221 MD-IIIDocument2 pagesAssignment 7221 MD-IIIkalikaPas encore d'évaluation

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- VMKV Engineering College Question Bank on Machine Design ElementsDocument14 pagesVMKV Engineering College Question Bank on Machine Design ElementsSatwik PriyadarshiPas encore d'évaluation

- CMOS IC Design Questions on Analog and Digital CircuitsDocument2 pagesCMOS IC Design Questions on Analog and Digital Circuitshumtum_shri5736Pas encore d'évaluation

- Time: 1:30 Hrs Max. Marks: 20: B. Tech. (PE) Fourth Semester Class Test-2 (March - 2021) Me-262 Machine Design - IDocument2 pagesTime: 1:30 Hrs Max. Marks: 20: B. Tech. (PE) Fourth Semester Class Test-2 (March - 2021) Me-262 Machine Design - Ionline onlinePas encore d'évaluation

- B.Tech. (Sem. 6th) II (Switchgear &protection) Subject Code: Ee 306 PaperDocument2 pagesB.Tech. (Sem. 6th) II (Switchgear &protection) Subject Code: Ee 306 PaperRaj KamalPas encore d'évaluation

- R7310305 Design of Machine Members - IDocument1 pageR7310305 Design of Machine Members - IsivabharathamurthyPas encore d'évaluation

- NR-310305-Design of Machine ElementsDocument9 pagesNR-310305-Design of Machine ElementsSrinivasa Rao GPas encore d'évaluation

- Microwave and Radar Engineering Old PTU Papers (EC-302)Document19 pagesMicrowave and Radar Engineering Old PTU Papers (EC-302)freakyloggerPas encore d'évaluation

- 08 r05310305 Design of Machine Members IDocument9 pages08 r05310305 Design of Machine Members IKrupanandareddyYarragudiPas encore d'évaluation

- Me 1Document436 pagesMe 1Akshay Mane0% (1)

- Dme Question BankDocument2 pagesDme Question BankHelHis GamingPas encore d'évaluation

- Design of Machine Elements Exam QuestionsDocument8 pagesDesign of Machine Elements Exam Questionsslv_prasaadPas encore d'évaluation

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyPas encore d'évaluation

- Mechatronics exam with questions on control systems and PLC applicationsDocument62 pagesMechatronics exam with questions on control systems and PLC applicationshaptooorPas encore d'évaluation

- 2019 May ME402-A - Ktu QbankDocument3 pages2019 May ME402-A - Ktu Qbankbilalfocus0% (1)

- Rr312404 Design of Machine ElementsDocument9 pagesRr312404 Design of Machine ElementsSrinivasa Rao GPas encore d'évaluation

- 9A03708 Modern Manufacturing MethodsDocument4 pages9A03708 Modern Manufacturing MethodssivabharathamurthyPas encore d'évaluation

- Be Winter 2022Document2 pagesBe Winter 2022Ele052 Patel MilanPas encore d'évaluation

- Conventional and CAD of Electrical Machines EEE023Document3 pagesConventional and CAD of Electrical Machines EEE023Dheeraj KumarPas encore d'évaluation

- Ec 302Document2 pagesEc 302Pankaj SharmaPas encore d'évaluation

- BTME 2nd Year AssignmentDocument15 pagesBTME 2nd Year AssignmentshishunalPas encore d'évaluation

- 15M502Document3 pages15M502CRAZY PIANO PLAYERPas encore d'évaluation

- Design of Machine Elements Module ProblemsDocument13 pagesDesign of Machine Elements Module ProblemsnikhilasoknPas encore d'évaluation

- Machine Design Question PaperDocument2 pagesMachine Design Question Papersushil.vgi100% (1)

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaPas encore d'évaluation

- B.Tech Exam Design of Machine Members QuestionsDocument8 pagesB.Tech Exam Design of Machine Members Questionsprk74Pas encore d'évaluation

- Machine Design FundamentalsDocument3 pagesMachine Design FundamentalsSantosh Kumar SinghPas encore d'évaluation

- PRODUCTIONTECHNOLOGYDocument4 pagesPRODUCTIONTECHNOLOGYSamiullah MohammedPas encore d'évaluation

- R09 B.Tech III Year I Semester Machine Elements ExamDocument1 pageR09 B.Tech III Year I Semester Machine Elements Examprasaad08Pas encore d'évaluation

- PR 2303Document4 pagesPR 2303Karthik Srinivas0% (1)

- Snist Dom Previous PaperDocument9 pagesSnist Dom Previous PaperKapil Siddhant DevulapalliPas encore d'évaluation

- M.E. (VLSI & Embedded System) : Asic Design and Modelling (2008 Course)Document9 pagesM.E. (VLSI & Embedded System) : Asic Design and Modelling (2008 Course)Manu SeaPas encore d'évaluation

- Mca2 DCN May09Document2 pagesMca2 DCN May09Chhinder PalPas encore d'évaluation

- R7410307 MechatronicsDocument4 pagesR7410307 MechatronicssivabharathamurthyPas encore d'évaluation

- Question PaperDocument28 pagesQuestion PaperVijayakumarPas encore d'évaluation

- Jaya Engineering College-7 SEM - B.E. / B.Tech MODEL EXAM-I 24.07.15 To 30.07.15Document1 pageJaya Engineering College-7 SEM - B.E. / B.Tech MODEL EXAM-I 24.07.15 To 30.07.15SEBI P RAJA BABUPas encore d'évaluation

