Académique Documents

Professionnel Documents

Culture Documents

Lab Tests On Permanent Materials Used in Construction and Its Reference With BS

Transféré par

Sandeep PillaiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lab Tests On Permanent Materials Used in Construction and Its Reference With BS

Transféré par

Sandeep PillaiDroits d'auteur :

Formats disponibles

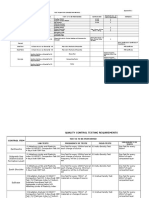

LABORATORY TEST PLAN

Sl. No. A 1 2 3 4 5 6 7 B 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 Aggregates Sampling Gradation Moisture content Materials finer than 75m. Organic impurities in sand Organic impurities strength of mortar Clay lumps and friable particles Light weight pieces Los Angeles abrasion ASTM D75 and D3665 ASTM C33 and C136 ASTM C70 and C566 ASTM C117 ASTM C40 ASTM C87 ASTM C142 ASTM C123 ASTM C131 or C535 Items to test Water and Ice Chemical limitations Compressive strength v/s distilled water standards Time of set v/s distilled water standards Chlorides Sulfates PH Total solids ASTM C94 ASTM C109 ASTM C191 ASTM D512 ASTM D516 ASTM D1293 AASHTO T26 Description of the test Referance standard

DUBAI POLICE- FORENSIC LAB

Acceptance crireria

Soundness (sodium sulfate at 5 cycles) ASTM C88 Specific gravity and absorption Alkali recativity Alkali- Aggregate reactivity Shell content and particle shape Chlorides sulfates ASTM C127 and 128 ASTM C1260 ASTM C227 and 289 ASTM C295 AASHTO T260 BS 1377 part 3

1/ 7

QA/ QC DEPARTMENT PRINTED ON: 10/17/2012

LABORATORY TEST PLAN

24 25 26 27 28 C 29 30 31 32 33 34 35 36 37 38 39 D 40 E 41 42 43 44 45 46 Fresh Concrete Sampling Slump test (Consistency of concrete) Air content Temperature Cement content Water content ASTM C31, C172 and C192 ASTM C143 ASTM C173 or C231 ASTM C1064 ASTM C1078 ASTM C1079 Admixtures Standard physical and chemical properties ASTM C494 Cement Standard Physical and chemical properties for portland cement Standard Physical and chemical properties for Ground Granulated Blast Furnace Slag Sampling Heat of hydration Chlorides Fineness of cement loss of ignition Setting time of cement Compressive strength Normal Consistency of cement Cube Strength of mortar (1:3 mix) ASTM C150 ASTM C595, ASTM C989, BS 146, BS 4247 ASTM C183 ASTM C186 AASHTO T260 BS4550 part 3, physical property tests. Sieve analysis preliminary field decantation test volume weight of compacted aggregates Aggregate crushing tests percentage of voids in aggregates

DUBAI POLICE- FORENSIC LAB

ASTM C109

2/ 7 QA/ QC DEPARTMENT PRINTED ON: 10/17/2012

LABORATORY TEST PLAN

F 47 48 49 50 G 51 52 53 54 55 56 57 58 H 59 60 61 I 62 J 63 K 64 65 66 67 Reinforcement Cold bend of bars Rebend tensile tests Chemical tests BS 18, BS 4449, BS 4482, BS 4483, ASTM A370, ASTM A751 (EN 10002-1) Concrete coating Adhesion ASTM D4541 Epoxy Grout Compressive strength ASTM C579 Non shrinkable cementitious Grout Compressive strength Water penetration Rapid chloride permeability test (RCPT) ASTM C109 DIN 1048 ASTM C1202 Concrete Material and requirements Rapid chloride permeability test (RCPT) Water penetration Porosity Chloride permeability (90 days ponding) Water absorption Total Chlorides Total Sulfates Air voids ASTM C1202 DIN 1048 RILEM CPC 11.3 AASHTO T259 and T260 ASTM C642 ASTM C1152 and C1218 ASTM C856 ASTM C457 Hardened Concrete Sampling Strength (cubes) Strength (drilled cores) Cement content ASTM C823 and BS 1881 part 101 BS 1881 part 108 ASTM C42 ASTM C85 and C1084

DUBAI POLICE- FORENSIC LAB

3/ 7

QA/ QC DEPARTMENT PRINTED ON: 10/17/2012

LABORATORY TEST PLAN

L Dowel Bars

DUBAI POLICE- FORENSIC LAB

Average bond stress on debonded bars from concrete shall be 1.4MN/sq.m at 7 days and the total movement of the dowel bar relative to the concrete shall be 0.25mm at the stress. Size of concrete specimen shall be 150mm*150mm*450mm

68

Pull out test

BS 4449

M 69 70 N 71 72 73 74 75 76 77 78 79 80 81 O 82 83 84 85

Concrete blocks Compression test of blocks Moisture content Suitable back filling material Optimum moisture content Liquid limit Plasticity index Total water soluble salts Minimum soaked CBR Maximum Particle size Maximum dry Density, MDD Sulphate content, acid soluble Chloride content, acid soluble In- situ Dry Density, layer 150mm In- situ Dry Density, layer >150mm Un suitable back filling material Organic material, stumps, and other perishable materials. material susceptable to spontaneous combustion Liquid limit exceeding 30% and plasticity index exceeding 6% Excessive moisture content BS1377 test 14 AASHTO T89 AASHTO T90 BS1377 BS1377 test 16 max. 30% max. 6% max. 5% 15% at 95% compaction. 100mm 95% ASTM C90

BS1377 test 13 BS1377 part 3 test max. 2.0% method 5 BS1377 part 3 test max. 2.0% method 7 Average shall be 95% of maximum dry BS1377 test 15A density and no individual results falls below 94%. BS1377 test 15B

4/ 7

QA/ QC DEPARTMENT PRINTED ON: 10/17/2012

LABORATORY TEST PLAN

P 86 87 Q 88 89 90 91 92 93 94 95 96 97 R S Rock Fill Dynamic compaction 98 99 100 101 S 102 103 Natural Stone Pavers (Indian sand stone) Density Compressive strength ASTM C97 ASTM C170 2560 kg/ m3 137,900 Kpa (20,000psi) CPT (Cone Penetrometer Test). Trial compaction tests CPT Prior to trial compaction test. CPT after trial compaction test. Spec. 31 45 16 Spec. 31 45 16 Spec. 31 45 16 Spec. 31 45 16 Granular Sub- base Grading CBR at 95% of modified proctor density (96 hrs soaked) Organic impurities Liquid limit plasticity index Compaction tests, modified proctor Field Density Linear shrinkage Sulphate content Chloride content BS1377 part 2 test 9.2 BS1377 part 4 test 7 BS1377 part 3 method 3 BS1377 BS1377 BS1377 part 4 method 3 BS1377 part 9 test 15 BS1377 part 2 method 6.5 BS1377 BS1377 Subkha soil Sieve analysis Minimum soaked CBR BS sieve no.200 BS1377 test 16

DUBAI POLICE- FORENSIC LAB

Not more than 30% by weight passing through the sieve. 30% at 95% compaction.

Min. 30% at 95% MDD Max. 2% Max. 30% Max. 6% 95% 95% min. MDD min. 3% max. 1% max. 1%

Average CPT tip resistance 'qc' shall be > 15Mpa on each building foot print. Minimum value of any CPT tip resistance 'qc' shall not be < 10Mpa

5/ 7

QA/ QC DEPARTMENT PRINTED ON: 10/17/2012

LABORATORY TEST PLAN

104 105 106 T 107 108 109 110 111 Asphalt Bed Percentage by weight of asphalt cement Viscosity grade od asphalt cement Percentage by weight of sand Sieve analysis Tack Coat (Neoprene modified asphalt) ASTM D3381 ASTM D3381 ASTM C136 ASTM C136 Spec. Sec. 32 14 00 7% Modulus of rupture Water absorption by weight Flexural strength ASTM C99 ASTM C97 ASTM C880 13,900 Kpa (2000 psi) < 1%

DUBAI POLICE- FORENSIC LAB

10 or 20 when heated to 300 F or 150 C 93% Passing through sieve no.4 2% neoprene, 10% fibre, 88% asphalt

Utility Pipes UPVC, Unplasticized PVC pipes and fittings for underground drainage for BS 4660 160mm. Unplasticized PVC pipes and fittings for gravity sewers and for underground drainage pipes of > 160mm. Poly propylene waste pipe and fittings, for 50mm . Thermoplastic/ UPVC waste pipe and fittings for > 50mm. UPV for domestic water services Code of practise for building drainage. BS 5481

BS 5254 BS 5255 BS 3505 Class E BS 8301

Code of practise for sanitary pipe works. BS 5572 Gully top and Manhole tops for vehicular BS EN 124: 1994 and pedestrian access area. GRP 6/ 7 QA/ QC DEPARTMENT PRINTED ON: 10/17/2012