- Design of Machine Members-I exam questionsDocument8 pagesDesign of Machine Members-I exam questionsMahesh Babu TalupulaPas encore d'évaluation

- Machine Design Model PaperDocument2 pagesMachine Design Model PaperVinay Karanam100% (1)

- DCM PDFDocument2 pagesDCM PDFvasava dipakPas encore d'évaluation

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesD'EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghPas encore d'évaluation

- Distribution of Electrical Power: Lecture Notes of Distribution of Electrical Power CourseD'EverandDistribution of Electrical Power: Lecture Notes of Distribution of Electrical Power CoursePas encore d'évaluation

- Manage Hospital Records with HMSDocument16 pagesManage Hospital Records with HMSDev SoniPas encore d'évaluation

- Duratone eDocument1 pageDuratone eandreinalicPas encore d'évaluation

- Bridge Ogres Little Fishes2Document18 pagesBridge Ogres Little Fishes2api-246705433Pas encore d'évaluation

- Real-Time Java and ATCDocument44 pagesReal-Time Java and ATCdnk_victon6248Pas encore d'évaluation

- Destruction FormDocument2 pagesDestruction FormHanabishi RekkaPas encore d'évaluation

- imageRUNNER_ADVANCE_715_615_525_III_Series_PC_r2_200122Document87 pagesimageRUNNER_ADVANCE_715_615_525_III_Series_PC_r2_200122techwisekgPas encore d'évaluation

- Banking Finance Agile TestingDocument4 pagesBanking Finance Agile Testinganil1karnatiPas encore d'évaluation

- MONETARY POLICY OBJECTIVES AND APPROACHESDocument2 pagesMONETARY POLICY OBJECTIVES AND APPROACHESMarielle Catiis100% (1)

- Keyence Laser MicrometerDocument20 pagesKeyence Laser MicrometerimrancenakkPas encore d'évaluation

- Unit 4: A World of Ideas: Learning CompassDocument3 pagesUnit 4: A World of Ideas: Learning CompassRica Mae Lepiten MendiolaPas encore d'évaluation

- EIA GuidelineDocument224 pagesEIA GuidelineAjlaa RahimPas encore d'évaluation

- Url Profile Results 200128191050Document25 pagesUrl Profile Results 200128191050Wafiboi O. EtanoPas encore d'évaluation

- Opening Up The Prescriptive Authority PipelineDocument10 pagesOpening Up The Prescriptive Authority PipelineJohn GavazziPas encore d'évaluation

- Risk Assessments-These Are The Risk Assessments Which Are Applicable To Works Onsite. Risk Definition and MatrixDocument8 pagesRisk Assessments-These Are The Risk Assessments Which Are Applicable To Works Onsite. Risk Definition and MatrixTimothy AziegbemiPas encore d'évaluation

- MODEL QUESTION PAPER OF HRM Open CourceDocument2 pagesMODEL QUESTION PAPER OF HRM Open CourceTitus Clement100% (3)

- Parts 3121106 1-2-12 ANSI EnglishDocument246 pagesParts 3121106 1-2-12 ANSI EnglishAndres JimenezPas encore d'évaluation

- Loan Agreement with Chattel Mortgage SecuredDocument6 pagesLoan Agreement with Chattel Mortgage SecuredManny DerainPas encore d'évaluation

- AirtelDocument2 pagesAirtelShraddha RawatPas encore d'évaluation

- 0 - Theories of MotivationDocument5 pages0 - Theories of Motivationswathi krishnaPas encore d'évaluation

- Caterpillar Cat 330L EXCAVATOR (Prefix 8FK) Service Repair Manual (8FK00001 and Up)Document27 pagesCaterpillar Cat 330L EXCAVATOR (Prefix 8FK) Service Repair Manual (8FK00001 and Up)kfm8seuuduPas encore d'évaluation

- WWII Engineer Amphibian TroopsDocument162 pagesWWII Engineer Amphibian TroopsCAP History Library67% (3)

- Interview Tips 1Document19 pagesInterview Tips 1mdsd57% (7)

- MunnarDocument5 pagesMunnarvisujinuPas encore d'évaluation

- Motorola l6Document54 pagesMotorola l6Marcelo AriasPas encore d'évaluation

- Patient Safety IngDocument6 pagesPatient Safety IngUlfani DewiPas encore d'évaluation

- Deploy A REST API Using Serverless, Express and Node - JsDocument13 pagesDeploy A REST API Using Serverless, Express and Node - JszaninnPas encore d'évaluation

- A DETAILED LESSON PLAN IN TLE DraftingDocument16 pagesA DETAILED LESSON PLAN IN TLE DraftingJude PellerinPas encore d'évaluation

- IPR GUIDE COVERS PATENTS, TRADEMARKS AND MOREDocument22 pagesIPR GUIDE COVERS PATENTS, TRADEMARKS AND MOREShaheen TajPas encore d'évaluation

- Tutorial: Energy Profiles ManagerDocument6 pagesTutorial: Energy Profiles ManagerDavid Yungan GonzalezPas encore d'évaluation

- Learn About Intensifiers and How to Use Them Effectively in WritingDocument3 pagesLearn About Intensifiers and How to Use Them Effectively in WritingCheryl CheowPas encore d'évaluation