LABORATORY TEST PLAN Raw Material: a) resin b) Sand c) glass Dimension Barcol Hardness Hydrostatic pressure test Visual Inspection Pipe composition. (loss of ignition) Destructive tests: Stiffness test Hoop tensile strength test Axial tensile strength BS 5480, AWWA C950, ASTM D 3754 BS 5480, ASTM D 3567 ASTM D 2583 ASTM 3517 ASTM D 2563 ASTM D 2584 ASTM D 2412 BS 5480, ASTM D 2290 ASTM D 638

DUBAI POLICE- FORENSIC LAB

7/ 7 QA/ QC DEPARTMENT PRINTED ON: 10/17/2012

Vous aimerez peut-être aussi

- ITP-01 - BackfillingDocument1 pageITP-01 - BackfillingMaddala Srinivasa Rao50% (2)

- Method Statement - Sub-Base and Aggregate Base CourseDocument9 pagesMethod Statement - Sub-Base and Aggregate Base CourseTAHER AMMAR100% (6)

- ITP-FW For Civil & Building WorksDocument17 pagesITP-FW For Civil & Building WorksRajnath Rajbhar Pancham86% (7)

- Bulk Earthworks - Method StatementDocument4 pagesBulk Earthworks - Method Statementmemekenya0% (1)

- ITP For Civil WorksDocument15 pagesITP For Civil WorksNoor A Qasim100% (8)

- Roadwork ChecklistDocument10 pagesRoadwork Checklistchinhon100% (1)

- FQP For Civil WorkDocument15 pagesFQP For Civil WorkManoj ShahPas encore d'évaluation

- Method of Statement For Honeycomb RepairDocument10 pagesMethod of Statement For Honeycomb RepairHansika RajapakshaPas encore d'évaluation

- 029-Itp Paving and Roads PDFDocument7 pages029-Itp Paving and Roads PDFKöksal Patan100% (3)

- 028-Itp For Building Works PDFDocument10 pages028-Itp For Building Works PDFKöksal Patan100% (3)

- Planning and Control EarthworkDocument117 pagesPlanning and Control EarthworkMuhamad_Zulhan_5306Pas encore d'évaluation

- Ce Project 1Document7 pagesCe Project 1emmaPas encore d'évaluation

- Civil Standard & Code No Area Code Standard AstmDocument10 pagesCivil Standard & Code No Area Code Standard AstmTri SeptaPas encore d'évaluation

- Method StatementDocument8 pagesMethod StatementardsilvaPas encore d'évaluation

- Itp Civil WorkDocument9 pagesItp Civil WorkChristian Albert Sinaga RumajarPas encore d'évaluation

- Back FillingDocument7 pagesBack FillingCheng EngiPas encore d'évaluation

- NAV-TP-0283 Scaffold ChecklistDocument2 pagesNAV-TP-0283 Scaffold ChecklistRicky Hawk100% (1)

- Concrete Work: (Please Provide Detail of Repair Activities E.G)Document2 pagesConcrete Work: (Please Provide Detail of Repair Activities E.G)Eze NonsoPas encore d'évaluation

- Kempegowda International Airport - NSPR: Before Concreting Description Checked & Found Ok Remarks YES NO N/ADocument2 pagesKempegowda International Airport - NSPR: Before Concreting Description Checked & Found Ok Remarks YES NO N/Adhanush gtPas encore d'évaluation

- BOQ - ConcreteDocument10 pagesBOQ - ConcreteAbhijit HavalPas encore d'évaluation

- Quality FormetDocument20 pagesQuality FormetVishal TiwariPas encore d'évaluation

- Check List For Back Filling: Company NameDocument1 pageCheck List For Back Filling: Company NameVipin Kumar ParasharPas encore d'évaluation

- Method Statement SurveyDocument3 pagesMethod Statement SurveyBadhur ZamanPas encore d'évaluation

- Method Statement For Construction of Access Bridge by MVVDocument12 pagesMethod Statement For Construction of Access Bridge by MVVPhong Trần100% (1)

- 203 - Roadway Excavation and Embankment (2012)Document12 pages203 - Roadway Excavation and Embankment (2012)lhikbaniPas encore d'évaluation

- Field ITP Civil Rev-8after Lump-Sump.Document17 pagesField ITP Civil Rev-8after Lump-Sump.Echik Kici100% (3)

- Checklist For PCCDocument2 pagesChecklist For PCCRajiv SirnaikPas encore d'évaluation

- Daily Site Meeting RecordDocument14 pagesDaily Site Meeting Recordselvam311Pas encore d'évaluation

- Concrete Mix Design - STFA - 09.06.2009Document40 pagesConcrete Mix Design - STFA - 09.06.2009masahinPas encore d'évaluation

- Construction MethodDocument33 pagesConstruction MethodUthayakumar Kovarth100% (1)

- Standard Protactor TestDocument8 pagesStandard Protactor TestNur ZakariaPas encore d'évaluation

- Concreting Inspection FormDocument2 pagesConcreting Inspection FormtunaungkyawPas encore d'évaluation

- Pour CardDocument2 pagesPour Cardrana pratap Singh100% (1)

- Quality Assurance in Buillding WorksDocument8 pagesQuality Assurance in Buillding WorksAtish KumarPas encore d'évaluation

- Excavation Earthwork and FillingDocument5 pagesExcavation Earthwork and FillingZaleha AzlanPas encore d'évaluation

- Method Statement For Drainage WorksDocument7 pagesMethod Statement For Drainage WorksAsfarina Shafiza100% (2)

- Earthworks ChecklistDocument1 pageEarthworks ChecklistLivian TeddyPas encore d'évaluation

- Request For InspectionDocument1 pageRequest For InspectionSturujPas encore d'évaluation

- Import Material ChecklistDocument2 pagesImport Material ChecklistMalinda AllenPas encore d'évaluation

- Method Statement For In-Situ Pull Off Test On MarbleDocument15 pagesMethod Statement For In-Situ Pull Off Test On MarbleGary Lo67% (3)

- Concrete CubesDocument5 pagesConcrete CubesDipti Ranjan Swain100% (1)

- Laboratory Testing SinobaoDocument43 pagesLaboratory Testing SinobaoKlinton CalañasPas encore d'évaluation

- Final Checklist-Site SupervisionDocument8 pagesFinal Checklist-Site SupervisionGsUpretiPas encore d'évaluation

- Generalprocedure Export PDFDocument20 pagesGeneralprocedure Export PDFUTTAL RAYPas encore d'évaluation

- Method Statment For AsphaltDocument22 pagesMethod Statment For AsphaltAmin KhanPas encore d'évaluation

- Method Statement Embankment: 1. GeneralDocument11 pagesMethod Statement Embankment: 1. GeneralReny AkmaliaPas encore d'évaluation

- Field Density Test Calculation ReportDocument1 pageField Density Test Calculation ReportCristina Dangla Cruz100% (1)

- Cube TestDocument1 pageCube TestRicha YadavPas encore d'évaluation

- Date-070209 SR - No. Description Unit Rate A Rcc. WorkDocument6 pagesDate-070209 SR - No. Description Unit Rate A Rcc. WorkAjay SinghPas encore d'évaluation

- ITP C 005 (Structural Concrete)Document4 pagesITP C 005 (Structural Concrete)segun ajibolaPas encore d'évaluation

- QA&QC Construction of Road & PavementDocument4 pagesQA&QC Construction of Road & PavementMuhammadZahirKhanPas encore d'évaluation

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Document37 pagesIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedPas encore d'évaluation

- 9.2 Check List For Concreting Work: ConstructionDocument2 pages9.2 Check List For Concreting Work: ConstructionMobinPas encore d'évaluation

- Constuction of Embankment/ Preparation of Subgrade: Highway ConstructionDocument11 pagesConstuction of Embankment/ Preparation of Subgrade: Highway ConstructionMohan Mylarappa100% (1)

- Method Statement For Survey and Setting Out (Rev 00)Document10 pagesMethod Statement For Survey and Setting Out (Rev 00)Kelvin Lau Hin HuatPas encore d'évaluation

- HelipadDocument53 pagesHelipadKandregulaPrameelaPas encore d'évaluation

- RequirementDocument8 pagesRequirementSTUDENT LIFEPas encore d'évaluation

- Civil Engineering Technical Question and AnswersDocument15 pagesCivil Engineering Technical Question and AnswersSudhan100% (2)

- 08 Shotcrete Quality Control & Testing For An Underground Mine in CanadaDocument42 pages08 Shotcrete Quality Control & Testing For An Underground Mine in Canadajusselino100% (3)

- Bagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesDocument15 pagesBagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesSoleh SulaemanPas encore d'évaluation

- TL 653 Cert NewDocument6 pagesTL 653 Cert Newmohd waseemPas encore d'évaluation

- Pin Joint en PDFDocument1 pagePin Joint en PDFCicPas encore d'évaluation

- Research Design: An Overview: Multiple Choice QuestionsDocument28 pagesResearch Design: An Overview: Multiple Choice QuestionsBashayerhmmPas encore d'évaluation

- Introduction To Soft Floor CoveringsDocument13 pagesIntroduction To Soft Floor CoveringsJothi Vel Murugan83% (6)

- EHVACDocument16 pagesEHVACsidharthchandak16Pas encore d'évaluation

- OMN-TRA-SSR-OETC-Course Workbook 2daysDocument55 pagesOMN-TRA-SSR-OETC-Course Workbook 2daysMANIKANDAN NARAYANASAMYPas encore d'évaluation

- Résumé Emily Martin FullDocument3 pagesRésumé Emily Martin FullEmily MartinPas encore d'évaluation

- Form 1 1 MicroscopeDocument46 pagesForm 1 1 MicroscopeHarshil PatelPas encore d'évaluation

- Digital Speed Control of DC Motor For Industrial Automation Using Pulse Width Modulation TechniqueDocument6 pagesDigital Speed Control of DC Motor For Industrial Automation Using Pulse Width Modulation TechniquevendiPas encore d'évaluation

- Vacon NX, Non-Regenerative Front End FI9 UD01217B PDFDocument48 pagesVacon NX, Non-Regenerative Front End FI9 UD01217B PDFSilvian IonescuPas encore d'évaluation

- Konsep Negara Hukum Dalam Perspektif Hukum IslamDocument11 pagesKonsep Negara Hukum Dalam Perspektif Hukum IslamSiti MasitohPas encore d'évaluation

- Change LogDocument145 pagesChange LogelhohitoPas encore d'évaluation

- PERSONAL DEVELOPMENT (What Is Personal Development?)Document37 pagesPERSONAL DEVELOPMENT (What Is Personal Development?)Ronafe Roncal GibaPas encore d'évaluation

- Arte PoveraDocument13 pagesArte PoveraSohini MaitiPas encore d'évaluation

- CH 2 PDFDocument85 pagesCH 2 PDFSajidPas encore d'évaluation

- English ID Student S Book 1 - 015Document1 pageEnglish ID Student S Book 1 - 015Williams RoldanPas encore d'évaluation

- History of JavaDocument3 pagesHistory of JavaKyra ParaisoPas encore d'évaluation

- Medha Servo Drives Written Exam Pattern Given by KV Sai KIshore (BVRIT-2005-09-ECE)Document2 pagesMedha Servo Drives Written Exam Pattern Given by KV Sai KIshore (BVRIT-2005-09-ECE)Varaprasad KanugulaPas encore d'évaluation

- Bulk Separator - V-1201 Method StatementDocument2 pagesBulk Separator - V-1201 Method StatementRoshin99Pas encore d'évaluation

- Beginning Cosmetic ChemistryDocument1 pageBeginning Cosmetic ChemistrySergio Rugerio0% (1)

- Top249 1 PDFDocument52 pagesTop249 1 PDFCarlos Henrique Dos SantosPas encore d'évaluation

- LampiranDocument26 pagesLampiranSekar BeningPas encore d'évaluation

- FDP VLSI Design at Deep Submicron Node PDFDocument2 pagesFDP VLSI Design at Deep Submicron Node PDFpraneethshubPas encore d'évaluation

- A Project Diary-Wps OfficeDocument4 pagesA Project Diary-Wps OfficeSameer ShaikhPas encore d'évaluation

- Week 2 - Sulphur DyesDocument5 pagesWeek 2 - Sulphur DyesRR TPas encore d'évaluation

- Boq Cme: 1 Pole Foundation Soil WorkDocument1 pageBoq Cme: 1 Pole Foundation Soil WorkyuwonoPas encore d'évaluation

- ILI9481 DatasheetDocument143 pagesILI9481 DatasheetdetonatPas encore d'évaluation

- Cognitive-Behavioral Interventions For PTSDDocument20 pagesCognitive-Behavioral Interventions For PTSDBusyMindsPas encore d'évaluation

- Ems Speed Sensor Com MotorDocument24 pagesEms Speed Sensor Com MotorKarina RickenPas encore d'évaluation

- SQL TestDocument10 pagesSQL TestGautam KatlaPas encore d'évaluation